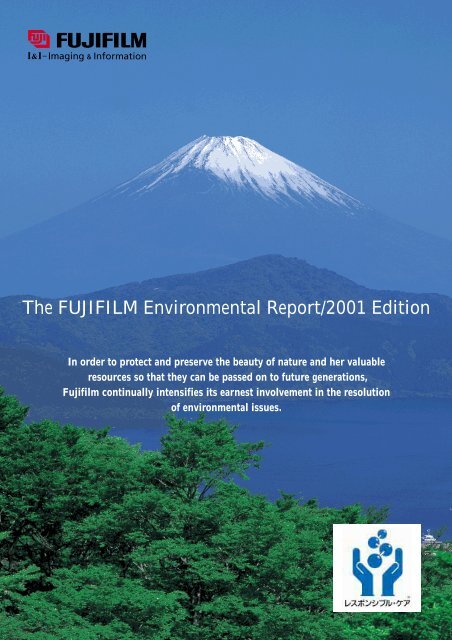

The FUJIFILM Environmental Report/2001 Edition

The FUJIFILM Environmental Report/2001 Edition

The FUJIFILM Environmental Report/2001 Edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>The</strong> <strong>FUJIFILM</strong> <strong>Environmental</strong> <strong>Report</strong>/<strong>2001</strong> <strong>Edition</strong><br />

In order to protect and preserve the beauty of nature and her valuable<br />

resources so that they can be passed on to future generations,<br />

Fujifilm continually intensifies its earnest involvement in the resolution<br />

of environmental issues.

CONCERNING THE DRAFTING OF THIS ENVIRONMENTAL REPORT<br />

<strong>The</strong> purpose of this report is to identify the environmental impact of Fuji Photo Film Co., Ltd.<br />

(Fujifilm)’s activities and products and to communicate the measures which it is taking to reduce<br />

this impact. This report covers chiefly the Company’s activities between April 1, 2000 and<br />

March 31, <strong>2001</strong>. However, some earlier activity information is also provided as background,<br />

along with our vision for the future and a range of consolidated information.<br />

To align this report with global guidelines, it has been compiled with reference to the<br />

Sustainability <strong>Report</strong>ing Guidelines published in June 2000 by the GRI (Global <strong>Report</strong>ing<br />

Initiative).<br />

Index<br />

Opening Remarks ............................................................................................................... 1<br />

Corporate Overview ............................................................................................................ 2<br />

Outline of <strong>Environmental</strong> Activities...................................................................................... 3<br />

Fujifilm Responsible Care Activities and Achievements...................................................... 4<br />

<strong>Environmental</strong> Impact of Fujifilm’s Corporate Activities ...................................................... 5<br />

Current Status of Measures and Future Vision ................................................................... 6<br />

Responsible Care Policies, Organization, and Management .............................................. 7<br />

What is Responsible Care?............................................................................................. 7<br />

Responsible Care and ISO 14001................................................................................... 7<br />

<strong>The</strong> Fujifilm Responsible Care Policy for Fiscal <strong>2001</strong> ..................................................... 8<br />

Fujifilm Responsible Care Organizations and Management ............................................... 9<br />

Current Status of Acquisition of ISO 14001 Certification..................................................... 10<br />

Assessment of the Safety of Chemical Substances............................................................ 11<br />

Green Purchasing and Green Procurement........................................................................ 12<br />

Environment-Friendly Containers and Packaging ............................................................... 13<br />

Environment-Friendly Design and LCA ............................................................................... 14<br />

<strong>Environmental</strong> Education and Awareness-Raising Activities .............................................. 15<br />

<strong>Environmental</strong> Accounting for Fiscal 2000 .......................................................................... 16<br />

Reducing <strong>Environmental</strong> Impact ......................................................................................... 18<br />

Reduction of VOC Emissions and Results of PRTR Survey ........................................... 18<br />

Zero Emissions................................................................................................................ 20<br />

Energy Saving and Curbing Global Warming.................................................................. 22<br />

<strong>Environmental</strong> Monitoring.................................................................................................... 24<br />

On-the-Job Safety ............................................................................................................... 26<br />

Complaints .......................................................................................................................... 26<br />

Fujifilm Products and the Environment................................................................................ 27<br />

Single-Use Cameras (Fujicolor QuickSnap).................................................................... 28<br />

Printing Systems ............................................................................................................. 30<br />

Imaging Systems............................................................................................................. 32<br />

Other Environment-Friendly Products ............................................................................. 33<br />

Communication Activities .................................................................................................... 35<br />

Social Contribution Activities ............................................................................................... 37<br />

Environment-Related Awards.............................................................................................. 38<br />

Groupwide <strong>Environmental</strong> Efforts........................................................................................ 39<br />

Glossary .............................................................................................................................. 40<br />

Independent Review <strong>Report</strong>................................................................................................ 41

OPENING REMARKS<br />

Minoru Ohnishi<br />

Chairman and Chief Executive Officer<br />

Masayuki Muneyuki<br />

Vice Chairman<br />

As we enter the 21st century, the population of the world<br />

continues to grow at an explosive rate. <strong>The</strong> current population of<br />

more than 6 billion is expected to rise to 8 billion by 2020 and<br />

exceed 10 billion by 2050. Population growth and lifestyle<br />

changes spotlight the importance of the preservation and<br />

protection of our natural resources, safely disposing of industrial<br />

and household waste, and combating pollution caused by<br />

chemical substances. As a global company, Fujifilm regards<br />

resource preservation and protection to be the highest priority.<br />

We believe it is essential to develop new energy- and resourcesaving<br />

technologies and to adopt progressive resource policies<br />

at a global level. For Fujifilm, the biggest concerns of the 21st<br />

century are, without a doubt, environmental awareness and<br />

protection.<br />

In the past, Fujifilm has centered its environmental policies on<br />

three basic pillars: constantly giving due consideration to the<br />

natural environment, ensuring safety with regard to chemicals,<br />

and preventing the wasteful use of resources (source reduction).<br />

To meet these obligations, Fujifilm follows a Responsible Care<br />

program. Under Responsible Care, companies independently<br />

set and pursue their own policies, targets, and standards for<br />

environmental protection across the full spectrum of their<br />

activities—from product development through manufacturing,<br />

distribution, use, and waste disposal. Responsible Care is an<br />

international protocol, and chemical companies across the world<br />

have committed themselves to meeting its goals. Fujifilm<br />

became a member of the Japan Responsible Care Council at<br />

the time of the council’s establishment in 1995 and began to<br />

publicize its Responsible Care activities. To support an<br />

integrated environmental management system, Fujifilm began<br />

obtaining ISO 14001 certification prior to Japan’s formal<br />

adoption of the <strong>Environmental</strong> Management Standard in fiscal<br />

