Spring 2009 - Robert M. Kerr Food & Agricultural Products Center

Spring 2009 - Robert M. Kerr Food & Agricultural Products Center

Spring 2009 - Robert M. Kerr Food & Agricultural Products Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

f a p c<br />

Adding Value to Oklahoma <strong>Spring</strong> <strong>2009</strong><br />

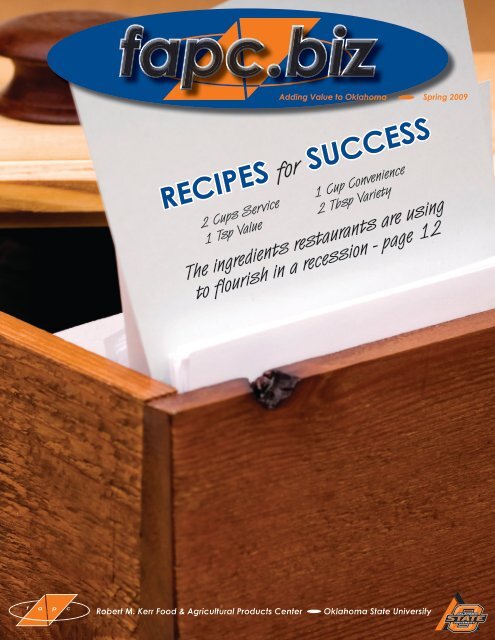

RECIPES for SUCCESS<br />

2 Cups Service 1 Cup Convenience<br />

1 Tsp Value 2 Tbsp Variety<br />

The ingredients restaurants are using<br />

to flourish in a recession - page 12<br />

<strong>Robert</strong> M. <strong>Kerr</strong> <strong>Food</strong> & <strong>Agricultural</strong> <strong>Products</strong> <strong>Center</strong> Oklahoma State University<br />

<strong>Spring</strong> <strong>2009</strong> 1

Adding Value to Oklahoma Volume 4 Issue 1<br />

news<br />

From the Director 3<br />

Graduate students awarded at FAPC Research Symposium 4<br />

By Stacy Patton, FAPC Communications Graduate Assistant<br />

FAPC Basic Training graduate bottles Oklahoma’s “deVine” history 6<br />

By Mandy Gross, FAPC Manager of Communications Services<br />

industry perspective<br />

Market for U.S. cotton shifts 8<br />

By Jay Cowart, Plains Cotton Cooperative Association<br />

foundation focus<br />

Unitherm supports food safety through equipment donation 9<br />

By Chuck Willoughby, FAPC Business & Marketing Relations Manager<br />

fuels of the future<br />

Methanol as a feedstock and transportation fuel 10<br />

By Nurhan Dunford, FAPC Oil/Oilseed Chemist<br />

business & marketing<br />

Recipes for success 12<br />

By Corey Stone, Business & Marketing Strategist<br />

Recession proof 14<br />

By Corey Stone, Business & Marketing Strategist<br />

pathogen patrol<br />

Another outbreak in peanut butter 16<br />

By Peter Muriana, FAPC <strong>Food</strong> Microbiologist<br />

from the test kitchen<br />

Sweet expectations 18<br />

By Darren Scott, FAPC Sensory Specialist<br />

food processing<br />

Finding your product niche 20<br />

By David Moe, FAPC Pilot Plant Manager<br />

quality management<br />

Using the basic quality tools 22<br />

By Jason Young, FAPC Quality Management Specialist<br />

FAPC Director<br />

J. Roy Escoubas<br />

Managing Editor<br />

Graphic Designer<br />

Mandy Gross<br />

Editor<br />

Stacy Patton<br />

Writers<br />

Jay Cowart, Nurhan Dunford, Roy<br />

Escoubas, Mandy Gross,<br />

David Moe, Peter Muriana,<br />

Stacy Patton, Darren Scott,<br />

Corey Stone, Chuck Willoughby,<br />

and Jason Young<br />

Adding Value to Oklahoma <strong>Spring</strong> <strong>2009</strong><br />

<strong>Robert</strong> M. <strong>Kerr</strong> <strong>Food</strong> & <strong>Agricultural</strong> <strong>Products</strong> <strong>Center</strong> Oklahoma State University<br />

About the cover...<br />

Amidst reports of recession, businesses<br />

must compete for consumers’<br />

constricted cash. This may be a recipe<br />

for disaster for some industries, but<br />

restaurants keep serving up sweet success.<br />

This is why consumers continue<br />

to leave the cooking to the chefs.<br />

Oklahoma State University, in compliance with Title VI and VII of the<br />

Civil Rights Act of 1964, Executive Order 11246 as amended, Title IX of<br />

the Education Amendments of 1972, Americans with Disabilities Act of<br />

1990, and other federal laws and regulations, does not discriminate on<br />

the basis of race, color, national origin, gender, age, religion, disability,<br />

or status as a veteran in any of its policies, practices or procedures. This<br />

includes but is not limited to admissions, employment, financial aid, and<br />

educational services.<br />

Issued in furtherance of Cooperative Extension work, acts of May 8 and<br />

June 30, 1914, in cooperation with the U.S. Department of Agriculture,<br />

<strong>Robert</strong> E. Whitson, Director of Oklahoma Cooperative Extension Service,<br />

Oklahoma State University, Stillwater, Oklahoma. This publication is<br />

printed and issued by Oklahoma State University as authorized by the<br />

Vice President, Dean, and Director of the Division of <strong>Agricultural</strong> Sciences<br />

and Natural Resources and has been prepared and distributed at a cost<br />

of $2346.96 for 700 copies. 0309<br />

2 fapc.biz<br />

f a p c<br />

RECIPES for SUCCESS<br />

2 Cups Service 1 Cup Convenience<br />

1 Tsp Value 2 Tbsp Variety<br />

The ingredients restaurants are using<br />

to flourish in a recession - page 12

news<br />

By Roy Escoubas<br />

FAPC Director<br />

roy.escoubas@okstate.edu<br />

In the last fapc.biz magazine, it was said the food industry in the United<br />

States is in constant change. The fact is everything around us is in constant<br />

