Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2012 • 01

index<br />

Porifera uk - nl - fr - du - es . . . . . . . . . . . . . . . . . . . . . . . . . . . .P03<br />

B4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P08<br />

B4 <strong>Trimless</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P09<br />

B8 - B8 <strong>Trimless</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P10<br />

Hook <strong>Pascal</strong> - Hook <strong>Pascal</strong> <strong>Trimless</strong> . . . . . . . . . . . . . . . . . . . . . .P12<br />

BR4 - BR4 <strong>Trimless</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P13<br />

Green <strong>Pascal</strong> - Green <strong>Pascal</strong> <strong>Trimless</strong> . . . . . . . . . . . . . . . . . . . . .P14<br />

Mini <strong>Tommy</strong> <strong>Pascal</strong> - Mini <strong>Tommy</strong> <strong>Pascal</strong> <strong>Trimless</strong> . . . . . . . . . .P15<br />

<strong>Tommy</strong> <strong>Pascal</strong> - <strong>Tommy</strong> <strong>Pascal</strong> <strong>Trimless</strong> . . . . . . . . . . . . . . . . . . .P16<br />

<strong>Pascal</strong> vs . <strong>Pascal</strong> MCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P17<br />

<strong>Tommy</strong> <strong>Pascal</strong> MCE - <strong>Tommy</strong> <strong>Pascal</strong> MCE <strong>Trimless</strong> . . . . . . . . . .P18<br />

Rasputin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P19<br />

Spina <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P20<br />

Cayley <strong>Pascal</strong> - Cayley Combi <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . .P21<br />

Ji<strong>be</strong> Mini <strong>Pascal</strong> - Ji<strong>be</strong> <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . .P23<br />

Mono Dostec Mini <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P24<br />

Pandora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P25<br />

Scoop <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P26<br />

Thor <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P27<br />

Dado S <strong>Pascal</strong> - Dado S <strong>Pascal</strong> MCE . . . . . . . . . . . . . . . . . . . . . .P28<br />

Mikks <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P29<br />

Curtis <strong>Pascal</strong> - Curtis Large <strong>Pascal</strong> . . . . . . . . . . . . . . . . . . . . . . .P30<br />

Spider <strong>Pascal</strong> - Spider <strong>Pascal</strong> MCE . . . . . . . . . . . . . . . . . . . . . . .P31<br />

