TECH TIPS - Extech Instruments

TECH TIPS - Extech Instruments

TECH TIPS - Extech Instruments

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Te<br />

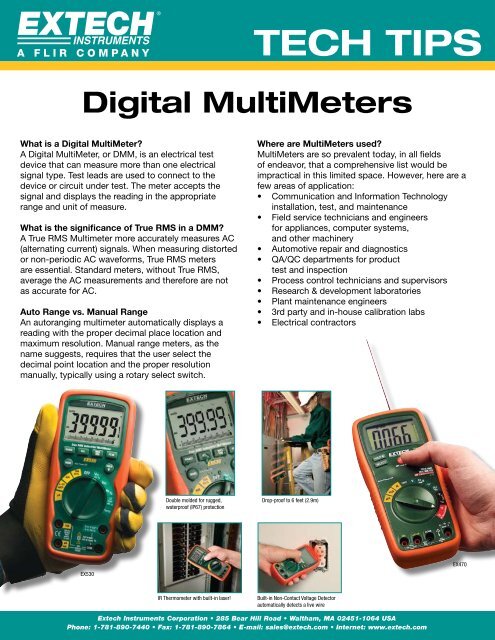

What is a Digital MultiMeter?<br />

A Digital MultiMeter, or DMM, is an electrical test<br />

device that can measure more than one electrical<br />

signal type. Test leads are used to connect to the<br />

device or circuit under test. The meter accepts the<br />

signal and displays the reading in the appropriate<br />

range and unit of measure.<br />

What is the significance of True RMS in a DMM?<br />

A True RMS Multimeter more accurately measures AC<br />

(alternating current) signals. When measuring distorted<br />

or non-periodic AC waveforms, True RMS meters<br />

are essential. Standard meters, without True RMS,<br />

average the AC measurements and therefore are not<br />

as accurate for AC.<br />

Auto Range vs. Manual Range<br />

An autoranging multimeter automatically displays a<br />

reading with the proper decimal place location and<br />

maximum resolution. Manual range meters, as the<br />

name suggests, requires that the user select the<br />

decimal point location and the proper resolution<br />

manually, typically using a rotary select switch.<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

Digital MultiMeters<br />

Double molded for rugged,<br />

waterproof (IP67) protection<br />

Where are MultiMeters used?<br />

MultiMeters are so prevalent today, in all fields<br />

of endeavor, that a comprehensive list would be<br />

impractical in this limited space. However, here are a<br />

few areas of application:<br />

• Communication and Information Technology<br />

installation, test, and maintenance<br />

Field service technicians and engineers<br />

EX530<br />

IR Thermometer with built-in laser! Built-in Non-Contact Voltage Detector <br />

<br />

<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

for appliances, computer systems,<br />

and other machinery<br />

Automotive repair and diagnostics<br />

QA/QC departments for product<br />

test and inspection<br />

Process control technicians and supervisors<br />

Research & development laboratories<br />

Plant maintenance engineers<br />

3rd party and in-house calibration labs<br />

Electrical contractors<br />

Drop-proof to 6 feet (2.9m)<br />

automatically detects a live wire<br />

EX470

What is a clamp meter?<br />

A clamp meter is a safe, convenient, and efficient<br />

way to measure current without having to use test<br />

leads. Since current flow through a conductor causes<br />

a magnetic field, the clamp meter can sense this<br />

field and provide a corresponding current reading (in<br />

amperes, or amps). Clamp meters do not interrupt<br />

current flow allowing the technician to make the<br />

measurement quickly and safely.<br />

Why True RMS Clamp-ons?<br />

A True RMS clamp meter more accurately measures<br />

AC (alternating current) signals. When measuring<br />

distorted or non-periodic AC waveforms, True RMS<br />

meters are essential. Standard meters, without True<br />

RMS, average the AC measurements and therefore are<br />

not as accurate for AC.<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

Clamp Meters<br />

Built-in IR Thermometer for quick<br />

and safe non-contact temperature<br />

measurements. Find hot spots fast!<br />

Applications for True RMS Clamp-On Meters<br />

• Power utility personnel for installation,<br />

maintenance, and diagnostics.<br />

• Electrical contractor supervisors and<br />

engineers and electrical journeymen<br />

• Building and facility maintenance<br />

technicians and supervisors<br />

• Manufacturing technicians and floor supervisors<br />

• Technicians for avionic electrical generation<br />

systems and ground support equipment<br />

Current Clamp Meters with DMM functionality<br />

<strong>Extech</strong> leads the market in multifunction current clamp<br />

meters. In the presence of high current flow, the need<br />

to measure volts, ohms, temperature, and frequency<br />

is imperative. Multifunction current clamp meters offer<br />

a value-added bonus for technicians, field engineers,<br />

and contractors.<br />

What is the significance of the IR thermometer?<br />

In areas where there are high current carrying<br />

conductors, safety is of utmost concern. With an<br />

IR thermometer built right into the clamp meter the<br />

technician can quickly and safely scan for ‘hotspots’<br />

on panels, conduits, and walls.<br />

EX830 EX623<br />

EX600 Series 5-in-1 meters feature built-in dual<br />

True RMS meter gives you accurate<br />

thermocouple inputs for T1, T2, and T1-T2 differential readings of non-sinusoidal <br />

