IEW CONSTRUCTION GROUP - Building With Binder Magazine

IEW CONSTRUCTION GROUP - Building With Binder Magazine

IEW CONSTRUCTION GROUP - Building With Binder Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

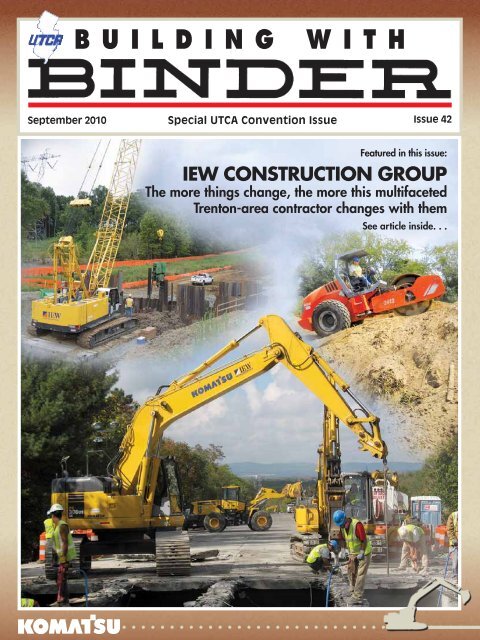

September 2010<br />

White logo is below<br />

B U I L D I N G W I T H<br />

Special UTCA Convention Issue<br />

Issue 42<br />

Featured in this issue:<br />

<strong>IEW</strong> <strong>CONSTRUCTION</strong> <strong>GROUP</strong><br />

The more things change, the more this multifaceted<br />

Trenton-area contractor changes with them<br />

See article inside. . .

BUILDING BUILDING WITH<br />

Dear Valued Reader:<br />

For all of us involved in the construction industry, the past couple of years have been<br />

challenging. Despite those challenges, there are three things you can always count on from<br />

<strong>Binder</strong> Machinery: (1) that we’ll always carry top products; (2) that we’ll always provide<br />

the best product support in the market; and (3) that we’ll always act in your best interest.<br />

Komatsu earthmoving equipment, Wirtgen paving-related machines, Kobelco cranes and<br />

Sennebogen material handlers are all industry-leading products in their respective fields.<br />

They all excel in terms of productivity, reliability and value. Stack them up against any<br />

of our competitors’ lines and we’re confident that our manufacturers compare favorably.<br />

We hope you’ll read what our featured customers <strong>IEW</strong> Construction Group, Aspen<br />

Landscaping Contracting Inc., Cirello Iron & Steel, Mount Construction and Perrello Inc.<br />

have to say about these products in this issue of your <strong>Building</strong> <strong>With</strong> <strong>Binder</strong> magazine.<br />

Regarding product support, that’s always been a hallmark of <strong>Binder</strong> Machinery<br />

Company. My father started <strong>Binder</strong> Machinery in 1957. From the beginning, our motto<br />

was “The Product Support Company,” and it remains our calling card today. If we sell you<br />

something, you can be assured that we’re going to stand behind it and that we’re going<br />

to provide the parts and service that keep you up and running. At <strong>Binder</strong>, that’s who and<br />

what we are.<br />

As for acting in your best interest, it’s not that we’re selfless. Like you, we have to make<br />

a profit to stay in business. That said, I can assure you that we’ll never gouge you and<br />

we’ll never be unfair to you. We believe a good business transaction is one that allows both<br />

parties to succeed. That’s what all of us at <strong>Binder</strong> Machinery strive for. By treating you right<br />

and providing value, we want to give you a reason to come back — and keep coming back.<br />

It looks as though an economic recovery has begun and will continue in the months and<br />

years to come. <strong>Binder</strong> Machinery Company has been here through good times and bad for<br />

the past 53 years, and we intend to remain here for the next 53 and beyond.<br />

As always, if there’s anything we can do for you, don’t hesitate to call or stop in.<br />

Alan J. <strong>Binder</strong><br />

Executive<br />

Vice President<br />

Carlin R. <strong>Binder</strong><br />

Director of<br />

Sales<br />

<strong>Binder</strong> Machinery Company<br />

Robert C. <strong>Binder</strong><br />

Chairman of the Board<br />

Joe Vazzano<br />

Chief Financial<br />

Officer<br />

Sincerely,<br />

Ashlee B. McMackin<br />

Director of<br />

Marketing<br />

Robert C. <strong>Binder</strong><br />

Chairman of the Board<br />

Brendan <strong>Binder</strong><br />

President and COO<br />

Charles Seelinger<br />

V.P. of Administration,<br />

North Jersey<br />

Armand Pizza<br />

General Manager,<br />

Parts<br />

Ann Marie Hebling<br />

V.P. of Administration,<br />

South Jersey<br />

C.J. Weir<br />

Director of Financial<br />

Services<br />

An Oshkosh Corporation Company

HERE’S THE DIRT...<br />

SPOTLIGHTS<br />

Read how <strong>IEW</strong> Construction Group, a multifaceted Trenton-area<br />

contractor, has changed during its 85-year history to grow<br />

and succeed . . . 4<br />

When Aspen Landscaping Contracting Inc. owners Maria and Don<br />

Fuentes took a gamble on opening their business, the odds were<br />

against them. See how they overcame obstacles and became<br />

winners in their field . . . 8<br />

Learn how two brothers-in-law teamed up to build Cirello Iron & Steel<br />

into a successful scrap-metal recycling business in Saddle Brook . . . 13<br />

Read all about Mount Construction, a diverse contractor in Berlin,<br />

N.J., that specializes in problem solving for its customers . . . 17<br />

As Perrello Inc. enters its 33rd year in business, see how founders<br />

Carl and Lisa Perrello of Lake Hopatcong have grown the company<br />

into heavy highway contracting that specializes in bridge and signstructure<br />

construction . . . 20<br />

FOCUSED On CUSTOMERS<br />

Director of Marketing Ashlee <strong>Binder</strong> McMackin brings you snapshots<br />

of <strong>Binder</strong> customers on the job . . . 24<br />

nEW PRODUCTS<br />

<strong>Binder</strong> Machinery has just added Kaeser compressors to its product<br />

