ExxonMobil and Abu Dhabi

ExxonMobil and Abu Dhabi

ExxonMobil and Abu Dhabi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

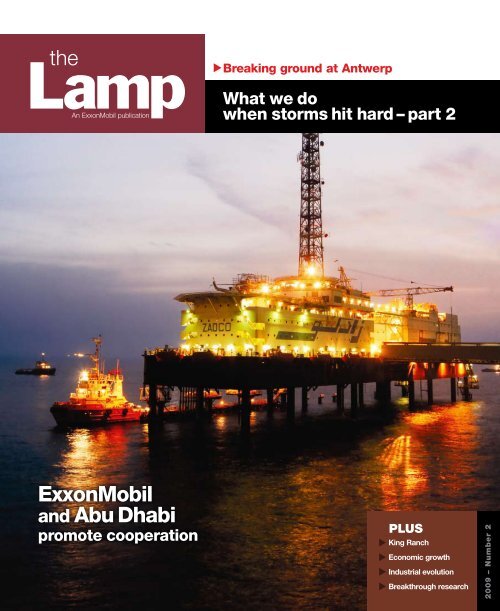

An <strong>ExxonMobil</strong> publication<br />

<strong>ExxonMobil</strong><br />

<strong>and</strong> <strong>Abu</strong> <strong>Dhabi</strong><br />

promote cooperation<br />

Breaking ground at Antwerp<br />

What we do<br />

when storms hit hard – part 2<br />

PLUS<br />

King Ranch<br />

Economic growth<br />

Industrial evolution<br />

Breakthrough research OFC<br />

2009 – Number 2

Viewpoint<br />

1<br />

Power<br />

Transportation<br />

Residential/<br />

Commercial<br />

Industry<br />

Energy saved<br />

through industrial<br />

efficiency gains<br />

Industrial evolution<br />

New technologies can help businesses<br />

become more energy-efficient.<br />

0 25 50 75 100 125<br />

Million barrels daily oil-equivalent<br />

If you drive a fuel-efficient car, you are helping<br />

the environment by conserving natural<br />

resources <strong>and</strong> reducing emissions of carbon<br />

dioxide (CO2) <strong>and</strong> other greenhouse gases.<br />

But what about the energy it took to produce<br />

the fuel <strong>and</strong> the other products we<br />

use? Can efficiency help there, too?<br />

The answer is yes. Businesses are major<br />

consumers of energy. In creating <strong>and</strong> delivering<br />

the goods <strong>and</strong> services we depend<br />

upon, they use large quantities of electric<br />

power <strong>and</strong> other energy sources. For example,<br />

the industrial sector alone accounts for<br />

about one-third of total energy consumption<br />

worldwide <strong>and</strong> more than 25 percent of<br />

energy-related CO2 emissions.<br />

By improving energy efficiency, <strong>and</strong> taking<br />

advantage of advanced efficiency technologies,<br />

industries have a tremendous opportunity<br />

to contribute to the global effort to<br />

reduce greenhouse gas emissions.<br />

At <strong>ExxonMobil</strong>, our high-efficiency cogeneration<br />

facilities throughout 10 U.S. sites<br />

generate up to 2,400 megawatts of electricity,<br />

while also producing steam <strong>and</strong> useful<br />

heat needed for industrial processes. At our<br />

refinery in Beaumont, Texas, one cogeneration<br />

plant – our largest worldwide – can<br />

produce about 500 megawatts of electricity,<br />

which not only powers refining operations<br />

but also supplements the local power grid.<br />

We have invested more than $600 million<br />

Estimated 2030<br />

world primary<br />

energy dem<strong>and</strong><br />

by sector<br />

in U.S. cogeneration facilities commissioned<br />

since 2004. When combined with our global<br />

cogeneration capacity, these investments<br />

have helped reduce global greenhouse gas<br />

emissions equivalent to taking more than<br />

1 million cars off U.S. roads.<br />

Clearly, increased energy efficiency<br />

is good for the environment. But it also<br />

enhances the global business environment.<br />

Companies can reduce costs, increase<br />

productivity <strong>and</strong> benefit shareholders by<br />

using advanced technology to make their<br />

operations more energy-efficient – a valuable<br />

asset during challenging economic times.<br />

The International Energy Agency calls<br />

efficiency a “triple win” solution – boosting<br />

economic performance, strengthening<br />

energy security <strong>and</strong> reducing greenhouse<br />

gas emissions.<br />

We agree. <strong>ExxonMobil</strong> has systematically<br />

worked to improve efficiency at our global<br />

operations, <strong>and</strong> we are making large investments<br />

in research <strong>and</strong> development of technologies<br />

that can advance the efficiency of<br />

how we produce energy <strong>and</strong> how consumers<br />

use our products.<br />

Today, companies <strong>and</strong> nations are being<br />

challenged to find creative ways to restore<br />

economic growth while protecting the environment.<br />

Investing in energy efficiency can<br />

help accomplish both.

Rex W. Tillerson<br />

Chairman <strong>and</strong> CEO<br />

Mark W. Albers<br />

Senior Vice President<br />

Michael J. Dolan<br />

Senior Vice President<br />

Donald D. Humphreys<br />

Senior Vice President<br />

Andrew P. Swiger<br />

Senior Vice President<br />

Kenneth P. Cohen<br />

Vice President-Public Affairs<br />

David S. Rosenthal<br />

Vice President-Investor Relations <strong>and</strong> Secretary<br />

Bob Davis<br />

Editor<br />

Pat Gabriel<br />

GCG<br />

Art Director<br />

Len Shelton<br />

Photography Coordinator<br />

Cynthia Solomon<br />

Production Coordinator<br />

Frances Bruscino<br />

Distribution Coordinator<br />

Please address all Lamp correspondence,<br />

including requests to reproduce any portion<br />

of the magazine, to the editor at Exxon Mobil<br />

Corporation, 5959 Las Colinas Blvd., Irving,<br />

TX 75039-2298.<br />

In this issue<br />

1<br />

Viewpoint<br />

Industrial evolution<br />

3<br />

Innovation is key<br />

Chairman Tillerson addresses<br />

global energy challenges<br />

5<br />

Exploring breakthrough<br />

technologies<br />

Options for innovative<br />

energy solutions<br />

23 7 14<br />

Upfront<br />

The goal of the Global Climate<br />

<strong>and</strong> Energy Project (GCEP),<br />

based at Stanford University<br />

<strong>and</strong> founded in 2002 with major<br />

support from <strong>ExxonMobil</strong>, is to<br />

develop research-based, scientific<br />

solutions to help countries<br />

address energy <strong>and</strong> environmental<br />

issues.<br />

Earlier this year, Chairman<br />

<strong>and</strong> CEO Rex W. Tillerson spoke<br />

at Stanford, noting how GCEP<br />

promotes the practical problemsolving<br />

necessary to advance<br />

broad-based commercial solutions.<br />

Chairman Tillerson went on<br />

to discuss <strong>ExxonMobil</strong>’s contributions<br />

to this effort, with breakthrough<br />

research in such areas<br />

as advanced polymer film for<br />

electric-vehicle batteries, hydrogen<br />

fuel-cell technology <strong>and</strong><br />

7<br />

When storms hit hard<br />

Getting products to customers<br />

when <strong>and</strong> where they’re needed<br />

12<br />

Much more than a plan<br />

How lessons learned aid<br />

storm response, recovery<br />

14<br />

New cogeneration<br />

plant starts up<br />

Antwerp facility improves<br />

efficiency <strong>and</strong> cuts emissions<br />

17<br />

Promoting cooperation<br />

in <strong>Abu</strong> <strong>Dhabi</strong><br />

Technology, creativity boost<br />

field recovery at lower cost<br />

21<br />

Reigniting economic growth<br />

Energy industry’s role in<br />

restoring confidence<br />

2 3<br />

Old friend, new lease<br />

<strong>ExxonMobil</strong> extends decadeslong<br />

relationship with King Ranch<br />

Technology key to<br />

<strong>ExxonMobil</strong> <strong>and</strong> <strong>Abu</strong><br />

<strong>Dhabi</strong> relationship<br />

A new technology center,<br />

artificial isl<strong>and</strong>s <strong>and</strong><br />

an innovative drilling<br />

organization highlight efforts<br />

to increase oil recovery at the<br />

Upper Zakum field.<br />

Cover photo courtesy of ZADCO<br />

advanced research in biofuels –<br />

including liquid-fuel production<br />

from algae <strong>and</strong> biomass.<br />

A summary of his Stanford<br />

speech begins on page 3.<br />

This issue’s cover story (page<br />

17) explores how close cooperation<br />

<strong>and</strong> technical prowess by<br />

<strong>ExxonMobil</strong>, the emirate of <strong>Abu</strong><br />

<strong>Dhabi</strong>, the <strong>Abu</strong> <strong>Dhabi</strong> National<br />