1996. All of our main Japanese plants had obtained certification<br />

before 1996.<br />

Recently, Fujifilm has initiated additional action programs to<br />

identify risks and hazards associated with chemicals, as part of<br />

Shigetaka Komori<br />

President<br />

efforts to avoid or modify the use of chemicals identified in specific<br />

classes. Risk management programs are regularly updated.<br />

Our basic identification-awareness tool is our proprietary<br />

Chemical and <strong>Environmental</strong> Safety Information Database.<br />

Through our in-house network, such information is available to all<br />

Company employees.<br />

All our policies for reducing the environmental impact of our<br />

activities are based on the following source-reduction measures:<br />

◆ Designing products with low energy consumption,<br />

◆ Reducing energy loss during product manufacturing,<br />

◆ Reducing environmental impact arising from the use of<br />

products, and<br />

◆ Recovering parts for reuse and repair while creating wastefree<br />

production cycles.<br />

A very high level of technological expertise is needed to make<br />

products environment-friendly while maintaining and improving<br />

their quality and functionality. But Fujifilm is determined to meet<br />

this challenge. A landmark achievement in this field is our<br />

environment-friendly production process for the Fujicolor<br />

QuickSnap single-use camera, which, in November 2000, won<br />

the “Nikkei Superior Trendsetting Factories and Offices Awards<br />

Millennium Award,” sponsored by the Nihon Keizai Shimbun<br />

Company, and the “47th Okouchi Memorial Technology Prize,”<br />

sponsored by the Okouchi Memorial Committee. We aim to<br />

design all our products to make them as environment-friendly as<br />

the Fujicolor QuickSnap, as we pursue source reduction.<br />

Zero Emission initiatives also form part of our source-reduction<br />

activities. Fujifilm already recycles all waste materials generated<br />

in base-material processing at its four main Japanese plants,<br />

and plans to achieve Zero Emissions for all waste products<br />

generated by all domestic business bases, including the sales<br />

division, by the end of fiscal 2002.<br />

Under the resolute leadership of Fujifilm’s management, every<br />

employee and organization within the Group is engaged in an<br />

ongoing effort to make Fujifilm a company that works for the<br />

environment and for product safety.<br />

1

CORPORATE OVERVIEW<br />

2<br />

Name Fuji Photo Film Co., Ltd.<br />

Establishment January 20, 1934<br />

Head Office Nakanuma 210, Minami Ashigara-shi, Kanagawa Prefecture<br />

250-0190<br />

Tel: 0465-74-1111 (main switchboard)<br />

Tokyo Head Office 2-26-30 Nishiazabu, Minato-ku, Tokyo 106-8620<br />

Tel: 03-3406-2111 (main switchboard)<br />

Main Factories Ashigara Factory, Odawara Factory (both in Kanagawa<br />

Prefecture)<br />

Fujinomiya Factory and Yoshida-Minami Factory (both in<br />

Shizuoka Prefecture)<br />

Capital ¥40,363 million (as of March 31, <strong>2001</strong>)<br />

Number of Employees 9,883 (parent only), 37,627 (Group) (as of March 31, <strong>2001</strong>)*<br />

Sales Volume ¥849.1 billion (parent only), ¥1,440.3 billion (Group)*<br />

(for fiscal year ended March 31, <strong>2001</strong>)<br />

Net Profit for Term Ended ¥63.1 billion (parent only), ¥102.7 billion (Group)*<br />

March 31, <strong>2001</strong><br />

Subsidiaries and Consolidated subsidiaries: 98*<br />

Affiliates Non consolidated subsidiaries: 57*<br />

Affiliates: 44*<br />

* On March 30, <strong>2001</strong>, Fuji Xerox became a consolidated subsidiary<br />

of Fujifilm, but is not included in fiscal 2000 financial statements.<br />

Overview of Fujifilm’s Businesses in Fiscal <strong>2001</strong><br />

Net sales in the period under review rose 3.9% from the previous<br />

fiscal year, to ¥849.1 billion, reflecting launches of new products,<br />

systems, services, and solutions, mainly in the digital imaging field,<br />

including e-Picture products. Of that total, ¥513.5 billion was<br />

generated by domestic sales, up 0.6%, and ¥335.6 billion was<br />

generated by exports, up 9.4%. Exports accounted for 39.5% of<br />

sales in the period under review. Recurring profit was ¥110.8<br />

billion, up 7.5%, and net income was ¥63.1 billion, up 6.8%.<br />

Performance per division was as follows.<br />

Imaging systems<br />

New product launches included the ZOOM MASTER 800 series<br />

with 4th Color Layer Technology—a unique Fujifilm color film<br />

technology—the SUPERIA 1600, and the FUJICHROME PROVIA<br />

100F and 400F series of color reversal films with the finest grain in<br />

the world.<br />

New camera launches included the NEXIA 4100ix Z, the world’s<br />

smallest and lightest APS camera with a 4x zoom lens, and the<br />

<strong>FUJIFILM</strong> KLASSE, an easy-to-use 35-mm compact camera with<br />

high image quality.<br />

In instant camera products, the Instax mini 20 and other models<br />

were added to the Cheki series.<br />

In digital cameras, such new launches as the FinePix 40 i, which<br />

can play MP3 audio, and the FinePix6800 Zoom, designed by <strong>The</strong><br />

Porsche Design Studio, were well received. Also, the FinePix<br />

“Picture the Future” system, which links digital cameras with the<br />

Internet, increased the fun and broadened the use of e-Pictures.<br />

In commercial-use videotape, Fujifilm enhanced its lineup of<br />

products with devices that are compatible with new digital formats.<br />

Sales in this division rose 9.5%, to ¥344.0 billion.<br />

Businesses<br />

Sales breakdown (parent only) for the fiscal year ended March 31, <strong>2001</strong><br />

Information systems<br />

◆Platemaking film<br />

◆PS plates<br />

◆Printing machinery<br />

◆X-ray film<br />

◆Medical imaging machinery<br />

◆Computer tape<br />

◆Electronic display materials, etc.<br />

Photofinishing systems<br />

42.5%<br />

17.0%<br />

40.5%<br />

Photofinishing systems<br />

◆Color printing paper<br />

◆Pictro-printing paper<br />

◆Developing chemicals<br />

◆Machinery<br />

◆Developing prints, etc.<br />

Imaging systems<br />

◆Color printing paper<br />

◆Motion picture film<br />

◆Cameras<br />

◆Digital cameras<br />

◆Videotape, etc.<br />

<strong>The</strong> Company enhanced its Frontier range of digital minilabs<br />

incorporating a proprietary, solid-state laser system. Using the FDi<br />

service, Fujifilm’s digital imaging service based on Frontier, the<br />

Company is expanding the on-line usage of digital image prints,<br />

enabling the creation of high-quality prints from digital film and digital<br />

cameras and the transfer of photo images onto CDs (FUJICOLOR<br />

CD). In this way, Fujifilm is facilitating the spread of e-Pictures.<br />

Net sales in this division totaled ¥144.6 billion, up 14.9% year<br />

on year.<br />

Information systems<br />

In equipment for printing and design systems, Fujifilm concentrated<br />

on computer-to-plate (CTP) systems for the digitization of printing<br />

processes. In diagnostic equipment, the Company launched its dry<br />

imager for digitizing X-ray images as well as the medical imaging<br />

network system SYNAPSE. In the mammography field, the<br />

Company launched the FCR5000MA system, which makes possible<br />

digital mammography image recording.<br />

In information system products, Fujifilm launched the Kassai<br />

series, which combines sophisticated thin-layer coating technology<br />

with fine chemical technology.<br />

In industrial materials, the Company enjoyed soaring sales of its<br />

FUJITAC, WV FILM, and TRANSER LCD materials.<br />

In data media, Fujifilm became the first company to launch<br />

Ultrium-use tape for upgrading and expanding memory volume<br />

based on Fujifilm’s proprietary Advanced Super-Thin-Layer and<br />

High-Output Metal Media (ATOMM) technology. In this field,<br />

Fujifilm has an industry-leading position. Net sales in the division<br />

totaled ¥360.5 billion, down 4.4% from the previous fiscal year.

◆ Outline of <strong>Environmental</strong> Activities<br />

1970 • Creation of Environment and Safety divisions at factories<br />

• Installation of activated sludge treatment facility at Ashigara Factory<br />

1971 • Creation of <strong>Environmental</strong> Management Department at Head Office<br />

1975 • Establishment of Fujifilm Material Safety Test Center<br />

1980<br />

1983 • Establishment of Fujifilm Green Fund Public Trust<br />

1986 • Launch of Fujicolor QuickSnap single-use camera<br />

1989 • Establishment of the <strong>Environmental</strong> Safety Countermeasures Promotion<br />

Committee<br />

• <strong>Environmental</strong> Management Division renamed the Environment and<br />

Safety Promotion Division<br />

1990<br />

Fujifilm Japan Overseas<br />

“inverse manufacturing system” for Fujicolor QuickSnap cameras<br />

2000<br />

1975 • Entry into effect of London Convention for the prevention of ocean<br />

pollution through the dumping of industrial and other waste<br />

• Entry into effect of the Washington Convention governing international<br />

trade in animals and plants considered to be in danger of extinction<br />

• Entry into effect of the Ramsar Convention for the protection of<br />

internationally important wetlands where waterfowl live<br />

• Entry into effect of the World Heritage Convention for the protection of<br />

cultural and natural heritage<br />

1989 • Exxon Valdez incident<br />

• Adoption of the Declaration of Helsinki (for the total abolition of<br />

specified CFCs)<br />

1990 • Establishment of the basic policy for environmental safety activities<br />

• Introduction of cogeneration facilities at Ashigara Factory<br />

• Fujicolor QuickSnap recycling center comes onstream (the establishment<br />

of a system for recovery)<br />

1990 • Action plan for combating global warming<br />

1991 • Compilation of guidelines for environment-friendly product development 1991 • Enactment of legislation to promote the regeneration of resources<br />

