DocLib_42_0-4905 ArcMaster 400MST CE.pdf - Victor Technologies ...

DocLib_42_0-4905 ArcMaster 400MST CE.pdf - Victor Technologies ...

DocLib_42_0-4905 ArcMaster 400MST CE.pdf - Victor Technologies ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

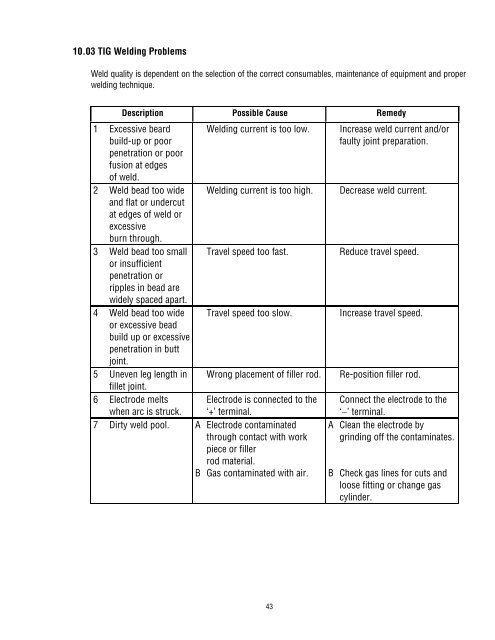

10.03 TIG Welding Problems<br />

Weld quality is dependent on the selection of the correct consumables, maintenance of equipment and proper<br />

welding technique.<br />

Description Possible Cause Remedy<br />

1 Excessive beard<br />

build-up or poor<br />

penetration or poor<br />

fusion at edges<br />

of weld.<br />

2 Weld bead too wide<br />

and flat or undercut<br />

at edges of weld or<br />

excessive<br />

burn through.<br />

3 Weld bead too small<br />

or insufficient<br />

penetration or<br />

ripples in bead are<br />

widely spaced apart.<br />

4 Weld bead too wide<br />

or excessive bead<br />

build up or excessive<br />

penetration in butt<br />

joint.<br />

5 Uneven leg length in<br />

fillet joint.<br />

6 Electrode melts<br />

when arc is struck.<br />

Welding current is too low. Increase weld current and/or<br />

faulty joint preparation.<br />

Welding current is too high. Decrease weld current.<br />

Travel speed too fast. Reduce travel speed.<br />

Travel speed too slow. Increase travel speed.<br />

Wrong placement of filler rod. Re-position filler rod.<br />

Electrode is connected to the Connect the electrode to the<br />

‘+’ terminal.<br />

‘−’ terminal.<br />

7 Dirty weld pool. A Electrode contaminated A Clean the electrode by<br />

through contact with work<br />

piece or filler<br />

rod material.<br />

grinding off the contaminates.<br />

B Gas contaminated with air. B Check gas lines for cuts and<br />

loose fitting or change gas<br />

cylinder.<br />

43