Technical product leaflet - Erbsloeh

Technical product leaflet - Erbsloeh

Technical product leaflet - Erbsloeh

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

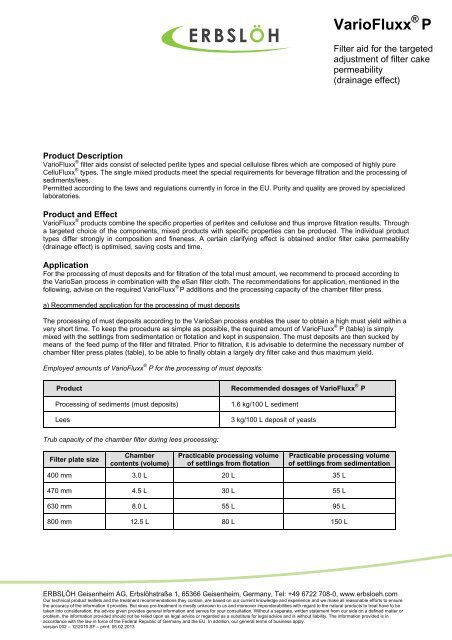

VarioFluxx ® P<br />

Filter aid for the targeted<br />

adjustment of filter cake<br />

permeability<br />

(drainage effect)<br />

Product Description<br />

VarioFluxx ® filter aids consist of selected perlite types and special cellulose fibres which are composed of highly pure<br />

CelluFluxx ® types. The single mixed <strong>product</strong>s meet the special requirements for beverage filtration and the processing of<br />

sediments/lees.<br />

Permitted according to the laws and regulations currently in force in the EU. Purity and quality are proved by specialized<br />

laboratories.<br />

Product and Effect<br />

VarioFluxx ® <strong>product</strong>s combine the specific properties of perlites and cellulose and thus improve filtration results. Through<br />

a targeted choice of the components, mixed <strong>product</strong>s with specific properties can be produced. The individual <strong>product</strong><br />

types differ strongly in composition and fineness. A certain clarifying effect is obtained and/or filter cake permeability<br />

(drainage effect) is optimised, saving costs and time.<br />

Application<br />

For the processing of must deposits and for filtration of the total must amount, we recommend to proceed according to<br />

the VarioSan process in combination with the eSan filter cloth. The recommendations for application, mentioned in the<br />

following, advise on the required VarioFluxx ® P additions and the processing capacity of the chamber filter press.<br />

a) Recommended application for the processing of must deposits<br />

The processing of must deposits according to the VarioSan process enables the user to obtain a high must yield within a<br />

very short time. To keep the procedure as simple as possible, the required amount of VarioFluxx ® P (table) is simply<br />

mixed with the settlings from sedimentation or flotation and kept in suspension. The must deposits are then sucked by<br />

means of the feed pump of the filter and filtrated. Prior to filtration, it is advisable to determine the necessary number of<br />

chamber filter press plates (table), to be able to finally obtain a largely dry filter cake and thus maximum yield.<br />

Employed amounts of VarioFluxx ® P for the processing of must deposits:<br />

Product Recommended dosages of VarioFluxx ® P<br />

Processing of sediments (must deposits) 1.6 kg/100 L sediment<br />

Lees 3 kg/100 L deposit of yeasts<br />

Trub capacity of the chamber filter during lees processing:<br />

Filter plate size<br />

Chamber<br />

contents (volume)<br />

Practicable processing volume<br />

of settlings from flotation<br />

Practicable processing volume<br />

of settlings from sedimentation<br />

400 mm 3.0 L 20 L 35 L<br />

470 mm 4.5 L 30 L 55 L<br />

630 mm 8.0 L 55 L 95 L<br />

800 mm 12.5 L 80 L 150 L<br />

ERBSLÖH Geisenheim AG, Erbslöhstraße 1, 65366 Geisenheim, Germany, Tel: +49 6722 708-0, www.erbsloeh.com<br />