change. It seems, however, in these recent times, the changes occur more<br />

quickly with more force and with more impact. Things that have occurred<br />

during a number of years are now causing immediate changes. Following are<br />

thoughts on these changes.<br />

<strong>Food</strong> safety issues<br />

In a January <strong>2009</strong> research report<br />

published by the U.S. Department of<br />

Agriculture Economic Research Service,<br />

a 20-year trend study showed<br />

U.S. livestock production has changed<br />

or shifted since 1987 to a highly industrialized<br />

and specialized business<br />

model with broiler operations becoming<br />

60 percent larger, fed-cattle operations<br />

becoming 100 percent larger,<br />

dairy operations becoming 240 percent<br />

larger, and hog operations becoming<br />

2,000 percent larger. Other information<br />

has shown that all agricultural,<br />

food manufacturing, food service, and<br />

food retail enterprises have changed<br />

(grown in scale), and these changes<br />

in size and scale have been driven in<br />

FOOD SAFETY ISSUES<br />

large part by economics and efficiencies<br />

of scale where, in the final analysis,<br />

the costs of food to consumers are<br />

improved.<br />

When a food safety interruption<br />

in the current market is discovered,<br />

consumers’ health and safety are af-<br />

fected, and because of the scale of the<br />

production and distribution base, large<br />

segments of the American population<br />

also are affected. In the process of<br />

addressing and solving food safety issues,<br />

the consumer base tends to lose<br />

confidence in the food industry and<br />

is loosing confidence in the government’s<br />

ability to assure food safety.<br />

Recently, Salmonella contamination<br />

in peanuts and peanut products<br />

has spread to almost every state. The<br />

<strong>Food</strong> and Drug Administration’s effec-<br />

From the Director<br />

tiveness has been called into question<br />

once more, and this event may result<br />

in changes that could affect a major<br />

change in FDA and USDA structure<br />

and function. Regardless of what happens<br />

at the agencies, changes in food<br />

safety compliance regulations will<br />

result and will affect the day-to-day<br />

safety compliance in all agricultural<br />

and food industry production and processing<br />

facilities.<br />

Environmental issues<br />

Changes continue to develop with<br />

regard to food industry operations<br />

and their impact on the environment.<br />

Green sourcing and the minimization<br />

of natural resources with a focus on<br />

renewable resources for manufacturing<br />

are in the forefront. A recent environmental<br />

topic relates to carbon dioxide<br />

regulation, the carbon footprint analysis,<br />

and carbon credit value assessments,<br />

and these will have an impact<br />

on Oklahoma.<br />

ENVIRONMENTAL ISSUES<br />

Operations costs<br />

The economic downturn has<br />

forced changes by food manufacturers<br />

to reassess the costs of operations.<br />

Non-essential components of businesses<br />

are again being trimmed away.<br />

It has been a general industry rule-ofthumb<br />

through the years that non-essential<br />

components of the business, or<br />

those components of the business that<br />

do not directly generate sales revenue,<br />

are closed when business profitability<br />

is compromised.<br />

OPERATIONS COSTS<br />

Work force<br />

Finally, an article was published<br />

recently in BusinessWeek,<br />

titled “Here Come The Millennials.”<br />

It seems that not only do the<br />

agricultural and food industries face<br />

changes in production, processing,<br />

new ingredients, new food safety issues,<br />

food safety compliance, new<br />

consumer and economic pressures,<br />

and greater pressure from globalization,<br />

but also agricultural and food<br />

industries must face a diverse and<br />

demanding labor force and a set of<br />

college graduating idealists and selffocused<br />

new young leaders. These<br />

graduating “Millennials” are said<br />

to be strong-willed and passionate,<br />

they like personal attention, they<br />

care about the world, and they expect<br />

success. This idealism mixed<br />

with a desire to work may be a good<br />

thing for the food industry. However,<br />

traditional managers must be<br />

prepared for a change in how these<br />

new “recruits” are mentored.<br />

WORK FORCE<br />

Adjusting to change<br />

These amazing demands on the<br />

food and agribusiness industries<br />

force us to be the best that we can<br />

be. A recent article in Supply Chain<br />

Management Review emphasized<br />

that a healthy and creative partnership<br />

with our stakeholders is fostered<br />

by a close business relationship,<br />

a willingness to discuss issues<br />

quickly and thoroughly, an attention<br />

to communicate thoroughly, an emphasis<br />

on flexibility, and a desire to<br />

create a learning environment at every<br />

opportunity.<br />

You are a valued stakeholder of<br />

the FAPC. Let us assist you as you<br />

compete in this market of change.<br />

Call our business and marketing specialists<br />

today.<br />

ADJUSTING TO CHANGE<br />

<strong>Spring</strong> <strong>2009</strong> 3

Graduate students awarded<br />

at FAPC Research Symposium<br />

T<br />

he <strong>Robert</strong> M. <strong>Kerr</strong> <strong>Food</strong> & <strong>Agricultural</strong><br />