temperature measurement.<br />

waveforms.

What is an Infrared Thermometer?<br />

An Infrared or ‘IR’ Thermometer is an instrument that<br />

can remotely sense the temperature of a surface and<br />

display that temperature digitally.<br />

How does an IR Thermometer work?<br />

An IR thermometer senses the infrared energy<br />

emitted by the surface under test. All materials emit<br />

infrared energy and the amount of energy emitted is<br />

proportional to the temperature of the material. The<br />

meter simply converts the infrared it collects into a<br />

temperature display.<br />

What are the Advantages of an IR Thermometer?<br />

• Non-Contact measurements are<br />

convenient and safe<br />

• IR measurements are extremely fast<br />

• IR thermometers can measure moving objects<br />

• IR thermometers measure from a safe distance<br />

What is Field of View or<br />

Distance to Spot (D/S) ratio?<br />

The IR sensor beam can be thought of as the beam<br />

of a flashlight; the closer a flashlight is to a wall,<br />

the smaller the light spot; the further from the wall,<br />

the larger the spot. If the D/S ratio of a given IR<br />

thermometer is 10:1, the spot will be a 1” diameter<br />

circle when the meter is held 10” from the surface. At a<br />

20”distance the spot will be 2” in diameter, and so on.<br />

The surface being measured should always be larger<br />

than the spot size for accurate measurements.<br />

Max hold indicates and holds the peak<br />

temperature for easy identification<br />

of hot spots<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

IR Thermometers<br />

Two laser points converge at a<br />

distance of 30”/76.2cm (model<br />

42512) or 12”/30.5cm (model 42511)<br />

and form a 1” (2.5cm) spot.<br />

Technical Definition of Emissivity<br />

Emissivity is defined as the ratio of the energy radiated<br />

by an object at a given temperature to the energy<br />

emitted by a perfect radiator, or blackbody, at the<br />

same temperature.<br />

Real World Discussion of Emissivity<br />

Emissivity is not of any concern when the surface<br />

under test is coated by flat black paint (known as a<br />

black body). A black body is considered the maximum<br />

emissivity. However in common practice surfaces<br />

can be highly polished and very reflective. These are<br />

known as low emissivity surfaces. In these cases<br />

the IR thermometer can have difficulty obtaining an<br />

accurate reading. This is where Emissivity comes<br />

into play. Many IR thermometers have an adjustable<br />

emissivity which compensates for low emissivity<br />

surface characteristics.<br />

Emissivity settings<br />

The emissivity of a blackbody is considered 1.0 (this<br />

is maximum emissivity). All values of emissivity fall<br />

between 0.0 and 1.0. Many infrared thermometers<br />

have a fixed emissivity of 0.95 which covers most<br />

materials. In the case of a very low emissivity, it is<br />

recommended to apply black paint or tape to the<br />

surface to effectively change the surface emissivity.<br />

<br />

42512 42510A IR201

Alternate Terms for Tachometers<br />

• Angular Speed Meter<br />

• Rotation Meter<br />

What is a tachometer?<br />

A tachometer is a device that measures the angular<br />

speed of a rotating shaft in revolutions per minute<br />

(RPM). A good example of a device that can be<br />

measured with a tachometer is a moving fan. Also,<br />

some tachometers can measure linear surface speed<br />

in terms of feet per minute (ft/min) or meters per<br />

minute (m/min). An example of a linear surface speed<br />

measurement is a conveyor belt or escalator hand-rail.<br />

How to select an <strong>Extech</strong> Tachometer<br />

Use a non-contact (photo) tachometer for applications<br />

where it is not feasible to have the tachometer come<br />

in contact with the rotating device. This is the case in<br />

high speed applications and where the object to be<br />

measured cannot be easily reached.<br />

Use a contact tachometer for applications where direct<br />

contact of the tachometer with the object is preferred.<br />

You can also purchase a combination (contact/noncontact)<br />

tachometer for the maximum in flexibility.<br />

How do Non-contact Tachometers Operate?<br />

Non-contact tachometers use light (photo) reflections<br />

to measure RPM. First, a small piece of reflective<br />

tape (approx. 1/4”) is mounted on the object to be<br />

measured. Second, the light source is directed toward<br />

the tape. The reflection from the tape allows the meter<br />

to measure and display an accurate RPM reading<br />

Accessory wheels enable<br />

tachometer to measure linear<br />

surface speeds<br />