Oil Company <strong>and</strong> Japan Oil are<br />

meeting the challenges in developing<br />

the world’s fourth-largest<br />

oil field. This complex project is<br />

expected to boost daily production<br />

at the 50-billion-barrel Upper<br />

Zakum field, helping to meet<br />

future world energy dem<strong>and</strong>.<br />

The conclusion of our<br />

two-part series on hurricane<br />

preparation <strong>and</strong> response starts<br />

on page 7, <strong>and</strong> profiles how<br />

the company’s refining, supply,<br />

lubes <strong>and</strong> fuels-marketing<br />

organizations safely overcame<br />

the effects of Hurricanes Gustav<br />

<strong>and</strong> Ike to get needed products<br />

to customers. A related<br />

story (page 12) details how<br />

the Beaumont Chemical Plant<br />

restored operations after more<br />

than eight feet of seawater <strong>and</strong><br />

mud impacted the facility.<br />

Plus, stories on pages 23 <strong>and</strong><br />

14 explore <strong>ExxonMobil</strong> operations<br />

at the King Ranch <strong>and</strong> in<br />

Antwerp, Belgium.<br />

We hope you enjoy this issue<br />

of The Lamp.<br />

Bob Davis<br />

Editor<br />

27<br />

A helping h<strong>and</strong> Down Under<br />

<strong>ExxonMobil</strong> aids communities<br />

after devastating wildfires<br />

29<br />

Panorama<br />

Business highlights<br />

from around the world<br />

30<br />

<strong>ExxonMobil</strong> quarterly<br />

financial summary<br />

2<br />

17

Meeting global energy<br />

<strong>and</strong> environmental challenges through innovation<br />

3<br />

Chairman Tillerson began his<br />

speech by saluting six years of<br />

promising energy research at the<br />

Stanford-based Global Climate<br />

<strong>and</strong> Energy Project (GCEP),<br />

founded in 2002 with <strong>ExxonMobil</strong><br />

as lead sponsor. He noted that<br />

GCEP’s network of scientists,<br />

engineers, researchers <strong>and</strong> students<br />

involves 20 research institutions<br />

on four continents, with<br />

Stanford at the hub. “GCEP’s<br />

work is ultimately about laying<br />

the scientific foundations for<br />

practical problem-solving that will<br />

help advance broad-based commercial<br />

solutions,” he said.<br />

Technology, said Tillerson, is<br />

the single, most vital element that<br />

should unite all efforts to attain<br />

our energy <strong>and</strong> environmental<br />

goals. He said <strong>ExxonMobil</strong> has<br />

invested more than $6 billion in<br />

technology in just the past six<br />

years, <strong>and</strong> maintains several<br />

company research centers in the<br />

United States <strong>and</strong> elsewhere.<br />

“Our 14,000 scientists <strong>and</strong> engineers<br />

are part of the broader<br />

technical <strong>and</strong> scientific community<br />

dedicated to energy <strong>and</strong><br />

environmental problem-solving<br />

through technology innovation.”<br />

Oil, natural gas continue as<br />

prime energy sources<br />

While the current global economic<br />

downturn has reduced<br />

energy dem<strong>and</strong> <strong>and</strong> prices,<br />

Tillerson said the world econ-<br />

Story by Thomas L. Torget<br />

In a February speech at Stanford University,<br />

<strong>ExxonMobil</strong> Chairman <strong>and</strong> CEO Rex W. Tillerson<br />

