Download

Download

Download

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10<br />

TEMPERATURE CONTROLLED LEAD-FREE SOLDERING STATION<br />

RX-711ASPH<br />

Wide Temperature Setting Range<br />

With a wide temperature setting<br />

range (200–480°C) and a digital<br />

display, the RX-711ASPH provides<br />

both accurate and easy temperature<br />

management.<br />

Quick Recovery Time<br />

LEAD<br />

FREE<br />

ANTI<br />

STATIC<br />

Improving lead-free soldering<br />

Advantages of the Preheat Effect<br />

●Allows soldering work to be done with<br />

a tip temperature similar to that for<br />

Eutectic solder (Sn-Pb), even though<br />

lead-free solder has a high melting point<br />

temperature.<br />

With the new sensor integrated into the ceramic heater (Patent<br />

Pending) a 60W large heat capacity allows faster temperature<br />

recovery during heavy soldering, reducing the reaction time even<br />

at lower temperature settings. Stability even during heavy soldering<br />

enables low temperature soldering and reduces the risk of<br />

thermal shock to low capacity electrical parts.<br />

Protective Cover (Patent Pending)<br />

The cover prevents tampering with temperature<br />

calibration and setting.<br />

CERAMIC<br />

HEATER<br />

●Enables quicker soldering because there is minimal<br />

temperature loss during soldering work.<br />

●Reduces solder splashing or damage caused by heatshocks<br />

during soldering by preheating the components or<br />

the solder itself.<br />

Advantages of Preheating with Nitrogen<br />

●Reduces oxidization of the solder joint area and the tip.<br />

●Improves the solder wetting and fillet shape.<br />

USES HOT AIR FOR<br />

PREHEATING EFFECT<br />

NITROGEN<br />

APPLICABLE<br />

ST-77 Soldering Iron<br />

Stand Included<br />

TEMPERATURE<br />

CONTROL<br />

Preheating is done by outputting gas from the clearance between<br />

the heater barrel and the tip. Using N2 (Nitrogen) gas results in<br />

reduction of oxidization and further improves solder wetting and<br />

fillet shape.<br />

NOTE<br />

It is not possible to use the Preheat effect with the<br />

RX-711ASPH alone. A Nitrogen gas canister or a gas server<br />

is also required. To control the gas flow-rate we recommend<br />

the use of the Output Controller NC-10 Series.<br />

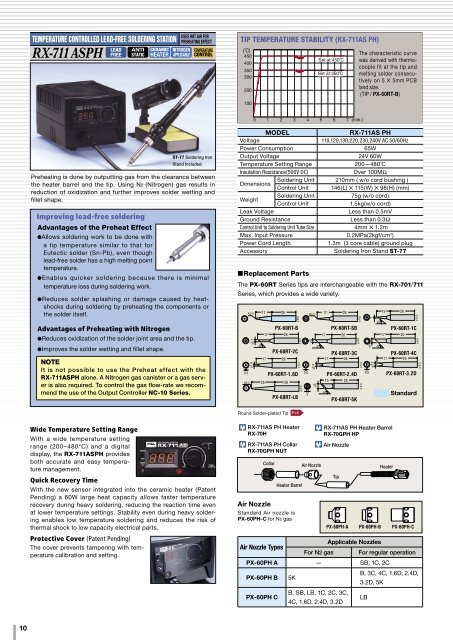

TIP TEMPERATURE STABILITY (RX-711AS PH)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

The PX-60RT Series tips are interchangeable with the RX-701/711<br />

Series, which provides a wide variety.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Round Solder-plated Tip P.15<br />

<br />

<br />

<br />

<br />

The characteristic curve<br />

was derived with thermocouple<br />

fit at the tip and<br />

melting solder consecutively<br />

on 5 ✕ 5mm PCB<br />

land size.<br />

(TIP / PX-60RT-B)<br />

MODEL RX-711AS PH<br />

Voltage 110,120,130,220,230,240V AC 50/60Hz<br />

Power Consumption 65W<br />

Output Voltage 24V 60W<br />

Temperature Setting Range 200—480˚C<br />

Insulation Resistance(500V DC) Over 100MΩ<br />

Dimensions<br />

Soldering Unit<br />

Control Unit<br />

210mm ( w/o cord bushing )<br />

146(L) ✕ 115(W) ✕ 98(H) (mm)<br />

Weight<br />

Soldering Unit<br />

Control Unit<br />

75g (w/o cord)<br />

1.5kg(w/o cord)<br />

Leak Voltage Less than 0.5mV<br />

Ground Resistance Less than 0.3Ω<br />

Control Unit to Soldering Unit Tube Size 4mm ✕ 1.2m<br />

Max. Input Pressure 0.2MPa(2kgf/cm 2 )<br />

Power Cord Length 1.3m (3 core cable) ground plug<br />

Accessory Soldering Iron Stand ST-77<br />

■Replacement Parts<br />

RX-711AS PH Heater<br />

RX-70H<br />

RX-711AS PH Collar<br />

RX-70GPH NUT<br />

<br />

Air Nozzle<br />

<br />

Standard Air nozzle is<br />

PX-60PH-C for N2 gas<br />

Air Nozzle Types<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

RX-711AS PH Heater Barrel<br />

RX-70GPH HP<br />

Air Nozzle<br />

<br />

<br />

<br />

<br />

Applicable Nozzles<br />

For N2 gas For regular operation<br />

PX-60PH A — SB, 1C, 2C<br />

PX-60PH B 5K<br />

PX-60PH C<br />

B, SB, LB, 1C, 2C, 3C,<br />

4C, 1.6D, 2.4D, 3.2D<br />

<br />

B, 3C, 4C, 1.6D, 2.4D,<br />

3.2D, 5K<br />

LB