Cobalarc Hardfacing Electrodes - Ferret

Cobalarc Hardfacing Electrodes - Ferret

Cobalarc Hardfacing Electrodes - Ferret

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

How to select the best COMWELD rod<br />

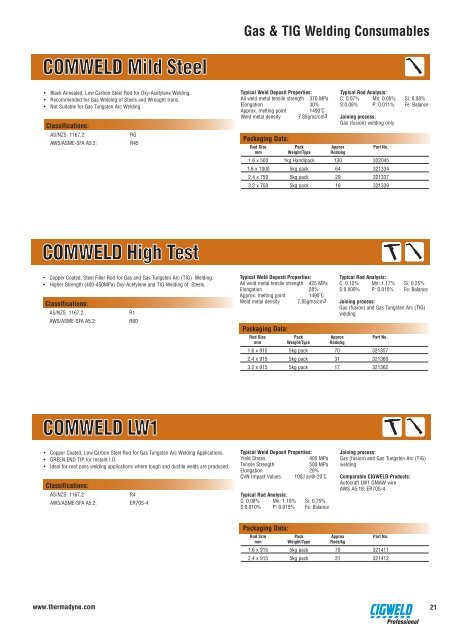

COMWELD Mild Steel<br />

• Black Annealed, Low Carbon Steel Rod for Oxy-Acetylene Welding.<br />

Typical Weld Deposit Properties:<br />

COMWELD • Recommended for Gas Welding of Steels High and Wrought Test<br />

Irons.<br />

All weld metal tensile strength 370 MPa<br />

• Not Suitable for Gas Tungsten Arc Welding.<br />

Elongation 30%<br />

Approx. melting point 1490˚C<br />

Weld metal density 7.85gms/cm3<br />

COMWELD Classifications: LW1<br />

AS/NZS 1167.2: RG<br />

AWS/ASME-SFA A5.2: R45<br />

COMWELD LW1-6<br />

www.thermadyne.com<br />

Gas & TIG Welding Consumables<br />

Packaging Data:<br />

COMWELD Super Steel<br />

How to select the best COMWELD rod<br />

COMWELD CrMo1<br />

COMWELD Mild Steel<br />

COMWELD CrMo2<br />

COMWELD High High Test<br />

COMWELD • Copper Coated, Steel Filler Rod for Gas 308L<br />

and Gas Tungsten Arc (TIG) Welding.<br />

Typical Weld Deposit Properties:<br />

COMWELD • Higher Strength (400-450MPa) Oxy-Acetylene LW1 and TIG Welding of Steels.<br />

All weld metal tensile strength 425 MPa<br />

Elongation 28%<br />

Approx. melting point 1490˚C<br />

Weld metal density 7.85gms/cm3<br />

Classifications:<br />

COMWELD LW1-6 309L<br />

AS/NZS 1167.2: R1<br />

AWS/ASME-SFA A5.2: R60<br />

Packaging Data:<br />

COMWELD How to select 316L Super the Steel best COMWELD rod<br />

COMWELD COMWELD CrMo1 Galvanising Mild Steel Bar<br />

COMWELD CrMo2<br />

COMWELD<br />

COMWELD<br />

AL1100<br />

High Test<br />

COMWELD<br />

COMWELD<br />

AL4043<br />

308L LW1<br />

• Copper Coated, Low Carbon Steel Rod for Gas Tungsten Arc Welding Applications. Typical Weld Deposit Properties:<br />

• GREEN END TIP for Instant I.D.<br />

Yield Stress 400 MPa<br />

COMWELD 309L LW1-6<br />

• Ideal for root pass welding applications where tough and ductile welds are produced. Tensile Strength 500 MPa<br />

Elongation 29%<br />

COMWELD AL4047<br />

CVN Impact Values 100J av@-20˚C<br />

Classifications: COMWELD AS/NZS 1167.2: Super R4 Steel Typical Rod Analysis:<br />

C: 0.08% Mn: 1.16% Si: 0.75%<br />

COMWELD AWS/ASME-SFA A5.2: COMWELD 316L<br />

ER70S-4<br />

S:0.010% P: 0.015% Fe: Balance<br />

AL5356<br />

COMWELD CrMo1<br />

Packaging Data:<br />

COMWELD<br />

COMWELD<br />

CrMo2<br />

General Galvanising Purpose, Bar mm Cast Weight/Type Iron Rods/kg Rod<br />

COMWELD COMWELD<br />

AL1100 Silicon 308L Bronze Rod<br />

COMWELD<br />

COMWELD Tobin AL4043<br />

309L Bronze Rod<br />

COMWELD AL4047<br />

Typical Rod Analysis:<br />

C: 0.07% Mn: 0.05% Si: 0.08%<br />

S:0.08% P: 0.011% Fe: Balance<br />

Joining process:<br />

Gas (fusion) welding only<br />

Rod Size Pack Approx Part No.<br />

mm Weight/Type Rods/kg<br />

1.6 x 500 1kg Handipack 130 322045<br />

1.6 x 1000 5kg pack 64 321334<br />

2.4 x 750 5kg pack 29 321337<br />

3.2 x 750 5kg pack 16 321339<br />

Typical Rod Analysis:<br />

C: 0.12% Mn: 1.17% Si: 0.25%<br />

S:0.009% P: 0.015% Fe: Balance<br />

Joining process:<br />

Gas (fusion) and Gas Tungsten Arc (TIG)<br />

welding<br />

Rod Size Pack Approx Part No.<br />

mm Weight/Type Rods/kg<br />

1.6 x 915 5kg pack 70 321357<br />

2.4 x 915 5kg pack 31 321360<br />

3.2 x 915 5kg pack 17 321362<br />

Joining process:<br />

Gas (fusion) and Gas Tungsten Arc (TIG)<br />

welding<br />

Comparable CIGWELD Products:<br />

Autocraft LW1 GMAW wire<br />

AWS A5.18: ER70S-4<br />

Rod Size Pack Approx Part No.<br />

1.6 x 915 5kg pack 70 321411<br />

2.4 x 915 5kg pack 31 321412<br />

21