Experimental Performance study Porifera . . . . . . . . . . . . . . . .P32<br />

2012 • 01

uk<br />

Porifera is a unique system for cooling powerleds<br />

and other electronic components through aluminium<br />

foam . The unique properties of this aluminium<br />

foam allow for a much higher cooling performance<br />

compared to conventional cooling bodies . LED<br />

light fixtures that make use of Porifera technology<br />

have greater efficiency, made possible through the<br />

following characteristics :<br />

• Large cooling surface : the foam has an extremely high<br />

surface aspect ratio thus creating a large surface within<br />

a small volume. The larger the cooling surface, the more<br />

heat can <strong>be</strong> dissipated.<br />

• Low mass per volume : the aluminium foam is very<br />

thin which brings the great advantage that the heat is<br />

transferred immediately to the environment (air) and is<br />

not first stored in the material itself like in conventional<br />

systems. Such traditional systems have a radiator effect<br />

i.e. the material fully heats up and only then interacts<br />

with its environment. So the thicker the material, the<br />

slower it cools down. The low mass per volume of<br />

Porifera results in a low heat capacity. It reacts almost<br />

instantly to temperature changes which results in very<br />

short transient regimes, making it a very controllable<br />

heat exchanger.<br />

• Porous : the open cell structure allows for a free flow<br />

of air through the mazes of the foam thus securing an<br />

optimal heat exchange with the environment.<br />

• Isotropic : the interconnected bubbles form a convoluted<br />

path for any gases or liquids flowing through them.<br />

Such a complex path continually brings the gases into<br />

contact with the metal walls. This results in outstanding<br />

convective heat transfers. An additional advantage of<br />

this isotropic structure is that heat is distributed evenly<br />

in a three-dimensional manner, so the performance is<br />

independent of the direction of the convective flow.<br />

Cooling LED fixtures with Porifera is much more efficient<br />

than cooling with conventional cooling elements thus<br />

providing increased life span as well as improved efficiency.<br />

An LED’s life span and its efficiency are directly correlated<br />

with its junction temperature. This correlation follows<br />

3<br />

2012 • 01<br />

an exponential line i.e. more efficient cooling has an<br />

enormous impact on these factors.<br />

Specifications of Porifera :<br />

• Open cell structure<br />

• Organic structure<br />

• Isotropic<br />

• Aluminium<br />

Porifera is a passive cooling system that brings all the<br />

advantages of an active cooling system without the<br />

downsides : greater efficiency without the need for<br />

maintenance and completely noiseless.<br />

Advantages :<br />

• Longer LED life span<br />

• Improved LED efficiency<br />

• Lower power consumption<br />

• Completely maintenance free<br />

• Noiseless

nl<br />

Porifera is een uniek systeem om vermogenleds<br />

en andere elektronische componenten te koelen<br />

door middel van opgeschuimd aluminium . Door de<br />

unieke eigenschappen van dit aluminium schuim<br />

wordt een veel hogere koelcapaciteit <strong>be</strong>reikt dan<br />

mogelijk is met conventionele koellichamen . De<br />

grotere efficiëntie van een ledtoestel met Porifera<br />

technologie wordt mogelijk gemaakt door de<br />

volgende factoren:<br />

• Groot koeloppervlak : het schuim heeft een extreem<br />

hoge oppervlakte aspect ratio. Hierdoor wordt een<br />

grote oppervlakte <strong>be</strong>komen binnen een klein volume.<br />

Hoe groter de koeloppervlakte, hoe meer warmte er<br />

afgevoerd kan worden.<br />

• Lage massa per volume : de wanddikte van het<br />

aluminiumschuim is enorm dun. Dit heeft als groot<br />

voordeel dat de warmte onmiddellijk wordt afgegeven<br />

aan de omgeving (lucht) en niet eerst wordt opgeslagen<br />

in het materiaal zelf, zoals bij een klassiek systeem. Bij<br />

klassieke systemen spreken we van het radiatoreffect;<br />

het materiaal warmt eerst volledig op en komt dan<br />

in interactie met zijn omgeving. Dus hoe dikker de<br />

wanddikte, hoe minder snel iets wordt afgekoeld.<br />

Door de lage massa per volume <strong>be</strong>zit Porifera een<br />

lage warmtecapaciteit; hierdoor reageert het bijna<br />

onmiddellijk op temperatuursveranderingen, waardoor<br />

de aanpassingstijd erg kort is.<br />

• Poreus : door de open cel structuur kan omgevingslucht<br />

in al de mazen van het schuim vrij <strong>be</strong>wegen, waardoor<br />

de warmtewisseling met de omgeving maximaal<br />

verloopt.<br />

• Isotroop : de met elkaar verbonden <strong>be</strong>llen vormen<br />

een onwillekeurig pad voor ieder gas dat erdoor<br />

vloeit. Dit complexe pad brengt voortdurend het gas<br />

in contact met de metalen wand. Dit resulteert in een<br />

extreem grote convectieve warmteoverdracht. Een<br />

bijkomend voordeel van de isotrope structuur is dat de<br />

warmteoverdracht in 3D verloopt, waardoor de werking<br />