<strong>Products</strong> <strong>Center</strong> and the<br />

Institute of <strong>Food</strong> Technologists-<br />

Oklahoma Section held a Research<br />

Symposium in conjunction with Oklahoma<br />

State University Research Week.<br />

The symposium featured a combination<br />

of oral and poster presentations,<br />

with student presenters in both<br />

categories competing for $250 prizes,<br />

said Peter Muriana, FAPC food microbiologist<br />

and chair of the symposium.<br />

“I lobbied hard for the Research<br />

Symposium early on, drawing from<br />

the positive experience I had as a graduate<br />

student where we put on a similar<br />

type of event,” Muriana said. “I am<br />

glad that it has been received well<br />

by all the faculty and students who<br />

take the time to participate. I always<br />

thought it benefited students in helping<br />

to provide another opportunity to present<br />

and discuss their research.”<br />

Kalpana Kushwaha, an OSU doctoral<br />

student in food science, took the<br />

prize with her oral presentation, titled<br />

“In vitro and In vivo virulence analysis<br />

of strong and weakly adherent strains<br />

of Listeria monocytogenes.”<br />

“It’s an honor for me to be recognized<br />

with best oral presentation for<br />

my research work at the FAPC/IFT-<br />

OK Research Symposium, and my sincere<br />

thanks to Dr. Muriana for giving<br />

me an opportunity to work with him,”<br />

Kushwaha said.<br />

Likewise, OSU food science doctoral<br />

student Dinesh Babu won the<br />

poster division with his presentation,<br />

titled “Rapid and sensitive detection<br />

of aflatoxins in animal feeds, cereal<br />

grains, and food products using immunomagnetic<br />

bead-based recovery and<br />

real-time PCR assay.”<br />

“Working with Dr. Muriana itself<br />

is a rewarding experience, and being<br />

recognized with the best poster presentation<br />

for our research work during<br />

the FAPC Research Symposium is an<br />

added bonus,” Babu said. “Thanks to<br />

FAPC/IFT-OK and sponsors for creating<br />

this opportunity to OSU students.”<br />

In addition to highlighting food<br />

and agricultural product research<br />

conducted by the FAPC and OSU,<br />

the symposium included a keynote<br />

address by Michael Davidson, food<br />

microbiology professor and head of<br />

the Department of <strong>Food</strong> Science and<br />

Technology at the University of Tennessee,<br />

Knoxville. Davidson addressed<br />

the issues of natural antimicrobials in<br />

the food industry.<br />

The FAPC was delighted that Davidson<br />

could be the keynote speaker,<br />

Muriana said.<br />

“Not only is he a noted expert in<br />

the field of food antimicrobials, but<br />

also it was nice to bring in someone<br />

that was so impressed with our facilities<br />

and in a position to possibly guide<br />

students in our direction as well,”<br />

Muriana said. “Dr. Davidson said he<br />

also benefited from his visit in that he<br />

picked up a lot of ideas on extension<br />

activities, and he would like to come<br />

back with some administrators to visit<br />

our operation again in the near future.”<br />

The event also included a tour of<br />

the FAPC facilities, including demonstrations<br />

in the wet processing room,<br />

enology laboratory, and microbiology<br />

laboratory.<br />

“Several of the participants commented<br />

that they enjoyed the tour,”<br />

said Chuck Willoughby, FAPC manager<br />

of business and marketing relations.<br />

“This was a great way to really show a<br />

few examples of research and development<br />

activities at the FAPC, beyond<br />

the oral and poster presentations.”<br />

Sponsors of the FAPC/IFT-OK<br />

Research Symposium included 3-M<br />

Microbiology, PetSci, and Unitherm<br />

<strong>Food</strong> Systems.<br />

“I lobbied hard for the Research Symposium early on, drawing<br />

from the positive experience I had as a graduate student<br />

where we put on a similar type of event. I am glad that it has<br />

been received well by all the faculty and students who take<br />

the time to participate. I always thought it benefited students<br />

in helping to provide another opportunity to present and discuss<br />

their research.”<br />

Peter Muriana, FAPC <strong>Food</strong> Microbiologist<br />

4 fapc.biz

Michael Davidson from the University of<br />

Tennessee, Knoxville, addresses the issue of<br />

natural antimicrobials in the food industry.<br />

news<br />

By Stacy Patton<br />

FAPC Communications Graduate Assistant<br />

stacy.patton@okstate.edu<br />

Chuck Willoughby, FAPC business<br />

and marketing relations manager,<br />

presents Kalpana Kushwaha, OSU<br />

doctoral student in food science,<br />

a certificate and check for $250<br />

for taking top honors in the oral<br />

presentations.<br />

Chuck Willoughby, FAPC business<br />

and marketing relations manager,<br />

presents Dinesh Babu, OSU<br />

food science doctoral student, a<br />

certificate and check for $250 for<br />

winning first place in the poster<br />

presentations.<br />

<strong>Spring</strong> <strong>2009</strong> 5

FAPC Basic Training graduate bottles<br />

Oklahoma’s “deVine” History<br />

B<br />

ottling a little of Oklahoma<br />

history is a dream come true<br />

for Max McDermott of Alva,<br />

Oklahoma.<br />

In 2003, the McDermott Living<br />

Trust purchased the natural water<br />

spring, commonly known by travelers<br />

as the “Artesian Well on Highway 11.”<br />

Drilled in 1954, the main well is located<br />

just north of the Great Salt Plains<br />

National Wildlife Refuge, which is<br />

just north of the original township of<br />

Vining, Oklahoma.<br />

“The well has been available to<br />

the public at no charge,” McDermott<br />

said. “People from all across the world<br />

have stopped to drink this thirstquenching<br />

water, and many locals fill<br />

their jugs and haul this water as their<br />

primary drinking water source.”<br />

Soon after purchasing the well,<br />

McDermott enrolled in Basic Training<br />

for <strong>Food</strong> Business Entrepreneurs, a<br />

one-day class offered by the <strong>Robert</strong><br />

M. <strong>Kerr</strong> <strong>Food</strong> & <strong>Agricultural</strong> <strong>Products</strong><br />

<strong>Center</strong> at Oklahoma State University,<br />

to learn what was needed to open his<br />

own bottled-water business.<br />

McDermott heard about the course<br />

through the process of gaining the water<br />

rights with the State of Oklahoma<br />

and coming in contact with many of<br />

the state agencies.<br />

“Just as I expected, the course was<br />

highly beneficial to our business plan,<br />

and I was pleased to gain knowledge<br />

pertaining to manufacturing,” Mc-<br />

Dermott said. “Our No. 1 goal was to<br />

build our own manufacturing plant and<br />

bottle our water at the source. By taking<br />

this course, I was fortunate to have<br />

an idea of the events to come.”<br />

During Basic Training, McDermott<br />

learned about business planning,<br />

marketing, good manufacturing practices<br />

and many other topics. McDermott’s<br />

first step following Basic Training<br />

was to work on the business plan.<br />

Chuck Willoughby, FAPC business<br />

and marketing relations manager, reviewed<br />

his plan and provided feedback.<br />

“Max’s plan was very well written<br />

and organized, and one thing he emphasized<br />

in the plan was the popularity<br />

and history of the well,” Willoughby<br />

said. “This provided a point of differentiation<br />

compared to other<br />

spring waters; the<br />

local consumers as well as many travelers<br />

are likely to have an emotional<br />

appeal to the water – a relational experience.<br />

I liked his idea for the brand<br />

name deVine, too – tying in the name<br />

of the local township and scripture.”<br />

Willoughby and his business and<br />

marketing team then provided a market<br />

study for the bottled-water industry<br />

that McDermott could incorporate into<br />

his business plan.<br />

Other assistance provided by<br />

the FAPC included an evaluation<br />

of used bot-<br />

6 fapc.biz

tling equipment by Tim Bowser, FAPC<br />

food process engineer. Unfortunately,<br />

suitable used equipment was scarce<br />

and the equipment McDermott had access<br />

to was substandard or over priced<br />

or had mismatched capacities.<br />

