specifications for approval samsung electronics co., ltd

specifications for approval samsung electronics co., ltd

specifications for approval samsung electronics co., ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPECIFICATIONS FOR APPROVAL<br />

To Our Valued Customer:<br />

SAMSUNG ELECTRONICS CO., LTD<br />

Mobile Communication Division<br />

Customer Part No.<br />

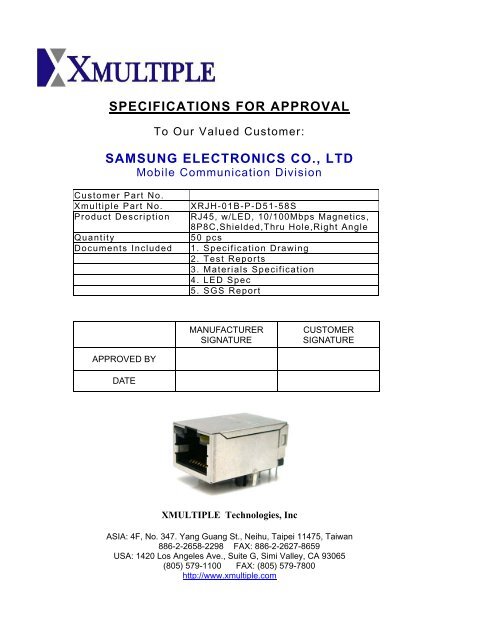

Xmultiple Part No. XRJH-01B-P-D51-58S<br />

Product Description RJ45, w/LED, 10/100Mbps Magnetics,<br />

8P8C,Shielded,Thru Hole,Right Angle<br />

Quantity 50 pcs<br />

Documents Included 1. Specification Drawing<br />

2. Test Reports<br />

3. Materials Specification<br />

4. LED Spec<br />

5. SGS Report<br />

APPROVED BY<br />

DATE<br />

MANUFACTURER<br />

SIGNATURE<br />

XMULTIPLE Technologies, Inc<br />

CUSTOMER<br />

SIGNATURE<br />

ASIA: 4F, No. 347. Yang Guang St., Neihu, Taipei 11475, Taiwan<br />

886-2-2658-2298 FAX: 886-2-2627-8659<br />

USA: 1420 Los Angeles Ave., Suite G, Simi Valley, CA 93065<br />

(805) 579-1100 FAX: (805) 579-7800<br />

http://www.xmultiple.<strong>co</strong>m

1. SCOPE<br />

1.1. CONTENT<br />

This specification document defines requirements <strong>for</strong> Xmultiple XRJH Series of RJ45<br />

Modular Jack integrated with LAN Magnetic. The specification specified herein defines<br />

the testing of per<strong>for</strong>mance, quality and reliability of the XRJH series with LAN<br />

Magnetic.<br />

1.2. QUALIFICATION<br />

When tests are per<strong>for</strong>med on the subject product line, all inspections shall be<br />

per<strong>for</strong>med using the applicable inspection plan and product drawing.<br />

2. APPLICABLE DOCUMENTS<br />

The specification, standards, and procedures described herein <strong>for</strong>m a part of this<br />

document to the extent specified herein. If there is any <strong>co</strong>nflict between the<br />

requirements of this specification and the product drawing, the product drawing shall<br />

take precedence. If there is any <strong>co</strong>nflict between the requirements of this specification<br />

and the referenced documents, this specification shall take precedence.<br />

2.1. SPECIFICATIONS<br />

XMULTIPLE Documents<br />

A.XPS-4489 Test <strong>specifications</strong><br />

B.XTR-4489 Test report.<br />

Federal<br />

QQ-B-626 Brass; bar, plate, rod, strip, flat wire and special shaped sections<br />

QQ-B-750 Bronze, phosphor; bar, plate, rod, sheet, strip, flat, wire, and structural<br />

and Special shaped sections<br />

QQ-N-290 Plating, nickel (electrodeposited)<br />

Military<br />

MIL-STD-105E Sampling procedures <strong>for</strong> inspection by attributes<br />

MIL-STD-1344A Test methods <strong>for</strong> electrical <strong>co</strong>nnectors<br />

MIL-C-39012C General specification <strong>for</strong> <strong>co</strong>nnectors, <strong>co</strong>axial, radio frequency<br />

MIL-G-45204 Gold plating (electrodeposited)<br />

Underwriters Laboratories, Inc.<br />

UL-std-94 Tests <strong>for</strong> flammability of plastic material <strong>for</strong> parts in devices and<br />

appliances.<br />

Others<br />

FCC Rules <strong>for</strong> Registration of Telephone Equipment Part 68, Subpart F, <strong>co</strong>nnectors.

