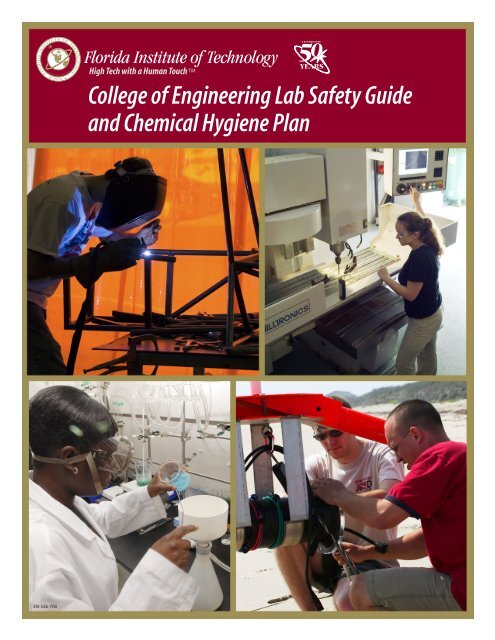

College of Engineering Lab Safety Guide and Chemical Hygiene Plan

College of Engineering Lab Safety Guide and Chemical Hygiene Plan

College of Engineering Lab Safety Guide and Chemical Hygiene Plan

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EN-526-708<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> <strong>Lab</strong> <strong>Safety</strong> <strong>Guide</strong><br />

<strong>and</strong> <strong>Chemical</strong> <strong>Hygiene</strong> <strong>Plan</strong>

OSHA <strong>Lab</strong> St<strong>and</strong>ard<br />

The use <strong>of</strong> hazardous materials in laboratory areas is addressed by the OSHA<br />

<strong>Lab</strong>oratory St<strong>and</strong>ard "Occupational Exposure to Hazardous <strong>Chemical</strong>s in<br />

<strong>Lab</strong>oratories." This st<strong>and</strong>ard m<strong>and</strong>ates the preparation <strong>of</strong> a <strong>Chemical</strong> <strong>Hygiene</strong> <strong>Plan</strong>,<br />

such as this <strong>Safety</strong> <strong>Guide</strong>, consisting <strong>of</strong> specific policies <strong>and</strong> procedures addressing the<br />

requirements <strong>of</strong> the regulation.<br />

Program Elements<br />

<strong>Safety</strong> walk down<br />

Buddy System<br />

MSDS Sheets<br />

Personal Protective Equipment<br />

Hazardous Operations Notification<br />

Fire Emergency Response<br />

Slip, Trip <strong>and</strong> Fall Prevention<br />

Spill Response <strong>and</strong> Clean Up<br />

First Aid <strong>Guide</strong><br />

Smoke Free Building<br />

Close Call Investigation <strong>and</strong> Reporting<br />

Accident Investigation <strong>and</strong> Reporting<br />

General <strong>Chemical</strong> Storage Rules<br />

Compressed Gases<br />

<strong>Chemical</strong> <strong>Lab</strong>els<br />

<strong>Chemical</strong> Disposal<br />

<strong>Lab</strong>oratory Inspections<br />

Particularly Hazardous Substances<br />

Cryogenics<br />

Ladder Use <strong>Guide</strong>lines<br />

General Machine Shop <strong>Safety</strong><br />

Equipment <strong>Safety</strong><br />

Laser <strong>Safety</strong><br />

Contact Information<br />

<strong>Safety</strong> Walk Down<br />

A safety walk down will be conducted <strong>of</strong> all COE lab spaces yearly by the Director <strong>of</strong><br />

<strong>Lab</strong>oratories or their designee. A checklist <strong>of</strong> areas to be inspected <strong>and</strong> inspection<br />

criteria is in Reference A.<br />

Buddy System<br />

The Buddy system requires two persons to be present in the laboratory areas when work<br />

is being performed. No person is to be working alone on laboratory equipment. A<br />