“Max was a great client to work<br />

with; his enthusiasm was contagious,”<br />

Bowser said. “I only wish suitable<br />

equipment had been available at the<br />

time.”<br />

After nearly giving up, McDermott’s<br />

entrepreneurial spirit prevailed,<br />

and he was able to locate bottling<br />

equipment.<br />

Because deVine water is bottled at<br />

the source, environmental displeasures<br />

cannot contaminate the taste nor content<br />

of the water throughout the bottling<br />

process, McDermott said.<br />

“Using only two very effective<br />

forms of disinfection, ozonation, and<br />

ultraviolet light, it is to our advantage<br />

and the consumers’ advantage<br />

that we are not<br />

required to use chlorine,” he said.<br />

“These, among many more, are all of<br />

the reasons deVine Natural Artesian<br />

Water truly is a taste of heaven on<br />

earth.”<br />

McDermott identified his motto as<br />

“I am the Vine, You are the Branches”<br />

from the scripture John 15:5. The<br />

name, deVine, was derived from the<br />

location and the McDermott family’s<br />

Christian values.<br />

“Like the ‘True Vine’ in God’s<br />

word (John 15:5), this Natural Artesian<br />

Water source is the vine and we,<br />

deVine LLC, are the branches,” Mc-<br />

Dermott said. “We in ourselves do not<br />

have the ability to produce this divine<br />

gift from nature, but our company is<br />

delighted to be the instrument through<br />

which it goes forth.”<br />

McDermott began his bottling<br />

company in a licensed clean room that<br />

he built at his residence north of Alva,<br />

with a small filling line purchased in<br />

San Antonio, Texas.<br />

He soon realized the water business<br />

was going to grow beyond his<br />

small facility, so McDer-<br />

news<br />

By Mandy Gross<br />

FAPC Manager of Communications Services<br />

mandy.gross@okstate.edu<br />

mott looked into finding a co-packer.<br />

Caldwell Bottling Inc. in Caldwell,<br />

Kansas, was already set up to bottle<br />

spring water.<br />

In 2006, McDermott purchased a<br />

5000-gallon food-grade stainless steel<br />

tanker and started hauling the water<br />

to Caldwell to be bottled, and on June<br />

7, 2007, he purchased the contents of<br />

Caldwell Bottling Inc. He continued to<br />

lease the building and bottle the water<br />

in Caldwell, while his new bottling<br />

plant was being built from February to<br />

July 2008.<br />

“We are excited about the natural<br />

bottled-water industry and everything<br />

it has to offer,” McDermott said.<br />

“Since the completion of our new facility,<br />

we have grown tremendously.”<br />

McDermott has continued his 3-<br />

and 5-gallon services in most of northwest<br />

Oklahoma, while also servicing<br />

routes in Kansas. His products include<br />

3- and 5- gallon bottles for home or<br />

office delivery; H/C water dispensers;<br />

many water accessories; 12-, 16.9- and<br />

20-ounce PET bottles; and the newest<br />

addition 750-milliliter glass bottles.<br />

Although deVine water is available<br />

for purchase at many locations<br />

and online at www.devinewater.com/,<br />

the main well by the highway still<br />

offers free access as a means of<br />

service to local and area travelers.<br />

This concept is the foundation of the<br />

deVine slogan, “The water is still free<br />

... All we charge for is the bottle and<br />

delivery.”<br />

Like many of the entrepreneurs<br />

FAPC works with, McDermott has that<br />

persistent, never give-up attitude, Willoughby<br />

said.<br />

“We were delighted to learn that<br />

Max never gave up on his dream,” he<br />

said. “Working with Max and folks<br />

like him inspire us to live out our mission<br />

– to add value to Oklahoma!”<br />

<strong>Spring</strong> <strong>2009</strong> 7

industry perspective<br />

By Jay Cowart<br />

Plains Cotton Cooperative Association<br />

jay.cowart@pcca.com<br />

Market for U.S. cotton shifts<br />

Most U.S. cotton now consumed overseas<br />

Changing world dynamics have<br />

forced U.S. cotton producers<br />

to sell the bulk of their<br />

cotton in the global market, resulting<br />

in more U.S. cotton being consumed<br />

outside the country. The diminishing<br />

use of cotton in the United States is a<br />

direct result of a struggling U.S. textile<br />

industry, leaving cotton producers in<br />

search of a market for their crops.<br />

The decline of the U.S. textile<br />

industry was not an overnight occurrence.<br />

In fact, the downturn began in<br />

1997 with a dramatic increase in governmental<br />

intervention in the textile<br />

and apparel export sectors in China<br />

and other Asian nations. The trade<br />

policies set in motion at that time have<br />

continually allowed these governments<br />

to, among other things, devalue their<br />

currency, provide export subsidies, offer<br />

free financing, and set artificially<br />

low prices for textile and apparel<br />

products, thereby crushing free-market<br />

competition.<br />

The U.S. textile industry has found<br />

it difficult to compete with foreign<br />

textile imports under these trade conditions.<br />

More than 500 textile facilities<br />

in the United States have been forced<br />

to close including more than 30 textile<br />

plants during the last 12 months,<br />

according to data compiled by the<br />

National Council of Textile Organizations.<br />

Literally, hundreds of thousands<br />

of U.S. textile workers have lost their<br />

jobs during the last 12 years.<br />

Weaker Asian currencies have allowed<br />

textile and apparel companies<br />

to offer products in this country at<br />

prices so low that it has fundamentally<br />

changed the buying pattern of many<br />

U.S. retailers and garment manufacturers,<br />

and more garments are sourced<br />

out of Asia than ever before. This<br />

scenario, coupled with downward spiraling<br />

consumer spending during the<br />

current global recession, makes it even<br />

more difficult for the few surviving<br />

U.S. textile mills.<br />

As a result of fewer textile facilities<br />

operating in the United States, the<br />

domestic consumption of cotton has<br />

plummeted. In 1998, National Cotton<br />

Council data showed U.S. textile mills<br />

were consuming cotton at a seasonally<br />

adjusted annualized rate of 11.35<br />

million bales per year. By 2008, an<br />

annualized rate of only 4.61 million<br />

bales of U.S. cotton were consumed<br />

within the United States. The amount<br />

of cotton is expected to decline further<br />

as U.S. Department of Agriculture’s<br />

most recent supply and demand report<br />

pegged domestic mill use at just 3.9<br />

million bales in <strong>2009</strong>.<br />

Despite falling domestic cotton<br />

use, the United States remains one of<br />

the top three cotton producing countries<br />

in the world, as American cotton<br />

farmers will produce more than<br />

13 million bales in <strong>2009</strong>. In order to<br />

secure buyers for their cotton, U.S.<br />

producers have been forced to export<br />

the majority of their crop. The amount<br />

of cotton exports continue to grow as<br />

more than 13 million bales of cotton<br />

were exported in 2008, while only 7.5<br />

million bales were sold abroad just 10<br />

years before. A record-breaking 17.5<br />

million bales of U.S. cotton were exported<br />

in 2006.<br />

The stream of cotton flowing out<br />

of the United States is expected to<br />

continue while U.S. textile mills see<br />

no quick resolution to their immediate<br />

plight. Far from ideal, many in the industry<br />

see the irony of the situation.<br />

“As a result of the strong dollar<br />

policies of the 1990s, the third largest<br />

cotton producing nation must export<br />

cotton halfway around the world to be<br />

turned into apparel that is then shipped<br />

back to the United States to be worn<br />

by the world’s most efficient cotton<br />

producers,” a cotton analyst said.<br />

8 fapc.biz

foundation focus<br />

By Chuck Willoughby<br />

FAPC Business & Marketing Relations Manager<br />

chuck.willoughby@okstate.edu<br />

Unitherm supports food safety through<br />

EQUIPMENT DONATION<br />

Foundation Focus serves to support<br />

and enhance the programs<br />

that carry out the mission of the<br />

<strong>Robert</strong> M. <strong>Kerr</strong> <strong>Food</strong> & <strong>Agricultural</strong><br />