onafhankelijk is van de orientatie.<br />

Met Porifera wordt een ledtoestel veel efficiënter gekoeld<br />

4<br />

2012 • 01<br />

dan met klassieke koelelementen, waardoor de levensduur<br />

van de leds verlengd wordt en het rendement van de leds,<br />

met name de hoeveelheid licht, veel hoger wordt.<br />

De efficiëntie en de levensduur van de leds staan in<br />

correlatie met de junctie-temperatuur van de leds.<br />

Deze correlatie volgt een exponentiële lijn, m.a.w. een<br />

efficiëntere koeling heeft een enorme impact op zowel de<br />

levensduur als het rendement van de led.<br />

Specificaties van Porifera :<br />

• Open cel structuur<br />

• Organische structuur<br />

• Isotroop<br />

• Aluminium<br />

Porifera is een passief koelsysteem met alle voordelen<br />

van een actief systeem, nl. grotere efficiëntie, zonder de<br />

nadelen ervan. Er is absoluut geen onderhoud nodig,<br />

er kan niets stuk gaan en het systeem werkt volledig<br />

geruisloos.<br />

Voordelen :<br />

• Langere levensduur van de leds<br />

• Meer lichtopbrengst van de leds<br />

• Lager elektriciteitsverbruik<br />

• Volledig onderhoudsvrij<br />

• Geruisloos

fr<br />

Porifera est un système unique pour refroidir les LED<br />

de puissance et les autres composants électroniques<br />

grâce à la mousse d’aluminium . De part ses propriétés<br />

uniques, la mousse d’aluminium possède une capacité<br />

de refroidissement <strong>be</strong>aucoup plus importante et<br />

aussi <strong>be</strong>aucoup plus rapide que les refroidisseurs<br />

traditionnels .<br />

L’efficacité accrue d’un appareil led avec le système<br />

Porifera est visible à travers les facteurs suivants:<br />

• Une grande surface de refroidissement: le ratio entre le<br />

volume et la surface de mousse est extrêmement grand.<br />

Même dans un volume restreint, la surface de dissipation<br />

de la chaleur est extrêmement élevée. Plus la surface<br />

de refroidissement est grande, plus la chaleur se dissipe<br />

rapidement.<br />

• Une densité faible : l’épaisseur de la mousse d’aluminium<br />

est très mince. Ceci a le grand avantage que la chaleur<br />

est directement en contact avec l’air ambiant et n’est<br />

donc pas d’abord stockée dans le matériau lui-même,<br />

comme dans un système classique. Dans les systèmes<br />

classiques, on parle même de l’effet « radiateur ».<br />

Le matériau emmagasine d’abord la chaleur puis la<br />

disperse dans l’air. Plus les parois du refroidisseur sont<br />

épaisses, plus celui-ci met de temps à évacuer la chaleur.<br />

La faible densité rend l’inertie thermique du Porifera<br />

extrêmement faible, ce qui lui permet de réagir presque<br />

instantanément aux changements de température.<br />

• Porosité : la structure de la mousse avec ses cellules<br />

ouvertes permet une circulation optimale de l’air dans<br />

toute la masse de l’aluminium, l’échange de chaleur<br />

avec l’environnement est optimal.<br />

• Isotropie : Les bulles forment un réseau de chemins que<br />

l’air traverse. Dans ce parcours l’air est constamment<br />

en contact avec la surface du métal. Il en résulte un<br />

transfert de chaleur par convection extrêmement<br />

important.<br />

Un avantage supplémentaire de la structure de cette<br />

mousse est quel est isotrope. Le transfert de chaleur est<br />

indépendant de l’orientation.<br />

5<br />

2012 • 01<br />

Un appareil LED équipé du système PORIFERA a un<br />

pouvoir de refroidissement élevé et prolonge la durée de<br />

vie ainsi que l’émission de lumière au niveau qualitatif et<br />

quantitatif.<br />

L’efficacité et la durée de vie des Leds sont en corrélation<br />

avec leur température de jonction. Ce rapport suit une<br />

ligne exponentielle. Un refroidissement efficace a donc<br />

un impact énorme sur la durée de vie et le rendement des<br />

leds.<br />

Caractéristique du Porifera :<br />

• Structure à cellules ouvertes<br />

• Structure organique<br />

• Isotrope<br />

• Aluminium<br />

Porifera est un système de refroidissement passif avec tous<br />

les avantages d’un système actif, tels que l’efficacité plus<br />

grande, sans ses inconvénients, il ne nécessite absolument<br />

aucun entretien, rien ne peut se défaire et le système est<br />

totalement silencieux.<br />

Avantages:<br />

• Longue durée de vie des LED<br />

• Plus de lumière des LED<br />

• Faible consommation d’énergie<br />

• Sans entretien<br />

• Silencieux

du<br />

Porifera ist ein einzigartiges System für die Kühlung<br />

von Power-LEDs und anderen elektronischen<br />

Komponenten durch geschäumtes Aluminium . Durch<br />

die einzigartigen Eigenschaften des Aluminium-<br />

Schaumes wird eine viel höhere Abkühlkapazität als<br />

mit herkömmlichen Kühlkörpern erreicht . Die höhere<br />

Effizienz einer LED Leuchte, die ü<strong>be</strong>r die Porifera<br />

Technologie verfügt, wird möglich durch folgenden<br />

Faktoren:<br />

• Große Kühlfläche: Der Schaum hat eine extrem hohe<br />

O<strong>be</strong>rfläche. Aspekt Verhältnis: hier ist eine große<br />

O<strong>be</strong>rfläche <strong>be</strong>i kleinem Volumen vorhanden. Je größer<br />