Literature Order Form<br />

Tachometers<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

How do Contact Tachometers Operate?<br />

To measure RPM with a contact tachometer, the<br />

tip of the tachometer’s sensor is placed in direct<br />

contact with the rotating object. After a short time an<br />

accurate reading is displayed. Linear surface speed<br />

can be measured in a similar way; a wheel attachment<br />

is connected to the sensor tip and touched to the<br />

moving belt. Three attachment accessories are<br />

provided: Disc, Conical, and Wheel.<br />

What is the significance of an IR Thermometer?<br />

In addition to saving time and cutting cost, the built-in<br />

IR thermometer permits the user to check for hot spots<br />

or to check surface temperature. The IR thermometer<br />

permits non-contact temperature measurements for<br />

areas difficult to reach or unsafe to touch.<br />

Tachometer Applications<br />

• Rotational motor speed<br />

• Moving fans, pumps, gears, and machinery<br />

• Production and automotive use<br />

• Propeller devices<br />

Non-contact model for use on<br />

machinery where high speed<br />

measurements are required<br />

<br />

461920 RPM10

Alternate Terms for Tachometers<br />

• Alternate Terms for Anemometers<br />

• Air Flow Meters<br />

• Air Velocity or Wind-speed Meters<br />

• Wind cups or weathervanes<br />

What is an Anemometer?<br />

Anemometers measure the speed (velocity) of moving<br />

air. Thermo-Anemometers also measure temperature<br />

by way of a thermometer located in the Anemometer<br />

sensor. The measurement units for Anemometers<br />

include: Feet per minute (ft/min), meters per second<br />

(m/s), kilometers per hour (km/hr), miles per hour<br />

(mph), nautical miles per hour (knots), and Beauforts.<br />

How does an Anemometer measure moving air?<br />

Anemometers measure moving air with a rotary sensor<br />

which acts very much like a weathervane and can be<br />

likened to the blades of a fan. The vane freely rotates<br />

in response to air flow and as the air moves through<br />

the vane the blades turn in proportion to the speed<br />

of the air.<br />

What is CFM / CMM?<br />

Cubic Feet per Minute (CFM) or Cubic Meters<br />

per Minute (CMM) are units of measure for Air<br />

Volume measurements. This is a measurement<br />

of the quantity of moving air through an air duct,<br />

passageway, or enclosure. In order to accomplish<br />

this, the area of the duct must be measured. The<br />

area value (in ft 2 or m 2 ) is entered by the user by<br />

pushbutton or keypad into the meter and an air<br />

velocity measurement is taken. The meter then<br />

calculates the CFM or CMM automatically.<br />

Built-in non-contact<br />

IR Thermometer<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

Anemometers<br />

What is the significance of a built-in IR<br />

thermometer?<br />

Having an IR thermometer as part of an Anemometer<br />

offers the user several important benefits:<br />

• Two tools in one<br />

• Save time and cost<br />

• Check for hot spots in duct work, electrical panels,<br />

and wiring conduits<br />

Typical Anemometer Applications<br />

• Air duct measurements<br />

• Positive pressure tests in clean rooms<br />

• Fume hood testing and verification<br />

• Automobile engines analysis<br />

• Automobile passenger compartment tests<br />

• Ionizer flow output monitoring<br />

• Ventilation system inspection<br />

Used in HVAC applications measuring airflow<br />

from heating vents.<br />

HD300<br />

<br />

<br />

<br />

AN200

What are Moisture Meters?<br />

Moisture Meters sense, measure and display the<br />

moisture content of wood and other building products.<br />

Materials such as sheet rock, wall board, mortar,<br />

concrete, plaster, cardboard, and others can be tested<br />

for moisture.<br />

How are Moisture Meters used?<br />

Moisture Meters are used to detect moisture in wood,<br />

wall board, and other building materials to gage<br />

damage from flooding, high humidity, or other causes,<br />

for example. Moisture meters are also used in furniture<br />

manufacturing and rebuilding, wood flooring, wood<br />

drying, flood insurance claims, building inspection,<br />

pest control, and many others.<br />

MO280<br />

Non-invasive Pinless<br />

technology<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

Moisture Meters<br />

MO290<br />

How do Moisture Meters operate?<br />

Moisture meters determine the moisture content of<br />

a material by way of pin-like probes that are inserted<br />

directly into the material under test. The moisture<br />

reading is then displayed on the meter. The unit of<br />