described the critical role of technology in meeting<br />

the challenge of delivering more energy while<br />

reducing greenhouse gas emissions.<br />

omy will recover, <strong>and</strong> so too will<br />

energy dem<strong>and</strong>.<br />

Growing populations in<br />

developing countries will drive<br />

increased energy dem<strong>and</strong>, which<br />

is expected to be 35 percent<br />

higher in 2030 than in 2005.<br />

Meeting this dem<strong>and</strong> requires<br />

that we develop all economic<br />

<strong>and</strong> environmentally sound<br />

sources of energy, including oil<br />

<strong>and</strong> natural gas, which Tillerson<br />

described as “abundant, available,<br />

versatile <strong>and</strong> affordable.”<br />

Tillerson noted that huge<br />

investments over many decades<br />

have enabled oil <strong>and</strong> gas to meet<br />

nearly 60 percent of world energy<br />

needs today, <strong>and</strong> that these<br />

same fuels will meet the majority<br />

of world energy dem<strong>and</strong> through<br />

at least 2030. Alternatives such<br />

as solar, wind, nuclear <strong>and</strong> biofuels<br />

will make a significant <strong>and</strong><br />

growing contribution, but no<br />

single energy source solves the<br />

dual challenge of meeting growing<br />

energy needs while reducing<br />

emissions. “For now <strong>and</strong> the foreseeable<br />

future, an integrated set<br />

of solutions is required,” he said.<br />

Turning to environmental<br />

challenges, Tillerson explained<br />

that thanks to greater energy<br />

efficiency <strong>and</strong> growing use of<br />

cleaner fuels such as natural<br />

gas, greenhouse gas emissions<br />

are expected to decline in some<br />

developed economies. U.S.<br />

energy-related carbon-dioxide<br />

emissions are approaching a<br />

plateau <strong>and</strong> will decrease over<br />

the next two decades, he said.<br />

“These trends are set to continue<br />

<strong>and</strong> potentially accelerate,<br />

not only in the United States but<br />

in other developed economies<br />

as well.”<br />

Greenhouse gas emissions<br />

to rise in developing nations<br />

But the challenge of reducing<br />

greenhouse gas emissions is<br />

more daunting for developing<br />

economies, said Tillerson. “By<br />

2030 China’s carbon-dioxide<br />

emissions will be comparable<br />

to those of the United States<br />

<strong>and</strong> Europe combined,” he said.<br />

“Even with dramatic gains in efficiency,<br />

rising dem<strong>and</strong> for energy<br />

will continue to push related<br />

carbon-dioxide emissions higher<br />

through 2030, an increase of 28<br />

percent from 2005.”<br />

Tillerson noted that any new<br />

technology – however promising<br />

– faces practical barriers in<br />

bringing it to the energy marketplace.<br />

These barriers include<br />

performance, cost, safety,<br />

environmental impacts <strong>and</strong> consumer<br />

acceptance.<br />

He said <strong>ExxonMobil</strong>’s integrated<br />

approach to increasing<br />

supplies <strong>and</strong> reducing emissions<br />

is exemplified by the company’s<br />

Global Energy Management<br />

System. The system involves daily<br />

tracking of more than 12,000<br />

energy variables throughout the<br />

company’s refining, marketing<br />

<strong>and</strong> chemical operations. “Since<br />

2000, we have identified $1.5 billion<br />

in potential efficiency savings,<br />

<strong>and</strong> approximately 60 percent of<br />

those savings have been captured<br />

to date,” he added.<br />

New technologies<br />

in transportation<br />

Tillerson mentioned several<br />

<strong>ExxonMobil</strong> technologies that<br />

are improving energy efficiency in<br />

the transportation sector. These<br />

include tire liners that keep tires<br />

inflated longer, advanced fuel

economy engine oil <strong>and</strong> lightweight<br />

automobile plastics.<br />

<strong>ExxonMobil</strong>’s internal research,<br />

said Tillerson, has produced<br />

breakthrough technology involving<br />

separator film made from<br />

advanced polymers. This film can<br />

significantly enhance the power,<br />

safety <strong>and</strong> reliability of lithium-ion<br />

batteries used to power hybrid<br />

<strong>and</strong> electric vehicles.<br />

Hydrogen fuel-cell technology<br />

is another area pioneered<br />

by <strong>ExxonMobil</strong> <strong>and</strong> its research<br />

partners, said Tillerson. This<br />

technology converts traditional<br />

hydrocarbon fuels into hydrogen<br />

directly onboard the vehicle,<br />

eliminating the need for separate<br />

infrastructure to produce <strong>and</strong><br />

distribute hydrogen. “Measured<br />

on a well-to-wheel basis, this<br />

on-vehicle fuel system could provide<br />

up to 80 percent better fuel<br />

economy <strong>and</strong> emit 45 percent<br />

less carbon dioxide than today’s<br />

vehicles,” he noted.<br />

One of the most promising<br />

areas of <strong>ExxonMobil</strong>’s research,<br />

said Tillerson, involves advanced<br />

biofuels, including production of<br />

liquid fuels from algae <strong>and</strong> biomass<br />

conversion. He said these<br />

technologies could reduce green-<br />

house gas <strong>and</strong> l<strong>and</strong> use impacts<br />

as compared to first-generation<br />

biofuels such as ethanol.<br />

Sound government<br />

policies needed<br />

Tillerson stressed that the complexities<br />

of new technologies <strong>and</strong><br />

the enormous scale of the global<br />

energy market mean that technological<br />

transformation takes<br />

time. That’s why government<br />

policies must allow for long-term<br />

planning <strong>and</strong> disciplined investments<br />

that lead to technological<br />

advances. Tillerson called for<br />

governments to provide invest-<br />

ment stability by implementing<br />

simple, transparent <strong>and</strong> predictable<br />

policies to mitigate greenhouse<br />

gas emissions.<br />

“Consistent with that view,<br />

we believe a carbon tax would<br />

be a more effective policy option<br />

to reduce greenhouse gas emissions<br />

than alternatives such as<br />

cap-<strong>and</strong>-trade,” said Tillerson.<br />

“A carbon tax should be offset<br />

by tax reductions in other areas<br />

to become revenue-neutral for<br />

government.” the Lamp<br />

4

5<br />

Energy conference<br />

explores breakthrough technologies<br />

Leading experts in breakthrough<br />

energy technologies<br />

from the United States <strong>and</strong><br />

Europe gathered in London<br />

earlier this year to share<br />

ideas <strong>and</strong> perspectives on<br />

key issues, including hydrocarbon-productiontechniques,<br />

improved efficiency<br />

in transportation, carbonemission<br />

mitigation <strong>and</strong><br />

alternative-energy options.<br />

Story by Thomas L. Torget<br />

The Financial Times Energy<br />

Conference, sponsored by<br />

<strong>ExxonMobil</strong>, explored technology<br />

options that could help<br />

meet increased energy dem<strong>and</strong><br />

in efficient <strong>and</strong> environmentally<br />

responsible ways.<br />

The ideas discussed included<br />

innovative approaches to oils<strong>and</strong>s<br />

production, extended-<br />

reach drilling, wave energy,<br />

advances in batteries (both for<br />

vehicles <strong>and</strong> for storing energy<br />

produced by hydro or wind<br />

power), hydrogen-powered<br />

cars, thin-film solar cells <strong>and</strong><br />

advanced biofuels.<br />

Attended by more than 100<br />

specialists in the field of energy<br />

technologies, the conference<br />

provided participants with the<br />

opportunity to question the<br />

experts, exchange ideas <strong>and</strong><br />

network with peers.<br />

Debates concentrated on four<br />

topics: new techniques that offer<br />

innovative approaches to find,<br />

produce <strong>and</strong> deliver hydrocarbon<br />

reserves; technological innovations<br />

that allow industries to use<br />

energy more efficiently; advancements<br />

in the large-scale reduction,<br />

removal <strong>and</strong> storage of carbon<br />

dioxide; <strong>and</strong> developments<br />

During his panel presentation,<br />

<strong>ExxonMobil</strong>’s Nazeer<br />

Bhore (second from left)<br />

discussed a number of<br />

promising technologies to<br />

increase vehicle efficiency<br />

<strong>and</strong> lower emissions.

in alternative-energy resources.<br />

Chaired by Neil Hirst of the<br />

International Energy Agency, the<br />

conference included speakers<br />

such as the chief scientific advisor<br />

to the British government, representatives<br />

from eight leading universities<br />

<strong>and</strong> research institutions,<br />

<strong>and</strong> specialists from Schlumberger,<br />

BP, General Motors, GE, Air<br />

Liquide, ALSTOM Power <strong>and</strong><br />

IBM. Professor Lynn Orr, former<br />

Global Climate <strong>and</strong> Energy Project<br />

director, Stanford University, was a<br />

speaker, along with <strong>ExxonMobil</strong>’s<br />

Nazeer Bhore, Corporate Strategic<br />

Planning senior technology advisor.<br />

In addition, Professor M. Stanley<br />

Whittingham of the State University<br />

of New York, who helped invent<br />

lithium-ion battery technology as<br />

an Exxon employee in the 1970s,<br />

was a key speaker.<br />

Technology improvements<br />

During the conference, Bhore<br />

discussed how new technologies<br />

can improve vehicle efficiency<br />

<strong>and</strong> reduce greenhouse gas<br />

emissions.<br />

“In the short term, we need to<br />

improve the efficiency of engines<br />

<strong>and</strong> transmissions, use improved<br />

tires, <strong>and</strong> also make vehicles<br />

lighter <strong>and</strong> more aerodynamically<br />

efficient,” he said.<br />

“In the mid-term, we will also<br />

need to further develop advanced<br />

power trains, such as hybrids <strong>and</strong><br />

advanced diesels, such that their<br />

cost is lowered to promote widespread<br />

adoption.<br />

“For the longer term, we need<br />

step-out technologies involving<br />

hydrogen fuel cells, electric cars<br />

<strong>and</strong> next-generation biofuels. I’m<br />

enthusiastic about all of these<br />

options.”<br />

Bhore said <strong>ExxonMobil</strong> is<br />

developing a highly promising<br />

technology that can produce<br />

hydrogen from liquid fuels<br />

onboard a vehicle. The technology<br />

uses a process called<br />

reforming to chemically convert<br />

gasoline, diesel or biofuel into<br />

fuel cell-ready hydrogen.<br />

“This is very exciting because it<br />

offers the potential to avoid many<br />

of the problems that make hydrogen<br />

use for transportation fuel<br />

such a huge challenge,” he said.<br />

“These challenges include finding<br />

ways to make hydrogen in large<br />

volumes, <strong>and</strong> then distributing it<br />

<strong>and</strong> storing it economically <strong>and</strong><br />

safely. None of that is easy.”<br />

Bhore reported that<br />

<strong>ExxonMobil</strong> engineers estimate<br />

this new on-board hydrogengeneration<br />

technology on a fuelcell<br />

vehicle can reduce fuel consumption<br />

<strong>and</strong> greenhouse gas<br />

emissions by 45 percent or boost<br />

fuel economy by 80 percent.<br />

He noted that this hydrogen<br />

technology is just one of many<br />

innovations <strong>ExxonMobil</strong> is pursuing,<br />

through its own research or<br />

in collaboration with others, to<br />

improve vehicle efficiency. Other<br />

efforts include the company’s<br />

recently introduced battery<br />

separator<br />

film technology,<br />

as well<br />

as numerous<br />

projects involving biofuels <strong>and</strong><br />

step-out engine technologies.<br />

“As a society, we must<br />

To learn more<br />

http://www.ftconferences<br />

.com/energytechnologies<br />

aggressively pursue a portfolio<br />

of options that potentially can<br />

improve vehicle efficiency <strong>and</strong><br />

reduce greenhouse gases,<br />

while also meeting society’s<br />

continuing needs for reliable<br />

<strong>and</strong> affordable transportation<br />

fuels,” he said. the Lamp<br />

Some findings<br />

There is no silver bullet to the energy challenges<br />

the world is facing, <strong>and</strong> a variety of innovative <strong>and</strong><br />

collaborative solutions is required.<br />

The energy future will be more diverse, with<br />

energy efficiency playing a major role in meeting<br />

the challenges.<br />

Carbon capture <strong>and</strong> storage is a key option that<br />

must be further developed <strong>and</strong> explored as part<br />

of efforts to manage greenhouse gas emissions.<br />

Meeting the challenges will require substantial<br />

progress in technology, <strong>and</strong> will depend on scientists<br />

<strong>and</strong> engineers to come up with solutions that<br />

are both scalable <strong>and</strong> cost effective.<br />

6

7<br />

What we do<br />

when storms hit hard<br />

Second of two parts<br />

Soon after Hurricane Gustav<br />

made a surprise, inl<strong>and</strong> assault<br />

on Baton Rouge, Louisiana,<br />

last September, Tom Moeller,<br />

<strong>ExxonMobil</strong> director of refining,<br />

Americas, arrived in the city to<br />

survey the storm damage that<br />

had shut down operations at the<br />

company’s second-largest U.S.<br />

refinery. En route from the airport,<br />

he observed long lines of anxious<br />

motorists at the few service stations<br />

that had the fuel, electrical<br />

power <strong>and</strong> staffing to remain<br />

open for business.<br />

“Scenes like that illustrate the<br />

role our industry plays in supporting<br />

the everyday infrastructure<br />

of society,” says Moeller. “It’s<br />

why we needed to get back up<br />

<strong>and</strong> running quickly.”<br />

When hurricanes hit, restoring<br />

normal operations is a guiding<br />

principle throughout <strong>ExxonMobil</strong>’s<br />

downstream business – from<br />

refining <strong>and</strong> supply, to pipeline<br />

<strong>and</strong> marine transportation, to<br />

John Palaszczuk leads a hurricane<br />

preparation drill at the<br />

Fairfax, Virginia, headquarters of<br />

<strong>ExxonMobil</strong>’s Refining, Supply,<br />

Fuels Marketing <strong>and</strong> Lubricants/<br />

Specialties organizations.<br />

Story by Shelley Moore Christiansen <strong>and</strong> Richard Cunningham<br />