lineup. Read more about the durable and reliable Mobilair M50 and<br />

M57 portable air compressors . . . 26<br />

Komatsu’s new D65-16 dozers offer a long list of new features,<br />

including six-way and Sigma blade options for more efficiency<br />

and lower O&O costs . . . 27<br />

See how the increased lifting force, digging force and dumping<br />

speed of Komatsu’s new 75-ton PC650LC-8 excavator can boost<br />

your company’s productivity . . . 31<br />

Komatsu’s new excavator models, the PC350LC-8, PC350HDLC-8 and<br />

PC450LC-8, offer increased durability with heavy-duty booms . . . 33<br />

Find out how the new PC228USLC-8 tight-tail-swing excavator<br />

provides increased lifting capacity in a variety of applications . . . 36<br />

Increase your productivity and reduce O&O costs with Komatsu’s<br />

new PC78US-8 compact excavator with upgraded features . . . 37<br />

InDUSTRY IMPACT<br />

Find out how Komatsu has been gearing up for the new Tier 4<br />

emission standards that begin next year. . . . 39<br />

AT YOUR SERvICE<br />

Find out how investing in a fresh paint job for your equipment<br />

can pay off . . . 41<br />

®<br />

<strong>Binder</strong> Machinery<br />

has two locations<br />

to serve you better<br />

CORPORATE HEADQUARTERS:<br />

2820 HAMILTON BLVD.<br />

SOUTH PLAINFIELD, NJ 07080<br />

(908) 561-9000<br />

Sales Representatives<br />

Robert Fornini<br />

Jim Gill<br />

Bill Kretschmer III<br />

Gary Repke<br />

Sales & Rental Coordinator<br />

Jim Casendino<br />

Training Manager<br />

Ed Snyder<br />

Product Support Representatives<br />

Roy Corriveau<br />

Kevin Kretschmer<br />

Rudy Martinez<br />

Service Manager<br />

John Malizia<br />

Field Service Manager<br />

Pete Meka<br />

SOUTH JERSEY BRANCH:<br />

201 NORTH ROUTE 73<br />

wINSLOw TOwNSHIP, NJ 08095<br />

(856) 767-5900<br />

Sales Representatives<br />

Scott Smith<br />

Dominick Vecchiarelli<br />

Field Sales Manager<br />

Harry Rice<br />

Product Support Representatives<br />

Ed Hoffman<br />

Shawn Mulvenna<br />

Service Manager<br />

Jim Reilly<br />

Service Administrator<br />

Wayne Jason<br />

Printed in U.S.A.<br />

© 2010 Construction Publications, Inc.<br />

All rights reserved<br />

®<br />

®

4<br />

SPOTLIGHTS<br />

<strong>IEW</strong> <strong>CONSTRUCTION</strong> <strong>GROUP</strong><br />

The more things change, the more this multifaceted<br />

Trenton-area contractor changes with them<br />

(L-R) <strong>IEW</strong> Equipment<br />

Manager Jim Pennell, Vice<br />

President Darrell Harms<br />

and Excecutive Vice<br />

President Harry Coleman<br />

4<br />

IIn 1925, Vaughan Grundy started a company<br />

called Ornamental Iron Works, which, as<br />

the name implies, fabricated and installed<br />

ornamental iron. Its work can still be seen at<br />

Masonic temples, churches, homes and schools<br />

in and around the company’s home base of<br />

Trenton, N.J.<br />

Through the years, Ornamental Iron<br />

Company evolved into a structural steel<br />

company, then into a firm that did a lot of<br />

manufacturing plant work (which is when<br />

the name changed to Industrial Engineering<br />

Works, which later became <strong>IEW</strong>), and<br />

eventually into heavy highway work,<br />

including bridge building.<br />

“One of our strengths has been our<br />

willingness to change focus, to do something<br />

different — whatever we had to do — in order to<br />

foster continued growth,” said third-generation<br />

President Vaughan Grundy III, who followed<br />

his father and grandfather in ownership of the<br />

family business. “When a market becomes soft,<br />

we’re willing and able to move into new markets<br />

that seem to be heating up.<br />

“For example, in the 1960s and 1970s,<br />

Industrial Engineering Works focused on the<br />

nuclear power industry, and also fabricated<br />

and installed very heavy steel work,” Grundy<br />

explained. “By the mid-1970s, the nuclear<br />

work was pretty much coming to an end.<br />

That coincided with the national emphasis<br />

on transportation infrastructure work —<br />

construction and repair of roads and bridges —<br />

so it was natural for us to move into that area.”<br />

“We follow the money,” is the way <strong>IEW</strong> Vice<br />

President Darrell Harms puts it. “Our crews<br />

are cross-trained and highly skilled so they’re<br />

able to take on a wide range of projects. For<br />

example, much of our bridge work includes a<br />

substantial amount of site work and we’re able<br />

to perform all aspects of the job in-house, with<br />

our own people. We think that’s an advantage<br />

for us and our clients.”<br />

Today, with more than 250 employees, <strong>IEW</strong><br />

is widely recognized as one of New Jersey’s<br />

leading full-service contracting firms. Bridge<br />

building remains a specialty (the company<br />

builds or rehabs about 50 bridges each year),<br />

but <strong>IEW</strong> is capable of doing almost any type of<br />

construction-related work, including general<br />

construction, site work and excavation,<br />

marine construction, plant maintenance, metal<br />

fabrication and emergency services.<br />

The early years<br />

Some of <strong>IEW</strong>’s notable early projects<br />

included such New Jersey landmarks as<br />

the War Memorial, the State House Annex,<br />

the State Museum, Rockefeller Institute in<br />

Princeton, Trenton Central High School,<br />

Lawrenceville School, several Princeton

In addition to its large fleet of Komatsu equipment,<br />

<strong>IEW</strong> has a number of Hamm rollers, which it uses on its<br />

earthwork projects.<br />

University projects and the heavy guard rails<br />

for the Trenton Makes Bridge.<br />

One memorable project as the company<br />

began doing bridge work was the replacement<br />

of the deck on the Burlington-Bristol Bridge<br />

over the Delaware River. Grundy said <strong>IEW</strong><br />

used an innovative technique that was<br />

virtually unknown at the time, but has since<br />

become commonplace.<br />

“We chose to pre-assemble components<br />

consisting of the structural steel, the concrete<br />

deck, the hand railing — the whole section,”<br />

he remembered. “We cut sections of the<br />

bridge out and, overnight, we’d drop the<br />

pre-assembled section in so the bridge was<br />

open to traffic in the morning. That technique<br />

is now routine, but that was the first time it<br />

had ever been done in the U.S.”<br />

Other projects illustrate the full circle of<br />

accomplishments throughout the long history<br />

of <strong>IEW</strong> Construction Group. In 2003, <strong>IEW</strong><br />

demolished a damaged pedestrian bridge<br />

over Route 38 serving Cherry Hill Mall. <strong>IEW</strong><br />

had originally fabricated and erected the<br />

structure in 1966. And in 2005, <strong>IEW</strong> did the<br />

structural steel work for the renovation of the<br />

War Memorial in Trenton — the same historic<br />

structure for which Grundy’s company<br />

had the original steel contract when it was<br />

constructed some 80 years earlier.<br />

Widening the New Jersey<br />

Turnpike<br />

The most recent example of <strong>IEW</strong>’s ability<br />

and willingness to transition into new<br />

markets is the large amount of work it’s<br />

now doing for the New Jersey Turnpike<br />

Authority. The Turnpike Authority has an<br />

aggressive widening program that will add<br />

six traffic lanes (for a total of 12 lanes) between<br />

Interchange 6 in Mansfield Township and<br />

Interchange 9 in East Brunswick Township<br />

— a distance of about 35 miles. The five-year,<br />

$2.5 billion project, designed to improve traffic<br />

flow and accommodate a projected large<br />

increase in future traffic volume, started last<br />

year and will be completed in 2014.<br />

To date, <strong>IEW</strong> has won four different contracts<br />

worth more than $125 million as part of the<br />

Turnpike Widening Program. The company’s<br />

work includes construction of 11 bridges<br />

and a substantial amount of highway work,<br />

from earthwork to drainage improvements<br />

to culvert extensions to MSE (mechanically<br />

stabilized earth) walls.<br />

“While the percentage of site work versus<br />

structure work is somewhat higher than is<br />

typical for us, doing site work is not new to<br />

<strong>IEW</strong>,” said Director of Business Development<br />

James Snyder. “There’s an element of that on<br />

most of our jobs. Where the Turnpike widening<br />

really falls in line with our strengths is the<br />

combination of a wide variety of tasks and<br />

the requirement to get it done in a short time<br />

frame. We pride ourselves on our ability to take<br />

on complicated projects with an accelerated<br />

schedule and complete them on-time and<br />

on-budget.”<br />

Komatsu and <strong>Binder</strong> are<br />

“excellent partners”<br />

Challenging projects require topnotch<br />

machinery, which is why <strong>IEW</strong> Construction<br />

Group utilizes a primarily Komatsu fleet, along<br />

with other equipment, from <strong>Binder</strong> Machinery<br />

Company. <strong>IEW</strong> owns more than 30 Komatsu<br />

units including Komatsu excavators ranging in<br />

size from PC78s to PC400s; Komatsu WA200,<br />

WA320 and WA380 wheel loaders; Komatsu<br />

D31, D39, D41, D61 and D65 dozers and<br />

Komatsu WB140 backhoe loaders.<br />

“Our equipment purchases are obviously<br />

performance-based,” said <strong>IEW</strong> Equipment<br />

Manager Jim Pennell. “We look for<br />

machines that are productive and reliable,<br />

Continued . . .<br />

Komatsu equipment is<br />

easy to find at an <strong>IEW</strong><br />

Construction Group<br />

jobsite, including the<br />

Komatsu PC308USLC<br />

and PC228USLC<br />

tight-tail-swing<br />

excavators seen here.<br />

“For what we do, we<br />

think the Komatsu line<br />

is the best fit in terms of<br />

performance, production<br />

and reliability,” said Vice<br />

President Darrell Harms.<br />

5

6<br />

<strong>IEW</strong> well-positioned to take advantage of opportunities<br />

. . . continued<br />

that our operators like to operate and that<br />

our mechanics like to work on. Komatsu<br />

equipment fits the bill on all counts. We<br />

especially like Komatsu tight-tail-swing<br />

machines, such as the PC228s and PC308s,<br />

because we can put a machine that has a large<br />

lifting capacity in a small work zone.”<br />

“We turn to <strong>Binder</strong> for the vast majority<br />

of our equipment, not just for Komatsu, but<br />

also for Hamm rollers, compressors and a<br />

Kobelco crane that we got about a year ago,”<br />

said Harms. “The 100-ton Kobelco CK1000 has<br />

been a great addition for our bridge work.<br />

“<strong>Binder</strong> Machinery has been an excellent<br />

partner to <strong>IEW</strong> through the years,” he added.<br />

“We have seen considerable growth in the<br />

last decade. When we first started needing<br />

earthmoving machinery, we were conservative<br />

in our approach to equipment acquisition,<br />

and <strong>Binder</strong> was willing to work with us. We<br />

appreciated that and we’ve been loyal to<br />

them. They, in turn, have been an excellent<br />

partner, delivering high-quality products and<br />

outstanding support.”<br />

“I can’t tell you how many times I’ve called<br />

our <strong>Binder</strong> Sales Rep Harry Rice after hours or<br />

on weekends and told him I needed something<br />

An <strong>IEW</strong> crew uses the company’s Kobelco CK1000 to install steel sheet piling at the<br />

