LONG PRODUCTS BULLETIN - SMS Meer GmbH

LONG PRODUCTS BULLETIN - SMS Meer GmbH

LONG PRODUCTS BULLETIN - SMS Meer GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

New order<br />

Greater availability. The goals of this expansion<br />

are to increase the availability of<br />

the rolling mill by reducing the changing,<br />

set-up and tuning times, and to optimize<br />

spare-parts stocking. All these procedures<br />

will be simplified thanks to the introduction<br />

of uniform stands in one size in the intermediate<br />

and the finishing train.<br />

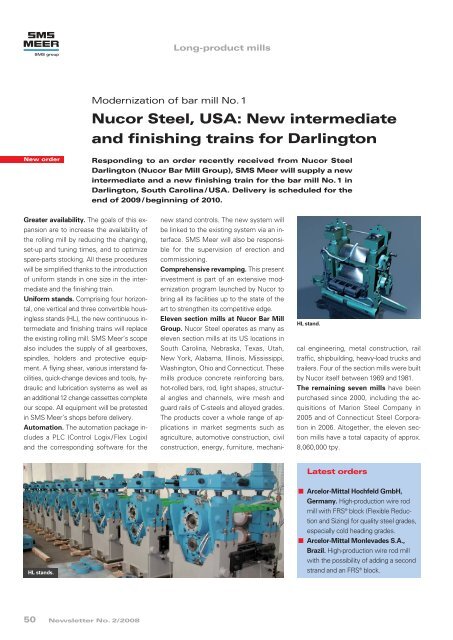

Uniform stands. Comprising four horizontal,<br />

one vertical and three convertible housingless<br />

stands (HL), the new continuous intermediate<br />

and finishing trains will replace<br />

the existing rolling mill. <strong>SMS</strong> <strong>Meer</strong>’s scope<br />

also includes the supply of all gearboxes,<br />

spindles, holders and protective equipment.<br />

A flying shear, various interstand facilities,<br />

quick-change devices and tools, hydraulic<br />

and lubrication systems as well as<br />

an additional12 change cassettes complete<br />

our scope. All equipment will be pretested<br />

in <strong>SMS</strong> <strong>Meer</strong>’s shops before delivery.<br />

Automation. The automation package includes<br />

a PLC (Control Logix/Flex Logix)<br />

and the corresponding software for the<br />

HL stands.<br />

50 Newsletter No. 2/2008<br />

Long-product mills<br />

Modernization of bar mill No.1<br />

Nucor Steel, USA: New intermediate<br />

and finishing trains for Darlington<br />

Responding to an order recently received from Nucor Steel<br />

Darlington (Nucor Bar Mill Group), <strong>SMS</strong> <strong>Meer</strong> will supply a new<br />

intermediate and a new finishing train for the bar mill No. 1 in<br />

Darlington, South Carolina / USA. Delivery is scheduled for the<br />

end of 2009 / beginning of 2010.<br />

new stand controls. The new system will<br />

be linked to the existing system via an interface.<br />

<strong>SMS</strong> <strong>Meer</strong> will also be responsible<br />

for the supervision of erection and<br />

commissioning.<br />

Comprehensive revamping. This present<br />

investment is part of an extensive modernization<br />

program launched by Nucor to<br />

bring all its facilities up to the state of the<br />

art to strengthen its competitive edge.<br />

Eleven section mills at Nucor Bar Mill<br />

Group. Nucor Steel operates as many as<br />

eleven section mills at its US locations in<br />

South Carolina, Nebraska, Texas, Utah,<br />

New York, Alabama, Illinois, Mississippi,<br />

Washington, Ohio and Connecticut. These<br />

mills produce concrete reinforcing bars,<br />

hot-rolled bars, rod, light shapes, structural<br />

angles and channels, wire mesh and<br />

guard rails of C-steels and alloyed grades.<br />

The products cover a whole range of applications<br />

in market segments such as<br />

agriculture, automotive construction, civil<br />

construction, energy, furniture, mechani-<br />

HL stand.<br />

cal engineering, metal construction, rail<br />

traffic, shipbuilding, heavy-load trucks and<br />

trailers. Four of the section mills were built<br />

by Nucor itself between 1969 and 1981.<br />

The remaining seven mills have been<br />

purchased since 2000, including the acquisitions<br />

of Marion Steel Company in<br />

2005 and of Connecticut Steel Corporation<br />

in 2006. Altogether, the eleven section<br />

mills have a total capacity of approx.<br />

8,060,000 tpy.<br />

Latest orders<br />

n Arcelor-Mittal Hochfeld <strong>GmbH</strong>,<br />

Germany. High-production wire rod<br />

mill with FRS ® block (Flexible Reduc -<br />

tion and Sizing) for quality steel grades,<br />

especially cold heading grades.<br />

n Arcelor-Mittal Monlevades S.A.,<br />

Brazil. High-production wire rod mill<br />

with the possibility of adding a second<br />

strand and an FRS ® block.