<strong>Products</strong> <strong>Center</strong> through donations of<br />

individual and industry partners to the<br />

Product Innovation Fund.<br />

Recently, David Howard, chief<br />

executive officer of Unitherm <strong>Food</strong><br />

Systems, provided a fully automated,<br />

walk-through boot wash system, valued<br />

at approximately $20,000, as a<br />

gift-in-kind to support food safety<br />

research and day-to-day food safety<br />

activities of the FAPC’s meat processing<br />

pilot plant.<br />

“We at Unitherm are pleased<br />

to be able to enhance<br />

the real-<br />

world experience the center offers,”<br />

Howard said. “The FAPC and its staff<br />

are world leaders in food safety; they<br />

have pioneered in pathogen control<br />

and HACCP plans across the country.”<br />

The FAPC’s pilot plant facilities<br />

are designed with the needs of<br />

the Oklahoma food and agricultural<br />

products processing industry in mind.<br />

Some of the services offered by the pilot<br />

plant facilities include training and<br />

demonstration; process system development<br />

and evaluation; new product<br />

development; equipment evaluation;<br />

evaluation of functional product ingredients;<br />

technology<br />

transfer; thermal process<br />

evaluation; and<br />

consumer market<br />

testing.<br />

This state-ofthe-art<br />

equipment<br />

has photo eye<br />

sensors to activate<br />

the system<br />

when a person<br />

enters. Meteredsanitizer<br />

mixes<br />

with water<br />

and is applied<br />

to<br />

the boot<br />

while brushes scrub the entire boot, including<br />

the sole, removing any debris<br />

on the boot.<br />

“The added cleaning ability this<br />

automated boot wash system provides<br />

will make our sanitation programs better,<br />

which means safer meat products<br />

coming out of our plant,” said Kyle<br />

Flynn, FAPC meat processing manager.<br />

“Many of FAPC’s meat industry<br />

clients look to FAPC as a role model<br />

in industry food safety practices,”<br />

Flynn said. “Microbial testing of the<br />

machine’s effectiveness is also being<br />

planned.”<br />

To date, the Product Innovation<br />

Fund has received nearly $500,000<br />

in contributions from the Oklahoma<br />

value-added industry and from private<br />

individuals. Future fapc.biz issues will<br />

feature other research and technical<br />

projects and programs supported by<br />

the FAPC Foundation Funds.<br />

To learn more about the Product<br />

Innovation Fund and how you can<br />

plant seeds of success, visit www.<br />

fapc.biz/fund/. For more information,<br />

please contact Chuck Willoughby,<br />

manager for business and marketing<br />

relations, by calling 405-744-6071 or<br />

by e-mailing chuck.willoughby@okstate.edu.<br />

Chuck Willoughby (left), FAPC business and<br />

marketing relations manager, and Kyle Flynn<br />

(right), FAPC meat plant manager, stand next<br />

to the boot wash donated by Unitherm <strong>Food</strong><br />

Systems.<br />

<strong>Spring</strong> <strong>2009</strong> 9

Great emphasis has been put<br />

on lignocellulosic material<br />

and starch-based ethanol as<br />

the alternative fuel of the future, which<br />

will lead to independence from foreign<br />

oil. Nevertheless, the transportation<br />

fuel industry’s long-term sustainability<br />

can be achieved only if all the domestically<br />

available resources are evaluated<br />

carefully and risks are mitigated<br />

by diversifying the alternative fuel<br />

portfolio for the future.<br />

There are many lessons to be<br />

learned from the demonstration of<br />

methanol as a transportation<br />

fuel in the 1980s and 1990s. The economic<br />

crises in the 1970s led federal<br />

and state officials to encourage the introduction<br />

of alternative fuel vehicles.<br />

At that time, use of coal-derived methanol<br />

was seen as a promising transportation<br />

fuel because of the ample coal<br />

reserves and advantages of methanol<br />

as a fuel. By the late 1970s, the California<br />

Energy Commission was testing<br />

dedicated, methanol-fueled vehicles.<br />

Yet, the use of methanol as a transpor-<br />

The energy experts agree there is no<br />

dence. There are a number of feedst<br />

be evaluated. Methanol has a prove<br />

a significant part of the future energy<br />

tation fuel died out by the late 1990s.<br />

The lessons learned from the active<br />

demonstration of methanol as a<br />

transportation fuel are discussed in an<br />

article titled “Methanol Transportation<br />

Fuels: A Look Back and a Look Forward”<br />

by Gregory A. Dolan, Methanol<br />

Institute vice president for communications<br />

and policy. 1<br />

In the article Dolan states, “From<br />

these demonstration efforts, we<br />

learned there are no technical barriers<br />

to building methanol-fueled vehicles.”<br />

Nevertheless, the lack of strong<br />

support from the automobile manufacturers<br />

discouraged the expansion of<br />

methanol-fueled vehicles. Given the<br />

current status of science and technology<br />

in the U.S., in most cases, technical<br />

issues can be resolved within<br />

a reasonable time frame. Economic,<br />

political, and social issues are the most<br />

challenging hurdles to be overcome<br />

for the establishment of an alternative<br />

fuel transportation system.<br />

Because ancient Egyptians first<br />

obtained it by condensing gases<br />

from burning wood, methanol is<br />

also known as wood alcohol. In<br />

1823, <strong>Robert</strong> Boyle isolated pure<br />

methanol. He called it “spirit of<br />

box” because he produced it by<br />

distilling liquid obtained from<br />

burning boxwood.<br />

Methanol is the simplest and light-<br />

10 fapc.biz

fuels of the future<br />

By Nurhan Dunford<br />

FAPC Oil/Oilseed Chemist<br />

nurhan.dunford@okstate.edu<br />

TRANSPORTATION FUEL<br />

single solution to energy indepenocks<br />

and technologies that need to<br />

n track record to be considered as<br />

portfolio.<br />

est alcohol. It can be produced from<br />

a wide range of feedstocks such as<br />

natural gas, coal, landfill gas, waste<br />

wood, and fermentation. At first<br />

glance, methanol does not look like a<br />

promising fuel. It has lower energy,<br />

approximately 64,500 Btu/gallon, than<br />

gasoline at 124,800 Btu/gallon and<br />

ethanol at 76,500 Btu/gallon. It is toxic<br />

when ingested and, like ethanol, is<br />

corrosive to tank liners, pipeline seals,<br />

and gaskets.<br />

On the other hand, methanol has<br />

a higher octane rating than gasoline<br />

and burns cleaner. It produces carbon<br />

dioxide but eliminates hazardous<br />

gasoline combustion products such as<br />

carcinogenic benzene and particulate<br />

emissions. The higher ignition point of<br />

methanol than gasoline makes it less<br />

of a fire hazard. Because methanol is<br />

miscible with water, it will dilute and<br />

biodegrade in the case of a spill. Methanol<br />

also is extremely flexible as a fuel<br />

and feedstock. It can be blended into<br />

existing transportation fuels or used<br />

as a neat fuel in light- and heavyduty<br />

vehicles powered by internal<br />

combustion engines. It is the ideal<br />

hydrogen carrier fuel for fuel cell<br />

vehicles.<br />

In an interview published<br />

in Chemical and Engineering<br />

News magazine 2 , Nobel Laureate<br />

George Olah, University<br />

of Southern California professor of<br />

chemistry and director of the Loker<br />

Hydrocarbon Research Institute, said,<br />

“Methanol can be transformed into everything<br />

now made from oil and gas,<br />

and it’s a prime way to store, transport,<br />

and utilize energy.”<br />

Olah is one of the proponents of<br />

methanol as a feedstock and fuel. He<br />

emphasizes, “I am not saying methanol<br />

is the only solution to the world’s<br />

energy problem but we should use ev-<br />

erything that is feasible. But in this big<br />

mix, methanol has a significant role.”<br />

The energy experts agree there is<br />

no single solution to energy independence.<br />

There are a number of feedstocks<br />

and technologies that need to<br />

be evaluated. Methanol has a proven<br />

track record to be considered as a<br />

significant part of the future energy<br />

portfolio.<br />

References:<br />

1 http://www.methanol.org/pdf/<br />

MIPaperforISAF.pdf<br />

2 www.CEN.online.org, December 3, 2007<br />

<strong>Spring</strong> <strong>2009</strong> 11

RECIPES SUCCESS<br />

The ingredients restaurants are<br />

using to flourish in a recession<br />

In tough economic times, consumers<br />

try to trim their budgets.<br />

Disposable income is diverted<br />

to savings, and people identify<br />

those comforts they can do without.<br />

Since most homes still come<br />

equipped with kitchens, eating in<br />

seems like a sure, cost-saving option.<br />

Consider the pure expense of<br />

eating out. Dinner for two for less<br />

than $25 is no longer an option at<br />

full-service restaurants. Even most<br />

fast-casual concepts can command<br />

more than $9 per person.<br />

But if you think premium pricing<br />

during an economic downturn<br />

is a disastrous recipe, think again.<br />

Restaurants are sticking with the<br />

recipe that put the industry where<br />

it is. In these unstable economic<br />

times, success has never tasted so<br />

sweet.<br />

Recession? What recession?<br />

Despite reports of a failing<br />

global economy, restaurant sales<br />

– though down from 2008 – re-<br />

mained stable in January and February,<br />

months that are notoriously bad for the<br />

industry. The steady business comes as<br />

no surprise to the restaurant industry.<br />

The National Restaurant Association<br />

is forecasting modest growth for <strong>2009</strong>,<br />

with restaurant sales projected to reach<br />

$566 billion, an increase of 2.5 percent<br />

during the last year.<br />

Fast food concepts are projected to<br />

post the largest increase at 4 percent.<br />

Full-service restaurants are expected to<br />

grow in sales by 1 percent, and taverns<br />

and similar establishments should see<br />

greater than a 2 percent increase.<br />

Still, $10 for a couple of enchiladas,<br />

rice, and beans does not seem like<br />

an option in a bleak economic climate.<br />

Customers regularly pay as much as<br />