turnpike-widening project the company is doing in Burlington County, N.J.<br />

first thing the next morning or Monday<br />

morning, and it’s always there,” related<br />

Pennell. “Harry and everybody at <strong>Binder</strong><br />

understand our situation. They know how<br />

important it is to us that our equipment works<br />

every day. They take great care to keep us up<br />

and running and to help us in any way they<br />

can, and that means a lot to us.”<br />

Infrastructure opportunities<br />

<strong>With</strong> the Turnpike project in full swing,<br />

<strong>IEW</strong> has a large amount of work right now.<br />

That’s a testament to a strong, aggressive,<br />

forward-thinking management team led by<br />

Executive Vice President Harry Coleman, Vice<br />

President Robert Tampellini and Controller<br />

John Dempsey, along with Grundy, Harms<br />

and Snyder. Together they have worked with<br />

all of the valued employees of <strong>IEW</strong> to get the<br />

company to where it is today.<br />

“<strong>With</strong> the Turnpike work, we’re in good<br />

shape for the next couple of years and we’re<br />

very thankful for that,” said Harms. “During<br />

that time, we hope that the economy will turn<br />

and we’ll see more private work as well as more<br />

state funding for needed infrastructure repairs.”<br />

“There’s no question that opportunities<br />

for future projects exist, as long as the<br />

necessary funding is in place,” said Snyder.<br />

“Government officials understand the need<br />

and so does the general public. They also<br />

understand that public works projects do more<br />

than improve infrastructure; they also generate<br />

jobs and jobs are how we’re going to build our<br />

way out of this economic slump.”<br />

Grundy said he believes <strong>IEW</strong> is<br />

well-positioned to take advantage of<br />

opportunities in the years to come. And with<br />

three young sons and a daughter at home,<br />

he’s hopeful this longtime family business will<br />

extend to a fourth generation.<br />

“I’m very proud of the work our company<br />

has done. Many of the projects we build are<br />

statements. They’re something people will<br />

drive by and see for the next 80 years, just like<br />

the projects that our earlier generations built<br />

before us. It’s a family legacy and a company<br />

legacy, and we certainly intend to continue it<br />

in the years and decades to come.” n

South Plainfield, NJ<br />

2820 Hamilton Blvd.<br />

(908) 561-9000<br />

www.bindermachinery.com<br />

Winslow Township, NJ<br />

201 North Route 73<br />

(856) 767-5900

8<br />

SPOTLIGHTS<br />

ASPEN LANDSCAPING<br />

CONTRACTING INC.<br />

Despite the odds, couple’s gamble on<br />

new opportunity is a winner<br />

WWhen Maria Fuentes decided to go into<br />

business for herself, she knew the odds of success<br />

were long. Statistics show most businesses fail<br />

in the first few years, even if the owners have<br />

experience in the field they’re going into. Maria<br />

didn’t. On top of that, she chose a field that’s<br />

historically been a man’s domain, stacking the<br />

chances for success even further against her.<br />

“I had people telling me from the beginning<br />

not to do it; that I’d never survive because<br />

it’s a tough market and a man’s world,” said<br />

Fuentes, President of Aspen Landscaping<br />

Contracting which she founded in 1996. “But I<br />

wanted a business of my own that allowed me<br />

to work from home and be with my kids.”<br />

She came up with the idea of starting a<br />

landscaping business while on maternity leave<br />

from her job at Motorola. Researching the<br />

Aspen Landscaping uses this PC160LC-7 excavator to dig, load and place materials. The<br />

company offers topsoil placement, planting, rooftop landscaping, wetlands restoration,<br />

soil-erosion control and landfill remediation.<br />

4<br />

Maria Fuentes,<br />

President<br />

Don Fuentes,<br />

Senior Project<br />

Manager<br />

industry, Fuentes realized there was a good<br />

opportunity in the New Jersey heavy highway<br />

landscaping marketplace.<br />

“Despite the opportunity and market, I<br />

had some uncertainty, because I didn’t know<br />

anyone in the heavy-highway or landscaping<br />

industries, or anything about the bidding<br />

process,” said Maria. “I just jumped in,<br />

learning as I went and self-teaching how to<br />

bid. Fortunately, there were general contractors<br />

who were willing to give me some feedback. I<br />

was certified with New Jersey Transit, the New<br />

Jersey Department of Transportation and Port<br />

Authority, and that helped because practically<br />

every governmental project has some form of<br />

landscaping attached to it.”<br />

Once the certifications were in place, Fuentes<br />

could bid as a prime contractor on state projects<br />

that are considered primarily landscaping —<br />

more than 51 percent of the total job is made up<br />

of landscaping. Aspen Landscaping Contracting<br />

landed about $2 million in work within its first<br />

couple of years, and business took off. <strong>With</strong> a<br />

firm foothold in the market and prospects good,<br />

Fuentes’ husband, Don, retired from his law<br />

enforcement job and joined Aspen as Senior<br />

Project Manager in 1999.<br />

“I’m extremely proud of what Maria has<br />

accomplished,” said Don, who helped research<br />

the industry and called on contractors to get<br />

Aspen Landscaping’s name out before joining<br />

the business full time. “There has been a lot<br />

of hard work behind it. When she started<br />

out, she’d be up in the middle of the night to<br />

type bids and fax them out in her office on the<br />

second floor of our home. During the day, I<br />

would often be on the first floor and hear the

Komatsu dozers such as this D41 are Aspen Landscaping’s main production units. “The Komatsu dozers allow us to spread topsoil with minimal<br />

ground disturbance,” said Senior Project Manager Don Fuentes. “The operator also has good visibility to the blade and material, so he can place material<br />

efficiently with minimal passes.”<br />

phone ring upstairs, hoping it was someone<br />

calling about a project.”<br />

Seeing both sides<br />

Aspen Landscaping Contracting’s phone has<br />

rung more and more frequently throughout the<br />

past decade, much of the business coming from<br />

repeat customers who turn to the company to<br />

sub the landscaping portion of heavy-highway<br />

projects. Aspen offers topsoil placement,<br />

planting, rooftop landscaping, wetlands<br />

restoration, soil-erosion control and landfill<br />

remediation. More information about Aspen’s<br />

services is available online at www.aspennj.net.<br />

“Working projects from both sides — as a<br />

sub and a prime — we’ve developed some<br />

longstanding relationships, and that’s a big part<br />

of our success,” said Maria. “Prime contractors<br />

have come to see that we have proven ourselves<br />

and are able to handle large projects. When<br />

we bid as a prime contractor, we believe we<br />

treat our subs the way we want to be treated.<br />

The bottom line, either way, is that we have to<br />

get the job done when we say we will, and we<br />

create good relationships based on our previous<br />

reputation. We’re always the last ones on the<br />

job, so there’s an urgency to not only do the job<br />

right, but on time because no one gets paid until<br />

the job is closed out.”<br />

Aspen Landscaping has closed out<br />

numerous jobs since, including one of its<br />

most challenging: Echo Lake Park wetland<br />

restoration. The company dewatered the site as<br />

part of the project, before planting more than a<br />

half-million plants throughout the 10-acre site.<br />

Plantings were done in “shelving level,” which<br />

meant installation at varying depths to ensure<br />

their survival. Adding to the challenge, Aspen<br />

had to boat to some of the areas in the wetland<br />

in order to put the plants in place.<br />

Aspen Landscaping Contracting generally has<br />

several projects going on at any one time during<br />

the company’s main season, which runs from<br />

March to December. Depending on work load,<br />

Aspen employs 20 to 50 workers, including<br />

key individuals such as Project Managers Bill<br />

Morgan and Anthony Williamson and General<br />

Foreman Frank Cunha.<br />

“Our ability to coordinate and execute a project<br />

successfully is directly tied to the experience, hard<br />

work and dedication of our employees,” Don<br />

emphasized. “Many have years in the industry<br />

and know going into a project what needs to be<br />

done in order to finish on time and on budget.<br />

Everyone — our laborers, project managers and<br />

foreman — is very good at offering alternative<br />

ideas for doing a project more efficiently. They’re<br />

an excellent group.”<br />

The right equipment match<br />

Also playing an integral role is equipment,<br />

especially the Komatsu D39, D41 and<br />

D65 dozers and PC160 excavator Aspen<br />

Landscaping Contracting uses for grading<br />

and moving material. Maria and Don worked<br />

Continued . . .<br />

9

10<br />

Aspen Aspen Landscaping Landscaping focused focused on customer customer relationships<br />