3. REQUIREMENTS<br />

3.1. DESIGN AND CONSTRUCTION<br />

Product shall be of the design, <strong>co</strong>nstruction and physical dimensions specified on the<br />

applicable product drawing.<br />

3.2. MATERIALS<br />

A. Housing: High Temp. Thermoplastic PBT UL94V-0, Black Color.<br />

B. Contacts: T=0.35mm Thick Phosphor-Bronze Plated With 15u” Gold In Contact<br />

Area.<br />

C. Solder pins: T= 0.4mm Thick Brass Plated with Tin in Solder Area<br />

D. Shield: T= 0.2mm SUS303 3/4H with Tin on Termination End<br />

3.3. RATINGS<br />

1. Relative Humidity: 70%±10%RH<br />

2. Operating Temperature: 0°C To 70°C<br />

3. Storage Temperature: -40°C To 85°C<br />

3.4. PERFORMANCE AND TEST DESCRIPTION<br />

The product is designed to meet the electrical, mechanical and environmental<br />

per<strong>for</strong>mance requirements specified in the product drawing. Cavity Con<strong>for</strong>ms to FCC<br />

Rules and Regulations Part 68, Subpart F.<br />

3.5 TEST REQUIREMENTS AND PROCEDURES SUMMARY<br />

3.5.1. Appearance<br />

N o ITEM TEST METHOD SPECIFICATION<br />

1 Appearance<br />

Visual, dimensional and<br />

functional per applicable Quality<br />

inspection plan<br />

Applies to the<br />

drawing (PDF)<br />

3.5.2. Electrical<br />

N o ITEM TEST METHOD SPECIFICATION<br />

1 Inductance At 100KHz/0.1V, 8 mA DC BIAS. 350 µH (Min.)<br />

2 DCR Test PIN: (J1-J2) (J3-J6) 1.2 OHMS (Max.)<br />

3 Hi-Pot test<br />

PIN(P1,P2,P3) To PIN(J1,J2)<br />

PIN(P6,P7,P8) To PIN(J3,J6)<br />

1,500VAC <strong>for</strong> 60<br />

se<strong>co</strong>nds<br />

4 Insertion Loss At 0.3 MHZ to 100 MHz -1.0 dB (Max.)<br />

5 Return Loss<br />

1MHz to 30 MHz<br />

30 MHz to 60 MHz<br />

60 to 80 MHz<br />

-20 dB (Min.)<br />

-15 dB (Min.)<br />

-10 dB (Min.)<br />

6 Cross Talk 1 MHz to 100 MHz -30 dB (Min.)<br />

7 CCMR 1 MHz to 100 MHz -30 dB (Min.)

3.5.3. Mechanical<br />

N o ITEM TEST METHOD SPECIFICATION<br />

1<br />

Insertion <strong>for</strong>ce<br />

(Mating)<br />

Mating with the modular plug. 2.2 Kgf Max.<br />

2<br />

Withdrawal<br />

<strong>for</strong>ce(Un-Mating)<br />

Un-mating with the modular plug 2.2 Kgf Max.<br />

3<br />

Retention strength<br />

<strong>for</strong>ce<br />

Between the Jack & Plug 7.5 Kgf Min.<br />

4 Durability<br />

5<br />

Vibration<br />

6 Solderability<br />

After 500 cycles life test. At the rate of 20~30 cycles<br />

Per minute. (Mating and Un-mating)<br />

Appearance Visual Control<br />

No evidence of<br />

damage<br />

Inductance Ref to 3.5.2 (1) 350 µH (Min.)<br />

DCR Test Ref to 3.5.2 (2) 1.2 OHMS (Max.)<br />

Hi-Pot Test Ref to 3.5.2 (3)<br />

1,500 VAC <strong>for</strong> 60<br />

se<strong>co</strong>nds<br />

Insertion Loss Ref to 3.5.2 (4) -1.0 dB (Max.)<br />

-20 dB (Min.)<br />

Return Loss Ref to 3.5.2 (5) -15 dB (Min.)<br />

-10 dB (Min.)<br />

Cross Talk Ref to 3.5.2 (6) -30 dB (Min.)<br />

CCMR Ref to 3.5.2 (7) -30 dB (Min.)<br />

After follower <strong>co</strong>ndition test.<br />

*Amplitude:1.5mm<br />

*Sweep time: 10~55~10Hz in 1 minute.<br />

*Duration: 2hour in each X.Y.Z axes.<br />

*Measure it after putting it at normal temperature (in<br />

the air) <strong>for</strong> 2 hours<br />

Appearance Visual Control<br />

No evidence of<br />

damage<br />

Inductance Ref to 3.5.2 (1) 350 µH (Min.)<br />

DCR Test Ref to 3.5.2 (2) 1.2 OHMS (Max.)<br />

Hi-Pot Test Ref to 3.5.2 (3)<br />

1,500 VAC <strong>for</strong> 60<br />

se<strong>co</strong>nds<br />

Insertion Loss Ref to 3.5.2 (4) -1.0 dB (Max.)<br />

Return Loss Ref to 3.5.2 (5)<br />

-20 dB (Min.)<br />

-15 dB (Min.)<br />

-10 dB (Min.)<br />

Cross Talk Ref to 3.5.2 (6) -30 dB (Min.)<br />

CCMR Ref to 3.5.2 (7) -30 dB (Min.)<br />

*Solder time:5±0.5 SEC<br />

*Solder Temperate: 235℃±5℃<br />

More than 90%<br />

solder

4. QUALITY ASSURANCE PROVISIONS<br />

4.1. SAMPLE SELECTION<br />

Modular jack test samples shall be selected at random from current production lots.<br />

They shall be prepared <strong>for</strong> testing in ac<strong>co</strong>rdance with current application <strong>specifications</strong><br />

and instruction sheets.<br />

4.2. ACCEPTANCE<br />

Acceptance is based on verification that the product meets the requirements of the<br />

product drawing. Failures attributed to equipment, test setup, or operator deficiencies<br />

shall not disqualify the product. When product failure occurs, <strong>co</strong>rrective action shall be<br />

taken and samples resubmitted <strong>for</strong> qualification. Testing to <strong>co</strong>nfirm <strong>co</strong>rrective action is<br />

required be<strong>for</strong>e resubmitted.<br />

4.3 QUALITY CONFORMANCE INSPECTION<br />

The applicable XMULTIPLE quality inspection plan will specify the sampling quality level<br />

to be used.<br />

Dimensional and functional requirements shall be in ac<strong>co</strong>rdance with the applicable<br />