four to five times the actual cost of the<br />

food they order at a full-service restaurant.<br />

This seems to defy logic upon<br />

cursory inspection; no meal can be that<br />

good.<br />

Secret ingredients<br />

A more scrutinizing look through<br />

the value-added lens reveals what<br />

consumers are really paying for. The<br />

convenience, specifically the savings<br />

of time and effort, of having a meal<br />

prepared is apparently worth a substantial<br />

premium. Add to this the fact consumers<br />

generally do not have the space<br />

nor expertise to purchase and utilize<br />

the myriad of herbs, spices, and secret<br />

ingredients available to restaurants.<br />

Dawn Sweeney, president and<br />

chief executive officer of the National<br />

Restaurant Association, says consumers<br />

are looking for value, variety,<br />

healthier options, and convenience,<br />

according to the association Web site. 1<br />

Restaurants are a key part of the American<br />

lifestyle. In <strong>2009</strong>, the Association<br />

predicts nearly half of consumers’ food<br />

budget will be spent in restaurants.<br />

Restaurants are at the high end<br />

of the value-added spectrum. These<br />

businesses offer to replace a meal at<br />

home, and do so with such speed and<br />

convenience as to warrant an appreciable<br />

premium. The industry is highly<br />

competitive, and competition breeds<br />

innovation. Consider some of the ways<br />

chefs plan to innovate in <strong>2009</strong>.<br />

12 fapc.biz

Menu inserts<br />

A recent National Restaurant Association<br />

survey of more than 1,600<br />

professional chefs, who are members<br />

of the American Culinary Federation,<br />

reveals nutrition and philosophy-driven<br />

food choices will be the hottest trends<br />

on restaurant menus in <strong>2009</strong>. Local<br />

produce, bite-size desserts, organic<br />

foods, healthful kids’ meals, and new<br />

cuts of meat top the list of more than<br />

200 items in the third annual “What’s<br />

Hot” chef survey. Rounding out the<br />

top 10 trends are vegetable or fruit side<br />

dishes for kids; superfruits, such as<br />

acai; small plates, tapas, mezze, or dim<br />

sum; artisan liquor; and sustainable<br />

seafood. 2<br />

National Restaurant Association<br />

research suggests Americans also<br />

are looking for healthier options and<br />

“greener” restaurants when dining<br />

out. Consumers also are showing an<br />

increased interest in value and convenience.<br />

Interestingly, “health and nutrition”<br />

did not quite break the top 10<br />

trends, coming in at No. 11.<br />

I’ll just have the usual<br />

Despite constant innovation, the<br />

restaurant industry is careful not to<br />

change its already successful core<br />

menu. Certainly, fewer consumer dollars<br />

are available these days.<br />

It is not that people are afraid to<br />

spend, but that they are making fewer<br />

choices when going out to dine.<br />

Well before these new culinary<br />

trends, the restaurant industry captured<br />

its piece of the consumer dollar by providing<br />

a service people were willing to<br />

business & marketing<br />

By Corey Stone<br />

Business & Marketing Strategist<br />

corey.stone@okstate.edu<br />

Fast food concepts are projected to post the largest<br />

increase at 4 percent. Full-service restaurants are expected<br />

to grow in sales by 1 percent and taverns and<br />

similar establishments should see greater than a 2 percent<br />

increase.<br />

pay a premium for. Consumers faced<br />

more time demands, families grew in<br />

size, and technology allowed more<br />

foods to be featured on menus. Do not<br />

expect restaurants to change this aspect<br />

of their business strategy anytime<br />

soon.<br />

With so many two-income homes<br />

and substantial suburban growth, modern<br />

families find it more difficult to<br />

make time to prepare meals at home.<br />

Consumers now demand convenience<br />

when making food choices. Wholesale<br />

clubs like Sam’s market bulk packaging<br />

and prepared family-size meals.<br />

While these retailers take up a portion<br />

of the convenience market, restaurants<br />

continue to dominate it.<br />

Service and convenience are hallmarks<br />

of the restaurant industry. Not<br />

only can a family meal be served more<br />

quickly and with more variety at a<br />

restaurant, but also every member of<br />

the family is free to enjoy each other’s<br />

company. No one is stuck in the kitchen<br />

preparing dinner.<br />

Restaurants also add value to the<br />

experience by providing entertainment.<br />

Servers are generally expected to be<br />

social with customers. Music appropriate<br />

to the genre of the eatery is piped<br />

through digital sound systems. Some<br />

concepts have interactive television to<br />

entertain customers while their food<br />

is prepared.<br />

Eating out is not an unreasonable<br />

decision. The customer may<br />

save up to an hour that would have<br />

been spent cooking and cleaning.<br />

Even if a $3 meal costs $10 at a restaurant,<br />

the customer has only spent<br />

$7 for the entertainment and convenience<br />

received in return.<br />

Many guests are regulars at a<br />

local restaurant. Of course, the restaurateur<br />

wants to do everything he<br />

or she can to bring business back<br />

in. Expect restaurants to strive to<br />

improve customer relations by stepping<br />

up service and being more personal<br />

with customer recognition.<br />

Just desserts<br />

Amidst reports of recession,<br />

businesses must compete for consumers’<br />

constricted cash. This may<br />

be a recipe for disaster for some industries,<br />

but restaurants keep serving<br />

up sweet success. This is why<br />

consumers continue to leave the<br />

cooking to the chefs.<br />

References:<br />

1 www.restaurant.org<br />

2 www.restaurant.org/research/chef_sur-<br />

vey_2008.cfm<br />

<strong>Spring</strong> <strong>2009</strong> 13

A look at how Oklahoma might not avoid the economic downturn<br />

urrent confidence in<br />

the global market is<br />

not high these days.<br />

Whether it is best characterized<br />

as a recession,<br />

an economic downturn, or an expected<br />

part of the cycle, the climate remains<br />

one of uncertainty. Foreclosures are on<br />

the rise as employment numbers fall.<br />

Evidence of a downturn was available<br />

in early 2008. At that time, some<br />

economists reported a recession had already<br />

begun. People reacted by spending<br />

less, downsizing their personal<br />

lifestyles. Then in April 2008, Forbes<br />

magazine released an interesting list:<br />

America’s Recession-Proof Cities.<br />

According to Forbes, four of the<br />

top 10 cities were in Texas, largely the<br />

result of technology and energy industries.<br />

North Carolina had two cities<br />

and three others were far to the west.<br />

However, the city that ranked highest<br />

is located at the nation’s crossroads.<br />

Forbes magazine listed Oklahoma<br />

City as the United States’ No. 1<br />

recession-proof location, writing the<br />

statement below:<br />

“With falling unemployment, one<br />

of the strongest housing markets in the<br />

country, and strong growth in agriculture,<br />

energy and manufacturing, Oklahoma<br />

City might not have received<br />

the recession memo, and it looks best<br />

positioned of the nation’s metropolitan<br />

areas to ride out the current crisis.<br />

Booming valuations of Oklahoma<br />

City’s largest companies, like Devon<br />

Energy and Chesapeake Energy, suggest<br />

the energy sector is the right place<br />

to be.” 1<br />

At that time, unemployment numbers<br />

were falling in Oklahoma City. Its<br />

metro area boasted one of the country’s<br />

strongest housing markets, fueled<br />

by solid growth in agriculture, energy,<br />

and manufacturing.<br />

Forbes’ focus on the Sooner State<br />

probably did not come as a shock to<br />

some Oklahomans. In January 2008,<br />

Bob Ball, economic research manager<br />

for the Tulsa Metro Chamber, told<br />

the Tulsa World that Tulsa typically<br />

lags behind the rest of nation by nine<br />

months or so in a national recession.<br />

It was, however, the strong price<br />

of oil futures that had Forbes singing<br />

Oklahoma City’s praises. The price of<br />

crude oil was climbing at the time. In<br />

fact, a barrel of crude oil jumped as<br />

high as $135 in June 2008, up from<br />

$87 in early February.<br />

However, by January <strong>2009</strong>, oil<br />

prices had fallen below $40 a barrel in<br />

Asia as investors questioned the health<br />

of the United States economy and de-<br />

mand for crude oil. A month later, oil<br />

was less than $35 a barrel.<br />

Many businesses still parlay the<br />

“Oklahoma is recession-proof” sentiment<br />

as an advertising angle. Interestingly,<br />

the real estate industry is a chief<br />

proponent of this mantra. In the meantime,<br />

brand new houses remain unsold<br />

and vacant.<br />

Make no mistake; Oklahoma is<br />

not immune to the effects of recession.<br />

The same economic synergy<br />

running through the inter-industrial<br />

connections of other states is present<br />

in Oklahoma. Business growth has a<br />

multiplier effect on a local economy;<br />

business decline brings a directly opposite<br />

result.<br />

This is best illustrated by looking<br />

at the industry that broke the bubble:<br />

real estate. By mid-2008, rumors were<br />

surfacing regarding the solvency of<br />

Circuit City. The electronics chain<br />

was facing potential bankruptcy, a fate<br />

from which no national electronics<br />

chain has ever recovered.<br />

Circuit City staved off the reports<br />

with hollow assurances and a few store<br />

closings. The electronics chain filed<br />

for bankruptcy in November 2008 and<br />

is now facing the same fate as houseware<br />

retailer Linens ‘n Things liquidation.<br />

Circuit City hired a third party to<br />

14 fapc.biz

Make no mistake; Oklahoma is not immune to the effects of<br />

recession. The same economic synergy running through the<br />

inter-industrial connections of other states is present in Oklahoma.<br />

Business growth has a multiplier effect on a local economy;<br />

business decline brings a directly opposite result.<br />

sell merchandise in the remaining 567<br />