relationships<br />

. . . continued<br />

with <strong>Binder</strong> Machinery Company Sales<br />

Representative Dominick Vecchiarelli to<br />

purchase its Komatsu pieces.<br />

“Because we’re usually the last ones on the<br />

job, it’s important that we don’t disturb the<br />

previous work completed by other contractors,<br />

so having the right equipment that allows<br />

for that, while giving us the performance<br />

to complete our job, is essential,” said Don.<br />

“For example, the Komatsu dozers allow<br />

us to spread topsoil with minimal ground<br />

(L-R) <strong>Binder</strong> Machinery Company Sales Representative Dominick Vecchiarelli meets<br />

with Aspen Landscaping Contracting General Foreman Frank Chna and Project Manager<br />

Bill Morgan. “Anytime we’ve had to call on Dominick or someone else at <strong>Binder</strong>, they’ve<br />

provided quick action,” said President Maria Fuentes. “We value the relationship we’ve<br />

built with <strong>Binder</strong>.”<br />

An Aspen Landscaping operator uses a D65PX-15 dozer to place material on a New York jobsite.<br />

disturbance. The operator also has good<br />

visibility to the blade and material, so he can<br />

place material efficiently with minimal passes.<br />

“The PC160 allows us to dig, place and load<br />

material, so it gives us versatility,” he added.<br />

“Because of its size (37,790 pounds) it’s easy to<br />

transport. That’s a nice feature, because we’re<br />

frequently moving, so we’re happy with the<br />

time savings.”<br />

The couple is also happy with the service they<br />

receive from <strong>Binder</strong> Machinery Company. They<br />

call on <strong>Binder</strong> as needed for service and parts.<br />

“We’ve built a good relationship with our<br />

customers, and in order for us to maintain that,<br />

we need to have good equipment that’s not<br />

going to cost us significant downtime, as well as<br />

a dealer that supports it,” said Maria. “<strong>Binder</strong><br />

understands that, and any time we’ve had to<br />

call on Dominick or someone else at <strong>Binder</strong>,<br />

they’ve provided quick action. Just as we value<br />

our relationships with our customers, we value<br />

the relationship we’ve built with <strong>Binder</strong>.”<br />

Constantly proving itself<br />

Maria and Don Fuentes readily point out that<br />

Aspen Landscaping Contracting won’t continue<br />

its success story without continuing to grow its<br />

customer relationships. The couple have built<br />

the company into one of the most respected<br />

heavy-highway landscaping operations in New<br />

Jersey. In more recent years, the company has<br />

also been working in the five boroughs of New<br />

York City and in upstate New York.<br />

“Aspen has been successful because we were<br />

willing to take a chance, and we’ve learned a lot<br />

along the way,” said Maria. “We’re still learning.<br />

Not only are we looking ahead to see what’s<br />

out there for future work, we’re focused on the<br />

present to ensure our current work is done right<br />

and on time. We also look at the past, reviewing<br />

jobs we’ve completed to see where we could<br />

have done something better or more efficiently.”<br />

“We have a solid footing now in<br />

landscaping, and the hard work and<br />

dedication we’ve put in has paid off,” added<br />

Don. “We’ve discussed diversifying, and that’s<br />

a good possibility going forward as long as it<br />

doesn’t hinder our ability to take care of our<br />

customers. That’s our top priority.” n

KA06<br />

100% control<br />

(productivity runs in this family)<br />

You’re committed to getting things done on time and on budget, and you need<br />

dependable, hard-working machines to meet your deadlines day after day. The<br />

Komatsu D31, D37, D39 and D51 dozers all feature the reliability and versatility<br />

that have made Komatsu the choice of owners and operators for years:<br />

• Hydrostatic Transmission (HST) for superb accuracy and smooth control<br />

• Excellent blade visibility that minimizes operator guesswork and reduces cycle times<br />

• All the daily maintenance items centralized in one location for convenient access<br />

Whether you’re looking for a 78, 89, 105 or 130 horsepower machine, you can be<br />

confident you’ll get a full day’s work—and then some—from dozers that are…<br />

100% Komatsu. 866.513.5778 www.komatsuamerica.com

SPOTLIGHTS<br />

CIRELLO IRON & STEEL<br />

Brothers-in-law team up to build growing scrap-metal<br />

recycling business in Saddle Brook<br />

T<br />

Thirty-two years ago, Frank Curcio called his<br />

brother-in-law Tony Cirello and asked him if he<br />

was interested in working together to expand<br />

upon what Curcio was doing in scrap-metal<br />

recycling. Since 1964, Curcio has run Curcio<br />

Scrap Metal, which only processes nonferrous<br />

materials such as copper, brass and aluminum.<br />

Cirello was running his own scrap yard<br />

in Florida, handling nonferrous materials as<br />

well, when Curcio called. Cirello sold that<br />

business and teamed up with Curcio in 1978<br />

to found Cirello Iron & Steel, which focuses<br />

on recycling ferrous metals, such as cast iron<br />

and steel. Cirello is President, Curcio Secretary<br />

and Curcio’s son Michael is Treasurer. Cirello’s<br />

son-in-law Jarrod Whidden is also involved in<br />

Cirello Iron & Steel.<br />

Cirello and Curcio set up Cirello Iron & Steel<br />

adjacent to Curcio Scrap Metal on the same<br />

site in Saddle Brook, a central location with<br />

Interstates 80 and 78 and U.S. 46 nearby. The<br />

two companies take in demolition contractors’<br />

debris and other items from individuals within<br />

about a 50-mile radius of Saddle Brook.<br />

“Much of the debris we take in comes from<br />

repeat customers with whom we’ve developed<br />

a good rapport,” noted Cirello. “We attribute<br />

that to taking a keen interest in customer<br />

service, including giving them a fair price and<br />

getting them in and out as quickly as possible.<br />

Going the extra mile to help them is essential<br />

— staying open late, or even opening on a<br />

Sunday to take in materials, for instance.”<br />

Cirello Iron & Steel takes in anywhere from<br />

80 to 175 tons of material per day, much of it<br />

ready to go directly into containers that are<br />

shipped out daily to mills and other entities<br />

that buy the scrap material to recycle. Cirello<br />

estimates 30 to 40 percent of the material<br />

coming in has to be processed on site before<br />

it’s ready to leave the yard.<br />

“Our volume has decreased due to the overall<br />

economy,” acknowledged Cirello. “We’ve had<br />

to tighten our belt during the past couple years<br />

because the construction industry slump is<br />

generating less scrap. However, our commitment<br />

to serving customers, regardless of the economy,<br />

has helped us through the tough times.”<br />

Komatsu, LaBounty make<br />

strong combination<br />

Cirello Iron & Steel handles much of its<br />

processing using a Komatsu PC270LC-8<br />

equipped with a LaBounty MSD2500 shear,<br />

Continued . . .<br />

Tony Cirello,<br />

President<br />

Frank Curcio,<br />

Secretary<br />

Cirello Iron & Steel uses a Komatsu PC270LC-8 with a LaBounty shear to process scrap<br />

metal at its yard in Saddle Brook. “It definitely lived up to its reputation by having the<br />

hydraulic power to run the shears and the ruggedness to stand up to a fairly challenging<br />

application,” said President Tony Cirello.<br />

13

14<br />

No slowdown in sight for Cirello Iron & Steel<br />

. . . continued<br />

<strong>Binder</strong> Machinery Service Technician Ray Hetu Mylene works on the<br />

LaBounty shear attached to Cirello Iron & Steel’s Komatsu PC270LC-8<br />

excavator. “<strong>Binder</strong> handles all our maintenance now, which is something<br />

we really like,” said President Tony Cirello.<br />

(L-R) <strong>Binder</strong> Machinery Sales Rep Robert Fornini, Cirello Iron & Steel Operator Jarrod<br />