From Texas to Louisiana, the Gulf Coast region<br />

is home to the nation’s highest concentration of<br />

refining <strong>and</strong> supply operations, a host of terminals,<br />

the origination points of the nation’s largest<br />

pipeline systems <strong>and</strong> extensive fuels-marketing<br />

networks. It has also been l<strong>and</strong>fall for some of<br />

history’s most destructive hurricanes.<br />

fuels <strong>and</strong> lubes marketing.<br />

As storms approach,<br />

<strong>ExxonMobil</strong>’s goal is to keep<br />

operations in the region going<br />

wherever they safely can.<br />

Where business is interrupted,<br />

company teams work quickly<br />

to restore product supply – or<br />

develop alternate, interim solutions.<br />

And they do it on a foundation<br />

of rigorous planning <strong>and</strong><br />

preparation that has repeatedly<br />

kept <strong>ExxonMobil</strong> a step ahead<br />

of the industry in times of crisis.<br />

Lessons learned<br />

Taking lessons learned from<br />

such storms as Gustav <strong>and</strong> Ike<br />

in 2008 <strong>and</strong> Katrina <strong>and</strong> Rita in<br />

2005, the company’s hurricaneresponse<br />

teams routinely conduct<br />

training <strong>and</strong> other emergency-response<br />

scenarios.<br />

They fine-tune day-to-day<br />

storm watch action plans <strong>and</strong><br />

update employee tracking data<br />

to make sure workers are safe<br />

if they have to evacuate. Team<br />

members conduct simulation<br />

Photo by Robert Seale

drills with internal <strong>and</strong> external<br />

partners, <strong>and</strong> plan where extra<br />

fuel might come from. And<br />

they provide information, guidance<br />

<strong>and</strong> support to industry<br />

associations, states, counties<br />

<strong>and</strong> municipalities regarding<br />

fuel-specification <strong>and</strong> other waivers<br />

that are considered when a<br />

storm is on its way.<br />

“Our ability to supply fuel to a<br />

particular marketplace where <strong>and</strong><br />

when it’s needed improves dramatically<br />

if we can temporarily shift<br />

from delivering, for example, 12<br />

formulations to delivering five or<br />

six,” says Erskine Frison, products<br />

optimization manager, Americas.<br />

“One of the core strengths that<br />

sets <strong>ExxonMobil</strong> apart from other<br />

companies during critical periods<br />

is the way we’re organized,”<br />

says Greg Cunningham, U.S.<br />

supply operations manager. “We<br />

work with many groups within<br />

our company – production,<br />

transportation, refining, supply,<br />

marketing – on a daily basis<br />

within our integrated business<br />

team process. During a hurricane,<br />

we just take that process<br />

<strong>and</strong> accelerate it.”<br />

Hurricane watch<br />

<strong>ExxonMobil</strong> operates four<br />

Gulf Coast-area refineries –<br />

in Baytown <strong>and</strong> Beaumont,<br />

Texas, <strong>and</strong> in Baton Rouge <strong>and</strong><br />

Chalmette, Louisiana – accounting<br />

for nearly a quarter of the<br />

Ominous clouds portending Hurricane Ike’s wrath loom over a Houston-area refinery.<br />

The storm actually tracked up the ship channel where many refineries are located.<br />