stores, and more than 30,000 people<br />

likely will lose their jobs.<br />

Although electronics may seem<br />

fairly unnecessary for day-to-day life,<br />

the recession’s effect is much broader.<br />

Belk’s and Dillard’s saw less than 75<br />

percent of customers return in 2008.<br />

“FOX Business” predicted in December<br />

2008 that Sears, Kmart, and<br />

Macy’s also might be candidates for<br />

bankruptcy.<br />

Consider the effect on real estate<br />

development. When Circuit City closes<br />

its Oklahoma City locations, the landowner<br />

does not get rent or, at most,<br />

three months from bankruptcy proceedings.<br />

The landlord is an unsecured<br />

creditor, who is waiting in line for<br />

scraps from the bankruptcy table. The<br />

landlord loses a vital income stream.<br />

The community loses tax revenue.<br />

If a corner store like Dillard’s goes<br />

under, other mall stores can pull out<br />

according to their contract. Eventually,<br />

the mall will shut down and jobs will<br />

be lost. Money will disappear from<br />

the local economy; money which was<br />

used on paper to secure home mortgages.<br />

This is why “FOX Business” reported<br />

potential trouble for Macy’s.<br />

Macy’s uses its prestige to contract<br />

for lower rents. The retailer signs covenants<br />

with malls based on a promise<br />

to generate traffic, so the mall offers<br />

to keep rent down. Now that Macy’s is<br />

not bringing in traffic, its retail outlets<br />

face substantial rent hikes.<br />

Retailers are in business to make<br />

money by providing consumable<br />

goods. If consumers do not need the<br />

retailers’ products, the failure of the<br />

business is a natural economic consequence.<br />

Perhaps a more sobering<br />

concern is the solvency of local governments.<br />

Most communities provide access<br />

to utilities for citizens. Utility companies<br />

issue bonds. Bond ratings are tied<br />

to the credit rating of the insurance<br />

company that underwrites the payment<br />

of the bond. Bonds come due under<br />

what might be referred to as a “calamity<br />

clause.” Simply, the bond comes<br />

due if something extraordinary from a<br />

predetermined list happens.<br />

One such calamity is a change in<br />

the bond rating. This effectively means<br />

that when the credit rating agency<br />

drops the rating of the underwriting<br />

insurance company, the bond comes<br />

due. The very real result is the utility<br />

company might not be able to operate.<br />

Unbelievable? Unfortunately, it<br />

is very realistic. As recently as September<br />

2008, radio station WBHM<br />

in Birmingham reported Jefferson<br />

County, Alabama, had already missed<br />

several bond payments for a sewer<br />

project. Local banks were engaged in<br />

emergency meetings to determine how<br />

to bail out the<br />

community.<br />

Oklahoma<br />

was predicted<br />

to survive the<br />

recession be-<br />

business & marketing<br />

By Corey Stone<br />

Business & Marketing Strategist<br />

corey.stone@okstate.edu<br />

cause of strong oil prices. That net has<br />

disappeared, but there are signs of stabilization.<br />

Prices of futures contracts<br />

for later this year suggest investors<br />

expect oil to recover. The March contract<br />

currently trades near $46 a barrel,<br />

while the April contract trades above<br />

$49. Some energy experts feel pricing<br />

will regain strength, and it’s not a<br />

question of if, but when.<br />

In a year’s time, a commodity that<br />

was theoretically priced according to<br />

supply and demand doubled from $69<br />

a barrel to nearly $150, and then, in a<br />

period of just three months, crashed<br />

along with the stock market. “60 Minutes”<br />

correspondent Steve Kroft reported<br />

the cause was complicated and<br />

the theories numerous. Many people<br />

believe it was a speculative bubble,<br />

similar to what caused the housing<br />

crisis, and that it had more to do with<br />

traders and speculators on Wall Street<br />

than with oil company executives or<br />

sheiks in Saudi Arabia.<br />

Oklahomans should remain wary<br />

of inferences that this state is immune<br />

to economic cycles. If oil prices rebound,<br />

the state will at best be insulated<br />

temporarily from the recession’s<br />

effects. It may truly be a good time to<br />

purchase real estate for planned business<br />

growth, but the decision to do so<br />

must be made with caution.<br />

1 The article, written by Joshua Zumbrun, was<br />

published April 29, 2008. It is available<br />

at http://www.forbes.com/2008/04/29/<br />

cities-recession-places-forbeslife-cx_<br />

jz_0429realestate.html<br />

<strong>Spring</strong> <strong>2009</strong> 15

Another outbreak<br />

in peanut butter<br />

This significance of the recent Salmonella<br />

peanut butter outbreak does<br />

not begin with the Peanut Corporation<br />

of America (PCA). It starts two years<br />

earlier in 2007 with an outbreak of<br />

Salmonella (serotype Tennessee) associated<br />

with Peter Pan and Great Value<br />

peanut butter produced by ConAgra’s<br />

Sylvester, Georgia, plant.<br />

2007 ConAgra Salmonella outbreak<br />

This outbreak occurred because,<br />

evidently, moisture/condensation in the<br />

plant was contaminated with Salmonella<br />

Tennessee and somehow got into<br />

the peanut butter. This was the first<br />

outbreak in the United States of Salmonella<br />

associated with peanut butter as a<br />

vehicle and not the typical food associated<br />

with Salmonella outbreaks.<br />

The magnitude was enormous as<br />

peanut butter is widely consumed, and<br />

these brands are among the largest in<br />

the U.S. The outbreak resulted in 627<br />

people getting sick in 47 states.<br />

This recall, however, was limited<br />

to jars of peanut butter. You can imagine<br />

an outbreak of such major brands<br />

that everyone is familiar with would<br />

resonate largely with consumers, especially<br />

since their children are likely the<br />

major household consumers of peanut<br />

butter.<br />

2008 PCA Salmonella outbreak<br />

Fast-forward less than two years<br />

later, in late 2008, with increasing<br />

number of cases starting to implicate<br />

peanut butter … Again. But the story<br />

of Stewart Parnell, president, chief<br />

executive officer, and owner of PCA<br />

is not one of accidental contamination<br />

but of personal avarice and greed.<br />

Parnell worked with his family in<br />

a peanut roasting/blanching operation,<br />

taking a $50,000 business to $30 million<br />

annually, before selling in 1995. In<br />

2000, he bought a peanut plant in Plainview,<br />

Texas, and in 2001, bought the<br />

Blakely, Georgia, operation; the family<br />

also had a plant in Suffolk, Virginia.<br />

Parnell was able to quickly show<br />

profits by buying the cheapest raw<br />

peanuts he could find, running the<br />

business on a bare-bones budget, and<br />

using minimum-wage labor. Sometimes<br />

cheap raw materials are “cheap”<br />

for a reason.<br />

In Parnell’s case, he had several<br />

prior lawsuits for supplying peanuts to<br />

customers that were allegedly contaminated<br />

with aflatoxin, and the products<br />

had to be recalled.<br />

People who knew him would not<br />

buy his peanuts to feed their pigs allegedly<br />

because of aflatoxins. This is<br />

partly where his clients “went wrong.”<br />

It is generally prudent in today’s<br />

climate that clients either need assurances<br />

that the goods they are buying<br />

are legitimate (letter of assurance or<br />

specifications) or they check up on<br />

the products by submitting incoming<br />

ingredients/products for testing (i.e.,<br />

self-audit), or both.<br />

This helps companies to identify<br />

suppliers that are providing sub-standard<br />

or unacceptable products. Large<br />

companies (like McDonald’s) can require<br />

a supplier to run safety programs<br />

that are not even required by law. The<br />

magnitude of the PCA Salmonella outbreak<br />

was so large because more than<br />

one “fail safe” programs failed.<br />

For instance, the current outbreak<br />

also involved running a food business<br />

without proper regulatory registration<br />

(i.e., with the <strong>Food</strong> and Drug Administration,<br />

FDA). The PCA plant in Texas<br />

was not licensed with the Texas Department<br />

of Agriculture. The inspector<br />

who was responsible listed them as<br />

“licensed” because he was told they<br />

“had submitted for one,” but they<br />

never did, and PCA never got licensed,<br />

although the inspector in subsequent<br />

years kept listing them as “licensed.”<br />

Since they were not actually licensed<br />

to run a food business, the plant was<br />

not known to exist by FDA and was<br />

16 fapc.biz

pathogen patrol<br />

By Peter Muriana<br />

FAPC <strong>Food</strong> Microbiologist<br />

peter.muriana@okstate.edu<br />

T<br />

The Salmonella outbreak stemming from the Peanut Corporation of America (PCA) adds further fuel to the fire<br />

supporting the need for sufficient food safety regulations, which cannot be undermined by greedy individuals.<br />

PCA is a private company in which Stewart Parnell was president, chief executive officer, and owner. As such,<br />

he was able to direct the alleged improper decision-making that would less likely occur in larger companies that have<br />

numerous administrative layers. Someone in a managerial position in a company that manufactures and distributes<br />

food should not have such disregard for customer and consumer health that they, as aleged in the media, knowingly<br />

ship Salmonella-tainted products.<br />

Normal, recurring outbreaks resulting from accidental contaminations have the potential to stir politicians to<br />

initiate new and more stringent regulations because the industry cannot seem to regulate themselves to prevent this<br />

from happening. It is significantly worse when, If as allegedly occurred with PCA, a nationwide outbreak results<br />

from personal greed and malfeasance. It has been interesting to notice that some of the largest corporations in the<br />

United States have called for greater regulatory oversight by the <strong>Food</strong> & Drug Administration, recognizing that rogue<br />

operators like Parnell have hurt the industry and affected legitimate companies in the peanut butter market.<br />