Whidden and <strong>Binder</strong> PSR Roy Corriveau get together to check out Cirello’s Komatsu PC270.<br />

which it purchased from <strong>Binder</strong> Machinery’s<br />

South Plainfield branch.<br />

“The PC270 replaced a stationary shear that<br />

we were having a lot of problems with,” said<br />

Cirello. “Komatsu has a good reputation, so<br />

when it came time to replace that stationary<br />

shear, that’s one of the first things we looked at.<br />

We also wanted something mobile; something<br />

we could move around the yard to get to the<br />

materials rather than bringing them to the shear.<br />

We contacted <strong>Binder</strong> about trying the PC270<br />

and ended up buying it. It definitely lived up to<br />

its reputation by having the hydraulic power to<br />

run the shears and the ruggedness to stand up<br />

to a fairly challenging application.<br />

“In addition, the LaBounty shear is a nice<br />

complement to the PC270. We really like the<br />

narrow opening, which allows for better control<br />

and cutting. Others we looked at were too<br />

wide and bulky. We’re cutting some sizeable<br />

materials, including I-beams, and the shear does<br />

a good job of cutting it quickly and efficiently.”<br />

Cirello also appreciates the efficient service<br />

<strong>Binder</strong> Machinery offers. “We have a long<br />

relationship with <strong>Binder</strong>, dating back to 1982<br />

when we bought a machine from Walter <strong>Binder</strong>,”<br />

he said. “They worked closely with us to make<br />

sure the machine and shear setup was the<br />

right match for our needs. <strong>Binder</strong> handles all<br />

the maintenance now, which is something we<br />

really like. They have the know-how to ensure<br />

it’s properly done, so our downtime stays to a<br />

minimum. That’s a huge benefit in this industry.”<br />

A growing trend<br />

Keeping that benefit will continue to be<br />

essential, as Cirello sees no slowdown in the<br />

amount of scrap Cirello Iron & Steel brings in.<br />

In fact, he thinks the total may grow.<br />

“It seems as though nearly everyone is<br />

active in scrapping metal. It used to be that our<br />

main source of materials was from demolition<br />

operations or people directly involved with<br />

scrap materials. <strong>With</strong> iron prices going up and<br />

a stronger push to recycle, we’re seeing more<br />

and more private individuals bringing things<br />

in. People go through their house and their<br />

belongings looking for items to scrap. It’s a<br />

growing trend.” n

Construction Photography By<br />

IMAGE UP STUDIO<br />

Project Documentation<br />

Preconstruction, Progress & Video<br />

Aerial Photography<br />

Helicopter & Fixed Wing<br />

Also call us for architectural photography, portraits, product<br />

and advertising photography, as well as image restoration.<br />

732-549-1845 | www.imageup.com | ask@imageup.com<br />

Serving the Construction Industry since 1978<br />

An SBE<br />

Company

South Plainfield, NJ<br />

2820 Hamilton Blvd.<br />

(908) 561-9000<br />

www.bindermachinery.com<br />

Winslow Township, NJ<br />

201 North Route 73<br />

(856) 767-5900

SPOTLIGHTS<br />

MOUNT <strong>CONSTRUCTION</strong><br />

This diverse, Berlin, N.J., company specializes<br />

in problem solving for its customers<br />

W<br />

When it comes to construction, there’s not<br />

much that Mount Construction (a division of The<br />

Mount Group) hasn’t done, can’t do or won’t<br />

learn. Based in Berlin, N.J., near Philadelphia, the<br />

company does earthwork, underground utility<br />

work, asphalt paving, milling and concrete. It<br />

also provides a host of emergency repair services<br />

for the state, counties and municipalities, ranging<br />

from water and sewer line breaks, to road cracks,<br />

to bridge deck failure<br />

Mount Construction also manufactures<br />

recycled products such as crushed concrete<br />

and crushed asphalt, and recently opened an<br />

environmental division, which specializes<br />

in underground pipe inspection and onsite<br />

recycling at environmentally sensitive locations.<br />

“We’re a heavy, civil construction company<br />

that builds roads, bridges and installs<br />

utilities, self-performing almost all aspects<br />

of the job,” said CEO Dave Smith. “That’s<br />

the description we’d put in the Yellow Pages,<br />

but we believe our specialty actually is<br />

problem-solving. That’s certainly what our<br />

environmental division is all about, and in<br />

the big picture, it’s what all our construction<br />

jobs are. Somebody needs something done.<br />

Problems crop up. We find an answer. That’s<br />

what we try to do for our clients on each and<br />

every job.”<br />

Problem-solving is not always external;<br />

sometimes it’s what you have to do within<br />

your business to keep it a viable enterprise.<br />

It’s what Smith did with Mount Construction<br />

when he saw signs of a slowdown coming four<br />

or five years ago.<br />

Continued . . .<br />

Dave Smith,<br />

CEO<br />

Mount Construction uses<br />

numerous Wirtgen group<br />

products on its paving jobs,<br />

including Wirtgen milling<br />

machines, Hamm rollers<br />

and Vögele pavers.<br />

17

18<br />

Wirtgen equipment provides paving solutions<br />

. . . continued<br />

Mount Construction’s<br />

newest paver, the Vögele<br />

5100-2 is at work on a major<br />

paving project on the New<br />

Jersey Turnpike. “We<br />

bought the Vögele 5100<br />

after having had remarkable<br />

success with our 5200,” said<br />

Mount Construction CEO<br />

Dave Smith.<br />

“At the time, we did about half commercial<br />

and half private work,” he recalled. “It became<br />

clear to me that we needed a new direction, so<br />

we adjusted. I believed public work was where<br />

the opportunities were going to be. We learned<br />

to be bridge builders because I knew that<br />

would be a growth area. We learned recycling<br />

because most jobs now have a recycling aspect<br />

to them. We cross-trained all our people so<br />

they would be able to go any direction and do<br />

anything that needed to be done.”<br />

As a result, Smith says Mount Construction<br />

has been able to not just maintain, but to grow<br />

during the recession. “It’s really gratifying and<br />

a credit to all our people. From our laborers,<br />

operators and foremen to superintendents,<br />

project managers and top management, I<br />

believe we have the best construction team<br />

in the area. We have a tremendous amount of<br />

talent and experience, and very low turnover.”<br />

In addition to Smith, key personnel include<br />

President John “Jay” Beirne, CFO Karen<br />

Littlefield, VP-Project Management Joe Iorio,<br />

VP-Estimating Alexander Guerrina and Safety<br />

Officer Chris Reese.<br />

Wirtgen delivers “lowest<br />

cost per ton”<br />

To handle the diverse projects that Mount<br />

Construction takes on, the company has a wide<br />

range of equipment consisting of about 250<br />

pieces. Much of the company’s road-building<br />

equipment consists of Wirtgen Group machines<br />

from <strong>Binder</strong> Machinery Company.<br />

“I’m not a sentimental equipment guy,” said<br />

Smith. “I get machines for one reason — to help<br />

my company make money. That’s it. I want<br />

equipment that delivers the best bang for the<br />

buck. It’s all about operational cost. What’s it cost<br />

to run? What’s it produce? How long does it last?<br />

Is it reliable? If it breaks down, how fast can we<br />

get it back up and running? Equipment we buy<br />

has to have the right answers to those questions.<br />

That’s why we have a number of Wirtgen mills,<br />

Vögele pavers and Hamm rollers.<br />

“In our opinion, Wirtgen milling machines<br />

are tremendous — the industry standard,” said<br />

Smith. “We have probably close to a dozen<br />

Hamm rollers, both asphalt and dirt rollers,<br />

and they’ve worked very well for us. And we<br />

have two Vögele pavers (5100-2 and 5200-2).<br />

We just bought the 5100, specifically because<br />

of the success we’ve had with the 5200. Like I<br />

said, we’re all about cost per ton and we found<br />

the Vögele 5200 delivers the lowest cost per<br />

ton of any paver we’ve ever owned.”<br />

President-elect of UTCA and<br />

proud of industry<br />

In addition to running The Mount Group,<br />

Smith also operates a charitable foundation<br />

that benefits sick and underprivileged children<br />

in south central New Jersey. He will also<br />

soon be sworn in as President of the Utility<br />

Transportation Contractors Association (UTCA).<br />

“I like to be involved and active — part of<br />

the solution, not part of the problem,” said<br />

Smith. “I’ve been a member of UTCA for many<br />

years. I think it’s important for people in this<br />

industry to support it, give back to it and learn<br />

from it. That’s what UTCA is all about. It’s our<br />

industry’s political arm. It’s a watchdog group<br />

that works to ensure funding for projects. It<br />

promotes safety, fair practices and an equal<br />

playing field. Membership is a way to give back<br />

to your industry and become educated about it<br />

at the same time.<br />

“Personally, I love this industry. I learn every<br />

day and I teach every day. I’m surrounded by<br />

great people, including my employees as well<br />

as other contractors, who I believe are the most<br />

entrepreneurial, hardworking group in any<br />

industry. They’re the MacGyvers of the world.<br />

They take on the toughest jobs in the most<br />

adverse conditions, figure out how to do them,<br />

then get them done. It’s inspiring and it makes<br />

me proud to be a part of an industry like that.” n

Available through <strong>Binder</strong> Machinery Company.