Buddy system will be used at all times.<br />

No student is allowed to be working without supervision <strong>of</strong> a paid university employee<br />

present.<br />

Student work stops if supervision is called out <strong>of</strong> the lab.<br />

No students are allowed access to the lab without supervision by a paid<br />

university employee.<br />

Page 2 <strong>of</strong> 23

Exception: <strong>Lab</strong>oratories which only house clerical, computer, <strong>and</strong>/or non-hazardous<br />

equipment <strong>and</strong>/ or assemble processes. These areas are to be controlled by key or<br />

swipe access.<br />

MSDS Sheets<br />

Under the right to know laws all MSDS (Material <strong>Safety</strong> Data Sheets) are to be<br />

accessible to all personnel. MSDS books are available in the lab areas. Additionally,<br />

MSDS sheets are located in the University <strong>Safety</strong> Office. Per the Hazard<br />

Communication St<strong>and</strong>ard <strong>of</strong> OSHA, a MSDS sheet MUST be obtained for every<br />

chemical used in the work place.<br />

Any chemical that is not in its original container must be labeled. This includes spray<br />

bottles for water.<br />

Waste containers used to dispose <strong>of</strong> chemical waste must be labeled. Contact the<br />

University <strong>Safety</strong> Officer for pick-up <strong>and</strong> disposal <strong>of</strong> waste products or unwanted<br />

chemicals.<br />

Personal Protective Equipment<br />

A critical aspect <strong>of</strong> working safely with hazardous materials is the proper selection <strong>and</strong><br />

use <strong>of</strong> personal protective equipment (PPE). All PPE should be carefully selected to<br />

ensure that it is appropriate for the hazards present <strong>and</strong> that the users will be able to<br />

perform their work in reasonable comfort wearing the protective equipment.<br />

Gloves<br />

Protective gloves should be worn whenever there is the potential for skin damage or<br />

absorption through the skin when using a chemical or working with a hazardous<br />

material. The gloves should be <strong>of</strong> a material appropriate for the chemical or material in<br />

question. Information as to appropriate materials is available in safety equipment<br />

catalogues from which gloves may be purchased or in the MSDS sheet for the material<br />

being used. Care should be taken to ensure that the gloves fit properly. Also, an<br />

individual's susceptibility to latex allergies should be considered when selecting gloves.<br />

Eyewear<br />

Protective eyewear is required to be worn in any situation where there is a potential for<br />

damage to the eye. These situations include protection from flying debris, protection<br />

from chemical splashes, <strong>and</strong> protection from hazardous radiation such as lasers or<br />

ultraviolet light, which are <strong>of</strong>ten produced in welding operations. It is critical that the<br />

proper protective eyewear be selected for use.<br />

Protective eyewear must <strong>of</strong>fer appropriate protection from the hazards presented. For<br />

example, safety glasses do not <strong>of</strong>fer sufficient protection from chemical splashes-goggles<br />

or safety shields are indicated for that use. When dealing with chemical<br />

splashes, be sure the eyewear <strong>of</strong>fers NO opportunity for chemical entry, such as <strong>of</strong>ten<br />

occurs with poorly placed ventilation holes.<br />

In the case <strong>of</strong> protection from radiation, the eyewear must not only address the specific<br />

wavelength <strong>of</strong> the radiation but also <strong>of</strong>fer sufficient protection from the power or intensity<br />

<strong>of</strong> the radiation.<br />

Page 3 <strong>of</strong> 23

Respiratory Protection<br />

As a minimum, dust masks are to be worn when performing operations that create fine<br />

dust, such as s<strong>and</strong>ing. S<strong>and</strong>ing should only be performed in an area with proper<br />

ventilation <strong>and</strong> where the dust will not damage other equipment in the area.<br />

When using chemicals or spray painting respiratory protection should be used. This<br />

could be proper ventilation, a hood or personal respirator. Proper training on use <strong>of</strong> a<br />

respirator should be completed before its use. The type <strong>of</strong> respirator should be matched<br />

to the hazard. For training contact the University <strong>Safety</strong> Officer. (Greg Peebles X 7715)<br />