die Kühlfläche, desto mehr Wärme abgeführt werden<br />

kann.<br />

• Geringe Masse pro Volumen: Die Wanddicke des<br />

Aluminium-Schaumes ist sehr dünn. Dies hat den<br />

Vorteil, dass die Wärme direkt an die Umgebung (an<br />

die Luft) abgege<strong>be</strong>n werden kann und nicht zuerst<br />

im Material selbst gespeichert wird, wie in einem<br />

klassischen Kühlsystem. In herkömmlichen Systemen,<br />

sprechen wir von dem Heizkörper-Effekt: das Material<br />

erhitzt sich zuerst komplett selbst und interagiert<br />

dann mit der Umgebung. Je dicker die Wanddicke, je<br />

langsamer erfolgt die Abkühlung. Durch die geringe<br />

Masse pro Volumen hat die Porifera eine geringe<br />

Wärmekapazität, deshalb reagiert sie fast augenblicklich<br />

auf Temperaturänderungen, wodurch die Zeiteinstellung<br />

der Anpassung bzw. Abkühlung sehr kurz ist.<br />

• Poröse Struktur: Durch die offene Zellstruktur kann<br />

die Umgebungsluft sich in alle Löcher des Schaumes<br />

frei <strong>be</strong>wegen, wodurch der Wärmeaustausch mit der<br />

Umgebung maximal ist.<br />

• Isotrop: Die miteinander in Verbindung stehenden<br />

Luftblasen bilden einen vorgege<strong>be</strong>nen Weg, wodurch<br />

das Gas (in diesem Fall Luft oder O2) fließt. Dieser<br />

komplexe Weg bringt ständig das Gas in Kontakt mit<br />

dem Metall der Wand. Dies führt zu einem extrem<br />

hohen konvektiven Wärmeü<strong>be</strong>rgang. Ein weiterer Vorteil<br />

der isotropen Struktur ist, dass die Wärmeü<strong>be</strong>rtragung<br />

sich dreidimensional entwickelt, so dass der Effekt<br />

unabhängig von der Ausrichtung ist.<br />

6<br />

2012 • 01<br />

Mit Porifera wird eine LED Leuchte viel effizienter gekühlt,<br />

wodurch die Le<strong>be</strong>nsdauer der LEDs und damit die Effizienz<br />

der LEDs in Bezug auf die Lichtmenge erhöht wird.<br />

Der Wirkungsgrad und die Le<strong>be</strong>nsdauer der LEDs stehen in<br />

Korrelation mit der Sperrschichttemperatur der LEDs.<br />

Diese Korrelation folgt einer exponentiellen Linie, das<br />

heißt, eine effizientere Kühlung hat einen großen Einfluss<br />

sowohl auf die Le<strong>be</strong>nsdauer und auf die Effizienz der LED.<br />

Technische Daten Porifera:<br />

• Offene Zellsstruktur<br />

• Organische Struktur<br />

• Isotrop<br />

• Aluminium<br />

Porifera ist ein passives Kühlsystem mit allen Vorteilen<br />

eines aktiven Systems, nämlich mehr Effizienz, ohne die<br />

Nachteile, eine Wartung ist nicht erforderlich, sie kann<br />

nicht versagen und das System ar<strong>be</strong>itet völlig geräuschlos.<br />

Vorteile :<br />

• Längere Le<strong>be</strong>nsdauer der LEDs<br />

• Mehr Lichtaus<strong>be</strong>ute der LEDs<br />

• Geringerer Stromverbrauch<br />

• Wartungsfrei<br />

• Geräuschlos

es<br />

Porifera es un sistema único de refrigeración<br />

powerled y otros componentes electrónicos a través<br />

de una espuma de aluminio . Las propiedades únicas<br />

de esta espuma de aluminio permiten un rendimiento<br />

de refrigeración mucho mayor en comparación<br />

con los convencionales . Las luminarias con LEDs<br />

que utilizan la tecnología de Porifera tienen una<br />

mayor eficiencia . Todo esto es posible a través de las<br />

siguientes características:<br />

• Gran superficie de refrigeración: la espuma de<br />

aluminio ocupa una gran superficie del aspecto de la<br />

luminaria, creando así una gran superficie dentro de un<br />

volumen pequeño. Cuanto mayor sea la superficie de<br />

refrigeración, más calor se puede disipar.<br />

• Baja masa por volumen: la espuma de aluminio es muy<br />

fina y aporta de esta manera una gran ventaja. El calor<br />

se li<strong>be</strong>ra de forma inmediata con el medio ambiente<br />

(aire) y no se almacena en la materia en sí como en los<br />

sistemas convencionales. Estos sistemas tradicionales<br />

tienen un efecto radiador es decir, el material se calienta<br />

por completo y sólo entonces interactúa con su entorno.<br />

Por lo tanto cuanto más grueso sea el material, más<br />

lenta será la refrigeración. El bajo peso por volumen<br />

de Porifera proporciona una baja capacidad calorífica.<br />

Porifera reacciona casi instantáneamente a los cambios<br />

de temperatura que resulta en los regímenes transitorios<br />

muy corto, por lo que es un intercambiador de calor es<br />

muy controlable.<br />

• Porosidad: la estructura celular abierta permite un flujo<br />

libre del aire a través de los la<strong>be</strong>rintos de la espuma<br />

asegurando así un intercambio de calor óptimo con el<br />

medio ambiente.<br />

• Isotropicó: las burbujas interconectadas forman un<br />

camino tortuoso para los gases o líquidos que fluyen a<br />

través de ellos. Este recorrido complejo pone los gases<br />

en contacto continuo con las paredes de metal. Este<br />

se traduce en un systema de transferencia de color<br />

perfecto. Una ventaja adicional de esta estructura<br />

isotropicó es que el calor se distribuye uniformemente<br />

en forma tridimensional, por lo que el rendimiento<br />

es independiente de la dirección de la corriente de<br />

convección.<br />

7<br />

2012 • 01<br />

Las luminarias con LED que utilizan la tecnología Porifera<br />

son mucho más eficientes que la refrigeración con<br />

elementos de refrigeración convencional proporcionando<br />

así una mayor longevidad y eficiencia de las luminarias.<br />

La vida útil del LED y su eficiencia está directamente<br />

relacionada con la temperatura de unión. Esta correlación<br />

sigue una línea exponencial, es decir, más eficiencia de<br />

enfriamiento tiene un enorme impacto en estos factores.<br />

Especificaciones de Porifera :<br />

• Estructura de célula abierta<br />

• Estructura orgánica<br />

• isotrópico<br />

• Aluminio<br />

Porifera es un sistema de refrigeración pasivo que ofrece<br />

todas las ventajas de un sistema de refrigeración activo<br />

sin las desventajas: mayor eficiencia, sin necesidad de<br />

mantenimiento y silencioso por completo.<br />

Ventajas:<br />

• Mayor vida útil del LED<br />

• Mejora de la eficiencia del LED<br />

• Menor consumo de energía<br />

• Totalmente libre de mantenimiento<br />

silencioso

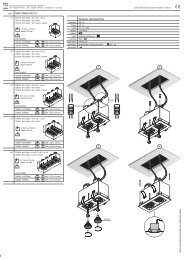

B4<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h<br />

B4 + Surface kit<br />

LEAF Springs TORSION Springs<br />

3000K 6250K 3000K 6250K<br />

10° 40° 10° 40° 10° 40° 10° 40°<br />

Textured White 193027 193127 193017 193117 194027 194127 194017 194117<br />

Textured Black 193026 193126 193016 193116 194026 194126 194016 194116<br />

Textured White + Chrome Focus 193020 193120 193010 193110 194020 194120 194010 194110<br />