20<br />

SPOTLIGHTS<br />

PERRELLO INC.<br />

Lake Hopatcong contractor enters into<br />

33rd year in business<br />

Carl and Lisa Perrello<br />

operate Perrello Inc., a<br />

Lake Hopatcong heavy<br />

highway contractor that<br />

specializes in bridge<br />

and sign-structure<br />

construction, as well as<br />

paving and pile driving.<br />

Carl founded the business<br />

in 1977 at the age of 16.<br />

4<br />

CCarl Perrello’s path to success may seem a<br />

typical story. Like many contractors, he started<br />

with a dump truck, and built from there. But<br />

Perrello’s story diverges from the others when<br />

you consider he bought that dump truck and<br />

founded Perrello Inc. at 16 years of age.<br />

“When I bought it, the dump truck wasn’t<br />

running,” recalled Perrello, who along with his<br />

wife, Lisa, runs the Lake Hopatcong company.<br />

Carl runs field operations, while Lisa keeps the<br />

books. “Admittedly, I wasn’t the best student.<br />

My mother told me I either had to work or go to<br />

school. I fixed the truck and started doing odd<br />

jobs around town, such as cleaning basements<br />

and backyards, whatever I could do.”<br />

Perrello began working in 1977, and less<br />

than a year into the endeavor, he started doing<br />

his own contracting jobs, demolishing old<br />

and constructing new driveways, sidewalks<br />

and patios. Not long after, he was bidding city<br />

sidewalk and curb projects.<br />

“It was difficult for a 17-year-old kid<br />

to get bonded to do municipal work, and<br />

the bonding company didn’t even want to<br />

talk to me,” Perrello said. “Eventually, we<br />

worked things out, and from that point on,<br />

governmental work has been my main focus.<br />

I went from the sidewalk and curb jobs into<br />

sewer work for a while, then started doing a<br />

lot of reinforced-concrete retaining walls.”<br />

It’s easy to see that Perrello Inc.’s projects<br />

were moving on an upward arc in terms of<br />

size. The next rung on the ladder was bridge<br />

work, which has become a specialty of<br />

Perrello’s during the past 25 years.<br />

The company’s first bridge project was for<br />

Sussex County, and it went so well that Perrello<br />

turned all his attention to building steel-beam<br />

and prestressed box-beam structures. Early<br />

on, Carl focused on county work, including<br />

completion of the 15 bridges in Hunterdon<br />

County, but has since moved up to New Jersey<br />

and New York Department of Transportation<br />

projects. Notable projects include the Lamington<br />

Road bridge in Bedminster, the Maple Avenue<br />

bridge in Rahway, the Main Avenue bridge in<br />

Clifton, and a large Park-N-Ride on the Taconic<br />

State Parkway in Yorktown Heights, N.Y.<br />

“We do some repair work, but the bulk of the<br />

bridge projects we do are reconstruction or new<br />

construction,” said Perrello, whose company also<br />

does some bridge demolition. “We’re willing to<br />

take on just about any bridge project, whether<br />

it’s a small one that takes a few months, to larger<br />

ones that take a couple years. I actually like the<br />

more complicated ones because of the challenge.”<br />

More services, high profile<br />

Perrello Inc. doesn’t just focus on challenging<br />

bridge projects anymore. During the past

several years it’s added more heavy highway<br />

and dredging work, along with offering barge<br />

chartering. Perrello estimates 60 percent of<br />

the company’s business is bridge building, 20<br />

percent constructing sign structures and the<br />

rest split among paving, pile driving and other<br />

types of work. All are done within about a<br />

60-mile radius of Lake Hopatcong.<br />

Perrello credits an experienced roster of<br />

employees for being able to meet challenges<br />

head on.<br />

“We typically do all the work ourselves,<br />

which I believe is a real benefit because we<br />

control the schedule,” Perrello noted. “We’ll<br />

sub out things like striping and guard rails on<br />

paving projects, but for the most part, we’re<br />

very self-sufficient.”<br />

In addition to notable bridge projects, Perrello<br />

Inc. has done other high-profile projects,<br />

including rebuilding the seawall on Liberty<br />

Island, home to the Statue of Liberty. Portions of<br />

the original granite seawall, constructed in the<br />

early 1800s, had fallen into the Hudson River<br />

making the repairs a rather interesting job,<br />

according to Perrello.<br />

“It was an extensive process, starting with<br />

pulling the original stones out of the river,”<br />

he explained of the Army Corps of Engineers<br />

project that Perrello Inc. completed during a<br />

couple of months in 2004. “We had to identify<br />

them and put them back in place where they<br />

came from, like putting a puzzle together.<br />

All the work had to be done during low tide,<br />

because we couldn’t get any debris or cement<br />

in the water. When the tide was out, we worked<br />

like mad to get the stones in place, using a<br />

cement that would cure quickly and hold up to<br />

the seawater when the tide came back in. It was<br />

all done while the island was open to public, so<br />

it was challenging, but very rewarding as well.”<br />

Komatsu equipment stands up<br />

to the challenge<br />

Because much of Perrello Inc.’s work is<br />

so challenging, Perrello looks for rugged<br />

equipment that will handle tough, heavy<br />

conditions. Working with <strong>Binder</strong> Machinery<br />

Sales Representative Robert Fornini, Perrello<br />

has added a Komatsu PC300LC-8 and a<br />

WB150 backhoe loader to the fleet.<br />

A Perrello Inc. crew uses a Komatsu PC300LC-8 to dig a footing for a New Jersey highway<br />

sign structure. The company also uses the machine to set shoring. “The bridge and<br />

sign-structure jobs we do often require deep footing digs, and with the PC300 we can<br />

easily go 20 feet if need be,” said Owner Carl Perrello.<br />

“The bridge and sign-structure jobs we do<br />

often require deep footing digs, and with the<br />

PC300 we can easily go 20 feet if need be,” said<br />

Perrello. “Even in the deeper digs it has good<br />

power, which is another feature that stood<br />

out to us. Because we have such deep digs,<br />

we need strength to put shoring in place. The<br />

PC300 handles that without any problems, and<br />

at the same time it’s smooth, comfortable and<br />

fuel-efficient.”<br />

Perrello also appreciates the strength and<br />

versatility the WB150 backhoe loader offers.<br />

“We were doing a job and needed a backhoe,<br />

so we had several dealers bring machines in to<br />

demo. The Komatsu stood out quite prominently<br />

because it had the lifting power we needed as<br />

well as a side-dump feature we wanted. It was a<br />

great machine at the best price with zero-percent<br />

financing, which no one else offered except<br />

<strong>Binder</strong>. There were quite a few precast catch<br />

basins on that project that weighed about a<br />

ton each, and the WB150 was the only one we<br />

demo’d that could pick them up.”<br />

Continued . . .<br />

21

22<br />

Bridge work, sign structures are Perrello Inc. specialties<br />

. . . continued<br />

Much of the service work required on Perrello<br />

Inc.’s Komatsu equipment is done by <strong>Binder</strong><br />

Machinery field service technicians at Perrello<br />

jobsites. “I’ve worked with <strong>Binder</strong> Machinery<br />

almost as long as I’ve been in business.<br />

They’ve always done a terrific job of getting<br />

(L-R) Perrello Inc.’s Rudy Martinez, <strong>Binder</strong> Sale Rep Robert Fornini and Perrello Inc.<br />

Owner Carl Perrello meet on a Perrello Inc. jobsite. “I’ve worked with <strong>Binder</strong> Machinery<br />

almost as long as I’ve been in business, and they’ve always done a terrific job of getting to us<br />

quickly when we need parts or service,” Perrello acknowledged.<br />

to us quickly,” Perrello acknowledged. “They<br />

have the knowledge and technical expertise to<br />

support the equipment, and that’s something<br />

we find essential to keeping our downtime to a<br />

minimum.”<br />

Take care of the customer<br />

Perrello Inc. has multiple projects going at<br />

once. Its staff of about 30 employees is split<br />

among up to three crews, depending on work<br />

load. Perrello believes that’s just about the right<br />

size for the company.<br />

“I’ve built a fairly good business from that<br />

original dump truck. When I was starting out,<br />

getting bonded was tough, and now I’m able to<br />

bid multimillion-dollar projects. That was my<br />

goal, and with hard work and determination,<br />

I’ve been able to achieve it.<br />

“At the same time, I’m able to control it, and<br />

if the business gets any bigger there’s a risk of<br />

that not being the case,” Perrello added. “I’ve<br />

seen a lot of contractors come and go in the 33<br />

years I’ve been in business. I don’t want that to<br />

happen to me. The people we work for expect<br />

the job to be done on time and on budget, and<br />

that’s what we do.” n<br />

Perrello Inc. uses a Komatsu WB150 backhoe loader for a variety of projects, including lifting small structures, digging and loading. “We were doing<br />

a job and needed a backhoe,” said Owner Carl Perrello. “The WB150 was the only one we demo’d that could pick up the precast catch basins on that<br />

project that weighed about a ton each.”