Hazardous Operations Notification<br />

If laboratory operations require leaving exposed hazards (chemical reagent, heat source,<br />

ect.) when the lab will be unoccupied, prior notification must be given to the below<br />

persons.<br />

National Management Resources Corp – X7326<br />

Facilities Management – X8038<br />

Security – X8111<br />

University <strong>Safety</strong> Officer X7715<br />

COE <strong>Lab</strong>oratory Director – X7349<br />

This notification will prevent unintended interruption or disturbance <strong>of</strong> your experiment as<br />

well as protecting those whose job requires them to enter labs.<br />

Fire Emergency Response<br />

According to the University policy on fire emergencies, employees are not required to<br />

fight fires <strong>and</strong> should evacuate the building immediately in the event <strong>of</strong> a fire. The local<br />

fire department has the primary responsibility for managing fire emergencies <strong>and</strong> must<br />

be notified immediately <strong>of</strong> such situations at their emergency number – 911.<br />

If fire is discovered, activate the nearest fire alarm <strong>and</strong> call 911. If the fire alarm does<br />

not work, or the building is not equipped with one, dial 911 <strong>and</strong> notify occupants verbally<br />

<strong>of</strong> the emergency <strong>and</strong> the need to evacuate.<br />

Hazardous equipment or processes should be shut down before leaving unless doing so<br />

presents a greater hazard. Close all doors when leaving, if conditions permit.<br />

Employees may use fire extinguishers to fight small, incipient stage fires (no larger than<br />

a waste paper basket) only if they have been trained in the proper use <strong>of</strong> fire<br />

extinguishers <strong>and</strong> are confident in their ability to cope with the hazards <strong>of</strong> a fire. In such<br />

cases fire fighting efforts must be terminated when it becomes obvious that there is<br />

danger <strong>of</strong> harm from smoke, heat, or flames.<br />

Page 4 <strong>of</strong> 23

Fire Extinguishers<br />

The use <strong>of</strong> fire extinguishers must follow OSHA <strong>Guide</strong> lines (OSHA St<strong>and</strong>ard 29CFR<br />

1910.157)<br />

Maintenance <strong>of</strong> fire extinguishers is performed by Security. Maintenance service is<br />

performed once a year.<br />

Fire prevention<br />

Proper housekeeping including prompt removal <strong>of</strong> waste <strong>and</strong> keeping the work space<br />

free <strong>of</strong> unnecessary combustible materials shall be performed by housekeeping <strong>and</strong><br />

shop personnel.<br />

Flammable liquids shall be stored in flammable storage cabinets provided in the lab<br />

areas. Storage <strong>of</strong> combustible materials such as card board boxes <strong>and</strong> newspaper shall<br />

be kept at a minimum.<br />

Electrical wiring should be maintained in good condition. Extension cords should be only<br />

for temporary use. Do not overload outlets by using gang plugs.<br />

Page 5 <strong>of</strong> 23

Slip, Trip <strong>and</strong> Fall Prevention<br />

Slips, trips, <strong>and</strong> falls account for 15% <strong>of</strong> all accidental deaths. The most important<br />

precautionary tip that applies in all these cases is to PAY ATTENTION TO WHAT YOU<br />

ARE DOING. This is among the most common causes <strong>of</strong> injuries <strong>and</strong> is the easiest to<br />

correct. The best walking surfaces <strong>and</strong> ideal weather conditions won’t be <strong>of</strong> any help if<br />

you are not watching where you are going.<br />

SLIPS<br />

Slips occur when there is too little friction or traction between your feet <strong>and</strong> the walking<br />

surface. The most common causes <strong>of</strong> slips are wet surfaces, weather hazards, spills,<br />