Textured White + Double Chrome 193021 193121 193011 193111 194021 194121 194011 194111<br />

8

B4 <strong>Trimless</strong><br />

3000K 6250K<br />

10° 40° 10° 40°<br />

B4 Porifera Histogram<br />

Textured White 192027 192127 192017 192117<br />

Textured Black 192026 192126 192016 192116<br />

Textured White + Chrome Focus 192020 192120 192010 192110<br />

9<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h

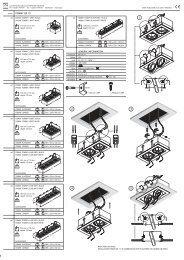

B8<br />

B8 <strong>Trimless</strong><br />

B8 + Surface kit<br />

2012 • 01<br />

LEAF Springs TORSION Springs<br />

3000K 6250K 3000K 6250K<br />

10° 40° 10° 40° 10° 40° 10° 40°<br />

Textured White 393027 393127 393017 393117 394027 394127 394017 394117<br />

Textured Black 393026 393126 393016 393116 394026 394126 394016 394116<br />

Textured White + Chrome Focus 393020 393120 393010 393110 394020 394120 394010 394110<br />

Textured White + Double Chrome 393021 393121 393011 393111 394021 394121 394011 394111<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 392027 392127 392017 392117<br />

Textured Black 392026 392126 392016 392116<br />

Textured White + Chrome Focus 392020 392120 392010 392110<br />

10<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 446 Lm 120.000h<br />

500mA 8W 838 Lm 80.000h<br />

700mA 12W 1096 Lm 52.000h

5 YEARS WARRANTY<br />

PATENTED LED TECHNOLOGY<br />

UNIQUE PORIFERA® SYSTEM<br />

CREE LEDS<br />

ALUMINIUM REFLECTORS<br />

OWN ALU CORE PCB DESIGN & LAY-OUT<br />

LONGER LIFETIME OF THE LED<br />

INCREASED LIGHT OUTPUT<br />

LOWER ENERGY CONSUMPTION<br />

MAINTENANCE FREE<br />

NOISE FREE<br />

®porifera is a registered trademark<br />

2012 • 01

Hook <strong>Pascal</strong><br />

Hook <strong>Pascal</strong> <strong>Trimless</strong><br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h<br />

LEAF Springs TORSION Springs<br />

3000K 6250K 3000K 6250K<br />

10° 40° 10° 40° 10° 40° 10° 40°<br />

Textured White 301627 301727 301617 301717 302627 302727 302617 302717<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 300627 300727 300617 300717<br />

12<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h

BR4<br />

BR4 <strong>Trimless</strong><br />

BR4 Porifera Thermal Test<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h<br />

LEAF Springs TORSION Springs<br />

3000K 6250K 3000K 6250K<br />

10° 40° 10° 40° 10° 40° 10° 40°<br />

Textured White 236027 236127 236017 236117 237027 237127 237017 237117<br />

Textured Black 236026 236126 236016 236116 237026 237126 237016 237116<br />

Textured White + Chrome Focus 236020 236120 236010 236110 237020 237120 237010 237110<br />

Textured White + Double Chrome 236021 236121 236011 236111 237021 237121 237011 237111<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 235027 235127 235017 235117<br />

Textured Black 235026 235126 235016 235116<br />

Textured White + Chrome Focus 235020 235120 235010 235110<br />

13<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h

Green <strong>Pascal</strong><br />

Green <strong>Pascal</strong> <strong>Trimless</strong><br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h<br />

LEAF Springs TORSION Springs<br />

3000K 6250K 3000K 6250K<br />

10° 40° 10° 40° 10° 40° 10° 40°<br />

Textured White 381627 381727 381617 381717 382627 382727 382617 382717<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 380627 380727 380617 380717<br />

14<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h

Mini <strong>Tommy</strong> <strong>Pascal</strong><br />

Textured<br />

White<br />

Textured<br />

Grey + Black<br />

Mini <strong>Tommy</strong> <strong>Pascal</strong> <strong>Trimless</strong><br />

Textured<br />

White<br />

Textured<br />

Black<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

324027 324127 324017 324117<br />

324026 324126 324016 324116<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

329027 329127 329017 329117<br />

329026 329126 329016 329116<br />

15<br />

Mini <strong>Tommy</strong> <strong>Pascal</strong> <strong>Trimless</strong> + Surface kit<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h

<strong>Tommy</strong> <strong>Pascal</strong><br />

Textured<br />

White<br />

Textured<br />

Grey + Black<br />

<strong>Tommy</strong> <strong>Pascal</strong> <strong>Trimless</strong><br />

Textured<br />

White<br />

Textured<br />

Black<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

324027 324127 324017 324117<br />

324026 324126 324016 324116<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

329027 329127 329017 329117<br />

329026 329126 329016 329116<br />

16<br />

Mini <strong>Tommy</strong> <strong>Pascal</strong> <strong>Trimless</strong> + Surface kit<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h