24<br />

FOCUSED ON<br />

CUSTOMERS<br />

ON THE JOB WITH BINDER CUSTOMERS<br />

Ashlee <strong>Binder</strong><br />

McMackin,<br />

Director of Marketing,<br />

brings you snapshots<br />

from the field.<br />

(L-R) Della Pello Construction Co. Superintendent Mike Cristaldi and<br />

VP Vincent Della Pello take a break from their work on Route 280 in<br />

West Orange, N.J., to visit with <strong>Binder</strong> Machinery Company Director of<br />

Sales Carlin <strong>Binder</strong>.<br />

4<br />

(L-R) Fiore Paving Company<br />

Inc. Head Roller Operator<br />

Eddie Fiore, <strong>Binder</strong> Machinery<br />

Company Sales Rep Dominick<br />

Vecciarelli, Fiore Paving<br />

Company Inc. President Vincent<br />

Fiore and Screed Operator Troy<br />

Hayes pause at the company’s<br />

Red Bank Catholic High School<br />

job in Red Bank, N.J.<br />

(L-R) <strong>Binder</strong> Machinery<br />

Company Director of Sales<br />

Carlin <strong>Binder</strong> and Director<br />

of Marketing Ashlee <strong>Binder</strong><br />

McMackin visit with Trevcon<br />

Construction Company,<br />

Inc. Project Engineer Ron<br />

Treveloni Jr. at the company’s<br />

Pier 35 and 36 project along the<br />

East River in New York City.<br />

<strong>Binder</strong> Machinery<br />

Company Director of<br />

Marketing Ashlee <strong>Binder</strong><br />

McMackin visits with<br />

Crisdel Group, Inc. VP<br />

Michael Criscola, Project<br />

Manager Raul Gonzalez,<br />

Project Superintendent Jeff<br />

Dekovitch and the rest of<br />

the Crisdel crew at their job<br />

on Route 80 over Berkshire<br />

Valley Road in Roxbury, N.J.

South Plainfield, NJ<br />

2820 Hamilton Blvd.<br />

(908) 561-9000<br />

www.bindermachinery.com<br />

Winslow Township, NJ<br />

201 North Route 73<br />

(856) 767-5900

26<br />

A SALUTE TO A CUSTOMER<br />

NEW<br />

PRODUCTS<br />

BINDER ADDS KAESER COMPRESSORS<br />

Mobilair M50 and M57 portable units offer<br />

excellent power on a variety of jobsites<br />

<strong>Binder</strong> Machinery now offers<br />

Kaeser Mobilair compressors for<br />

a variety of jobsite needs. The<br />

M50 (right) and the M57 (below)<br />

are equipped with heavy-duty<br />

engines, energy-saving Sigma<br />

Profile airends, large fuel tanks<br />

and features that let users<br />

operate the compressors in<br />

extreme heat and cold.<br />

Y<br />

Your business is versatile, so you need<br />

a portable air compressor that works in a<br />

variety of applications, such as heavy-duty<br />

civil and commercial construction, demolition,<br />

sand blasting, site work and as a backup for<br />

stationary units. <strong>With</strong> the addition of Kaeser<br />

Mobilair compressors to its equipment<br />

offerings, <strong>Binder</strong> Machinery has you covered.<br />

“We’re looking forward to working with the<br />

experienced professionals at <strong>Binder</strong> Machinery<br />

to serve our customers in the New York/<br />

New Jersey area,” commented Gary Mueller,<br />

District Manager for Kaeser Compressors, Inc.<br />

“Designed for years of dependable service,<br />

Kaeser’s rugged Mobilair compressors are<br />

the perfect complement to <strong>Binder</strong>’s extensive<br />

construction equipment offering.”<br />

Kaeser’s complete product line of Mobilair<br />

portable compressors includes the popular<br />

M50, delivering 185 cfm at 100 psig, as well as<br />

the M57, delivering 210 cfm at 100 psig. Both<br />

get their power from heavy-duty, four-cylinder<br />

engines that are combined with energy-saving<br />

Sigma Profile airends for more air production<br />

with less horsepower. Both meet Tier 4 EPA<br />

emissions standards.<br />

Like all Mobilair units, the M50 and M57 are<br />

designed for durability and reliability. Large<br />

fuel tanks provide extended operation of the<br />

super-soundproofed units that operate with<br />

decibel levels below 80 when measured at 23<br />

feet. They include high-capacity, cold-start<br />

batteries that ensure operation even under<br />

extreme conditions, and a proprietary,<br />

antifrost, thermostatic valve that virtually<br />

eliminates tool freeze-up.<br />

Powder-coated canopies and solid-steel<br />

flooring protect the engine, airend and critical<br />

components from dirt, water and other<br />

potential contaminants. Kaeser added highly<br />

efficient cooling systems that allow operation<br />

up to 122 degrees. The units are user-friendly,<br />

with easy-to-read control panels that include a<br />

push-to-load switch. Optional features include<br />

a complete line of air tools, hose reels and a<br />

skid mount for the M50.<br />

For more information on Mobilair portable<br />

compressors, contact your <strong>Binder</strong> Machinery<br />

sales representative or your nearest branch<br />

location. n

NEW<br />

PRODUCTS<br />

NEW D65-16 DOZERS<br />

A long list of new features, including 6-way and Sigma<br />

blade options, adds to efficiency and lowers O&O costs<br />

M<br />

More dozing capacity and greater efficiency<br />

in a variety of applications are always an<br />

advantage. Komatsu’s new D65-16 model<br />

dozers — EX, WX and PX — provide both,<br />

thanks to a long list of new features, including<br />

a Power Angle Tilt (PAT) blade and a<br />

fuel-efficient, 205-horsepower, Tier 3 engine.<br />

Unavailable in some previous models, a<br />

six-way PAT blade can now be used on all new<br />

D65s. The hydraulic blade tilt, angling functions<br />

and manually adjustable blade pitch expand<br />

versatility and productivity in a wide range of<br />

applications. It’s well balanced for light and<br />

medium dozing operations as well as providing<br />

precise grade cutting required in site prep, golf<br />

course or house pad applications. The blade is<br />

100-percent Komatsu, and is stringently tested for<br />

durability.<br />

“Users like the PAT blade because it<br />

rolls material forward so well, it takes less<br />

horsepower to move it,” said Product Manager<br />

Bruce Boebel. “Komatsu designed the blade<br />

to keep that material rolling in front of it and<br />

away from hoses and cylinders. That extends<br />

their life and reduces maintenance costs.”<br />

Boebel said adding a PAT blade to all new<br />

D65s came about as a result of customer<br />

feedback, but it’s not the only blade option. A<br />

revolutionary Komatsu Sigma blade is available<br />

for the D65EX-16 and D65WX-16 models. It’s<br />

designed for heavy-dozing applications and<br />

keeps more material to the center, giving it a<br />

15-percent boost in productivity when compared<br />

to a typical semi-U. PX and EX models can also<br />

be equipped with a straight blade.<br />

“Having blade options allows users to<br />

choose what’s going to best suit their business<br />

and the type of work they do,” said Boebel.<br />

“Each blade has its particular purpose, and<br />

matching the blade to the application is a vital<br />

part of being able to move material efficiently<br />

so per-yard costs stay low.”<br />

Lock-up torque converter,<br />

two modes<br />

Power to push any blade full of material<br />

comes from a highly efficient lock-up torque<br />

converter that automatically transfers engine<br />

power directly to the transmission. The result<br />

is increased dozing speeds compared to<br />

Continued . . .<br />

Brief Specs on the Komatsu D65-16 Dozer<br />

Model Operating Weight Net Horsepower<br />

D65EX-16 43,980 lbs. 205 hp.<br />

D65PX-16 46,960 lbs. 205 hp.<br />

All new D65-16 models can be equipped with a six-way<br />

Power Angle Tilt blade that rolls materials forward,<br />

resulting in less horsepower used and better fuel<br />

efficiency. A lock-up torque converter and two-mode<br />

transmission are also new features in the Tier 3 machines.<br />

Bruce Boebel,<br />

Product Manager<br />

NEw!<br />

D65WX-16 45,570 lbs. 205 hp. online<br />

video<br />

To see this machine in action,<br />

find this article in our online<br />

magazine at<br />

www.<strong>Building</strong><strong>With</strong><strong>Binder</strong>.com<br />