• Beginning of the mutual supply of recovered parts from single-use<br />

cameras with other companies<br />

• Introduction of cogeneration facilities at Fujinomiya Factory<br />

• Inclusion of Keidanren Global <strong>Environmental</strong> Charter<br />

1992 • Compilation of guidelines for safety, hygiene, and environmental<br />

1992 • Entry into effect of Basel Convention restricting the removal and disposal<br />

protection at Fujifilm factories<br />

of hazardous waste products beyond national borders<br />

• Launch of “inverse manufacturing system” for Fujicolor QuickSnap cameras<br />

• World Summit at Rio de Janeiro<br />

• Establishment of standards used for products with restricted substances<br />

• Amendment of Montreal Protocol<br />

1993 • Complete end of use of CFCs of any kind in manufacturing<br />

1993 • Enactment of basic environmental legislation, abolition of basic 1993 • Entry into effect of the Conventional Biological Diversity Agreement<br />

• Compilation of environment action plan<br />

legislation on pollution control<br />

• Approval of basic environmental plan<br />

1994 • Establishment of Fujifilm environmental management system standards<br />

• Establishment of Basic Policies on the Environment<br />

1995 • Entry into Japan Responsible Care Council<br />

• <strong>Environmental</strong> Protection Committee renamed Fujifilm Responsible Care<br />

Committee<br />

• Reuse and recycling of Fujicolor QuickSnap cameras begun at U.S. and<br />

European factories<br />

1970 • Enactment of water pollution legislation<br />

• Enactment of industrial waste processing and cleaning legislation<br />

1971 • Establishment of Environment Agency<br />

1995 • Enactment of Container and Packaging Recycling Law<br />

1994 • Entry into effect of the United Nations Convention to Combat<br />

Desertification (UNCCD)<br />

• Entry into effect of the Framework Convention on Climate Change<br />

1995 • First meeting of signatories to the Framework Convention on Climate<br />

Change (COP1) in Berlin, Germany<br />

1996 • Publication of Fujifilm’s first environmental report<br />

1996 • ISO international standards introduced<br />

• Second meeting of signatories to the Framework Convention on Climate<br />

Change (COP2) in Geneva, Switzerland<br />

1997 • Third meeting of signatories to the Framework Convention on Climate<br />

Change (COP3) in Kyoto, Japan<br />

1998 • Construction of “inverse manufacturing system” factory for Fujicolor 1998 • Enactment of legislation for the reuse of specified domestic appliances 1998 • Fourth meeting of signatories to the Framework Convention on Climate<br />

QuickSnap cameras<br />

• Enactment of legislation for the promotion of measures to control global<br />

Change (COP4) in Buenos Aires, Argentina<br />

• Signing of “<strong>Environmental</strong> Preservation Compliance Agreement” between<br />

Ashigara Factory and Minami-Ashigara City<br />

warming<br />

1999 • Drafting of Fujifilm’s Responsible Care management manual<br />

1999 • Enactment of special legislation for the control of dioxins<br />

1999 • Fifth meeting of signatories to the Framework Convention on Climate<br />

• Fujifilm wins the “Coexistence with the Community” prize in the<br />

• Enactment of the Chemical Substance Emission Management Promotion<br />

Change (COP5) in Bonn, Germany<br />

“Corporate Social Contribution Awards” sponsored by the Asahi<br />

Shimbun Foundation<br />

• Fujifilm wins the “Earth Environment Committee Award for Corporate<br />

Excellence” and the 8th “Global Environment Award” sponsored by the<br />

Japan Industrial Journal<br />

• Fujifilm wins the 17th “Superior Trendsetting Factories and Offices<br />

Special Award,” sponsored by the Nihon Keizai Shimbun Company, for its<br />

Law<br />

2000 • Fujifilm receives the fiscal 2000 “Excellent Consumer-Oriented Company 2000 • Full enactment of the Container and Packaging Recycling Law<br />

2000 • Sixth meeting of signatories to the Framework Convention on Climate<br />

Commendation” from the Minister of International Trade and Industry<br />

• Establishment of basic legislation to promote a recycling-oriented society<br />

Change (COP6) in the Hague, Netherlands<br />

• Introduction of cogeneration facilities at Yoshida-Minami Factory<br />

• Amendment of legislation relating to the disposal and cleansing of waste • Adoption of protocols relating to preparations of Rio+10 at the 8th<br />

• Regeneration and reuse of all waste products from raw material<br />

products (waste processing law)<br />

meeting of the U.N. Commission on Sustainable Development (CSD8)<br />

processing at the Yoshida-Minami and Fujinomiya factories and the<br />

• Amendment of legislation relating to the promotion of the reuse of • Publication of Sustainable <strong>Report</strong>ing Guidelines by the GRI<br />

Miyanodai Technology Development Center<br />

resources (recycling law)<br />

• Fujifilm wins the “Nikkei Superior Trendsetting Factories and Offices<br />

• Enactment of the law promoting the reuse of building materials<br />

Awards Millennium Award” sponsored by the Nihon Keizai Shimbun<br />

(construction recycling law)<br />

Company, for its “inverse manufacturing system” for Fujicolor QuickSnap • Enactment of the law to promote the reuse of waste food (waste food<br />

cameras<br />

reuse law)<br />

• Fujifilm wins the fiscal 2000 “Global Warming Prevention Activities<br />

• Enactment of law promoting environment-friendly procurement by public<br />

Ministerial Commendation” sponsored by the Environment<br />

bodies (Green Purchasing Law)<br />

Protection Agency<br />

• Publication by the Environment Protection Agency of guidelines for the<br />

establishment of environmental accounting systems<br />

<strong>2001</strong> • <strong>The</strong> “inverse manufacturing system” for Fujicolor QuickSnap cameras <strong>2001</strong> • Environment Protection Agency becomes Ministry of the Environment in <strong>2001</strong> • Publication of evaluation report in the IPCC Third Assessment <strong>Report</strong><br />

wins the 47th Okouchi Memorial Technology Prize sponsored by the<br />

an overhaul of Japan’s bureaucracy<br />

Okouchi Memorial Committee<br />

• Enactment of domestic appliance recycling legislation<br />

• Achievement of Zero Emissions of all waste products at Yoshida-Minami<br />

• Enactment of Green Purchasing Law<br />

Factory and Asaka Research Laboratories<br />

• Publication of environmental reporting guidelines (2000 edition) and<br />

• Yoshida-Minami Factory wins the fiscal 2000 “Prefectural Governor’s<br />

environmental performance benchmarks for businesses by the Ministry<br />

Award for Merit in Industrial Waste Disposal ”<br />

of the Environment<br />

3

<strong>FUJIFILM</strong> RESPONSIBLE CARE ACTIVITIES AND ACHIEVEMENTS<br />

Main Responsible Care Priorities in<br />

Fiscal 2000<br />

Arranging and strengthening management<br />

systems based on ISO 14001<br />

Enhancing risk management systems for chemical<br />

substances<br />

Enhancing chemical management systems to comply<br />

with the PRTR Law<br />

Enhancing Green Purchasing and Green Procurement<br />

systems<br />

Establishing an environmental accounting system<br />

Setting up a system for reducing the environmental<br />

impact of packaging<br />

Improvement of environmental and safety performance<br />

Reducing use of chemicals of environmental concern,<br />

reducing emissions, developing alternatives to pollutants<br />

Reducing emissions of VOCs into the atmosphere<br />

Reduction of waste volumes, reuse, and regeneration of<br />

resources to attain Zero Emission goals<br />

Promote energy conservation measures and carbon<br />

dioxide emission reduction measures<br />

Appropriate communication with the community<br />

Setting up a system to provide necessary environmental<br />

and safety information to customers through enhanced<br />

MSDS disclosure, etc.<br />

Publicizing Fujifilm’s Responsible Care activities<br />

through a more detailed environmental report and on<br />

Fujifilm’s Web site<br />

* Self-rating: satisfactory progress, some progress, unsatisfactory progress<br />

4<br />

Progress in Fiscal 2000<br />

We linked overseas subsidiaries with our recently completed chemical safety database.<br />

We amended in-house rules to clarify the management of environmental hormones and other chemical<br />

substances with unclear legal and pollutant status but that are the object of growing social concern.<br />

We included in this report information relating to certain chemicals not subject to the PRTR Law, and<br />

which are not PRTR-designated substances, which we are treating specially on our own initiative.<br />

