819 • 822 • 824 • 826 • 828 - Fendt

819 • 822 • 824 • 826 • 828 - Fendt

819 • 822 • 824 • 826 • 828 - Fendt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

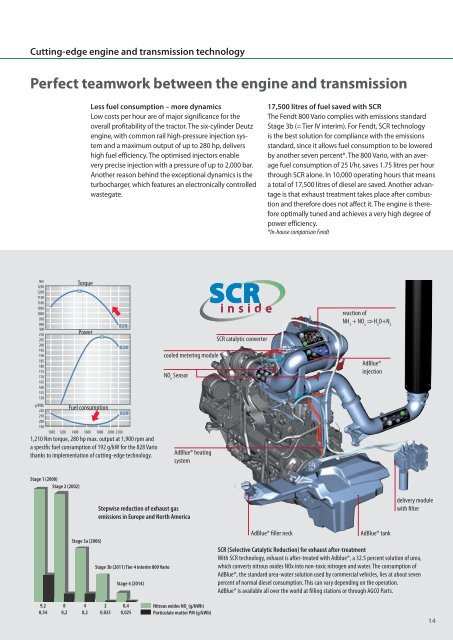

Cutting-edge engine and transmission technology<br />

Perfect teamwork between the engine and transmission<br />

Nm<br />

1250<br />

1200<br />

1150<br />

1100<br />

1050<br />

1000<br />

950<br />

900<br />

kW<br />

210<br />

205<br />

200<br />

195<br />

190<br />

185<br />

180<br />

175<br />

170<br />

165<br />

160<br />

155<br />

150<br />

g/kWh<br />

220<br />

210<br />

200<br />

190<br />

<strong>828</strong><br />

<strong>828</strong><br />

1000 1200 1400 1600 1800 2000 2100<br />

Stage 1 (2000)<br />

Stage 2 (2002)<br />

Torque<br />

Power<br />

Fuel consumption<br />

<strong>828</strong><br />

9,2 8 4 2 0,4<br />

0,54 0,2 0,2 0,025 0,025<br />

Less fuel consumption – more dynamics<br />

Low costs per hour are of major significance for the<br />

overall profitability of the tractor. The six-cylinder Deutz<br />

engine, with common rail high-pressure injection system<br />

and a maximum output of up to 280 hp, delivers<br />

high fuel efficiency. The optimised injectors enable<br />

very precise injection with a pressure of up to 2,000 bar.<br />

Another reason behind the exceptional dynamics is the<br />

turbocharger, which features an electronically controlled<br />

wastegate.<br />

1,210 Nm torque, 280 hp max. output at 1,900 rpm and<br />

a specific fuel consumption of 192 g/kW for the <strong>828</strong> Vario<br />

thanks to implementation of cutting-edge technology.<br />

Stage 3a (2006)<br />

Stepwise reduction of exhaust gas<br />

emissions in Europe and North America<br />

Stage 3b (2011) Tier 4 interim 800 Vario<br />

Stage 4 (2014)<br />

cooled metering module<br />

NO x Sensor<br />

AdBlue® heating<br />

system<br />

Nitrous oxides NO x (g/kWh)<br />

Particulate matter PM (g/kWh)<br />

SCR catalytic converter<br />

17,500 litres of fuel saved with SCR<br />

The <strong>Fendt</strong> 800 Vario complies with emissions standard<br />

Stage 3b (= Tier IV interim). For <strong>Fendt</strong>, SCR technology<br />

is the best solution for compliance with the emissions<br />

standard, since it allows fuel consumption to be lowered<br />

by another seven percent*. The 800 Vario, with an average<br />

fuel consumption of 25 l/hr, saves 1.75 litres per hour<br />

through SCR alone. In 10,000 operating hours that means<br />

a total of 17,500 litres of diesel are saved. Another advantage<br />

is that exhaust treatment takes place after combustion<br />

and therefore does not affect it. The engine is therefore<br />

optimally tuned and achieves a very high degree of<br />

power efficiency.<br />

*In-house comparison <strong>Fendt</strong><br />

AdBlue® filler neck<br />

reaction of<br />

NH 3 + NO x => H 2 O+N 2<br />

AdBlue®<br />

injection<br />

AdBlue® tank<br />

delivery module<br />

with filter<br />

SCR (Selective Catalytic Reduction) for exhaust after-treatment<br />

With SCR technology, exhaust is after-treated with Adblue®, a 32.5 percent solution of urea,<br />

which converts nitrous oxides NOx into non-toxic nitrogen and water. The consumption of<br />

AdBlue®, the standard urea-water solution used by commercial vehicles, lies at about seven<br />

percent of normal diesel consumption. This can vary depending on the operation.<br />

AdBlue® is available all over the world at filling stations or through AGCO Parts.<br />

14