Our technical <strong>product</strong> <strong>leaflet</strong>s and the treatment recommendations they contain, are based on our current knowledge and experience and we make all reasonable efforts to ensure<br />

the accuracy of the information it provides. But since pre-treatment is mostly unknown to us and moreover imponderabilities with regard to the natural <strong>product</strong>s to treat have to be<br />

taken into consideration, the advice given provides general information and serves for your consultation. Without a separate, written statement from our side on a defined matter or<br />

problem, the information provided should not be relied upon as legal advice or regarded as a substitute for legal advice and is without liability. The information provided is in<br />

accordance with the law in force of the Federal Republic of Germany and the EU. In addition, our general terms of business apply.<br />

version 002 – 12/2010 SF – print: 05.02.2013

) Recommended procedure for the filtration of the total must amount<br />

VarioFluxx ® P<br />

Filter aid for the targeted<br />

adjustment of filter cake<br />

permeability<br />

(drainage effect)<br />

Factories not wanting to use flotation or sedimentation, have the possibility to filtrate the total must amount by means of<br />

the VarioSan process. The result are sharply clarified musts with very low NTU-values, which is particularly favourable<br />

for clean-flavour fermentation.<br />

The following prerequisites must be fulfilled for a smooth, unproblematic must filtration:<br />

1. Sufficient pectin degradation by enzymation: Trenolin ® Super DF 3-8 mL/100 L; contact time 2-8 hours;<br />

temperature >15 °C. At temperatures < 12 °C the cold clarification enzyme Trenolin ® Frio DF must absolutely be<br />

used<br />

2. Sufficient dosage of VarioFluxx ® P (table)<br />

3. Uniform distribution of VarioFluxx ® P in the must (stir)<br />

4. Determination of the required number of filter plates (trub capacity) of the chamber filter press (table)<br />

Dosages of VarioFluxx P for the filtration of the total must amount:<br />

Product Recommended addition of VarioFluxx ® P<br />

Supernatant 200 – 400 g/100 L<br />

Total must amount (stirred up) 600 – 800 g/100 L<br />

Problematic vine varieties (Silvaner) and<br />

insufficiently enzyme treated must<br />

800 – 1000 g/100 L<br />

Filterable total must amount in relation of the VarioFluxx ® P filter aid dosage and filter plate size of the chamber filter<br />

press:<br />

Filter<br />

plate size<br />

Chamber<br />

contents<br />

(volume)<br />

Filter aid/<br />

chamber<br />

200 g filter<br />

aid/100 L<br />

400 g filter<br />

aid/100 L<br />

600 g filter<br />

aid/100 L<br />

800 g filter<br />

aid/100 L<br />

1,000 g filter<br />

aid/100 L<br />

400 mm 3.0 L 0.6 kg 300 L 150 L 100 L 75 L 60 L<br />

470 mm 4.5 L 0.9 kg 450 L 225 L 150 L 110 L 90 L<br />

630 mm 8.0 L 1.6 kg 800 L 400 L 270 L 200 L 160 L<br />

800 mm 12.5 L 2.5 kg 1,250 L 625 L 420 L 310 L 250 L<br />

Storage<br />

VarioFluxx ® filter aids must be protected from foreign odours and moisture. Opened packagings must be resealed<br />

immediately after taking out <strong>product</strong>.<br />

Disposal<br />

VarioFluxx ® consists of mineral and biological/organic components. The <strong>product</strong>s are free from kieselguhr<br />

(diatomaceous earth). Dispose of in accordance with current local, state or federal regulations.<br />

ERBSLÖH Geisenheim AG, Erbslöhstraße 1, 65366 Geisenheim, Germany, Tel: +49 6722 708-0, www.erbsloeh.com<br />

Our technical <strong>product</strong> <strong>leaflet</strong>s and the treatment recommendations they contain, are based on our current knowledge and experience and we make all reasonable efforts to ensure<br />

the accuracy of the information it provides. But since pre-treatment is mostly unknown to us and moreover imponderabilities with regard to the natural <strong>product</strong>s to treat have to be<br />

taken into consideration, the advice given provides general information and serves for your consultation. Without a separate, written statement from our side on a defined matter or<br />

problem, the information provided should not be relied upon as legal advice or regarded as a substitute for legal advice and is without liability. The information provided is in<br />

accordance with the law in force of the Federal Republic of Germany and the EU. In addition, our general terms of business apply.<br />

version 002 – 12/2010 SF – print: 05.02.2013