We have rewritten all our Material Safety Data Sheets (MSDS), covering approximately 1,000 materials,<br />

to make them easier to understand, and have amended the content to bring it into conformity with PRTR<br />

and other legislation. Our MSDS can be seen on our home page: http://www.fujifilm.co.jp/msds<br />

We are working to reach our goal of 100% Green Purchasing and Green Procurement during fiscal 2003<br />

(in fiscal 2000, we achieved a Green Purchasing rate of 52% and a Green Procurement rate of 66%). We<br />

have set up a database to handle information relating to Green Purchasing, and are now able to calculate<br />

the Green Purchasing rate at seven business bases in Japan.<br />

With regard to Green Purchasing, we ask our suppliers of important base materials and parts to fill in a<br />

questionnaire, which we use as a basis for calculating Green Procurement rates.<br />

We established a new system for environmental accounting, using aggregated accounting. We included<br />

environmental accounting statistics for fiscal 2000 using this system in this report.<br />

We revised our standards in this area to bring us into clearer conformity with “reduce, reuse, and<br />

recycle” practices. In fiscal 2000, we reduced paper packaging in domestic sales 315 tons compared<br />

with fiscal 1999 and reduced the use of plastic containers and packaging 139 tons compared with fiscal<br />

1999 (based on Container and Packaging Recycling Law definition).<br />

We are working to revise standards and reduce emissions of Volatile Organic Chemicals (VOCs) into the<br />

atmosphere. Progress has also been made in reducing specified CFC use and liquid waste processing at<br />

customer sites.<br />

We are working toward a goal of reducing atmospheric emissions of VOCs by fiscal 2002 50%<br />

compared with fiscal 1996 levels. Over the last three years, we have reduced VOC emissions into the<br />

atmosphere 750 tons. Taking account of increases due to expanded production, we have brought<br />

emissions down from 3,300 tons in fiscal 1997 to 3,100 tons in fiscal 2000.<br />

Zero Emission targets have been reached for all waste products generated by the Yoshida-Minami<br />

Factory and Asaka Research Laboratories in fiscal 2000.<br />

Zero Emissions of waste products from industrial base materials have also been achieved at the<br />

Fujinomiya Factory and Miyanodai Technology Development Center.<br />

Full operation of cogeneration facilities at the Yoshida-Minami Factory from January 2000 has<br />

contributed to both energy saving and CO2 emission reduction. In fiscal 2000, our four domestic plants<br />

subject to grade one energy management guidelines of the Ministry of Economy, Trade and Industry<br />

achieved 4.4% savings in energy cost units, far in excess of the Ministry’s recommended 1%.<br />

We linked affiliated and overseas units to our proprietary MSDS database.<br />

In response to the enactment of the PRTR Law, the amendment of labor safety and hygiene legislation,<br />

and decrees on highly toxic chemicals, we redrafted all of the approximately 1,000 items in our MSDS to<br />

make them clearer and brought their content more closely in line with the law.<br />

<strong>The</strong> MSDS are listed on our home page at: http://www/fujifilm.co.jp/msds<br />

In the Fujifilm <strong>Environmental</strong> <strong>Report</strong> (1999 Fiscal Year Data Sheet) published in September 2000, we<br />

outlined our environmental protection achievements in fiscal 1999. More information on Fujifilm’s<br />

environmental activities can be found at:<br />

http://www.fujifilm.co.jp/kankyo/index.html<br />

We also publish site reports for the Ashigara and Fujinomiya factories.<br />

*Self-<br />

Rating<br />

See Pages<br />

11<br />

18, 19, 35<br />

12<br />

16, 17<br />

13<br />

11, 17, 18<br />

18, 19<br />

20, 21<br />

22, 23<br />

18, 35<br />

35, 36

ENVIRONMENTAL IMPACT OF <strong>FUJIFILM</strong>’S CORPORATE ACTIVITIES<br />

Discharge<br />

Resources Used<br />

Silver (thousand tons per year).............................................. 1.1<br />

Gelatin (thousand tons per year) ........................................... 4.3<br />

TAC (thousand tons per year)................................................ 11.9<br />

Aluminum (thousand tons per year)....................................... 47.5<br />

Paper container and packaging materials (tons per year) .... 8,406<br />

Plastic container and packaging materials (tons per year) ... 3,843<br />

Production Operations<br />

Waste materials for incinerators/landfill sites<br />

(thousand tons per year)...................................................... 4.6<br />

Recycling rate (%).................................................................. 92.8<br />

Energy source unit index ....................................................... 84.0<br />

(fiscal 1993=100 under energy-saving law)<br />

CO2 emissions (thousand tons per year) ............................... 639.1<br />

SOx emissions (tons per year)................................................ 467<br />

NOx emissions (tons per year) ............................................... 658<br />

Soot emissions (tons per year ).............................................. 28<br />

Chemical Oxygen Demand (COD) emissions<br />

(tons per year)...................................................................... 213<br />

Industrial-use water (million tons per year) ............................ 49<br />

Distribution<br />

Reductions in CO2 emissions in fiscal 1999 (tons)................. 208<br />

(based on data supplied by <strong>FUJIFILM</strong> Logistics Co., Ltd.)<br />

Products<br />

Imaging systems<br />

Color printing paper, motion picture film, cameras, digital<br />

cameras, videotape, etc.<br />

Photofinishing systems<br />

Color printing paper, Pictro-printing paper, developing chemicals,<br />

machinery, developing prints, etc.<br />

Information systems<br />

Platemaking film, presensitized plates, printing machinery, X-ray<br />

film, medical imaging machinery, computer tape, electronic<br />

display materials, etc.<br />

Waste<br />

5

CURRENT STATUS OF MEASURES AND FUTURE VISION<br />

A key principle of “Our Common Future,” published in 1987 by<br />

the United Nations’ World Commission on Environment and<br />

Development, is that “states shall conserve and use the<br />

environment and natural resources for the benefit of present and<br />

future generations.” This concept of sustainable development<br />

was evolved further in 1992, which saw the adoption of a global<br />

action plan for achieving sustainable development in the 21st<br />

century—Agenda 21—at the Earth Summit held in Rio de<br />

Janeiro. In recent years, environmental initiatives around the<br />

world have generally followed Agenda 21’s lead in emphasizing<br />

sustainable development.<br />

6<br />

Fujifilm will continue to conduct its business in the interests of<br />

global sustainable development, following its three-pronged<br />

policy of constantly giving due consideration to the natural<br />

environment, ensuring safety with regard to chemicals, and<br />

preventing the wasteful use of resources (source reduction).<br />

Another key concept of the 21st century will be eco-efficiency,<br />

which can be calculated using a formula in which environmental<br />

burden is expressed as a ratio of a product’s quality, function,<br />

and the services it renders—in other words, environmental<br />

burden as measured over the product’s full life cycle. If the<br />

environmental burden is a certain fraction of the cost of product<br />

development, manufacture, and marketing, cost-efficiency is<br />

achieved. Continually raising cost-efficiency and eco-efficiency<br />

can be said to be the foundation of Fujifilm’s environmental<br />

activities in the 21st century.<br />

Our goal is to reduce the environmental burden of Fujifilm<br />

products and production activities and bring our operations in<br />

line with reduce, reuse, and recycle practices to the greatest<br />

possible extent. By continually raising the eco-efficiency of<br />

products created as part of our basic Imaging & Information<br />

philosophy, we believe we are contributing to the cause of<br />

sustainable development in the global environment. Fujifilm will<br />

continue to seek ways of raising eco-efficiency in all of its<br />

production processes, from R&D to waste disposal.<br />

Below are examples of measures taken to date to raise eco-<br />

efficiency:<br />

1) Reduction of the volume of silver used in photosensitized<br />

materials for photography<br />

Over approximately 20 years, Fujifilm has reduced the amount of<br />

silver used in color negative film by more than half, and the<br />

amount of silver used in color print paper by around two-thirds.<br />

Naturally, we continued to enhance product performance even<br />

as we reduced silver levels. Photosensitized materials for<br />

photography are the product of a reaction of silver nitrate and<br />

halogen compounds in a gelatin aqueous solution. However,<br />

very small changes in the type of halogen compound, mix of the<br />

aqueous solution, type of gelatin, or temperature can have a<br />

major impact on the quality of the photo. Only by achieving a<br />

very careful mix of these variables is it possible to create high-<br />

performing photosensitized materials for photography with very<br />

small amounts of silver.<br />

2) Reduction of the amount of developer needed for color<br />

paper print films<br />

Over approximately 10 years, Fujifilm has reduced the volume of<br />

developer needed for color negative prints by more than half,<br />

and for color paper prints by four-fifths. This too is a result of a<br />

general review and improvement of the mix of constituents of<br />

photosensitized materials as well as of the capabilities of<br />

developing equipment. <strong>The</strong>se measures have enabled us to<br />

greatly reduce the amount of liquid waste from developing<br />

processes.<br />

3) Energy-saving design for Fujicolor QuickSnap<br />

Since the launch of the Fujicolor QuickSnap, single-use camera<br />

bodies have become slimmer and smaller, and other continual<br />

design improvements have been undertaken. Current models<br />

are approximately half the weight of the first Fujicolor QuickSnap.<br />

In addition to such resource reduction policies, Fujifilm aims<br />

to create products with still higher eco-efficiency through<br />

environment-friendly designs.