region’s industrywide refining<br />

capacity of about 8 million barrels<br />

of crude oil a day.<br />

When a major hurricane is still<br />

seven days away from l<strong>and</strong>fall, it<br />

is far too soon to predict which,<br />

if any, <strong>ExxonMobil</strong> refineries may<br />

be affected. Nevertheless, preemptive<br />

inspections <strong>and</strong> preparations<br />

occur to assure that facilities<br />

are well-prepared for severe<br />

weather conditions.<br />

As the l<strong>and</strong>fall clock winds<br />

down, the hurricane’s path may<br />

still be uncertain. “But once<br />

it hits, you can’t hide,” says<br />

Moeller. So, with about four<br />

days to go, the coastal refineries<br />

(Baytown, Beaumont <strong>and</strong><br />

Chalmette) proceed either to<br />

shut down or to shift into what’s<br />

called “safe park,” a reducedoutput<br />

state that helps conserve<br />

crude oil <strong>and</strong> other key supplies<br />

that may soon be interrupted by<br />

the storm.<br />

While refineries close to the<br />

coast are more exposed to the<br />

effects of severe weather, Baton<br />

Rouge, a hundred miles inl<strong>and</strong>, is<br />

more protected <strong>and</strong> more likely<br />

to maintain operations. After a<br />

storm, Baton Rouge’s continued<br />

output can become vital to the<br />

industry as a whole, providing<br />

emergency supplies to downstream<br />

pipelines <strong>and</strong> terminals to<br />

keep fuel moving to regions far<br />

away from impacted areas.<br />

8

9<br />

Helping communities<br />

<strong>and</strong> businesses<br />

“For hurricanes, we exp<strong>and</strong> our<br />

philosophy of keeping our own<br />

system adequately supplied to<br />

one of helping the overall industry<br />

get back to normal,” says<br />

Cunningham.<br />

<strong>ExxonMobil</strong> refineries also help<br />

their surrounding communities<br />

during power outages, providing<br />

electricity from their cogeneration<br />

plants for use by area households<br />

<strong>and</strong> businesses.<br />

The company’s Supply organization<br />

identifies <strong>and</strong> buys additional<br />

volumes of fuel before it’s<br />

clear that the company needs<br />

them to make up for the shortfalls<br />

that sometimes occur. Those<br />

sources might be from locations<br />

several days away, like New York.<br />

They may even be cargoes at<br />

sea – during Hurricanes Gustav<br />

<strong>and</strong> Ike the company diverted 14<br />

waterborne cargoes from other<br />

geographic markets, including<br />

Europe <strong>and</strong> Asia, to fill gaps<br />

in supply while the Texas <strong>and</strong><br />

Louisiana refineries were coming<br />

back up.<br />

“From the downstream perspective,<br />

our biggest challenge<br />

is to keep fuel moving, not only<br />

to customers in the hurricane<br />

zones but to all the others who<br />

depend on refined products<br />

from the Gulf Coast,” says Mark<br />

DiZio, manager of global products<br />

supply <strong>and</strong> trading.<br />

“People in places like North<br />

Carolina sometimes wonder, ‘If<br />

Members of the company’s<br />

Supply response team conduct<br />

drills before hurricane season to<br />

continuously improve the organization’s<br />

effectiveness when a storm<br />

hits. Seated in foreground (left<br />

to right) are Andre Pennington,<br />

Donna Scanlon <strong>and</strong> Ryan House.<br />

Adel <strong>Abu</strong>nasser (left) <strong>and</strong> Greg<br />

Cunningham are pictured at rear<br />

discussing the exercise scenario.<br />

Photo by Robert Seale

Photo by Mark Wilson/Getty Images<br />

the hurricane struck Texas, why<br />

are we without gasoline?’” adds<br />

John Palaszczuk, manager of<br />

U.S. product trading. “The answer<br />

is often related to the length <strong>and</strong><br />

complexity of the supply chain,<br />

variations in product specifications<br />

<strong>and</strong> industry infrastructure.”<br />

Minimizing those disruptions<br />

on a local, regional or<br />

national level is a top priority<br />

for <strong>ExxonMobil</strong> <strong>and</strong> its affiliates.<br />

For example, the company’s<br />

marine affiliates play a vital role<br />

in maintaining the critical flow of<br />

energy by safely <strong>and</strong> efficiently<br />

moving or redirecting important<br />

cargoes to affected markets to<br />

help restore the flow of crude oil,<br />

feedstocks, refined products <strong>and</strong><br />

chemicals.<br />

<strong>ExxonMobil</strong> Pipeline Company<br />

(EMPCo) also plays a critical<br />

infrastructure role to minimize the<br />

impact of hurricanes on crude<br />

<strong>and</strong> refined products deliveries.<br />

Securing <strong>and</strong> coordinating the<br />

placement of portable generators<br />

at key pipeline <strong>and</strong> terminal<br />

facilities is but one example of<br />

EMPCo’s efforts to restore power<br />

<strong>and</strong> resume operations quickly,<br />

safely <strong>and</strong> flawlessly.<br />

Lubricants’ customer focus<br />

Similarly, the lube-oil blend<br />

plants on the Gulf Coast readied<br />

themselves for the hurricanes,<br />

idling operations, moving product<br />

inventories into the network<br />

<strong>and</strong> staging response teams<br />

in the area. Within days of<br />

each hurricane strike, delivery<br />

operations were restored, <strong>and</strong><br />

the plants were operational,<br />

but raw material supplies were<br />

critically impacted. <strong>ExxonMobil</strong>’s<br />

Lubricants & Petroleum<br />

Specialties Company relies on<br />

<strong>ExxonMobil</strong> refineries for basestocks<br />

<strong>and</strong> company chemical<br />

plants for much of its supply<br />

of polyalpha olefins used in the<br />

blending of high-quality lubes<br />

<strong>and</strong> other products.<br />

“We built up significant<br />

product inventory in preparation<br />

for the hurricane,” says<br />

Lynne Lachenmyer, operations<br />

vice president of Lubricants<br />

An emergency worker inspects damage in front of Houston’s JP Morgan Chase Tower<br />

the morning after Hurricane Ike passed through the city on September 13, 2008. The<br />

storm made l<strong>and</strong>fall in the middle of the night, causing extensive damage to buildings.<br />

<strong>and</strong> Specialties. “Despite these<br />

efforts, the storm’s impact<br />

was significant. We took quick<br />

mitigation steps to manage the<br />

disruption of our base-oil supply,<br />

ensuring supply to singlesourced<br />

customers <strong>and</strong> those<br />

providing emergency response.<br />

Unfortunately, customer allocations<br />

were required to manage<br />

supplies. Communication was<br />

key throughout this process. We<br />

were in regular contact with our<br />

customers, providing them with<br />

updates on our recovery plans.”<br />

Marketing’s timely<br />

response<br />

<strong>ExxonMobil</strong> has 81 companyowned<br />

stores in the Houston<br />

area <strong>and</strong> 275 distributor locations,<br />

which are Exxon- or<br />

Mobil-br<strong>and</strong>ed stations that are<br />

owned <strong>and</strong> operated by others.<br />

All were closed as a result of Ike.<br />

Few were damaged in the storm<br />

but most needed emergency<br />

power to reopen.<br />

“We keep 100 large emergency<br />

generators staged in<br />

three cities within 200 miles of<br />

the Gulf Coast,” says Mike Gore,<br />

company-owned retail store<br />

manager. “The generators are<br />

big enough to run all aspects<br />

of a retail site. Since all of our<br />

stores are designed to ‘plug<strong>and</strong>-play,’<br />

we deliver the generator,<br />

plug it in <strong>and</strong> run the site as<br />

if it were on grid power.”<br />

The generators are loaded on<br />

flatbed trucks <strong>and</strong> ready to roll<br />

well before a hurricane makes<br />

l<strong>and</strong>fall. A generator can be<br />

powering any company-owned<br />

store within 24 hours.<br />

And after Ike, <strong>ExxonMobil</strong> was<br />

able to offer 20 of its extra generators<br />

to distributor locations<br />

until power from the grid was<br />

restored.<br />

“Before the storm, we made<br />

sure that our key stores on<br />

evacuation routes had plenty of<br />

fuel <strong>and</strong> stayed open as long as<br />

possible,” Gore says.<br />

“After the hurricane passed,<br />

we reopened those same stores<br />

quickly so that people could get<br />

back into affected areas. We had<br />

10

Coordination team ensures<br />

critical business continues<br />

Well before Hurricane Ike made l<strong>and</strong>fall, <strong>ExxonMobil</strong> activated<br />

its Regional Response Coordination Team (RRCT) to monitor<br />

the storm <strong>and</strong> take the necessary steps to ensure business<br />

continuity, ultimately deploying more than 400 essential personnel<br />

to the company’s Pegasus Place facility in Dallas.<br />

The purpose of the RRCT, which consists of representatives<br />

from all business <strong>and</strong> service lines including Information<br />

Technology, Facilities Management, Procurement, Safety,<br />

Health <strong>and</strong> Environment, Security, Human Resources <strong>and</strong><br />

other support groups, is to provide cross-functional coordination<br />

during the recovery efforts <strong>and</strong> to assist in operating<br />

<strong>ExxonMobil</strong>’s businesses as smoothly as possible while the<br />

affected infrastructure is returning to normal.<br />

For example, the company’s Global Real Estate <strong>and</strong><br />

Facilities unit coordinated the inspection of more than 9,000<br />

Houston-area offices <strong>and</strong> workstations within five days of<br />

l<strong>and</strong>fall, assessing damage <strong>and</strong> initiating repairs, <strong>and</strong> making<br />

sure facilities were safe for staff to return to work.<br />

Information Technology (IT) assigned personnel to the<br />

Houston data center who worked in shifts around the clock<br />

during <strong>and</strong> after the storm to ensure <strong>ExxonMobil</strong>’s critical<br />

processes were not interrupted. Facilities <strong>and</strong> IT also collaborated<br />

to provide close to 500 alternative work locations<br />

for employees in the early recovery phase.<br />

The company’s Procurement group placed close to 1,000<br />

purchase orders to support the immediate recovery process,<br />

from portable generators to more than 10,000 bottles<br />

of water for employees, while utility <strong>and</strong> city services were<br />

unavailable.<br />

“Communication is key,” says Andreas Goldschmid, of the<br />

RRCT leadership team. “To ensure business continuity, we<br />

coordinate not only with every <strong>ExxonMobil</strong> company, but with<br />

the weather service, government <strong>and</strong> emergency-response<br />

officials, employees <strong>and</strong> contractors to make sure we underst<strong>and</strong><br />