<strong>Pascal</strong> <strong>Pascal</strong> MCE<br />

<strong>Pascal</strong> and Mini <strong>Pascal</strong> uses latest CREE XR-E leds<br />

PCB by TAL with XR-E led<br />

Easy White<br />

2012 • 01<br />

<strong>Pascal</strong> MCE uses CREE MC-E EASYWHITE<br />

PCB by TAL with MC-E led<br />

Detail of <strong>Pascal</strong> with XR-E led Detail of <strong>Pascal</strong> MCE with MC-E led<br />

Easy White is an innovation by CREE that simplifies LED system design and improves LED - to - LED color consistency.<br />

Easy White bins are 75% smaller than the ANSI C78.377 standard color regions.<br />

With Easy White the color consistency remains within 2 - step Mc. Adam Ellipses, so you don’t need to specify bins<br />

anymore to get the same color temperature.<br />

17

<strong>Tommy</strong> <strong>Pascal</strong> MCE<br />

3000K<br />

40°<br />

Textured White 321127<br />

Textured Grey + Black 321126<br />

<strong>Tommy</strong> <strong>Pascal</strong> MCE <strong>Trimless</strong><br />

3000K<br />

40°<br />

Textured White 326127<br />

Textured Grey + Black 326126<br />

18<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 16W 1280 Lm 52.000h<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 16W 1280 Lm 52.000h<br />

Mini <strong>Tommy</strong> <strong>Pascal</strong> MCE <strong>Trimless</strong> + Surface kit

Rasputin<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 319027 319127 319017 319117<br />

Textured Black 319026 319126 319016 319116<br />

Textured White + Chrome Focus 319020 319120 319010 319110<br />

19<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h

Spina <strong>Pascal</strong><br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Ano + Textured Black 315321 315320 315421 315420<br />

Textured White + Textured Black 315331 315330 315431 315430<br />

Textured White 315341 315340 315441 315440<br />

Textured Black 315351 315350 315451 315450<br />

20<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h

Cayley <strong>Pascal</strong><br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 333027 333127 333017 333117<br />

Cayley Combi <strong>Pascal</strong><br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 335027 335127 335017 335117<br />

21<br />

2012 • 01<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 4,8W 223 Lm 120.000h<br />

500mA 8W 419 Lm 80.000h<br />

700mA 12W 548 Lm 52.000h<br />

CONTROL POWER LUMEN LIFE TIME<br />

350mA 3W 242 Lm 120.000h<br />

500mA 5W 314 Lm 80.000h<br />

700mA 7W 411 Lm 52.000h

ovoorstel LONGER LIFETIME OF THE LED<br />

INCREASED LIGHT OUTPUT<br />

LOWER ENERGY CONSUMPTION<br />

MAINTENANCE FREE<br />

NOISE FREE<br />

®porifera is a registered trademark<br />

2012 • 01

Ji<strong>be</strong> Mini <strong>Pascal</strong> Ji<strong>be</strong> <strong>Pascal</strong><br />

Textured<br />

White<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

479027 479127 479017 479117<br />

23<br />

Textured<br />

White<br />

2012 • 01<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

479427 479417 479227 479217

Mono Dostec Mini <strong>Pascal</strong><br />

411<br />

lumen<br />

3000K<br />

40°<br />

Textured White 549147<br />

Textured Black 549126<br />

24<br />

2012 • 01

Pandora<br />

546<br />

lumen<br />

3000K<br />

10° 40°<br />

Textured White 391047 391147<br />

Textured Black 391026 391126<br />

25<br />

2012 • 01

Scoop <strong>Pascal</strong><br />

546<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 331027 331127 331017 331117<br />

Textured White + Chrome Focus 331020 331120 331010 331110<br />

26<br />

2012 • 01

Thor <strong>Pascal</strong><br />

546<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 318027 318127 318017 318117<br />

Textured Black 318026 318126 318016 318116<br />

Textured White<br />

+ Chrome Focus<br />

318020 318120 318010 318110<br />

27<br />

2x546<br />

lumen<br />

2012 • 01<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 332027 332127 332017 332117<br />

Textured Black 332026 332126 332016 332116<br />

Textured White<br />

+ Chrome Focus<br />

332020 332120 332010 332110

2012 • 01<br />

Dado S <strong>Pascal</strong> Dado S <strong>Pascal</strong> MCE<br />

546<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 371527 371627 371517 371617<br />

Textured Black 371526 371626 371516 371616<br />

28<br />

1280<br />

lumen<br />

3000K<br />

40°<br />

Textured White 371827<br />

Textured Black 371826

Mikks <strong>Pascal</strong><br />

546<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 136060 136061 136062 136063<br />

29<br />

2012 • 01

2012 • 01<br />

Curtis <strong>Pascal</strong> Curtis Large <strong>Pascal</strong><br />

411<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 336027 336127 336017 336117<br />

Textured Black 336026 336126 336016 336116<br />

30<br />

3x411<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 337027 337127 337017 337117<br />