RESPONSIBLE CARE POLICIES, ORGANIZATION, AND MANAGEMENT<br />

What is Responsible Care?<br />

Responsible Care is an effort to ensure “environmental<br />

preservation, safety, and health” throughout the entire life cycle<br />

of a product by means of voluntary management efforts by<br />

business operators. In more concrete terms, Responsible Care is<br />

an effort to which each country of the world is devoting itself and<br />

whose main points are: a) the making of a pledge, in one’s<br />

operational policy, to ensure environmental preservation and<br />

safety throughout the total business process, from product<br />

development through production, distribution, and use to waste<br />

disposal; b) the implementation of countermeasures; and c) the<br />

planning of improvements. <strong>The</strong> comprehensive effort, referred to<br />

Responsible Care and ISO 14001<br />

Fujifilm’s basic philosophy in its environmental stance is realizing<br />

the goals of Responsible Care through the establishment of and<br />

adherence to management norms that conform with ISO 14001<br />

standards. Fujifilm has a policy of setting even tougher targets in<br />

Fujifilm’s Responsible Care Procedures<br />

◆ Implementation of Fujifilm<br />

Responsible Care Audits<br />

◆ Review of High-Priority<br />

Implementation Items by<br />

Fujifilm Responsible Care<br />

Committee<br />

◆Taking Corrective Measures<br />

Audits and Assessments<br />

Creation of <strong>Report</strong>s<br />

◆ Creation of Responsible Care<br />

Annual <strong>Report</strong>s by Each<br />

Organization<br />

◆ Creation of Implementation<br />

<strong>Report</strong>s by the Specified Issues<br />

Promotion Committees<br />

◆ Distribution of the <strong>Environmental</strong><br />

<strong>Report</strong><br />

◆ Public Disclosure of Performance<br />

by Each Organization and<br />

Dialogues with Communities<br />

◆ Public Disclosure of Information<br />

via the Internet<br />

as Responsible Care, that comprises these main points is based<br />

on a foundation of self-determination and self-responsibility on<br />

the part of business operators.<br />

<strong>The</strong> Japan Chemical Industry Association established the<br />

Japan Responsible Care Council in 1995. Fujifilm immediately<br />

took a Japan Responsible Care Council Responsible Care<br />

Implementation Oath and became a member. In order to ensure<br />

the preservation of the beauty of nature and her valuable<br />

resources, we established a Fujifilm Responsible Care Policy<br />

and are earnestly devoting ourselves to the efforts set forth in<br />

that policy.<br />

its voluntary environmental initiatives than those required by law.<br />

We pursue continuous improvement by repeating the PDCA cycle<br />

through the effective use of ISO 14001 standards as a<br />

management tool.<br />

Company President’s Oath<br />

Establishment of Policy<br />

ACT<br />

CHECK PLAN<br />

DO<br />

Implementation<br />

Public Announcement of<br />

Results & Dialogues with<br />

Communities<br />

◆ Fujifilm Responsible Care Committee<br />

◆ Specified Issues Promotion Committees<br />

◆ Environment and Safety Divisions at<br />

Business Locations (under the Jurisdiction<br />

of the Fujifilm Responsible Care<br />

Committee)<br />

Arrangement of Systems<br />

Establishment of Implementation Plans<br />

◆Establishment of Implementation Plans by<br />

Specified Issues Promotion Committees<br />

◆Establishment of Responsible Care<br />

Measures by Each Organization<br />

◆ Execution of Implementation Plans by<br />

Specified Issues Promotion Committees<br />

◆Promotion of Responsible Care<br />

Implementation Plans by Each Organization<br />

7

8<br />

<strong>The</strong> Fujifilm Responsible Care Policy for Fiscal <strong>2001</strong><br />

1. Fundamental Policy<br />

Through voluntary, continuous dedication to Responsible Care<br />

efforts, each and every employee will strive to realize a “sound<br />

Fujifilm committed to environmental protection and safety.”<br />

2. Action Guidelines<br />

(A) Consider environmental, economic, and social aspects and<br />

devote ourselves to measures for ensuring sustainability.<br />

(B) Comply with the law and all other agreed-upon requirements.<br />

(C) Strive to reduce environmental impact and ensure safety by<br />

taking into consideration every stage of the product life<br />

cycle, including selection and procurement of raw materials,<br />

manufacturing, distribution, product use, and product<br />

disposal.<br />

(D) Achieve Zero Emissions.<br />

(E) Conduct operations with no accidents and no disasters.<br />

(F) Actively provide information, maintain appropriate<br />

communication, and strengthen partnerships with concerned<br />

parties outside the Company.<br />

3. Priority Implementation Items<br />

(A) Organizing and Strengthening Management Systems<br />

Based on ISO 14001 Standards<br />

(a) Continuously improve our management of chemical<br />

substances.<br />

(b) Strengthen our “Green Purchasing” and “Green<br />

Procurement” systems for raw materials, machines,<br />

fixtures, supplies, etc.<br />

(c) Construct environmental accounting systems.<br />

(d) Establish a system for reducing environmental impact<br />

related to containers and packaging.<br />

(e) Establish a management system for environment-<br />

conscious designing.<br />

(f) Establish a management system for Responsible Care<br />

education.<br />

(B) Improvement of <strong>Environmental</strong> and Safety Performance<br />

(a) Mitigate risk by reducing usage of chemical substances of<br />

concern, reducing emissions, and developing alternative<br />

substances, etc.<br />

(b) Reduce the amount of volatile organic compounds emitted<br />

into the air. *1<br />

(c) Promote the reduction of waste disposal, reuse, and<br />

recycling and achieve Zero Emissions. *2<br />

(d) Promote energy conservation and measures for reducing<br />

carbon dioxide emissions. *3<br />

(e) Strengthen environmental monitoring at manufacturing sites.<br />

Quantitative Performance Goals for Fuji Photo Film, Ltd.<br />

*1 Reduce the amount of volatile organic compounds emitted into the air 50%<br />

by the fiscal year 2002 (compared with fiscal year 1996).<br />

*2 Reduce waste material incinerated or disposed of in landfills at each site to<br />

zero by fiscal year 2002.<br />

*3 Implement measures to reduce carbon dioxide emissions by at least 51,000<br />

C tons /year, by fiscal year 2010. (This reduction amount is equivalent to<br />

26% of the amount of carbon dioxide emitted in fiscal year 1998.)<br />

(C) Ensuring Appropriate Communication and Strengthening<br />

Partnerships with Concerned Parties outside the Company<br />

(a) Establish systems for appropriately providing necessary<br />

environmental and safety information to concerned parties<br />

outside the Company, such as utilizing MSDS for<br />

information disclosure.<br />

(b) Enrich contents of environmental reports, issue site<br />

reports, utilize Fujifilm’s Web site to adequately and<br />

actively communicate the Company’s Responsible Care<br />

efforts to the public.<br />

(c) Actively cooperate with governmental and industrial<br />

activities as well as participate in community activities.