<strong>and</strong> manage the cross-functional needs of the corporation<br />

while getting activities safely back to normal.”<br />

11<br />

limited products, but we focused<br />

on the things people needed<br />

most: fuel, water, batteries <strong>and</strong><br />

ice. And our retail employees<br />

were crucial to this effort, going<br />

above <strong>and</strong> beyond what was<br />

expected during the evacuation<br />

<strong>and</strong> recovery periods.”<br />

Each <strong>ExxonMobil</strong> store<br />

reopened only if members of<br />

Gore’s team were certain they had<br />

what they call the three “P’s” in<br />

place: People able to safely come<br />

back to work; Product to keep<br />

the location stocked with fuel; <strong>and</strong><br />

Power supplied either by a generator<br />

or by the utility company.<br />

More trucks <strong>and</strong> drivers<br />

After Hurricane Ike, <strong>ExxonMobil</strong><br />

opened stores in Houston days<br />

ahead of most other suppliers,<br />

so additional fuel trucks were<br />

brought in to meet the dem<strong>and</strong>.<br />

“Our base operation in Houston<br />

is eight trucks with 25 drivers,”<br />

says June Harper, North America<br />

customer service manager. “To<br />

respond to Ike, we increased that<br />

to 14 trucks <strong>and</strong> 43 drivers. We<br />

brought in trucks from nearby cities<br />

<strong>and</strong> flew the drivers to Texas<br />

from across the country.”<br />

Normally, one truckload of<br />

gasoline – about 9,000 gallons –<br />

lasts two or three days. Larger<br />

stores might take two truckloads<br />

a day, but when there are cars<br />

waiting in line, a load lasts barely<br />

four hours.<br />

For safety, extra drivers were<br />

used to make sure the trucks<br />

could keep running around the<br />

clock <strong>and</strong> that the drivers would<br />

get enough rest between shifts.<br />

In the aftermath of Gustav<br />

<strong>and</strong> Ike, the safety record across<br />

the entire retail organization was<br />

outst<strong>and</strong>ing. Even with all of the<br />

extra drivers <strong>and</strong> more than 700<br />

workers helping to reopen stores,<br />

there was not a single accident.<br />

Focused response<br />

to hurricane fury<br />

Although hurricane l<strong>and</strong>fall,<br />

severity <strong>and</strong> impact are unpredictable,<br />

the <strong>ExxonMobil</strong><br />

response is second to none. The<br />

focus is on taking care of our<br />

people, facilities, customers <strong>and</strong><br />

communities where we operate.<br />

“We plan, prepare <strong>and</strong> have<br />

strong processes in place<br />

across the downstream to deal<br />

with hurricanes,” notes Denny<br />

Houston, who leads the downstream<br />

hurricane response<br />

organization. “We quickly <strong>and</strong><br />

fully utilize our<br />

flexibility, experience<br />

<strong>and</strong> global<br />

collaboration<br />

to manage the response. The<br />

To learn more<br />

exxonmobil.com/<br />

stormupdates<br />

<strong>ExxonMobil</strong> response to Gustav<br />

<strong>and</strong> Ike is a great story for our<br />

shareholders, employees, customers<br />

<strong>and</strong> communities. We<br />

are all proud of what we accomplished<br />

as a team.” the Lamp<br />

After Hurricane Ike, <strong>ExxonMobil</strong> was able<br />

to open its Houston retail stores days<br />

ahead of most other suppliers, <strong>and</strong> extra<br />

drivers <strong>and</strong> trucks were brought to the city<br />

to keep deliveries moving to customers.<br />

Photo by Gary Blockley

Much more than a plan<br />

Last year’s hurricanes in the Gulf of<br />

Mexico left scars on the coast <strong>and</strong><br />

affected chemical markets worldwide,<br />

but lessons learned from earlier storms<br />

helped <strong>ExxonMobil</strong> employees respond<br />

much faster this time around.<br />

Photo by Guiseppe Barranco/The Beaumont Enterprise<br />

Call it a worst-case scenario. A<br />

major hurricane fills the Gulf of<br />

Mexico <strong>and</strong> l<strong>and</strong>s on the most<br />

heavily industrialized stretch<br />

of the upper Texas coast.<br />

<strong>ExxonMobil</strong>’s Houston offices<br />

lose power, <strong>and</strong> several of the<br />

company’s manufacturing sites<br />

are damaged. Specialty products<br />

– some supporting global<br />

supply networks – are suddenly<br />

unavailable to customers in the<br />

Americas, Europe <strong>and</strong> Asia.<br />

Although it’s the kind of emergency<br />

that <strong>ExxonMobil</strong> employees<br />

plan <strong>and</strong> practice for each<br />

year, only similar experiences<br />

following the violent Gulf storms<br />

of 2005 could fully prepare them<br />

for the hurricanes of 2008.<br />

“We prepare for this, but it was<br />

difficult to anticipate the extent<br />

of damage caused by Hurricane<br />

Ike,” says Will Cirioli, <strong>ExxonMobil</strong><br />

Chemical Company regional<br />

director, Americas, who also<br />

heads the company’s Emergency<br />

Support Group (ESG).<br />

“One enhancement we made<br />

to our emergency-response plan<br />

after Hurricanes Katrina <strong>and</strong> Rita<br />

in 2005 was to add a regional<br />

response team that can quickly<br />

relocate our headquarters operations<br />

from Houston to Dallas,”<br />

he says. “Hurricane Ike was the<br />

first time we had to put that plan<br />

in motion.”<br />

A measured response<br />

The goal of <strong>ExxonMobil</strong>’s hurricane-response<br />

plan is to secure<br />

facilities, protect the public,<br />

make sure employees are safe,<br />

<strong>and</strong> continue serving customers.<br />

The response is measured, following<br />

plans that are made well<br />

in advance.<br />

“This is not a situation that<br />

you make up as you go,” Cirioli<br />

Boats moored for safety at the Port of Beaumont thrash wildly as Hurricane Ike roars ashore.<br />

A ship captain estimated waters rose 11 feet at the port, almost lifting vessels onto their docks.<br />

explains. “We make our decisions<br />

long before there’s a<br />

threat. When hurricanes do<br />

threaten, our response is preprogrammed,<br />

based on a series<br />

of triggers that are dictated by<br />

the storm.”<br />

<strong>ExxonMobil</strong> operates many<br />

oil <strong>and</strong> gas facilities, four large<br />

refineries, two lube-oil blending<br />

plants <strong>and</strong> nine major chemicalmanufacturing<br />

sites along the<br />

coast from Texas to Florida.<br />

Some facilities can be shut<br />

down in as little as 12 hours, but<br />

others take two or three days,<br />

so the moment a tropical storm<br />

or hurricane threatens the Gulf<br />

of Mexico, the ESG begins communicating<br />

with all the sites <strong>and</strong><br />

monitoring the weather several<br />

times a day.<br />

By Tuesday, September 9,<br />

there was enough certainty in<br />

the forecast that Cirioli moved<br />

Chemical’s ESG to Dallas. Other<br />

Houston-based <strong>ExxonMobil</strong><br />

companies did the same, joining<br />

forces with <strong>ExxonMobil</strong>’s<br />

Regional Response Team, sharing<br />

office space that is kept<br />

ready year-round with all the<br />

computers, supplies <strong>and</strong> phone<br />

lines needed to run the global<br />

business.<br />

As Ike grew in size <strong>and</strong><br />

continued toward the Texas-<br />

Louisiana coast, it triggered the<br />

next stages of the emergencyresponse<br />

plan. Generators,<br />

food, water, radios <strong>and</strong> all the<br />

other equipment needed during<br />

recovery were pre-positioned<br />

so they could be trucked in<br />

quickly once the storm passed.<br />

On Wednesday, plants started<br />

shutting down. By noon Friday,<br />

the ones nearest Houston were<br />

bracing for the worst.<br />

Story by Richard Cunningham<br />

12

Clockwise from upper left: 1) The impact of floodwaters that inundated the Beaumont Chemical Plant can be<br />

seen in this view taken from the adjacent refinery looking east. The plant’s administration building is at the<br />

upper left of the photo. 2) The same shot after water was pumped off the grounds <strong>and</strong> operations restored. 3)<br />

The area around the administration building after cleanup is a far different sight today than 4) the way it looked<br />

just after Hurricane Ike, which caused water levels to rise more than 10 feet in some locations.<br />