<strong>and</strong> poor tread on footwear. Preventive measures include:<br />

Wet surfaces: Shorten your stride, walk with feet pointed out slightly, <strong>and</strong> make wider<br />

turns.<br />

Spills: Clean up immediately. If you are unfamiliar with the contents <strong>of</strong> the spill, contact<br />

the <strong>Safety</strong> Officer or <strong>Lab</strong> Director<br />

Weather hazards: Rain creates wet slippery conditions. Walk more slowly so you can<br />

react to traction changes. Wear slip resistant shoes <strong>and</strong> dry <strong>of</strong>f shoes as soon as<br />

possible after entering a building (wet shoes on dry floors are as dangerous as dry<br />

shoes on wet floors). Wear sunglasses on sunny winter days so you can more easily<br />

see slippery areas.<br />

Poor tread on footwear or generally poor traction: Wear slip resistant footwear, apply<br />

abrasive strips to smooth walking surfaces, post warnings.<br />

TRIPS<br />

Trips commonly occur when you foot strikes an object <strong>and</strong> your momentum throws you<br />

<strong>of</strong>f balance. To minimize the potential for this type <strong>of</strong> injury:<br />

Do not allow carried packages to obstruct your view.<br />

If glasses fog due to atmospheric changes, clear them immediately.<br />

Use only proven walkways.<br />

Close desk <strong>and</strong> file drawers when not in use.<br />

Report burned out or missing lights.<br />

Be aware <strong>of</strong> elevator threshold positions.<br />

Report any uneven or broken pavement, sidewalks, or h<strong>and</strong>rails.<br />

FALLS<br />

Falls usually take place from one level to another, such as falling down stairs. Another<br />

involves using chairs as ladders. Preventive measures include:<br />

Page 8 <strong>of</strong> 23

NEVER st<strong>and</strong> on a chair to reach a high object. Always use a ladder.<br />

When using ladders, select the proper type <strong>and</strong> size, <strong>and</strong> use it properly.<br />

Walk up <strong>and</strong> down stairs, <strong>and</strong> never jump from the last step.<br />

Use h<strong>and</strong>rails.<br />

Walk, don’t run.<br />

Report any unsafe conditions.<br />

Spill Response <strong>and</strong> Clean Up<br />

If a spill causes an uncontrolled fire emergency, call 911<br />

In the event <strong>of</strong> a small (depends on the MSDS as to what constitutes a small non-life<br />

threatening spill) chemical spill, the individuals who caused the spill are responsible for<br />

prompt <strong>and</strong> proper clean-up. It is also their responsibility to have spill control <strong>and</strong><br />

personal protective equipment appropriate for the chemicals being h<strong>and</strong>led readily<br />

available. The following are general guidelines to be followed for a small chemical spill.<br />

Immediately alert area occupants <strong>and</strong> supervisor <strong>and</strong> evacuate the area, if necessary.<br />

If there is a fire or medical attention is needed, contact public safety at 911.<br />

Attend to any people who may be contaminated. Contaminated clothing must be<br />

removed immediately <strong>and</strong> the skin flushed with water for no less than fifteen minutes.<br />

Clothing must be laundered before reuse.<br />

If a volatile, flammable material is spilled, immediately warn everyone, control sources <strong>of</strong><br />

ignition <strong>and</strong> ventilate the area.<br />

Protect floor drains or other means for environmental release.<br />

When spilled materials have been absorbed, use brush <strong>and</strong> scoop to place materials in<br />

an appropriate container.<br />

Consult the MSDS sheet for proper method <strong>of</strong> spill clean up <strong>and</strong> decontamination <strong>of</strong> the<br />

surface where the spill occurred.<br />

Report all spills to your supervisor or the University <strong>Safety</strong> Officer.<br />

If a spill is large (per the MSDS) or is life threatening contact the 24/7 FIT Hazardous<br />

spill contractor – ACT – at 800-226-0911 & follow their direction. Immediately contact<br />

both FIT Security – 321-674-8111 (x8111) <strong>and</strong> the current Emergency Coordinator per<br />

the posted yellow emergency contacts sheet.<br />

SPILL CONTROL<br />

Spill Kits are placed in Olin 117, Frueauff 107, Quad 404, Quad 407, Link 320 <strong>and</strong><br />

building 538. <strong>Lab</strong>oratories must have a minimum amount <strong>of</strong> personal protective<br />

equipment (PPE) <strong>and</strong> appropriate clean-up materials present prior to an incident<br />