27

28<br />

Longer Longer undercarriage undercarriage life, easier easier maintenance<br />

maintenance<br />

. . . continued<br />

previous D65 models. Operators can select<br />

from two gearshift modes, automatic and<br />

manual, to fit the appropriate application.<br />

At the same time, in Auto mode the<br />

lock-up torque converter helps reduce fuel<br />

consumption by as much as 10 percent with<br />

the new D65s. New Power and Economy<br />

modes allow operators to match the needed<br />

performance to the job for maximum<br />

efficiency. E mode can be used for all general<br />

dozing, leveling and spreading applications,<br />

providing the right mix of speed and power<br />

for maximum fuel savings. P mode is for slot<br />

dozing, ripping or other applications requiring<br />

maximum production where engine power<br />

has priority over fuel efficiency.<br />

“Our excavator users rave about the ability to<br />

choose modes based on work load, and it makes<br />

sense in dozing as well,” stated Boebel. “If you<br />

don’t need full power to get the job done, why<br />

use it? The ability to change modes to suit the<br />

application gives users added versatility. They<br />

have one machine for multiple uses.”<br />

PLUS extends undercarriage life<br />

The new D65-16 models come with Komatsu’s<br />

Parallel Link Undercarriage System (PLUS) —<br />

the EX and WX models also have an additional<br />

foot of track on ground — that provides<br />

up to double the wear life of conventional<br />

undercarriages. The rotary bushing system<br />

virtually eliminates bushing wear, and wear<br />

EX and WX models can be equipped with a SIGMA blade designed for heavy dozing<br />

applications. Blade visibility is better in the new D65s as the cab was designed to move<br />

the operator up and forward.<br />

4<br />

limits of the link and carrier roller are increased<br />

to balance the extended life of the bushing.<br />

Added undercarriage life also comes from<br />

an improved, self-adjusting, idler support<br />

that applies constant downward pressure to<br />

the wear plate of the idler guide, preventing<br />

bouncing and vibration and reducing noise.<br />

It also acts as a scraper that keeps materials<br />

out. A full guarding package, designed with<br />

customer feedback, offers added durability<br />

and lower maintenance time and cost.<br />

“The biggest cost of owning and operating a<br />

dozer is the undercarriage, and by extending<br />

its life, Komatsu is keeping that cost down,”<br />

noted Boebel. “We want customers to produce<br />

with these machines for a long time to come,<br />

and the new and enhanced features we added<br />

to the undercarriage accomplish that.”<br />

Efficient maintenance<br />

Added efficiency in the D65-16s comes from<br />

better visibility in the larger ROPS/FOPS<br />

cab that puts the operator higher and more<br />

forward for improved sight to the blade. The<br />

cab is ultra quiet at a 75-decibel rating, and an<br />

air-ride seat and rear hydraulics are standard.<br />

A seven-inch, in-cab, color monitor allows<br />

owners and operators to track fuel consumption<br />

and idle time, as well as other functions, using<br />

Komatsu’s KOMTRAX technology that comes<br />

standard and is free for the first five years.<br />

KOMTRAX helps provide better<br />

maintenance tracking to ensure proper service<br />

intervals are met, further keeping owning and<br />

operating costs down. Komatsu’s new D65<br />

models also feature easy routine maintenance<br />

that includes daily engine checks grouped at<br />

the left-hand side of the engine compartment.<br />

A wide-core cooling package and manually<br />

reversing fan allow for quick cleaning of the<br />

radiator without leaving the cab.<br />

“There are so many things you can point<br />

to that make these new models an upgrade<br />

over previous ones,” said Boebel, who<br />

noted that the dozers can come with Topcon<br />

plug-and-play or Trimble ready. “We designed<br />

these from the ground up with a list of<br />

enhancements our customers wanted. The<br />

result is more efficient and reliable machines,<br />

which is what they asked for.” n

NEW<br />

PRODUCTS<br />

KOMATSU’S NEW 75-TON EXCAVATOR<br />

Increased lifting force, digging force<br />

and dumping speed in PC650LC-8<br />

D<br />

Depending on your point-of-view, the<br />

Komatsu PC650LC-8 hydraulic excavator is<br />

a large mid-size machine or a smallish large<br />

machine. Regardless of where it fits in your<br />

fleet, the approximately 75-ton, 429-hp unit is<br />

a productive, reliable piece of equipment that<br />

significantly improves upon the PC600LC-7.<br />

The most significant production improvements<br />

of the PC650LC-8 center around increased lifting<br />

and digging forces, as well as increased dumping<br />

speeds. By selecting Lifting Mode, you increase<br />

hydraulic pressure, which in turn increases lifting<br />

capacity by 17 percent. Similarly, the one-touch<br />

Power Max function boosts maximum digging<br />

force and arm-crowd force by 8 percent.<br />

Additionally, an Arm Quick Return Circuit<br />

on the PC650LC-8 returns a portion of oil<br />

flow to the hydraulic tank at arm dumping to<br />

reduce hydraulic pressure loss. Combined with<br />

increased bucket-dumping speed, this enables<br />

faster truck loading.<br />

Beyond these direct productivity<br />

improvements, the PC650LC-8 has other<br />

enhancements that owners and operators will<br />

appreciate. For example, the boom and arm<br />

have been strengthened; a fuel pre-filter with<br />

water separator is now standard equipment;<br />

and the renowned Komatsu hydraulic system<br />

is protected with the most extensive filtration<br />

system available, including high-pressure<br />

in-line filters for each main pump. These<br />

features improve machine reliability and<br />

reduce the likelihood that the unit will break<br />

down on the job resulting in costly downtime.<br />

The PC650LC-8 is also a class leader in terms<br />

of reducing fuel consumption and harmful<br />

emissions. It offers several operational modes<br />

that allow the operator to match engine output<br />

to the work at hand, thereby lowering fuel<br />

consumption. NOx emissions are 40 percent<br />

less than with the previous model.<br />

As with all Komatsu excavators, the PC650LC-8<br />

comes with an industry-leading, low-noise,<br />

comfort cab; easy access to maintenance and<br />

service functions; and the KOMTRAX machine<br />

monitoring and management system that allows<br />

<strong>Binder</strong> Machinery to help you keep an eye on<br />

your machine to assure that it’s running properly<br />

and to remind you about service intervals. n<br />

For more information on the PC650LC-8, contact your <strong>Binder</strong><br />

Machinery Sales Rep or the nearest <strong>Binder</strong> branch location.<br />

Brief Specs on Komatsu PC650LC-8<br />

Model Power Operating Weight Bucket capacity<br />

PC650LC-8 429 hp 146,390 lbs. 5 cu. yd.<br />

The Komatsu PC650LC-8 has 17 percent more lifting capacity and 8 percent more<br />

maximum digging force than the previous model.<br />

31

100%<br />

(the LOGICAL CHOICE<br />

for your next excavator)<br />

KA03<br />

LC<br />

Komatsu excavators have set the standards for productivity, operator comfort and reliability over the<br />

years. And, with the introduction of our mid-sized –8 series, the standards have been raised yet again.<br />

• Tier-3 engines deliver reduced emissions without sacrificing power or productivity.<br />

• Electronics, engine and hydraulics are optimized for maximum efficiency and<br />

minimum fuel consumption (10% reduction compared to –7 models).<br />

• Multi-function LCD monitor provides critical operating information at a glance<br />

(and it can do this in 10 languages).<br />

From enhanced safety features to extended maintenance intervals, the PC200LC-8, PC220LC-8<br />

and PC270LC-8 show what happens when the best engineers put the latest technology to work.<br />