measure for moisture content varies from instrument<br />

to instrument some use ‘%’ and others use a relative<br />

scale from 0 to 100 where 100 represents maximum<br />

and 0 represents minimum moisture. Many meters also<br />

use a Dry, Moist, and Wet indicator for convenience.<br />

MO280-KW<br />

Pin Moisture Probe included for making<br />

contact moisture measurements

What are Electrical Testers?<br />

Electrical testers are a family of products that can<br />

detect the presence of voltage and/or current<br />

quickly and easily. Electrical testers are portable<br />

and ergonomic, allowing the user to safely hold the<br />

instrument near the source of electricity for testing.<br />

Electrical testers can detect AC only, DC only, or both<br />

AC and DC signals. Some testers can also provide<br />

continuity and phase tests.<br />

Contact and Non-Contact Electrical Testers<br />

There are two types of testers: Contact and Non-<br />

Contact. Contact testers, as the name implies, have<br />

probes that must physically come in contact with the<br />

signal under test in order to make a measurement.<br />

Non-contact devices detect the electrical signal<br />

through magnetic induction and therefore do not need<br />

a physical connection to make a measurement.<br />

AC and DC Electrical Testers<br />

The most common testers measure AC signals. AC<br />

(alternating current) is the power that is provided by<br />

utility companies to homes, offices, and manufacturing<br />

plants. AC signals are present at breaker panels,<br />

wall outlets, switches, light fixtures, etc. DC testers<br />

(direct current) are geared toward the measurement of<br />

low voltage signals associated with battery powered<br />

circuits.<br />

Built-in IR Thermometer with<br />

LCD displays non-contact<br />

temperature measurements<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

<br />

Electrical Testers<br />

How are Electrical Testers used?<br />

Electrical Testers detect the presence of voltage or<br />

current at an outlet, power strip, light fixture, wall<br />

switch, or any location where electricity may be<br />

present. The user places the tester near (in the case<br />

of a non-contact tester) or in touch with (in the case of<br />

a contact tester) an electrical circuit. The tester may<br />

provide the measurement results audibly, visually, or<br />

by both means. Audible detection is usually by way<br />

of chirping tones that grow louder and more insistent<br />

as the electricity amount increases. Visual alerts<br />

can be simple LED lights or full digital readouts with<br />

bargraphs.<br />

A note about sensitivity adjustments<br />

Many Electrical Testers include a sensitivity<br />

adjustment. Such an adjustment allows the user to<br />

more accurately detect the presence of electricity<br />

by mitigating the possibility of false detection. False<br />

detection can occur when there is a large amount of<br />

static electricity present that triggers the Electrical<br />

Tester. This can confuse the user as to the presence<br />

of electricity in the circuit under test. By adjusting<br />

the tester’s sensitivity, the false triggering can be<br />

minimized.<br />

Quickly check for the presence of live Check voltage in breakerss<br />

wires before testing<br />

DVA30<br />

DV40 <br />

<br />

<br />

VT30

What is a Sound Level Alert?<br />

The <strong>Extech</strong> Sound Level Alert displays sound level<br />

readings on an extra large LCD ideal for viewing from a<br />

distance. Sound level is displayed in db (decibels) and<br />

also represented by bright, color-coded status LEDs.<br />

The user can program a sound level limit that when<br />

exceeded will change the LEDs from green to flashing<br />

red and display an ‘OVER’ message.<br />

How are Sound Level Alerts used?<br />

The Sound Level Alert can be placed in auditoriums,<br />

hospital wards, class rooms, and other school areas.<br />

When the noise level reaches a predetermined alarm<br />

level, the alert LEDs will warn the occupants. The relay<br />

output permits the user to connect an external audio<br />

or visual device for more dramatic, customized alerts.<br />

What is a Sound Level Datalogger?<br />

The HD600 Datalogging Sound Level meter measures,<br />

displays, and stores sound level measurement data.<br />

Up to 20,000 readings can be stored in the meter,<br />

each with the date and time stamp. Readings can<br />

be recalled on the meter’s display or they can by<br />

downloaded to a PC. Included software permits<br />

the user to view, graph, print, and export data<br />

to a spreadsheet.<br />

How are Sound Level Dataloggers used?<br />

Since a Sound Level Datalogger can automatically<br />

