The Sneek Bridge - Wood Design & Building - Summer 2013

The Sneek Bridge - Wood Design & Building - Summer 2013

The Sneek Bridge - Wood Design & Building - Summer 2013

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

26<br />

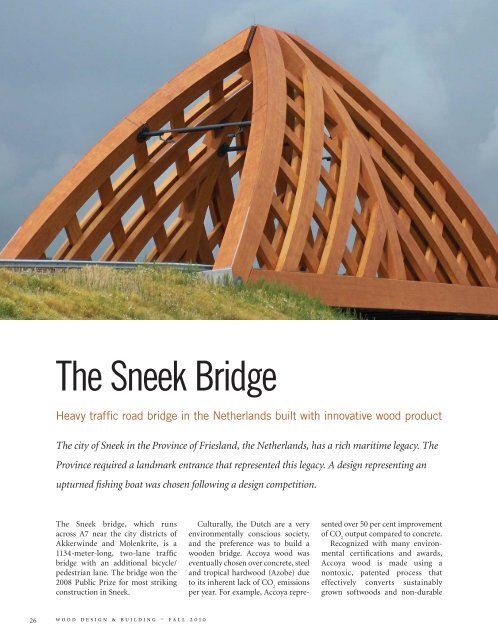

<strong>The</strong> <strong>Sneek</strong> <strong>Bridge</strong><br />

Heavy traffic road bridge in the Netherlands built with innovative wood product<br />

<strong>The</strong> city of <strong>Sneek</strong> in the Province of Friesland, the Netherlands, has a rich maritime legacy. <strong>The</strong><br />

Province required a landmark entrance that represented this legacy. A design representing an<br />

upturned fishing boat was chosen following a design competition.<br />

<strong>The</strong> <strong>Sneek</strong> bridge, which runs<br />

across A7 near the city districts of<br />

Akkerwinde and Molenkrite, is a<br />

1134-meter-long, two-lane traffic<br />

bridge with an additional bicycle/<br />

pedestrian lane. <strong>The</strong> bridge won the<br />

2008 Public Prize for most striking<br />

construction in <strong>Sneek</strong>.<br />

wood design & building ‒ fall 2010<br />

Culturally, the Dutch are a very<br />

environmentally conscious society,<br />

and the preference was to build a<br />

wooden bridge. Accoya wood was<br />

eventually chosen over concrete, steel<br />

and tropical hardwood (Azobe) due<br />

to its inherent lack of CO 2 emissions<br />

per year. For example, Accoya repre-<br />

sented over 50 per cent improvement<br />

of CO 2 output compared to concrete.<br />

Recognized with many environmental<br />

certifications and awards,<br />

Accoya wood is made using a<br />

nontoxic, patented process that<br />

effectively converts sustainably<br />

grown softwoods and non-durable

Opposite and below: Approximately 1,200 cubic meters of Accoya wood was used in the production of the <strong>Sneek</strong> bridge.<br />

<strong>The</strong> supporting beams that stretch into the sky are 1 x 1.4-m. thick and made by finger jointing and laminating processes.<br />

wood design & building ‒ fall 2010 27

Big <strong>Wood</strong>.<br />

Big Story.<br />

Panama Canal<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

FSC® CERTIFIED HARDWOODS SHIPPED WORLDWIDE<br />

<br />

<br />

<br />

604.327.2600<br />

<br />

Pre-stressed cables with a 180-ton force were used to<br />

apply tension to the supporting beams. This induced<br />

shrinkage of only 9mm in the principal girder<br />

500 m3 of<br />

Accoya ® wood<br />

were used in its<br />

construction.<br />

This equates<br />

to 255 tons of<br />

timber and 13 full<br />

truck loads<br />

of Accoya ® wood.<br />

hardwoods into a high-performance,<br />

sustainable wood product that is<br />

beautiful, durable and stable.<br />

All bridges built in the Netherlands<br />

must have a minimum 80-year lifespan.<br />

<strong>Sneek</strong> commissioned a design<br />

team to set a testing and qualification<br />

program for Accoya which was<br />

specific to the design project. <strong>The</strong><br />

expected life of a steel bridge was 55<br />

years; pre-stressed concrete was 90<br />

years; and tropical Azobe hardwood<br />

was 45 years. Tests concluded that<br />

Accoya wood’s outstanding durability<br />

(over 80 years in the bridge<br />

application) made it the perfect<br />

material for use in the bridge.<br />

Approximately 1,200 cubic<br />

meters of Accoya wood was used in<br />

the production of the <strong>Sneek</strong> bridge.<br />

<strong>The</strong> supporting beams that stretch<br />

into the sky are 1 x 1.4 meters thick<br />

and made by finger jointing and<br />

laminating processes. <strong>The</strong> <strong>Sneek</strong><br />

bridge was primarily manufactured<br />

off site, then lifted into place for<br />

final construction.<br />

28<br />

wood design & building ‒ fall 2010<br />

ARCHITECT<br />

Achterbosch Architectuur<br />

(Hans Achterbosch) and<br />

Onix (Alex van de Beld, Haiko Meijer)<br />

Leeuwarden, NL<br />

CLIENT<br />

Province of Friesland<br />

Leeuwarden, NL<br />

GENERAL CONTRACTOR<br />

Schaffitzel Holzindustrie GmbH<br />

Schwäbisch Hall, NL<br />

ENGINEERING<br />

H.E. Lüning Adviesbureau voor<br />

technische houtconstructies<br />

Oranjewoud Mobiliteit &<br />

Infrastructuur<br />

GLC Houtconstructies<br />

Leeuwarden, NL<br />

WOOD PRODUCT SUPPLIER<br />

Accsys Technologies<br />

London, UK, Arnhem, NL and Dallas, TX