INSPECTION STANDARD - Oceaneering

INSPECTION STANDARD - Oceaneering

INSPECTION STANDARD - Oceaneering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE <strong>INSPECTION</strong> <strong>STANDARD</strong><br />

Nuclear Stations<br />

vessel entry training<br />

A team of 20 <strong>Oceaneering</strong> technicians led by Chris<br />

Smith, NDT Inspection Engineer, have once again<br />

undergone training on boiler simulators located in<br />

Newcastle, England in preparation for completing<br />

inspection work in the most testing of conditions<br />

- boilers in close proximity to the reactor core on<br />

nuclear installations. This work has proved vital to<br />

the efficiency of the boilers in the past although the<br />

conditions encountered could not get much more<br />

challenging.<br />

Due to the heat and potential contamination in the<br />

boilers the inspectors wear air-fed suits and have<br />

to manoeuvre through a complex set of boiler<br />

tubes to get in the correct position to complete the<br />

testing. To apply the ALARP (As Low As Reasonably<br />

Practicable) principle requires practise in safe<br />

conditions. For this reason simulators create the<br />

conditions and work scopes are developed to<br />

allow the inspectors to become acclimatised and<br />

confident in the simulated conditions within a<br />

safe environment before the actual site work is<br />

performed. The inspectors are monitored by video<br />

and radio communications from a manned control<br />

room while completeing the tasks, while keeping<br />

the number of personnel allowed into the hazardous<br />

conditions to a minimum.<br />

Over the past years a vast amount of successful<br />

inspections have been completed on the boilers<br />

due to the diligent attitude of the inspectors and the<br />

professional training completed.<br />

7<br />

Eggborough Power<br />

Station safety award<br />

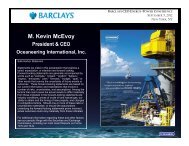

<strong>Oceaneering</strong> personnel are renowned for<br />

their vigilance and an eye for detail and this<br />

was proved again when a team of technicians<br />

identified a defect with the potential to cause a<br />

significant safety issue.<br />

During the 2011 shutdown, Dale Sutcliffe,<br />

Gary Cook and Carl McElvaney formed the<br />

<strong>Oceaneering</strong> inspection team tasked with carrying<br />

out a routine inspection of a high pressure<br />

pipework bend on Unit 3 Eggborough Power<br />

Station. The coal fired station has been generating<br />

electricity since 1967 and is located in East<br />

Yorkshire, England.<br />

Members of the team noticed a crack propagating<br />

from a ‘tapping point’ branch weld to an adjacent<br />

‘warming’ branch weld. The defect was in an<br />

area outside the area scheduled for inspection.<br />

Nevertheless the alert team immediately reported<br />

to the Station Engineer, an action which resulted in<br />

a change to the inspection scope for this and other<br />

station units.<br />

In recognition of their diligence the three men<br />

were proposed for a Safety Award which<br />

was presented to them by Paul Tomlinson, the<br />

Power Station’s Chief Operating Officer on the<br />

14th of June. <strong>Oceaneering</strong> also recognised<br />

this conscientious approach, by presenting<br />

each individual with a monetary voucher and<br />

expressing great thanks to all involved.<br />

Carl McElvaney - Left Gary Cook - Left