Textured Black 337026 337126 337016 337116

2012 • 01<br />

Spider <strong>Pascal</strong> Spider <strong>Pascal</strong> MCE<br />

4x546<br />

lumen<br />

3000K 6250K<br />

10° 40° 10° 40°<br />

Textured White 395442 395443 395440 395441<br />

Textured Black 395452 395453 395450 395451<br />

31<br />

4x1280<br />

lumen<br />

3000K<br />

40°<br />

Textured White 395445<br />

Textured Black 395455

Experimental Performance<br />

study Porifera<br />

Due to its relatively high efficiency, its wide applicability<br />

and especially its long life expectancy, LED lighting has<br />

<strong>be</strong>come one of the most promising technologies<br />

in order to reduce energy consumption. LED can <strong>be</strong> used in<br />

a wide range of applications. However the efficiency and life<br />

expectancy depend strongly on the LED junction temperature.<br />

The temperature reduction can <strong>be</strong> achieved in different ways.<br />

The most applied solution is integrating a classical heatsink<br />

with fan. However this solution has several disadvantages. The<br />

solution proposed in this paper is using open cell metal foam.<br />

This is a very light weight<br />

structure, considering it consists for about 95 % out of<br />

air.<br />

APPARATUS AND PROCEDURE<br />

The experimental setup consists of a rectangular heater<br />

element with a length of 254.0 mm (10 inch) and a width of<br />

25.4 mm (1 inch). To make the temperature distribution more<br />

uniform, two copper plates are placed on top of this heater.<br />

Between these two copper plates six thermocouples of type K<br />

are installed. Above the upper copper plate the test sample is<br />

attached.<br />

Under this assembly and to its longest sides, guard heaters<br />

are placed to minimize the heat losses. Three thermocouples<br />

are placed on a copper plate which in turn is placed on the<br />

bottommost guard heaters. On each of the lateral guard<br />

heaters a copper plate with three thermocouples is placed.<br />

Between the heater and the guard heaters and on top of the<br />

lateral guard heaters Microtherm®’s Standard Block insulation<br />

is positioned. Around this entity (except on the top surface)<br />

more insulation is provisioned. Upon this a box was placed<br />

with dimensions of 68.5 cm long, 60.0 cm wide and 45.0<br />

cm high. To improve the conductivity <strong>be</strong>tween the different<br />

components, a thermal paste is applied. The temperature<br />

variations across the surfaces do not exceed 0,80 °C for a flat<br />

surface. The main heater’s resistance is about 580 _ ± 15 %.<br />

The main heater’s temperature varies <strong>be</strong>tween 55 °C and 95<br />

°C for all measurements performed in this experiment.<br />

The total heat loss is calculated as the sum of the heat loss of<br />

the main heater’s to the guard heaters<br />

(Qloss, 1), the heat loss occurring on the insulation’s top<br />

(Qloss, 2) and the heat losses occurring at the heater’s<br />

ends (Qloss, 3). The first heat loss is estimated conservatively<br />

by calculating the heat loss as if it were a conduction loss<br />

taking into account the temperature difference <strong>be</strong>tween the<br />

main heater and the concerned<br />

guard heater, the concerned guard heater’s surface, the<br />

shortest distance <strong>be</strong>tween the main heater and the<br />

concerned guard heater and the insulation’s conduction<br />

coefficient (<strong>be</strong>ing 0.022 W/mK). This 1D conduction<br />

32<br />

2012 • 01<br />

model is permitted <strong>be</strong>cause the temperature of all<br />

heaters are presumed uniform and the corresponding<br />

heat losses are considered to <strong>be</strong> small.<br />

The second heat loss is calculated as the surface<br />

integral of the product of the conduction coefficient<br />

and the temperature gradient over the upper 5 mm of<br />

the guard heater’s sides.<br />

The temperature as a function of the area is derived<br />

as the solution of a Robin problem. Solving the problem<br />

shows that the heat loss can <strong>be</strong> neglected, so further on it is<br />

presumed that Qloss, 2= 0. The third heat loss is calculated in<br />

the same way as the second heat loss. This heat loss can also<br />

<strong>be</strong> neglected, so further on it is presumed that Qloss,3= 0.<br />

In this paper two types of metallic foam will <strong>be</strong> examined:<br />

metallic foam of 10 PPI with a porosity of 93.73 % and<br />

metallic foam of 20 PPI with a porosity of 93.31 %. The<br />

maximal heights are respectively 40 mm and 18 mm. To<br />

compare the results to each other as well as to compare them<br />

to the results found in other papers, the Nusselt num<strong>be</strong>r will<br />