The supplies needed to clean up a spill will depend on the quantity <strong>and</strong> type <strong>of</strong> chemical<br />

that is spilled. You may not proceed with your work until the proper spill equipment &<br />

appropriate PPE are on h<strong>and</strong>. Contact the <strong>Lab</strong> Director or the University <strong>Safety</strong> Officer<br />

for assistance <strong>and</strong> approval <strong>of</strong> your equipment.<br />

Page 9 <strong>of</strong> 23

Clean-up Procedures<br />

The responsibility <strong>of</strong> the first responder is to limit access to the spill so that unsuspecting<br />

persons do not inadvertently encounter spilled material <strong>and</strong> either contaminate<br />

themselves or spread the spilled material beyond the immediate spill area <strong>and</strong> notify<br />

supervision. Call numbers are posted in all laboratories.<br />

Don the appropriate personal protective equipment <strong>and</strong> control further release <strong>and</strong><br />

spread <strong>of</strong> material, if possible. This step <strong>of</strong>ten involves righting containers <strong>and</strong> placing<br />

absorbent or other diking material around the spill to prevent the spread <strong>of</strong> the spill<br />

beyond the containment area.<br />

Then, review Material <strong>Safety</strong> Data Sheets (MSDS) or other references for recommended<br />

spill cleanup methods.<br />

Once the spill has been contained, the responder should absorb any free liquid Acquire<br />

sufficient quantities <strong>and</strong> types <strong>of</strong> appropriate spill control materials to contain any spills<br />

that can be reasonably anticipated. The need for equipment to disperse, collect <strong>and</strong><br />

contain spill control materials (e.g., brushes, scoops, containers, etc.) should also be<br />

reviewed.<br />

Many spills involve broken glass. The responder must be careful not to get cut by broken<br />

glass during the clean-up process. Use tongs to pick-up the broken glass.<br />

Once all <strong>of</strong> the free liquids are absorbed, place all <strong>of</strong> the absorbents <strong>and</strong> other<br />

contaminated spill clean-up materials into the appropriate container.<br />

<strong>Lab</strong>el the container as hazardous waste <strong>and</strong> specify the contents. Then request that the<br />

materials be removed from the laboratory as hazardous waste. Call the University<br />

<strong>Safety</strong> Officer for removal <strong>of</strong> the material.<br />

First Aid <strong>Guide</strong><br />

The first aid policy provides procedures for responding to sudden illness or accidents<br />

where an injury has occurred. The policy is as follows:<br />

When immediate aid is needed, call 911. Then contact FIT Security at 321-674-8111<br />

(x8111).<br />

After notifying emergency response at 911, if there are individuals qualified to render first<br />

aid, seek their assistance, i.e. FIT security. Personal protective equipment should be<br />

used when there is the potential for exposure to blood or other body fluids. Do not<br />

attempt to clean any blood spills. Contact security to have our cleaning contractor who<br />

are equipped & qualified to do this type <strong>of</strong> cleaning.<br />

First aid for life threatening situations such as stopped breathing or excessive bleeding<br />

should be rendered as soon as possible.<br />

Treatments such as b<strong>and</strong>aging or splinting should not be attempted, except under the<br />

supervision <strong>of</strong> medical personnel.<br />

Persons with injuries or illness, which require emergency department facilities, are to be<br />

transported directly to a medical facility.<br />

Page 10 <strong>of</strong> 23

Persons with cuts which require b<strong>and</strong>-aides are to report to the nurse for evaluation,<br />

within 24 hours <strong>of</strong> the injury. Persons who are injured in the machine shop shall be<br />

transported over to the nurse at the time <strong>of</strong> the injury by shop supervision.<br />