product drawing and this specification.<br />

Requirements:<br />

No evidence of physical damaged.<br />

Figure 2

TEST REPORT<br />

ITEM RJ45 JACK, Latch Up, Integrated with 10/100<br />

Base-T LAN Magnetic built in<br />

TEST DATE Dec.08.2006<br />

PART NO XRJH-01B-P-D51-58S TEST Qty 5 PCS<br />

1. ELECTRICAL, MECHANICAL, PHYSICAL<br />

No Test Description SPEC.<br />

1 2<br />

DATA<br />

3 4 5<br />

RESULT<br />

1 Inductance 350 µH (Min.) 572 560 519 517 523 PASS<br />

2 DCR Test 1.2 OHMS (Max.) 0.770 0.747 0.803 0.761 0.814 PASS<br />

3 Hi-Pot Test 1,500 VAC <strong>for</strong> 60 se<strong>co</strong>nds OK OK OK OK OK PASS<br />

4 Insertion Loss -1.0 dB (Max.) -0.68 -0.69 -0.79 -0.76 -0.78 PASS<br />

5 Return Loss -20 dB (Min.) -25.9 -26.2 -25.7 -25.2 -25.8 PASS<br />

-15 dB (Min.) -18.7 -19.1 -20.5 -20.1 -19.5 PASS<br />

-10 dB (Min.) -16.9 -16.0 -16.5 -15.9 -16.4 PASS<br />

6 Cross Talk -30 dB (Min.) -42.6 -43.2 -40.4 -40.7 -42.3 PASS<br />

7 CCMR -30 dB (Min.) -38.1 -36.8 -38.9 -38.3 -37.7 PASS<br />

8 Insertion <strong>for</strong>ce 2.2 Kgf Max. 1.78 1.89 1.76 1.68 1.85 PASS<br />

9 Withdrawal <strong>for</strong>ce 2.2 Kgf Max. 1.78 1.89 1.76 1.68 1.85 PASS<br />

10 Retention strength<br />

<strong>for</strong>ce<br />

7.5 Kgf Min. 8.18 8.29 8.13 8.28 8.19 PASS<br />

11 Durability Appearance No evidence of<br />

damage<br />

OK OK OK OK OK PASS<br />

Inductance 350 µH (Min.) 572 560 519 517 523 PASS<br />

DCR Test 1.2 OHMS<br />

(Max.)<br />

0.770 0.747 0.803 0.761 0.814 PASS<br />

Hi-Pot Test 1,500VAC <strong>for</strong><br />

60 se<strong>co</strong>nds<br />

OK OK OK OK OK PASS<br />

Insertion Loss -1.0 dB (Max.) -0.68 -0.69 -0.79 -0.76 -0.78 PASS<br />

Return Loss -20 dB (Min.) -25.9 -26.2 -25.7 -25.2 -25.8 PASS<br />

-15 dB (Min.) -18.7 -19.1 -20.5 -20.1 -19.5 PASS<br />

-10 dB (Min.) -16.9 -16.0 -16.5 -15.9 -16.4 PASS<br />

Cross Talk<br />

-30 dB (Min.) -42.6 -43.2 -40.4 -40.7 -42.3 PASS<br />

12 Vibration<br />

CCMR -30 dB (Min.) -38.1 -36.8 -38.9 -38.3 -37.7 PASS<br />

Appearance No evidence of<br />

damage<br />

OK OK OK OK OK PASS<br />

Inductance 350 µH (Min.) 572 560 519 517 523 PASS<br />

DCR Test 1.2 OHMS<br />

(Max.)<br />

0.770 0.747 0.803 0.761 0.814 PASS<br />

Hi-Pot Test 1,500VAC <strong>for</strong><br />