L<strong>and</strong>fall<br />

Early Saturday morning, the center<br />

of Ike surged through Galveston<br />

Bay <strong>and</strong> up the Houston Ship<br />

Channel. By dawn, more than 90<br />

percent of the region was without<br />

power. Historic Galveston <strong>and</strong><br />

communities all along the coast<br />

sustained widespread damage.<br />

The Beaumont Chemical Plant, on<br />

what’s called the “wet side” of the<br />

storm, was impacted with more<br />

than 11 feet of storm surge.<br />

“When people saw the damage<br />

here, they thought we would<br />

be down for years,” says Dick<br />

Townsend, Beaumont Chemical<br />

Plant manager. “By Saturday<br />

afternoon, we had a small group<br />

of workers inside, making sure<br />

there were no leaks or spills.<br />

Damage assessment crews<br />

moved in the following day.”<br />

Almost every part of the plant<br />

was damaged, <strong>and</strong> anything<br />

13<br />

electrical that was lower than<br />

10 feet from the ground was<br />

destroyed.<br />

“We had to replace approximately<br />

5,000 instruments, 2,000<br />

valves, 800 pumps, 700 motors,<br />

650 junction boxes, 500 online<br />

analyzers, 45 air conditioners<br />

<strong>and</strong> 25 switch-gear buildings,”<br />

Townsend says. “We removed<br />

13 million pounds of debris <strong>and</strong><br />

used more than 300 generators<br />

for temporary power while we<br />

were doing all the work.”<br />

Business continuity<br />

“The Beaumont Chemical Plant<br />

is a critical supplier of polyalpha<br />

olefins,” says John Lyon,<br />

Synthetics vice president. “PAOs<br />

are the basestock that our customers<br />

use to blend high-quality<br />

lubricants for heavy machinery,<br />

such as the gearboxes of the<br />

giant wind turbines used to gen-<br />

erate electricity. The plant also<br />

produces synthetic basestock<br />

used in Mobil 1.”<br />

A nonstop effort by the various<br />

emergency groups <strong>and</strong> regional<br />

response members in Dallas<br />

managed the recovery, held<br />

supply networks together <strong>and</strong><br />

advised global customers on<br />

what to expect. The companies<br />

that blend <strong>and</strong> market synthetic<br />

lubricants routinely keep some<br />

amount of basestock in reserve,<br />

but would they have enough to<br />

last until the Beaumont plant was<br />

back on stream?<br />

“Given the inventory levels<br />

of some of our lubes manufacturing<br />

customers,” Lyon says,<br />

“we began allocating our own<br />

inventory <strong>and</strong> working with them<br />

to develop options to maintain<br />

supplies to their customers.”<br />

As many as 2,000 people<br />

worked in shifts around the clock<br />

to repair the Specialties units at<br />

the Beaumont Chemical Plant.<br />

“The storm hit in mid-September,”<br />

Lyon recalls, “<strong>and</strong> by early<br />

December both the Synthetics<br />

<strong>and</strong> the Catalyst units at the<br />

chemical plant were back on<br />

line. We began increasing allocations,<br />

<strong>and</strong> by mid-January, we<br />

were back to 100 percent.”<br />

Efficient manufacturing<br />

Once the Synthetics <strong>and</strong> Catalyst<br />

units were running again, they<br />

performed extremely reliably, <strong>and</strong><br />

that helped increase inventories<br />

faster than anyone expected.<br />

“In most cases, we replaced<br />

damaged equipment with newer<br />

<strong>and</strong> more efficient technology,”<br />

Townsend says. “Our goal was<br />

to come back strong, <strong>and</strong> we<br />

did. At least in terms of the electrical<br />

system, we have a br<strong>and</strong><br />

new plant.” the Lamp

Antwerp<br />

cogeneration plant<br />

breaks new ground<br />

A new facility in Belgium uses technology<br />

to make productive use of excess heat in<br />

the generation of electricity. The result:<br />

improved efficiency <strong>and</strong> reduced emissions.<br />

Startup of a new cogeneration<br />

plant at the <strong>ExxonMobil</strong> Refinery<br />

in Antwerp, Belgium, is another<br />

major step by <strong>ExxonMobil</strong> in using<br />

energy more efficiently <strong>and</strong> reducing<br />

greenhouse gas emissions.<br />

Inauguration of the facility<br />

at Antwerp, <strong>ExxonMobil</strong>’s<br />

second-largest refinery in Europe,<br />

exp<strong>and</strong>s the company’s interests<br />

to about 100 cogeneration installations<br />

at 30 worldwide sites,<br />

generating some 4,600 megawatts<br />

(MW) of additional power.<br />

That’s enough electricity to supply<br />

the needs of approximately<br />

2 million U.S. homes.<br />

With cogeneration technology,<br />

<strong>ExxonMobil</strong> can produce electricity<br />

to power its operations <strong>and</strong><br />

also capture heat, in the form<br />

of high-pressure steam that, in<br />

turn, can be used to transform<br />

raw materials into a variety of<br />

products. Cogeneration provides<br />

a more efficient source of power<br />

than purchasing electricity from a<br />

local utility – in some cases up to<br />

50 percent more efficient.<br />

How it works<br />

Cogeneration starts with the<br />

burning of fuel, often natural<br />

gas, in a large gas turbine that<br />

provides the power to rotate an<br />

electric generator.<br />

The hot exhaust gases from<br />

the turbine are then routed to a<br />

heat-recovery unit that captures<br />

additional energy otherwise lost<br />

to the atmosphere. Steam from<br />

the process is typically used in a<br />

refinery’s manufacturing units.<br />

At Antwerp, however, there<br />

is only a limited requirement for<br />

additional steam, so the excess<br />

energy is also used to heat the<br />

refinery’s crude oil directly, significantly<br />

reducing the energy<br />

needed to convert the crude into<br />

clean fuels. Using heat this way,<br />

on such a gr<strong>and</strong> scale, is what<br />

sets the Antwerp Refinery – <strong>and</strong><br />

its cogeneration unit – apart.<br />

“The Antwerp cogeneration<br />

process generates about 125 MW<br />

of electricity – enough to power<br />

the refinery, as well as the needs<br />

of most of <strong>ExxonMobil</strong>’s other<br />

Belgian manufacturing operations,”<br />

says Richard Henderson,<br />

the refinery’s technical manager.<br />

Moreover, the process is highly<br />

energy-efficient, so carbon-dioxide<br />

emissions are reduced. In fact,<br />

the total impact of this project<br />

is a reduction of Belgium’s CO 2<br />

emissions by approximately<br />

200,000 tons a year. Worldwide,<br />

<strong>ExxonMobil</strong>’s investment in<br />

cogeneration has lowered greenhouse<br />

gas emissions equal to<br />

removing more than 1 million cars<br />

off U.S. roadways.<br />

<strong>ExxonMobil</strong>’s newest cogeneration facility is in<br />

Antwerp, Belgium, with 125-megawatt capacity.<br />

Construction in a tight space<br />

Construction of this cogeneration<br />

plant presented a special set of<br />

challenges.<br />

“The Antwerp refinery is<br />

densely built,” says David<br />

McLatchie, project executive.<br />

“There’s very little extra l<strong>and</strong> available<br />

for new construction. Given<br />

the small plot space the team<br />

had to work with, it was essential<br />

to come up with something completely<br />

out of the ordinary in order<br />

to accommodate this new plant.”<br />

Normally, the two major components<br />

of a cogeneration facility<br />

– the gas turbine that creates<br />

electricity <strong>and</strong> the heat-recovery<br />

unit that generates steam – are<br />

built adjacent to each other. At<br />

Antwerp, this wasn’t possible, so<br />

it was necessary to construct the<br />

heat-recovery unit on top of the<br />

gas turbine, more than three stories<br />

above it.<br />

Photo by Kees Stuip<br />

Story by Bill Corporon<br />

14

The toy cars held by children attending the inauguration<br />

ceremonies for the startup of Antwerp’s new cogeneration<br />

plant are symbolic of the emissions reduction the plant will<br />

bring: the equivalent of removing 90,000 cars off the roads.<br />

Construction required highprecision<br />

lifting operations from<br />

crane operators to get all the<br />

equipment in position for assembly.<br />

With much of the work<br />

being performed in<br />

tight conditions high<br />

above the ground,<br />

developing plans for<br />

working safely was paramount.<br />

“We made sure that safety<br />

considerations were part of every<br />

step of the planning <strong>and</strong> construction<br />

process,” says Gilbert<br />

Asselman, refinery manager.<br />

At its peak, construction of<br />

the facility employed some 400<br />

people. Commissioning activities<br />

began in December 2008, with<br />

startup <strong>and</strong> testing successfully<br />

completed in January 2009.<br />

To learn more<br />

exxonmobil.com/<br />

cogeneration<br />

Inauguration day<br />

The Antwerp refinery hosted an<br />

inauguration ceremony for the<br />

new cogeneration unit in March.<br />

It drew more than 200 representatives<br />

from government,<br />

business, the community <strong>and</strong><br />

<strong>ExxonMobil</strong> as well as numerous<br />

members of the news media.<br />

15<br />

Photo by Stefan Dewickere<br />

Flemish Prime Minister Kris<br />

Peeters recognized the company<br />

for its additional investment<br />

in cogeneration. He also<br />

emphasized the importance of<br />

energy efficiency in reducing<br />

emissions <strong>and</strong> elaborated on the<br />

government’s policy to promote<br />

cogeneration.<br />

Hilde Crevits, the Flemish minister<br />

of energy <strong>and</strong> the environment,<br />

<strong>and</strong> Cathy Berx, governor<br />

of the province of Antwerp, also<br />

attended the event.<br />

Senior <strong>ExxonMobil</strong> executives<br />

included Olivia Owen, corporate<br />

vice president for safety, security,<br />

health <strong>and</strong> environment;<br />

Darren Woods, refining director<br />

for Europe/Africa/Middle East;<br />

<strong>and</strong> Joost van Roost, the company’s<br />

lead country manager for<br />

Belgium, the Netherl<strong>and</strong>s <strong>and</strong><br />

Luxembourg.<br />

The inauguration was a<br />

memorable launch to an extraordinary<br />

project that promises to<br />

meet the needs of the Antwerp<br />

Refinery <strong>and</strong> the Belgian people<br />

while also helping the environment.<br />

the Lamp<br />

Canada<br />

More than<br />

100 installations<br />

worldwide<br />

<strong>ExxonMobil</strong> self-generates<br />

more than half of it’s<br />

total electricity dem<strong>and</strong>.<br />

More than 50 percent of<br />

the corporation’s global<br />

cogeneration capacity is<br />

in the United States, <strong>and</strong><br />

all seven of the company’s<br />

U.S. refineries have<br />

cogeneration facilities.<br />

<strong>ExxonMobil</strong> is a<br />

Canada<br />

United States<br />

United States<br />

Argentina<br />

19 megawatts Argentina<br />

Includes fully owned/operated <strong>and</strong> equity-interest facilities

global leader in cogeneration technology<br />

United Kingdom<br />

France<br />

The Netherl<strong>and</strong>s<br />

Belgium<br />

Italy<br />

Chad<br />

Germany<br />

Austria<br />

<strong>ExxonMobil</strong> <strong>and</strong> cogeneration:<br />

More than 100 installations in 30 locations worldwide<br />

Kazakhstan<br />

More than 4,600 megawatts of cogeneration capacity – enough to<br />

power more than 2 million U.S. homes<br />

<strong>ExxonMobil</strong>’s investment in cogeneration has lowered greenhouse gas<br />

emissions equal to taking more than 1 million cars off U.S. roads<br />

Largest <strong>ExxonMobil</strong> cogeneration plant, with 500 megawatts of power<br />

capacity, is in Beaumont, Texas<br />

Africa<br />

168<br />

Thail<strong>and</strong><br />

Singapore<br />

Cogeneration capacity<br />

by region<br />

(megawatts)<br />

Europe/<br />

Caspian<br />

605<br />

Asia Pacific<br />

728<br />

Americas<br />

3,127<br />

Japan<br />

Australia<br />

16

17<br />

Technology key to <strong>ExxonMobil</strong><br />

<strong>and</strong> <strong>Abu</strong> <strong>Dhabi</strong> relationship<br />