All first aid supplies are maintained in the laboratory, except on the third floor <strong>of</strong> Olin<br />

<strong>Engineering</strong>, where they are located in the ECE department <strong>of</strong>fice <strong>and</strong> GSA <strong>of</strong>fice.<br />

First aid supplies are limited to household supplies, such as b<strong>and</strong> aids <strong>and</strong> sterile gauze<br />

pads.<br />

Persons who wish to acquire first aid or CPR training are encouraged to avail<br />

themselves <strong>of</strong> local resources such as the Red Cross, local first aid squads, or<br />

University programs when <strong>of</strong>fered<br />

Smoke-Free Buildings<br />

At Florida Institute <strong>of</strong> Technology, smoking is prohibited in all education buildings per<br />

Florida State law. Smoking is prohibited in all university-owned transportation vehicles.<br />

In addition, smoking is prohibited within 10 feet <strong>of</strong> all <strong>College</strong> <strong>of</strong> <strong>Engineering</strong> building<br />

entrances.<br />

Adverse health affects are also found in people exposed to second-h<strong>and</strong> smoke. In<br />

addition, people with lung diseases, such as asthma, find second-h<strong>and</strong> smoke highly<br />

irritating <strong>and</strong> a trigger to attacks.<br />

Close Call Investigation <strong>and</strong> Reporting<br />

Reporting is key to improving everyone’s safety. Even minor injuries are warnings that<br />

something happened that wasn’t planned. Unless we know about injuries, or even those<br />

incidents that don’t result in injuries (referred to as “Close call” accidents), we can’t<br />

correct the problem that led to the incident. Left uncorrected, it can easily happen again,<br />

<strong>and</strong> it may be more serious the next time. Help management <strong>and</strong> everyone around you<br />

by reporting every incident that causes, or has the potential to cause, an injury. The<br />

<strong>College</strong> <strong>of</strong> <strong>Engineering</strong> with the University <strong>Safety</strong> Officer will investigate <strong>and</strong> determine<br />

what can be done to prevent a recurrence.<br />

A close call is an event that had the potential for personal injury or major equipment<br />

damage, but that only lead to equipment damage in under <strong>of</strong> $50.<br />

Reporting will consist <strong>of</strong> having all parties present fill out an investigation form.<br />

Reference B<br />

Upon review <strong>of</strong> these forms, the Director <strong>of</strong> <strong>Lab</strong>oratories or the University <strong>Safety</strong> Officer<br />

has the authority to have a formal review committee review the incident. At a minimum<br />

this committee will consist <strong>of</strong> the supervisor <strong>of</strong> the area where the incident occurred, the<br />

student or employee performing the work, the safety <strong>of</strong>ficer, <strong>and</strong> the director <strong>of</strong><br />

laboratories. Other individuals may be requested to participate at the request <strong>of</strong> director<br />

<strong>of</strong> <strong>Lab</strong>oratories or the University <strong>Safety</strong> Officer<br />

A formal incident report will be completed <strong>and</strong> filed in the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong>.<br />

Corrective actions will be tracked to verify they are complete<br />

Page 11 <strong>of</strong> 23

Accident Investigation <strong>and</strong> Reporting<br />

An accident is any personal injury that required pr<strong>of</strong>essional medical care or any<br />

equipment damage in excess <strong>of</strong> $50.<br />

All Workers Compensation claims will be h<strong>and</strong>led as defined in the Employee H<strong>and</strong>book<br />

<strong>and</strong> Human Resources policies <strong>and</strong> procedures. In addition, the <strong>College</strong> <strong>of</strong> <strong>Engineering</strong><br />

with the University <strong>Safety</strong> Officer will investigate <strong>and</strong> determine what can be done to<br />

prevent a recurrence using the method defined under close call investigation.<br />

General <strong>Chemical</strong> Storage Rules<br />

Minimize the amount <strong>of</strong> chemicals stored in the laboratory.<br />