◆ Fujifilm Responsible Care Organization and Management<br />

As a manufacturer handling chemical products, Fujifilm has been<br />

involved in environmental initiatives from an early stage. In 1970, it<br />

set up environmental and safety management divisions in its<br />

factories and in its headquarters in 1971. Currently, the Company<br />

has environment and safety officers deployed in every business<br />

and research facility who are responsible for key line organizations.<br />

Furthermore, in 1989 an environment and safety committee<br />

was established as a cross-organization executive-level body to<br />

<strong>The</strong> Fujifilm Responsible Care Promotion System<br />

Linear Organization (Organization by Vertical Order)<br />

Company<br />

President<br />

Director in Charge of<br />

the Environment<br />

General Manager of<br />

Each Marketing Division<br />

General Manager of<br />

Each Factory<br />

General Manager of Each<br />

Business Location<br />

General Manager of Each<br />

Research Laboratory<br />

Committee Organization (Organization by Horizontal Order)<br />

Fujifilm Responsible Care Committee<br />

Committee Chairman Director in Charge of the<br />

Environment (Senior<br />

Vice President)<br />

Members Concerned Executive<br />

Officers<br />

Secretariat General Manager of the<br />

<strong>Environmental</strong> Protection &<br />

Products Safety Division<br />

promote environmental and safety issues across the Group. In<br />

1995, this committee became the Fujifilm Responsible Care<br />

Committee when the Company joined the Japan Responsible<br />

Care Council, and set clear Responsible Care goals for the<br />

Company. Action teams have been set up under the Fujifilm<br />

Responsible Care Committee to further Responsible Care<br />

interests across the Company.<br />

<strong>Environmental</strong> Protection<br />

& Products Safety Division<br />

Division in Charge of<br />

Environment & Safety<br />

Material Safety<br />

Test Center<br />

Person(s) in Charge of<br />

<strong>Environmental</strong> Affairs<br />

Environment &<br />

Safety Department<br />

Person(s) in Charge of<br />

<strong>Environmental</strong> Affairs<br />

Person(s) in Charge of<br />

<strong>Environmental</strong> Affairs<br />

Specified Issues Promotion Committees<br />

• Green Purchasing Promotion Committee<br />

• Committee for the Promotion of the Green<br />

Procurement of Raw Materials<br />

• Zero Emissions Promotion Committee<br />

• Energy-Saving and Carbonic Gas Reduction<br />

Promotion Committee<br />

• Packaging Responsible Care Promotion Committee<br />

• Promotion Committee for Setting Basic Principles for<br />

<strong>Environmental</strong> Accounting<br />

• Promotion Committee for Establishing Methods for<br />

Life Cycle Assessment (LCA) Standards<br />

• Fujifilm Responsible Care Educational Activities<br />

Committee<br />

• Promotion Committee for Establishing<br />

<strong>Environmental</strong> Accounting Systems<br />

Fujifilm Responsible Care Audit Committee<br />

9

◆ Current Status of Acquisition of ISO 14001 Certification<br />

Fujifilm has long regarded acquisition of ISO 14001 certification<br />

as a priority in its Responsible Care program and has been active<br />

in this area from an early stage. <strong>The</strong> first facility was certified in<br />

August 1996. By January 1997, all four factories in Japan had<br />

been certified, and we are now working to acquire the<br />

certification of domestic and overseas subsidiaries and affiliates.<br />

In fiscal 2000, two more business locations acquired certification,<br />

bringing the total number of certified sites to 23. ISO 14001<br />

10<br />

Current Status of Acquisition of ISO 14001 Certification<br />

◆ Certified sites in Japan: 15<br />

■ Fuji Photo Film Co., Ltd.<br />

Fujinomiya Factory (August 1996)<br />

<strong>The</strong> manufacture of the paper base for photographic<br />

prints, information recording paper (pressure-sensitive<br />

and thermo-sensitive paper), X-ray film, etc.<br />

■ Fuji Photo Film Co., Ltd.<br />

Yoshida-Minami Factory (January 1997)<br />

<strong>The</strong> research, development, and manufacture of the<br />

platemaking materials (PS plates) used in offset printing<br />

■ Fujifilm Arch Co., Ltd.<br />

Shizuoka Factory (June 1998)<br />

<strong>The</strong> manufacture and marketing of photoresists for<br />

semiconductors, color filter materials for LCDs, and<br />

other such photosensitized materials for the electronics<br />

industry<br />

■ Fuji Photo Film Co., Ltd.<br />

Ashigara Factory (December 1996)<br />

<strong>The</strong> manufacture of photosensitized materials for<br />

photography, such as films and print paper, as well as<br />

industrial materials<br />

■ Fuji Photo Film Co., Ltd.<br />

Odawara Factory (October 1996)<br />

<strong>The</strong> manufacture of recording media, silver nitrate,<br />

photographic chemicals, and film for LCDs<br />

◆ Certified sites overseas: 8<br />

■ Fuji Magnetics G.m.b.H.<br />

(Germany) (October 1999)<br />

<strong>The</strong> manufacture and marketing of recording media products<br />

■ Fuji Photo Film B.V.<br />

(Holland) (November 1997)<br />

<strong>The</strong> manufacture of films and platemaking materials (PS plates)<br />

■ Okaya Fuji Koki Co., Ltd. (March 1998)<br />

<strong>The</strong> assembly of photographic and printing equipment<br />

and the processing of precision plate metals<br />

■ Fuji Photo Film Co., Ltd.<br />

Miyanodai Technology Development Center (March 1998)<br />

<strong>The</strong> R&D of equipment for medical imaging diagnosis,<br />

color photos, and printing systems<br />

■ Fuji Photo Equipment Co., Ltd. (March 1998)<br />

<strong>The</strong> development of imaging systems for the medical,<br />

printing, and imaging fields as well as the manufacture<br />

of functional packaging materials for photography<br />

■ Fuji Graphic Systems Canada, Inc.<br />

(Canada) (December, 1998)<br />

<strong>The</strong> marketing of PS plates used in printing<br />

<strong>The</strong> following business locations acquired ISO 14001 certification in fiscal <strong>2001</strong><br />

certification has also been acquired by Panac Industries, Inc., a<br />

partner company that recovers and recycles film base materials<br />

and silver, and by Nankai Co., Ltd., to which we consign recovery<br />

and processing of used Fujicolor QuickSnap single-use cameras.<br />

We are preparing to obtain certification for our marketing and<br />

logistics companies, and in 2003, we plan to obtain ISO 14001<br />

certification through a single environmental management system<br />

(EMS) for the whole Group.<br />

■ Fujifilm Imaging Systems (Suzhou) Co., Ltd.<br />

(China) (October 2000)<br />

■ Fuji Photo Film da Amazonia, Ltda.<br />

(Brazil) (November 1998)<br />

<strong>The</strong> manufacture of photosensitized materials for photography<br />

(as of June 30, <strong>2001</strong>)<br />

■ Fuji Hunt Photographic Chemicals Pte. Ltd. (Singapore) (April <strong>2001</strong>)<br />

<strong>The</strong> manufacture and marketing of chemicals for photosensitized materials used in<br />

photography, etc.<br />

■ Fuji Photo Film Canada, Inc. (Canada) (June <strong>2001</strong>)<br />

<strong>The</strong> marketing of photosensitized materials for photography, etc.<br />

■ Fuji Magne-Disk Co., Ltd. (Chofu City, Tokyo) (June <strong>2001</strong>)<br />

<strong>The</strong> manufacture of floppy disks and CD-ROMs as well as computer-media user<br />

services<br />

Sites that acquired<br />

certification in fiscal 2000<br />

<strong>The</strong> dates in parentheses show<br />

when certification was acquired.<br />

■ Sano Fuji Koki Co., Ltd. (March 1998)<br />

<strong>The</strong> machine processing and assembly of precision<br />

equipment as well as the design and special processing<br />

of metal molds for various optical parts<br />

■ Fujifilm Photonix Co., Ltd. (April 1999)<br />

<strong>The</strong> manufacture of such electronic imaging equipment<br />

as digital still cameras<br />

■ Fujifilm Microdevices Co., Ltd. (March 2000)<br />

<strong>The</strong> manufacture of such large-scale integration (LSI)<br />

products as charge-coupled devices (CCDs) for digital<br />

cameras and image signal processing ICs for the<br />

construction of digital imaging and multimedia systems<br />

■ Mito Fuji Koki Co., Ltd. (January 1998)<br />

<strong>The</strong> assembly of medium-sized cameras and the<br />

processing and assembly of lenses<br />

■ Fuji Photo Optical Co., Ltd. (January 1998)<br />

<strong>The</strong> production of cameras and photographic and<br />

printing equipment as well as the production and<br />

marketing of such optical equipment as lenses<br />

and medical equipment<br />

■ Fuji Photo Film Co., Ltd.<br />

Asaka Research Laboratories (March 1999)<br />

<strong>The</strong> research, development, and manufacture of clinical<br />

examination systems utilizing the medical diagnostic<br />

film format<br />

■ Fuji Technics Co., Ltd. (April 2000)<br />

Processing of industrial-use light-sensitive materials,<br />

such as information processing pressure-sensitive and<br />

thermo-sensitive paper, printing-use markup film, and<br />

industrial-use X-ray film<br />

■ Fuji Hunt Photographic Chemicals, Inc.<br />

(USA) (September 1997)<br />

<strong>The</strong> production and marketing of photoprocessing chemicals<br />

■ Fuji Photo Film, Inc.<br />

(USA) (April 1999)<br />

<strong>The</strong> manufacture of films, PS plates used in offset printing, and<br />

videotape<br />

■ Fuji Photo Film do Brasil, Ltda.<br />

(Brazil) (December 1998)<br />

<strong>The</strong> manufacture of photosensitized materials for photography<br />

<strong>The</strong> increase in the number of business sites reflects a broadening of the<br />

scope of certification compared with the Fujifilm <strong>Environmental</strong> <strong>Report</strong> 2000.