<strong>ExxonMobil</strong>, <strong>Abu</strong> <strong>Dhabi</strong><br />

National Oil Company (ADNOC)<br />

<strong>and</strong> Japan Oil Development<br />

Company (JODCO), co-venturers<br />

in the Zakum Development<br />

Company (ZADCO), have<br />

launched a major project to<br />

exp<strong>and</strong> development of the<br />

world’s fourth-largest oil field,<br />

<strong>and</strong> the development is on track<br />

to meet its targets.<br />

Containing an estimated 50<br />

billion barrels of oil, the Upper<br />

Zakum field produces more than<br />

one-half million barrels a day.<br />

Through the efforts of professionals<br />

from <strong>ExxonMobil</strong>, ZADCO,<br />

ADNOC <strong>and</strong> JODCO, <strong>and</strong> by<br />

applying <strong>ExxonMobil</strong>’s leading-<br />

Story by Bill Corporon Photography courtesy of ZADCO<br />

<strong>ExxonMobil</strong> is working closely with its co-venturers to develop one of the world’s<br />

largest oil fields. A new technology center, artificial isl<strong>and</strong>s <strong>and</strong> an innovative<br />

drilling organization highlight efforts to boost recovery at a lower cost.<br />

edge technology, the project could<br />

boost daily field production by<br />

200,000 barrels over the next six<br />

to seven years – a sizable contribution<br />

toward meeting future<br />

growth in global oil dem<strong>and</strong>.<br />

Upper Zakum lies about 50<br />

miles northwest of the city of <strong>Abu</strong><br />

<strong>Dhabi</strong>, the capital of the seven<br />

emirates that make up the United<br />

Arab Emirates (UAE). The offshore<br />

field covers more than 450<br />

square miles <strong>and</strong> contains some<br />

450 wells drilled from more than<br />

90 existing platforms. Wells typically<br />

extend 7,000 to 8,000 feet<br />

below the earth’s surface.<br />

Oil flows through a pipeline<br />

network to one of four main pro-<br />

cessing facilities. After the oil is<br />

treated, it’s fed into another pipeline<br />

for a 35-mile journey to Zirku<br />

Isl<strong>and</strong>. There it’s held in large<br />

storage tanks to await export.<br />

<strong>ExxonMobil</strong> holds a 28 percent<br />

joint-venture interest in the<br />

field <strong>and</strong> in ZADCO, the field’s<br />

operator. ADNOC owns 60 percent,<br />

with JODCO holding the<br />

remaining 12 percent stake.<br />

Opening doors<br />

Less than 10 percent of the field’s<br />

oil has been produced, testimony<br />

to the imposing technical challenges<br />

it presents. Much of the<br />

reservoir is made of low-permeability<br />

rock, making the oil difficult

– <strong>and</strong> expensive – to extract.<br />

Nevertheless, says Frank<br />

Kemnetz, president of<br />

<strong>ExxonMobil</strong> <strong>Abu</strong> <strong>Dhabi</strong> Offshore<br />

Petroleum Company, Ltd.,<br />

development is well under way<br />

<strong>and</strong> on schedule.<br />

He attributes this to the spirit<br />

of cooperation among the <strong>Abu</strong><br />

<strong>Dhabi</strong> government, ADNOC,<br />

ZADCO <strong>and</strong> the private oilcompany<br />

co-venturers, <strong>and</strong><br />

stresses the importance of a<br />

disciplined approach that relies<br />

on cutting-edge technology to<br />

solve problems.<br />

“First you have to underst<strong>and</strong><br />

the resource,” he says. “If you<br />

don’t know much about the res-<br />

Right: <strong>ExxonMobil</strong> retains<br />

offices in the Sheikh<br />

Khalifa Energy Complex<br />

in <strong>Abu</strong> <strong>Dhabi</strong>, which is<br />

also headquarters for the<br />

<strong>Abu</strong> <strong>Dhabi</strong> National Oil<br />

Company <strong>and</strong> the Zakum<br />

Development Company.<br />

Below: The huge central<br />

complex at the Upper<br />

Zakum field, some 85 miles<br />

offshore of <strong>Abu</strong> <strong>Dhabi</strong>,<br />

houses some 650 workers<br />

<strong>and</strong> processes more than<br />

550,000 barrels of oil <strong>and</strong><br />

130 million cubic feet of<br />

natural gas a day.<br />

18

The <strong>Abu</strong> <strong>Dhabi</strong> Technology Center promotes research <strong>and</strong> collaboration<br />

between United Arab Emirates <strong>and</strong> <strong>ExxonMobil</strong> professionals.<br />

ervoir rock, you don’t know what<br />

will happen when you drill. We use<br />

<strong>ExxonMobil</strong>’s 3-D seismic technology<br />

to get the picture we need.”<br />

The next step is to create models,<br />

using <strong>ExxonMobil</strong>’s proprietary<br />

EM power reservoir-simulation<br />

technology, which helps predict<br />

how the reservoirs will perform.<br />

“Then,” says Kemnetz, “we<br />

apply our decision-making tools<br />

to determine how to maximize<br />

recovery at the lowest cost <strong>and</strong><br />

risk. Technology adds value by<br />

reducing costs <strong>and</strong> enhancing<br />

resource recovery. It opens the<br />

door to more options.”<br />

A first for <strong>ExxonMobil</strong><br />

To open that door further,<br />

<strong>ExxonMobil</strong> has established a<br />

unique technology center in<br />

<strong>Abu</strong> <strong>Dhabi</strong>.<br />

“The center’s mission is twofold,”<br />

says <strong>ExxonMobil</strong>’s Ram<br />

Rajagopalan, the center’s operations<br />

manager. “We want to apply<br />

high-impact technology that<br />

benefits Upper Zakum while still<br />

protecting our proprietary technology.<br />

And we want to promote<br />

a good working relationship<br />

between ZADCO <strong>and</strong> <strong>ExxonMobil</strong><br />

professionals.”<br />

19<br />

The technology center is the<br />

first to be established at an<br />

<strong>ExxonMobil</strong> joint-interest facility.<br />

It’s managed <strong>and</strong> operated by<br />

<strong>ExxonMobil</strong> staff.<br />

“The technology center<br />

provides a window into the<br />

<strong>ExxonMobil</strong> world,” says<br />

Rajagopalan. “It enables ZADCO<br />

to pair the best technology with<br />

a state-of-the-art computing<br />

environment to achieve its development<br />

targets.”<br />

Employees of <strong>ExxonMobil</strong><br />

work closely with members of<br />

the ZADCO team that manages<br />

the Upper Zakum field. Together,<br />

they seek to meet the field’s<br />

development challenges.<br />

The center places a strong<br />

emphasis on training. From<br />

2007 through 2008, it conducted<br />

11 courses for more<br />

than 122 people. In addition,<br />

about 25 <strong>ExxonMobil</strong> employees<br />

were “seconded,” or temporarily<br />

assigned, to ZADCO to further<br />

enable the transfer of technical<br />

expertise. The center also hired<br />

<strong>and</strong> trained UAE nationals in line<br />

with a strategy set out by the<br />

government.<br />

In addition to making technology<br />

<strong>and</strong> expertise available in<br />

Photo by Keith Wood<br />

<strong>Abu</strong> <strong>Dhabi</strong>, <strong>ExxonMobil</strong> brings<br />

ZADCO’s Emirati nationals to the<br />