Dairy equipment â On-farm cheese making - A-S-T-A-eismann GmbH

Dairy equipment â On-farm cheese making - A-S-T-A-eismann GmbH

Dairy equipment â On-farm cheese making - A-S-T-A-eismann GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Industriegebiet Mark I · Nr.16<br />

D-59269 Neubeckum<br />

<strong>Dairy</strong> <strong>equipment</strong> – <strong>On</strong>-<strong>farm</strong> <strong>cheese</strong> <strong>making</strong><br />

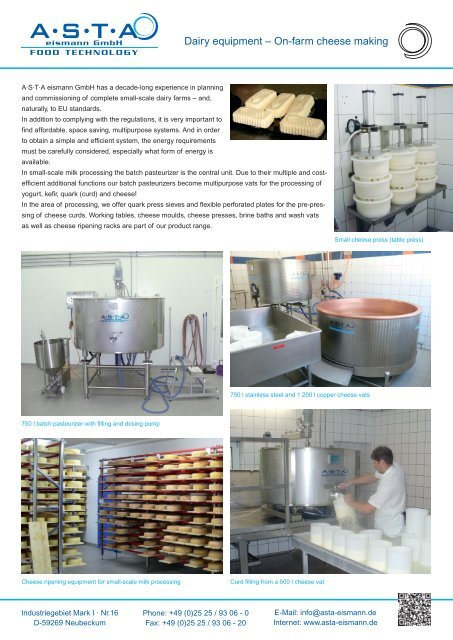

A·S·T·A <strong>eismann</strong> <strong>GmbH</strong> has a decade-long experience in planning<br />

and commissioning of complete small-scale dairy <strong>farm</strong>s – and,<br />

naturally, to EU standards.<br />

In addition to complying with the regulations, it is very important to<br />

find affordable, space saving, multipurpose systems. And in order<br />

to obtain a simple and efficient system, the energy requirements<br />

must be carefully considered, especially what form of energy is<br />

available.<br />

In small-scale milk processing the batch pasteurizer is the central unit. Due to their multiple and costefficient<br />

additional functions our batch pasteurizers become multipurpose vats for the processing of<br />

yogurt, kefir, quark (curd) and <strong>cheese</strong>!<br />

In the area of processing, we offer quark press sieves and flexible perforated plates for the pre-pressing<br />

of <strong>cheese</strong> curds. Working tables, <strong>cheese</strong> moulds, <strong>cheese</strong> presses, brine baths and wash vats<br />

as well as <strong>cheese</strong> ripening racks are part of our product range.<br />

750 l batch pasteurizer with filling and dosing pump<br />

Cheese ripening <strong>equipment</strong> for small-scale milk processing<br />

Phone: +49 (0)25 25 / 93 06 - 0<br />

Fax: +49 (0)25 25 / 93 06 - 20<br />

750 l stainless steel and 1 200 l copper <strong>cheese</strong> vats<br />

Curd filling from a 500 l <strong>cheese</strong> vat<br />

Small <strong>cheese</strong> press (table press)<br />

E-Mail: info@asta-<strong>eismann</strong>.de<br />

Internet: www.asta-<strong>eismann</strong>.de

Filling and dosing <strong>equipment</strong><br />

This efficient and economic system enables a precise dosing and<br />

filling of yogurt and quark. It has proven throughout time to be a<br />

precision filling system up to volumes of 120 g.<br />

The A·S·T·A <strong>eismann</strong> filling and dosing pump can be easily integrated<br />

into other packaging systems, such as cup fillers.<br />

Filling system for processed <strong>cheese</strong> or fresh <strong>cheese</strong> in artificial gut<br />

50 l butter maker<br />

Industriegebiet Mark I · Nr.16<br />

D-59269 Neubeckum<br />

<strong>Dairy</strong> <strong>equipment</strong> – <strong>On</strong>-<strong>farm</strong> <strong>cheese</strong> <strong>making</strong><br />

Phone: +49 (0)25 25 / 93 06 - 0<br />

Fax: +49 (0)25 25 / 93 06 - 20<br />

Cup filler combined with A·S·T·A filling and dosing pump<br />

300 l butter churn with kneader<br />

Butter maker<br />

The butter maker with paddles and kneader mounted on the<br />

bottom has withstood the test of time. In this unit, cream can be<br />

easily churned to butter; thereafter washing and draining takes<br />

place. At request, the butter maker can also have multiple uses:<br />

due to the heating and cooling functions, the same container can<br />

be used for pasteurization or cooling. In this way, the butter maker<br />

is also suitable for cream production.<br />

E-Mail: info@asta-<strong>eismann</strong>.de<br />

Internet: www.asta-<strong>eismann</strong>.de