ASSESSMENT OF THE SAFETY OF CHEMICAL SUBSTANCES<br />

Safety Testing at the Fujifilm Material Safety Test Center<br />

At our Material Safety Test Center, which was established in<br />

1975, diverse safety tests are carried out for all of the chemical<br />

substances in use at Fujifilm. When new chemical substances<br />

are produced, we report the appropriate safety test data, and<br />

the substances are examined and registered by the Ministry of<br />

Economy, Trade and Industry and the Ministry of Health, Labor<br />

and Welfare in accordance with the “Law Concerning the<br />

Examination and Regulation of Manufacture, etc., of Chemical<br />

substances” and by the Ministry of Health, Labor and Welfare in<br />

accordance with the “Labor Safety and Health Law.” At our<br />

overseas business locations as well, chemical substances<br />

undergo similar statutory examinations. Our Material Safety Test<br />

Center has been certified as meeting the Good Laboratory<br />

Practice (GLP) standards of the Ministry of Economy, Trade and<br />

Industry and the Ministry of Health, Labor and Welfare.<br />

Safety Tests<br />

◆ Ames Test ◆ Skin Irritation Test<br />

◆ Chromosomal ◆ Skin Sensitization Test<br />

Aberration Test ◆ Biodegradation Test<br />

◆ Micronucleus Test ◆ Bioaccumulation Test<br />

◆ Acute Toxicity Test<br />

◆ Subacute Toxicity Test<br />

◆ Explosion Danger Test<br />

Risk Management Based on Our Database<br />

Safety Testing<br />

Review<br />

Examination of Hazards and<br />

Legal Aspects<br />

Risk Management<br />

Classification<br />

Risk Assessment<br />

Risk Management<br />

Fujifilm has developed a proprietary database containing<br />

information on Japanese and overseas legal provisions for more<br />

than 70,000 commonly found chemical substances. In fiscal<br />

2000, we completed our database for the safety classification of<br />

chemical substances used by Fujifilm and linked overseas<br />

subsidiaries with it. Based on this database and other resources,<br />

we carried out a four-level safety standard ranking (C1-C4) of the<br />

roughly 3,600 chemical substances in use at Fujifilm, in<br />

accordance with the “Basic Provisions for the <strong>Environmental</strong> and<br />

Safety Management of Chemical Substances” established by<br />

Fujifilm. In fiscal 2000, we revised this principle so that it not only<br />

covers the hazards and legal aspects of chemical substances<br />

but also lays down management practices for chemical<br />

substances of rising social concern, such as environmental<br />

hormones. In the case of chemicals vital to our operations, we<br />

carry out priority risk evaluations and make continual changes<br />

Biodegradation test<br />

Chromosomal aberration test<br />

Chemical and <strong>Environmental</strong> Safety<br />

Information Database<br />

Access<br />

Contents of the Chemical and <strong>Environmental</strong> Safety<br />

Information Database<br />

(1) Laws in Japan, the United States, and Europe, including<br />

ordinances in each state of the United States as well as Europe<br />

(2) Toxicity, ignitability, and other hazards<br />

(3) Physiochemical properties<br />

Database<br />

We have established<br />

a four-level safety<br />

standard ranking for<br />

chemical substances.<br />

and improvements to their management in line with ISO 14001<br />

standards. In fiscal <strong>2001</strong>, we broadened the scope of<br />

application of the “Basic Provisions for the <strong>Environmental</strong> and<br />

Safety Management of Chemical Substances” and began<br />

introducing a single unified standard for chemical substances for<br />

Fujifilm Group bases in Japan and abroad as they develop their<br />

business globally.<br />

Fujifilm Chemical Substance Risk Classification<br />

C1 C2 C3 C4<br />

Specialmanaged<br />

Prohibited Use prohibited — — —<br />

Restricted Subject to risk-avoidance directives<br />

and/or special restrictions<br />

— —<br />

Risk-managed Risk management according<br />

to established procedure<br />

—<br />

General-managed Managed according to<br />

internal-use MSDS<br />

11

GREEN PURCHASING AND GREEN PROCUREMENT<br />

In February 2000, the Fujifilm Group announced the launch of<br />

Green Purchasing and Green Procurement activities. In<br />

purchasing raw materials and items for everyday operation,<br />

making the right choice of supplier and product type are<br />

important factors in environmental preservation. Among the<br />

economic activities of any company, purchasing and<br />

procurement also have environmental aspects that have to be<br />

taken into account. In light of this, we are vigorously pursuing<br />

Green Purchasing and Green Procurement.<br />

At Fujifilm, a Green Purchasing Promotion Committee and a<br />

Committee for the Promotion of the Green Procurement of Raw<br />

Materials have been set up under the Fujifilm Responsible Care<br />

Committee as Specified Issues Promotion Committees. In fiscal<br />

2000, the Committee for the Promotion of the Green Procurement<br />

of Raw Materials researched ordered materials and parts<br />

through a questionnaire sent to suppliers. <strong>The</strong> questionnaire was<br />

sent to suppliers who, altogether, accounted for 70% of the total<br />

value of all materials and parts purchased (including chemical<br />

feedstock) and 80% of packaging materials purchased.<br />

Suppliers were assessed according to 14 measurements,<br />

including the observance of environmental safety legislation and<br />

avoidance of use of specially classified chemical substances in<br />

their raw materials. <strong>The</strong> Green Procurement Rate reflects the<br />

proportion of suppliers who met these requirements; at the end<br />

of fiscal 2000 it stood at 66%. <strong>The</strong> Committee for the Promotion<br />

of the Green Procurement of Raw Materials is aiming for 100%<br />

Green Procurement in parts and materials, including chemical<br />

feedstock, and packaging materials by the end of fiscal 2003.<br />

<strong>The</strong> Green Purchasing Promotion Committee applies its Green<br />

Purchasing Rate to Fujifilm’s seven Japanese production and<br />

research locations (Fujifilm Tokyo head office, four factories, and<br />

two R&D laboratories). <strong>The</strong> rate, which is calculated by processing<br />

database information, was 52% at the end of fiscal 2000. <strong>The</strong><br />

Committee aims to achieve a Green Purchasing rate of 100% by the<br />

end of fiscal 2003. It is also encouraging the purchase of certain<br />

substances not included in the calculation of the Green Purchasing<br />

rate. Fujifilm plans to expand the Green Purchasing monitoring<br />

program to marketing businesses and affiliates in Japan.<br />

What are Green Purchasing and<br />

Green Procurement?<br />

Market<br />

Continuous improvement<br />

Company with good environmental protection record<br />

12<br />

• Products with low<br />

environmental burden<br />

• Eco-design<br />

Preferential purchase<br />

Assessment of corporate environment<br />

Green Procurement Rate<br />

<strong>The</strong> proportion of Fujifilm suppliers meeting Green Procurement<br />

standards set by the Committee for the Promotion of the Green<br />

Procurement of Raw Materials is assessed based on the results<br />

of a questionnaire. <strong>The</strong> questionnaire is sent out by Fujifilm, Fuji<br />