<strong>be</strong> computed in function of the Rayleigh num<strong>be</strong>r. Therefore<br />

the convection coefficient need <strong>be</strong> calculated as follows:<br />

To compare the results for a flat surface, the convection<br />

coefficient is calculated in the same manner, with the<br />

exception that radiation heat is subtracted from the heat input<br />

Q. The characteristic length (L*) is determined by following<br />

formula:<br />

RESULTS<br />

To evaluate the test setup, the Nusselt num<strong>be</strong>r is calculated<br />

from the measurements for different Rayleigh<br />

num<strong>be</strong>rs for an ordinary flat aluminum plate. In this<br />

figure two trend lines for natural convection adjacent<br />

to a horizontal flat surface are also depicted, namely<br />

Lloyd and Moran’s trend line and Mikheyev’s trend<br />

line. As can <strong>be</strong> seen, the trend line based on the experimental<br />

data, which has a maximal error of ±3.2 %, is<br />

in good accordance with Lloyd and Moran’s regression.<br />

The trend line is in accordance with this regression

with a maximal difference of 4 %. The trend line is in<br />

accordance with Mikheyev’s regression: the maximal<br />

difference <strong>be</strong>tween both is 5 %. To verify the metal foam<br />

height’s influence for the 10 PPI metal foam, measurements<br />

have <strong>be</strong>en performed for five different metal foam heights.<br />

The metal foam height’s influence on the heat transfer is<br />

clearly distinguishable. As the metal foam height increases,<br />

the heat transfer improves. The increase is affected by raising<br />

Rayleigh num<strong>be</strong>rs. The increase however diminishes as the<br />

metal foam height increases. Comparing the measurements<br />

for different metal foam heights to the results obtained for a<br />

flat surface, one notices that the latter curve is flatter. Finally<br />

the obtained results are compared to the trend line obtained<br />

by Phanikumar et al. Extrapolating the Nusselt num<strong>be</strong>r as a<br />

power function of metal foam height using the test results,<br />

one <strong>be</strong>comes the values as expected using Phanikumar’s trend<br />

line.<br />

To verify the influence of the metal foam height for the 20 PPI<br />

metal foam, measurements have <strong>be</strong>en performed for three<br />

different heights. The metal foam height’s effect is clearly<br />

visible. The convection coefficient and the corresponding<br />

Nusselt num<strong>be</strong>r increase as the metal foam height increases.<br />

The increase is affected by raising Rayleigh num<strong>be</strong>rs.<br />

Figure 1 measurements 20 PPI sample, different foam heights<br />

The conclusion is valid for all trend lines. Moreover Nusselt<br />

num<strong>be</strong>r augments as the metal foam height increases.<br />

Finally the results are compared with the Phanikumar’s and<br />

Hetseroni’s trend lines. Surprisingly the heat transfer for<br />

Hetseroni’s 10 mm trend line is higher than the heat transfer<br />

measured at a metal foam height of 12 mm. This can <strong>be</strong><br />

explained by the fact that in Hetseroni’s experiments the foam<br />

was not attached to the base plate, it was clamped on both<br />

sides instead . The sample was heated by sending a current<br />

through the metal foam. Therefore the transferred power<br />

was distributed more uniform over the metal foam, moreover<br />

the air could move more freely through the metal foam.<br />

Phanikumar’s trend line corresponds very well to the obtained<br />

test results.<br />

33<br />

2012 • 01<br />

Figure 2 measurements brazed test sample vs epoxy glued<br />

The metal foam can <strong>be</strong> connected to the base plate in<br />

different ways, two of these are investigated in this work: the<br />

first is called ‘brazing the metal foam to the base plate’, while<br />

the second one is called ‘gluing the metal foam to the base<br />

plate using epoxy glue’. The average improvement obtained<br />

by brazing is around 11 % Finally Bhattacharya’s trend line<br />

is compared to the obtained results. The trend line almost<br />

depicts the same increase as does the 12 mm epoxy glued<br />

metal foam trend line.<br />

The influence of the pore density has also <strong>be</strong>en examined. For<br />

each metal foam height the heat transfer is less in the 20 PPI<br />

metal foam. On average the Nusselt num<strong>be</strong>r increases with<br />

about 20 % using the 10 PPI metal foam in comparison with<br />

the 20 PPI metal foam.<br />

The two metal foam types have also <strong>be</strong>en compared to a<br />

classical heatsink with a height of 18 mm. One can conclude<br />

that at identical metal foam height 10 PPI metal foam causes<br />

the greatest heat transfer, while the classical heatsink causes<br />

the smallest heat transfer. In the 4,000 – 6,000 interval of<br />

Rayleigh num<strong>be</strong>rs, 10 PPI metal foam gives rise to Nusselt<br />

num<strong>be</strong>rs that are on average 70 % higher than those<br />

corresponding to a classical heatsink. For 20 PPI metal<br />

foam the effect diminishes to about 45 %.<br />

In order to verify the influence of the box’s geometry,<br />

18 experiments have <strong>be</strong>en conducted. To perform these<br />

experiments, metal foam height, box width, box height and<br />

base plate temperature have <strong>be</strong>en varied.<br />

The obtained regression equation was:<br />

© Robin Reynders

visit us at:<br />

Light & Building 2012<br />

hall 3.0 booth A31<br />

15/04 - 20/04 Messe Frankfurt<br />

Joos de ter Beerstlaan 33<br />

8740 Pittem<br />

Belgium<br />

T +32 (0)51 46 43 41<br />

F +32 (0)51 46 43 42<br />

info@tal-lighting.com<br />

www.tal-lighting.com<br />

coming soon:<br />

Launch at Light+Building<br />

follow on www.tal.<strong>be</strong><br />

NEW<br />

catalogue<br />

2012-2012