60 se<strong>co</strong>nds<br />

OK OK OK OK OK PASS<br />

Insertion Loss -1.0 dB (Max.) -0.68 -0.69 -0.79 -0.76 -0.78 PASS<br />

Return Loss -20 dB (Min.)<br />

-15 dB (Min.)<br />

-10 dB (Min.)<br />

-25.9<br />

-18.7<br />

-16.9<br />

-26.2<br />

-19.1<br />

-16.0<br />

-25.7<br />

-20.5<br />

-16.5<br />

-25.2<br />

-20.1<br />

-15.9<br />

-25.8<br />

-19.5<br />

-16.4<br />

PASS<br />

PASS<br />

PASS<br />

Cross Talk -30 dB (Min.) -42.6 -43.2 -40.4 -40.7 -42.3 PASS<br />

13 Solderability More than 90% solder OK OK OK OK OK PASS

2. APPEARANCE, MATERIAL, PLATING<br />

No Test Description<br />

SPEC 1 2<br />

DATA<br />

3 4 5<br />

RESULT<br />

1 Resin PBT (UL 94V-0) OK OK OK OK OK PASS<br />

2 Contact Phosphor-Bronze/Au Plated OK OK OK OK OK PASS<br />

3 EMI Shield SUS303 3/4H 0.20mm OK OK OK OK OK PASS<br />

Dimension Test Report<br />

No. Dimension<br />

1 2<br />

DATA<br />

3 4 5<br />

RESULT<br />

1 16.20±0.20 16.23 16.20 16.22 16.20 16.20 PASS<br />

2 1.27±0.20 1.26 1.27 1.25 1.26 1.26 PASS<br />

3 12.70±0.20 12.72 12.70 12.71 12.72 12.72 PASS<br />

4 25.40±0.20 25.28 25.23 25.25 25.22 25.22 PASS<br />

5 12.80±0.20 12.89 12.85 12.87 12.90 12.90 PASS<br />

6 12.75±0.20 12.72 12.70 12.71 12.76 12.75 PASS<br />

7 1.30±0.20 1.30 1.28 1.30 1.30 1.31 PASS<br />

8 10.80±0.20 10.75 10.76 10.75 10.75 10.75 PASS<br />

9 3.05±0.20 3.11 3.08 3.08 3.11 3.10 PASS<br />

10 6.35±0.20 6.30 6.41 6.41 6.39 6.37 PASS<br />

11 8.89±0.20 8.84 8.90 8.85 8.90 8.90 PASS<br />

12 13.63±0.20 13.75 13.80 13.75 13.69 13.79 PASS<br />

13 12.70±0.20 12.73 12.70 12.71 12.70 12.70 PASS<br />

14 3.40±0.20 3.34 3.35 3.36 3.34 3.54 PASS<br />

15 3.20±0.20 3.23 3.21 3.20 3.23 3.24 PASS<br />

16 1.75±0.20 1.71 1.70 1.71 1.70 1.70 PASS<br />

17 2.15±0.20 2.17 2.15 2.16 2.17 2.16 PASS<br />

18 3.30±0.20 3.29 3.30 3.27 3.27 3.30 PASS<br />

19 1.00±0.20 0.95 0.97 0.98 0.95 0.95 PASS<br />

20 3.35±0.20 3.55 3.55 3.55 3.55 3.55 PASS

XMULTIPLE Asia Xmultiple USA<br />

ASIA: 4F, No. 347. Yang Guang St., Neihu, 1420 Los Angeles Ave. #G<br />

Taipei 11475, Taiwan Simi Valley, CA93065<br />

Tel: +886-2-2658-2298 Tel: 1-805-5791100<br />

FAX: +886-2-2627-8659 Fax: 1-805-5797800<br />

http://www.xmultiple.<strong>co</strong>m