Always use safety cans to store flammables when removed from original<br />

container, unless less than 8 oz is to be stored.<br />

Use OSHA's St<strong>and</strong>ards approved firepro<strong>of</strong> cabinets for storing flammables.<br />

Make sure that all containers are properly labeled.<br />

Do not store flammables where they are exposed to direct sunlight.<br />

Periodically check that the storage areas are adequately ventilated.<br />

Do not fill closed lid containers to the top.<br />

Always separate acids from bases <strong>and</strong> fuel from oxidizers.<br />

Compressed Gas<br />

Many gases have hazardous attributes, such as being poisonous, causing asphyxiation,<br />

supporting fires, or having other dangerous properties. When these gases are<br />

compressed in containers, their high pressure adds a special hazard to their use <strong>and</strong><br />

storage. Always read the MSDS for a given gas before purchase or use. Be sure to have<br />

any needed safety equipment in place before obtaining a gas that is hazardous.<br />

All persons h<strong>and</strong>ling compressed gas cylinders must have University <strong>Safety</strong> Office<br />

approved training.<br />

- Cylinders must be secured in an upright position using a belt or a chain. In no case<br />

may the cylinder be secured to plumbing or electrical conduits.<br />

- All cylinders are color-coded. This color code is used to identify the contents <strong>of</strong> the<br />

cylinder. - Never change the color <strong>of</strong> cylinder.<br />

- The valve protection caps must be replaced when cylinders are not in use.<br />

- Care must be taken when h<strong>and</strong>ling the cylinders to prevent physical damage. Cylinders<br />

should be transported using suitable h<strong>and</strong> trucks <strong>and</strong> should never be rolled or dragged.<br />

- When cylinders are stored they must be separated according to their contents. See<br />

MSDS.<br />

- Full <strong>and</strong> empty cylinders must be stored separately. All cylinders must be tagged to<br />

indicate whether they are full or empty.<br />

- Cylinders not in use should be removed from the laboratory. The number <strong>of</strong> cylinders<br />

used in the lab should be limited to minimize fire <strong>and</strong> toxicity hazards.<br />

- Using compressed gases should be conducted in well-ventilated areas.<br />

- No smoking is permitted at all by stored gases.<br />

- The conditions <strong>of</strong> the cylinders, valves <strong>and</strong> related equipment must be checked<br />

regularly for leaks <strong>and</strong> physical damage. The user <strong>of</strong> the cylinder should check for leaks<br />

with a soap <strong>and</strong> water test solution.<br />

- Cylinders must pass hydrostatic pressure test within the past 10 years. It is the<br />

responsibility <strong>of</strong> the cylinder owner to perform m<strong>and</strong>atory inspections on the integrity <strong>of</strong><br />

Page 12 <strong>of</strong> 23

the cylinder. If you have been in possession <strong>of</strong> a cylinder for 5 years, it must be either<br />

returned or re-inspected.<br />

<strong>Chemical</strong> <strong>Lab</strong>els<br />

All chemicals are to be labeled at all times. Temporary storage or use containers, like<br />

squeeze bottles are to be labeled with there contents. Any container without a label or<br />

which is blank shall be labeled with the NFPA label described below.<br />

Exemptions for labeling requirements shall be made for chemical transfers from a<br />

labeled container into a container which is intended only for the immediate use <strong>of</strong> the<br />

employee who performed the transfer. Examples are the transfer <strong>of</strong> material into a<br />

graduated cylinder to measure volume or the use <strong>of</strong> a beaker or container to measure<br />

weight <strong>of</strong> a substance.<br />

By law, chemicals supplied by manufactures are labeled to indicate the name <strong>of</strong> the<br />

product <strong>and</strong> list the hazardous ingredients present. The label must also provide<br />

information regarding the hazards associated with using the material. This is <strong>of</strong>ten done<br />

both with text information as well as with symbols. There are two common symbols<br />

used on labels to quickly provide information <strong>of</strong> the relative hazards <strong>of</strong> a material. One<br />

is called the National Fire Protection Association (NFPA) warning diamond, which<br />

appears below as Figure 1. The other is the Hazard Materials Information System<br />