never inspected, but the plant was operating<br />

for more than 10 years.<br />

The Georgia plant had 12 isolations<br />

of Salmonella during the prior<br />

year, and product sample results that<br />

tested “positive” for Salmonella were<br />

allegedly resubmitted until a “negative”<br />

test result was achieved.<br />

It is understood that Salmonella<br />

that gets into peanut butter can survive<br />

in localized pockets and not necessarily<br />

be evenly distributed throughout<br />

the entire product. Most large, publicly-held<br />

companies know this would<br />

be a “death knell” and would never<br />

resort to such, although a rogue manager<br />

could still attempt such improper<br />

activities.<br />

In PCA’s situation, Parnell was<br />

the person making these decisions ...<br />

There was no one higher to override<br />

him and the decisions he made. One of<br />

the backlashes from this outbreak was<br />

for possible legislation (either state or<br />

federal) requiring companies to share<br />

results of product testing with FDA or<br />

other regulatory body. How this aspect<br />

of the case may eventually resolve<br />

itself is not yet clear and may not get<br />

worked out for some time.<br />

The current PCA outbreak in-<br />

volves peanuts and peanut butter contaminated<br />

with Salmonella serotype<br />

Typhimurium as both product and<br />

ingredient, which has resulted in more<br />

than 691 illnesses in 46 states. What<br />

is most alarming about this outbreak<br />

is the products that have been recalled<br />

are not similar-packaged food items as<br />

in the previous peanut butter outbreak.<br />

These products include more than<br />

3,500 items including peanut butter,<br />

peanut butter crackers, cookies, cake,<br />

pies, brownies, candy and cereal products,<br />

donuts, dressing and seasoning,<br />

dried fruits and vegetables, ice cream,<br />

snack bars, snack mix, pet food, and<br />

pre-package meals. This is one huge<br />

mess involving a lot of companies.<br />

The fact about Salmonella<br />

How does this get so out of hand?<br />

Are peanuts not heated? The answer is<br />

yes; they are roasted at temperatures<br />

sufficient to kill Salmonella.<br />

However, roasting occurs early in<br />

the long process that turns them into<br />

peanut butter, and if they get contaminated<br />

at some point thereafter, there is<br />

nothing to kill the Salmonella. Salmonella<br />

can survive in peanut butter, and<br />

the fat can protect the bacterial cells<br />

during its passage through the acidic<br />

human stomach and, subsequently,<br />

cause infection in the intestinal tract.<br />

In fact, in my food microbiology<br />

laboratory at the FAPC, researchers<br />

are currently testing whether growth in<br />

peanut butter provides heat resistance<br />

properties to Salmonella that may help<br />

them to overcome subsequent thermal<br />

or baking regimens.<br />

Ensuring product quality<br />

In conclusion, this is another example<br />

of why companies need to keep<br />

a close eye on their suppliers. The<br />

largest companies even go so far as<br />

to perform “audits” of their suppliers’<br />

premises to ensure the quality of the<br />

ingredients they receive. In the very<br />

least, they can require “letters of guarantee”<br />

or specifications, require receipt<br />

of independent laboratory results,<br />

require annual visit to the suppliers’<br />

plants, or other means to ensure the<br />

high quality of their suppliers’ products<br />

and ingredients.<br />

Failure to do so is “just not good<br />

business” and can put a company’s<br />

reputation and product safety in someone<br />

else’s hands.<br />

<strong>Spring</strong> <strong>2009</strong> 17

Expectations<br />

Sugar is probably one of the most<br />

common, well-known food ingredients,<br />

which is no surprise<br />

given the long relationship with it. For<br />

the purposes of this article, sugar refers<br />

to sucrose.<br />

According to the <strong>Food</strong> and <strong>Agricultural</strong><br />

Organization of the United<br />

Nations, the current top three countries<br />

responsible for sugar cane production<br />

are, in descending order, Brazil, India,<br />

and China.<br />

It is believed the first species<br />

of sugar cane to be domesticated<br />

was Saccharum officinarum in New<br />

Guinea; however, it also has been suggested<br />

additional species may have<br />

been domesticated at approximately<br />

the same time, in areas such as India<br />

and Indonesia.<br />

The first definitive written record<br />

of sugar production appears in a Hindu<br />

religious document called the Buddhagosa,<br />

or Discourse on Moral Consciousness.<br />

This early sugar was probably not<br />

hard and brittle, but more like taffy in<br />

texture.<br />

It is believed Arabs improved<br />

upon the Indian techniques for cultivating<br />

sugar cane and producing<br />

sugar and, as they expanded westward,<br />

introduced sugar to Europe between<br />

700 and 900 A.D. Again, it is believed<br />

this early sugar was probably not the<br />

equivalent of the white, crystalline<br />

powder known today, but its exact<br />

form is unknown.<br />

Despite being quite commonplace<br />

today, sugar was once reserved for the<br />

very rich and powerful. In fact, the<br />

earliest written document referring<br />

to sugar in England is from the 12th<br />

century and is a record of the royal income<br />

of King Henry II (1154-89).<br />

It is interesting to note that because<br />

of its great expense and rarity,<br />

sugar would have been used exclusively<br />

as a spice or condiment in cooking.<br />

This means sugar would have been<br />

used to change the flavor of a food<br />

without plainly sweetening it.<br />

Before moving on to the present, it<br />

must be mentioned that along with its<br />

sweetness, sugar has had a very bitter<br />

edge. This was best summarized by J.<br />

H. Bernardin de Saint Pierre in volume<br />

one of his book “Voyage to Isle<br />

de France, Isle de Bourbon, The Cape<br />

of Good Hope … With New Observations<br />

on Nature and Mankind by an<br />

Officer of the King” (1773):<br />

“I do not know if coffee and sugar<br />

are essential to the happiness of Europe,<br />

but I know well that these two<br />

products have accounted for the unhappiness<br />

of two great regions of the<br />

world: America has been depopulated<br />

so as to have land on which to plant<br />

them; Africa has been depopulated so<br />

as to have people to cultivate them.”<br />

The modern process of making<br />

sugar is roughly divided into the following<br />

steps. First, the sucrose is<br />

extracted from the plant tissue. Sugar<br />

18 fapc.biz

cane and beets are the most important<br />

plant sources for the contemporary industrial<br />

production of sugar. However,<br />

palm, date, and sorghum also can be<br />

used.<br />

If the source is cane, this is accomplished<br />

by roller presses; however,<br />

if the source is beet, this step is accomplished<br />

by countercurrent extraction<br />

with hot water. This results in a<br />

solution with a purity ranging from 84<br />

to 86 percent with retained dry solids<br />

(RDS) of 14 to 16 percent, and remaining<br />

impurities from the plant tissue.<br />

These impurities may be removed<br />

by mechanical screening or separated<br />

by settling and filtering.<br />

The next step is evaporation,<br />

where large volumes of water are removed<br />

from the juice so that an RDS<br />

of 65 to 71 percent is achieved. The<br />

resulting syrup is called “thick juice.”<br />

It then undergoes crystallization in<br />

vacuum pans, where the dissolved<br />

sugar is processed into crystals mixed<br />

with a high-density liquid, or “mother<br />

liquor.” The mother liquor is centrifuged<br />

to remove the crystals from the<br />

liquid phase. The sugar crystals then<br />

are dried by hot air in rotating drums,<br />

cooled, passed through screens to<br />

determine particle size, then sent to<br />

packaging or bulk storage.<br />

Because of consumer demand,<br />

some manufacturers have begun to<br />

utilize raw cane sugar and honey<br />

rather than refined sugar. In the United<br />

States, Deluxe Honeydrop has created<br />

such a line of flavored waters that use<br />

honey for both sweetness and flavor.<br />

However, simply replacing sugar<br />

with an alternate sweetener may not<br />

be easy because sugar often performs<br />

several functions within a food system,<br />

so additional reformulation may be<br />

from the test kitchen<br />

By Darren Scott<br />

FAPC Sensory Specialist<br />

darren.scott@okstate.edu<br />

necessary. When J.M. Smucker introduced<br />

a sugar-free strawberry preserve<br />

sweetened with Splenda, the company<br />

utilized a combination of locust bean<br />

gum and fruit pectin to help maintain<br />

texture in the absence of sugar.<br />

Sugar also has a distinct flavor that<br />

may not easily be matched, depending<br />

upon the food application. Therefore,<br />

a combination of replacement sweeteners<br />

may be required to reach the<br />

equivalent desired flavor.<br />

Sugar continues to be a widely<br />

used and enjoyed sweetener. However,<br />

the intended target market or target<br />

application may limit its use. Being<br />

mindful of these factors will help ensure<br />

a product will meet everyone’s<br />

sweet expectations.<br />

References:<br />

1 Hitting the shelves. Prepared <strong>Food</strong>s. September 2008.<br />

2 New product trends. Prepared <strong>Food</strong>s. January <strong>2009</strong>.<br />

3 Sweetners: Nutritive. 1998. Eagan Press. Saint Paul, MN. Alexander, R. J.<br />

4 Sweetness and power: The place of sugar in modern history. 1985. Penguin Books. New<br />

York, New York. Mintz, S. W.<br />

5 Http://www.fao.org/es/ess/top/commodity.html?lang=en&item=156&year=2005<br />

<strong>Spring</strong> <strong>2009</strong> 19

Finding your<br />

PRODUCT NICHE<br />

I<br />

n the last article, we looked at the<br />