store readings at a user-programmable sample rate,<br />

they are the ideal tool for taking readings ‘unattended’<br />

for long periods of time. After readings are stored<br />

they can be transferred to a PC to be viewed,<br />

graphed, printed, or exported to a spreadsheet for<br />

further analysis. This capability can be applied to<br />

many applications such as airport noise analysis,<br />

construction zone monitoring, traffic intersections,<br />

concert venues, environmental impact studies,<br />

and many others.<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

ISO 9001:2000 CERTIFIED<br />

Sound Level Meters<br />

What is ‘A’ and ‘C’ Frequency Weighting?<br />

Frequency “weighting” selections allow the user to<br />

choose how the meter will treat sound measurements<br />

over the meter’s specified frequency range. In ‘A’<br />

weighting mode, the meter gives more “weight” to<br />

certain frequencies. In other words, sound levels at<br />

certain frequencies will be boosted or cut (to match<br />

how the human ear responds to sound). “A” weighting<br />

is useful for OSHA compliance testing. The “C”<br />

weighting selection provides a more “flat” response,<br />

meaning that all frequencies are treated basically<br />

the same (no boosting or cutting of sound level). “C”<br />

weighting is suitable for machine analysis<br />

and diagnostics.<br />

What is the significance of FAST / SLOW<br />

Response Time?<br />

Response Time selections refer to how fast or slow<br />

the meter will respond to sound. Most meters have<br />

a slow and a fast selection. “Slow” response is most<br />

often used for hearing conservation/OSHA programs<br />

and is an “averaging” of sound level over time. “Fast”<br />

response is most commonly used for product noise<br />

reduction efforts and can detect quick noise bursts<br />

(For example: fireworks).<br />

“Make Mine an <strong>Extech</strong>! The HD600 Datalogging Sound Level Meter meets new<br />

IEC 61672-1 Class 2 accuracy standard for OSHA and<br />

other local and national noise ordinances<br />

407732 ”<br />

<strong>Extech</strong> <strong>Instruments</strong> Corporation • 285 Bear Hill Road • Waltham, MA 02451-1064 USA<br />

Phone: 1-781-890-7440 • Fax: 1-781-890-7864 • E-mail: sales@extech.com • Internet: www.extech.com<br />

HD600

What is a Hygro-Thermometer?<br />

A hygro-thermometer measures relative humidity<br />

(RH) and temperature. The unit of measure for relative<br />

humidity is percent (the range is 0.0 to 100.0%). 100%<br />

relative humidity is the maximum amount of moisture<br />

that air can hold without condensation. Temperature<br />

is sensed on <strong>Extech</strong> Hygro-Thermometers by a<br />

thermistor and is displayed in °C or °F.<br />

What is Dew Point?<br />

Dew Point is the temperature at which water vapor<br />

condenses. It is not as common as relative humidity<br />

measurements but has applications in meteorological,<br />

chemical, and electronic assembly areas.<br />

What is a Psychrometer?<br />

A Psychrometer is a Hygro-Thermometer that uses<br />

Wet/Dry Bulb technology. Wet/Dry Bulb is a complex<br />

humidity-temperature measuring technology that<br />

<strong>Extech</strong> meters simulate using an internal algorithm.<br />

Literature Order Form<br />

<strong>TECH</strong> <strong>TIPS</strong><br />

ISO 9001:2000 CERTIFIED<br />

Hygro-Thermometers<br />

The RH490 Precision Hygro-Thermometer<br />

Psychrometer is specifically designed for HVAC<br />

and water damage restoration contractors<br />

Patented non-contact InfraRed<br />

Thermometer technology built<br />

into a Hygro-Thermometer like<br />

the HD500 is perfect for Home<br />

inspection applications.<br />

Hygro-Thermometer Applications<br />

• Semiconductor fabrication clean rooms<br />

• Environmental analysis<br />

• Electronic assembly<br />

• Food processing and serving areas<br />

• Computer and other workstation environments<br />

• Processes requiring gases in manufacturing<br />

• HVAC applications<br />

• Greenhouses<br />

• Flood restoration<br />

Calibration Bottles<br />

<strong>Extech</strong> offers calibration references for 33% and 75%<br />

relative humidity. The calibration references are small<br />

bottles that accept the humidity sensor. Periodic<br />

calibration is necessary to insure precise readings.<br />

Check the listings for the appropriate reference bottles<br />

for a given meter.<br />

“Make Mine an <strong>Extech</strong>! RH490 ”<br />

<strong>Extech</strong> <strong>Instruments</strong> Corporation • 285 Bear Hill Road • Waltham, MA 02451-1064 USA<br />

Phone: 1-781-890-7440 • Fax: 1-781-890-7864 • E-mail: sales@extech.com • Internet: www.extech.com<br />

HD500