Photo Equipment Co., Ltd., and Fuji Photo Optical Co., Ltd.<br />

Green Purchasing Rate<br />

This rate is the proportion of funds spent on environmentally<br />

sound products compared with total purchasing expenditures.<br />

Products covered by the Green Purchasing Ratio include office<br />

equipment, printing paper, copiers, printers, fax machines, PCs,<br />

stationery, office-use materials, and everyday products.<br />

Quality/price/<br />

function/safety<br />

+<br />

Environment<br />

<strong>Environmental</strong>ly aware consumers<br />

<strong>The</strong> Fujifilm Group’s Green Purchasing and<br />

Procurement handbook<br />

Green<br />

Purchasing<br />

Green<br />

Procurement<br />

Putting priority on environmentfriendliness<br />

when buying<br />

products or services<br />

Procurement of materials<br />

and parts that have little<br />

environmental impact from<br />

suppliers who take care to<br />

respect the environment

ENVIRONMENT-FRIENDLY CONTAINERS AND PACKAGING<br />

1. <strong>The</strong> Container and Packaging Recycling Law<br />

On April 1, 2000, Japan’s Container and Packaging Recycling<br />

Law came into full effect. This law is designed to reduce the<br />

volume of container and packaging materials, which account for<br />

some 60% by volume of all household garbage, and encourage<br />

the recycling of garbage into reusable materials.<br />

Fujifilm products use large amounts of paper and plastic<br />

packaging of the type designated for compulsory recycling by<br />

the law. <strong>The</strong>refore, we have decided to assume the expenses of<br />

calculating what volume of packaging needs to be recycled<br />

under the law and of entrusting the recycling work to Japan<br />

Container and Packaging Recycling Association.<br />

2. Progress in Reducing Container and Packaging Garbage<br />

<strong>The</strong> basic policy of reducing packaging waste consists of the<br />

3Rs, reduce, reuse, and recycle. Fujifilm applies these principles<br />

as effectively as possible according to the nature of the product;<br />

however, it places priority on reduction, to keep the environmental<br />

burden to a minimum.<br />

◆ Example of reduction<br />

Fujifilm has stopped using plastic cases for APS films and has<br />

substituted them with aluminum steam-adhesive packaging to<br />

reduce the environmental burden. <strong>The</strong> changeover was<br />

completed in May <strong>2001</strong>.<br />

◆ Example of reuse<br />

We reuse cartridges (developing and fixing solution containers)<br />

for the CEPROS automatic developing system for medical-use<br />

film, after recovering them from hospitals all over the country and<br />

cleaning and inspecting them.<br />

◆ Example of recycling<br />

Plastic film cases are recovered from large laboratories,<br />

shredded, and reused as base materials for other Fujifilm<br />

products.<br />

In fiscal 2000, we reduced the volume of paper containers and<br />

packaging generated by domestic marketing activities by 315<br />

tons and the volume of plastic containers and packaging by 139<br />

tons (in both cases, compared with fiscal 1999, and based on the<br />

definitions of the Container and Packaging Recycling Law).<br />

3. Further Reducing Packaging<br />

• Standards for the assessment of the environmental impact of<br />

packaging<br />

In 1995, Fujifilm established standards for assessing the<br />

environmental burden of its packaging in semi-quantifiable<br />

terms. In <strong>2001</strong>, this standard was revised, making possible<br />

clearer comparisons of old and new products and furthering the<br />

cause of reducing the environmental burden.<br />

• Container and packaging database<br />

Before, container and packaging databases were operated<br />

separately by each department, but now a single system serving<br />

the whole Company is under development. This will make it<br />

possible to integrate packaging material purchase management<br />

systems and LCA inventory data, helping us create more<br />

environment-friendly designs for containers and packaging. <strong>The</strong><br />

system is scheduled to come on stream in 2002.<br />

Volumes of containers and packaging used in Japan<br />

(Tons)<br />

10,000<br />

8,000<br />

6,000<br />

4,000<br />

2,000<br />

0<br />

8,701<br />

4,283<br />

8,721<br />

1998 1999<br />

3,982<br />

Paper containers and packaging<br />

Plastic containers and packaging<br />

8,406<br />

3,843<br />

2000<br />

(Fiscal year)<br />

13

ENVIRONMENT-FRIENDLY DESIGN AND LCA<br />

1. What is Environment-Friendly Design?<br />

Since its foundation, Fujifilm has always stressed environment-<br />

friendliness and safety in its own operations and with respect to<br />

the product user. We have also made every effort to save<br />

resources by following the 3R principle, as typified by our<br />

Fujicolor QuickSnap single-use camera. In fiscal <strong>2001</strong>, based on<br />

our experiences, we made our basic environment-friendly design<br />

principles and LCA practices still more thoroughgoing with<br />

regard to environment-friendliness, as detailed below.<br />

1) We are prioritizing and enhancing environmental quality to<br />

create even higher-quality products.<br />

2) We are working to introduce environment-friendly design<br />

based on the 3Rs, risk assessment, and LCA at all stages of a<br />

product’s life cycle, from the purchase of raw materials through<br />

manufacture, distribution, use, discarding, and final disposal. We<br />

are assessing the degree to which environment-friendly design<br />

standards are met at every stage of product development.<br />

3) We are establishing a unified LCA procedure for the whole<br />

Company, for use in evaluation purposes at every stage of<br />

product development, and whenever changes are made to<br />

production methods.<br />

2. Environment-Friendly Design over Full Life Cycle of a Product<br />

14<br />

Purchase Manufacture Packaging Distribution Use<br />

3. LCA Program (software currently under development)<br />

Reuse/Recycle Transportation<br />

Discarding Final Disposal

ENVIRONMENTAL EDUCATION AND AWARENESS-RAISING ACTIVITIES<br />

Fujifilm Responsible Care Educational Activities<br />

<strong>The</strong> Fujifilm Organizing Committee for Responsible Care Education<br />

Programs, a standing committee under the Fujifilm Responsible Care<br />

Committee, plans and promotes environmental educational activities<br />

throughout the Company. It carefully monitors societal attitudes<br />

toward the environment and, each fiscal year, drafts educational<br />

programs for the whole Company. <strong>The</strong>se programs consist of an<br />

introductory course for new employees, a course for management<br />

staff, a course for EHS technical staff, and a course for regular<br />

employees. Topics covered in the introductory course are the history<br />

of Fujifilm’s Responsible Care activities and its stance toward current<br />

and future environmental issues. In the managers’ course, topics<br />

covered include overall trends inside and outside the Company<br />

relating to Responsible Care matters as well as the enactment and<br />

amendment of legislation. <strong>The</strong> course of EHS technical staff deals<br />

with Fujifilm’s rules for managing chemical substances and database<br />

operation as well as associated legal issues. In this way, Fujifilm is<br />

working to raise environmental awareness throughout the Company.<br />

<strong>The</strong>se courses are conducted every fiscal year. <strong>The</strong> results are<br />

reported to the Committee and are reflected in the programs for the<br />

following fiscal year after due deliberation.<br />

Fujifilm Responsible Care Policy Notices<br />

To ensure all employees are aware of Fujifilm Responsible Care<br />

Committee’s policies, posters displaying Responsible Care<br />

information are compiled and hung up in every office. In fiscal<br />

<strong>2001</strong>, these posters were also displayed at subsidiaries, in line<br />

with the expansion of the scope of the Fujifilm Responsible Care<br />

Committee’s policies.<br />

<strong>Environmental</strong> Educational Activities in Factories<br />

Fujifilm has developed its own educational program for raising<br />

the awareness of environmental safety in factories, where<br />

workers are confronted with many more environmental issues<br />

than elsewhere in the Company. <strong>The</strong> Ashigara Factory compiles<br />

an environmental handbook, organizes environmental protection<br />

weeks to enhance education, and publishes a quarterly<br />

newsletter, “EA Ashigara.” <strong>The</strong> Fujinomiya Factory regularly<br />

publishes an environment manual and a newsletter, “Green<br />

Fujinomiya,” and bases its environmental education activities on<br />

these publications. It also organizes an environmental protection<br />

month (June), in which priorities are established and the<br />

environmental awareness of all employees is raised through<br />

various activities.<br />

Fujifilm Responsible Care policy notices<br />

15

ENVIRONMENTAL ACCOUNTING FOR FISCAL 2000<br />

Considering the balance between environmental protection and<br />

economic feasibility is extremely important for ensuring the<br />

sustainable development of society and companies. In the past,<br />