(HMIS) system, which appears below as Figure 2. Both systems use a numerical rating<br />

<strong>of</strong> hazards in each <strong>of</strong> three sections (health hazard, fire/flammability hazard <strong>and</strong><br />

reactivity hazard). The key to the hazards associated with the numerical ratings is<br />

provided below.<br />

Figure 1 Figure 2<br />

Health Hazard Ratings: 0 - Ordinary combustible hazards in a fire<br />

1 - Slightly hazardous<br />

2 – Hazardous<br />

3 - Extreme danger<br />

4 – Deadly<br />

Page 13 <strong>of</strong> 23

Flammability Hazard Ratings 0 - Will not burn<br />

1 - Will ignite if preheated<br />

2 - Will ignite if moderately heated<br />

3 - Will ignite at most ambient conditions<br />

4 - Burns readily at ambient conditions<br />

Reactivity Hazard Ratings 0 - Stable <strong>and</strong> not reactive with water<br />

1 - Unstable if heated<br />

2 - Violent chemical change<br />

3 – Shock <strong>and</strong> heat may detonate<br />

4 – May detonate<br />

<strong>Chemical</strong> Disposal<br />

If chemicals are no longer needed or are expired, they should be deposited into your<br />

laboratory’s hazardous waste Satellite Accumulation Area (if you do not have a SAA you<br />

need to contact the University <strong>Safety</strong> Office to set one up). When your SAA containers<br />

are approaching full - contact the University <strong>Safety</strong> Officer for disposal. All aerosol<br />

containers are to be sent to the University <strong>Safety</strong> Officer or placed in the proper<br />

container for disposal. Empty aerosols which contained food or personal hygiene items<br />

may be disposed <strong>of</strong> in the blue university recycling bins. An SAA for aerosol collection is<br />

located on the east side <strong>of</strong> building 538, the machine shop.<br />

Never dispose <strong>of</strong> chemicals, aerosol containers or potentially hazardous materials in<br />

trash containers.<br />

Always separate acids from bases <strong>and</strong> fuel from oxidizers.<br />

Never pour chemicals down a sink.<br />

<strong>Lab</strong>oratory Inspections<br />

The Department <strong>of</strong> Environmental Health <strong>and</strong> <strong>Safety</strong> requires all laboratory areas to be<br />

inspected once per year. Help ensure a successful inspection by reviewing the<br />

inspection criteria in the <strong>Lab</strong>oratory Inspection Form in Reference A<br />

Particularly Hazardous Substances<br />

The OSHA <strong>Lab</strong>oratory St<strong>and</strong>ard specifies that special precautions be taken when<br />

Particularly Hazardous Substances (PHS) are used in the laboratory. Florida Institute <strong>of</strong><br />

Technology requires the preparation <strong>of</strong> a written procedure for the use <strong>and</strong> h<strong>and</strong>ling <strong>of</strong> a<br />

PHS in a laboratory. Any chemical that has carcinogenic effects in its MSDS sheet is<br />

considered a PHS.<br />

Fume Hoods<br />

The primary control for protecting laboratory employees from exposure to chemical<br />

hazards in the lab is the fume hood. They are inspected during safety walk downs to<br />

assure that fume hoods are properly working <strong>and</strong> maintained.<br />

Page 14 <strong>of</strong> 23

Cryogenics<br />

Cryogenic materials are any material that is below–150 °C ( –238 °F or 123 K). When<br />

using cryogenic materials the proper PPE includes gloves, full face goggle, apron, <strong>and</strong><br />

long pants, long sleeved shirt or lab coat, <strong>and</strong> shoes with socks. The most used<br />

material is liquid nitrogen.<br />

Precautions<br />

Liquid nitrogen is extremely cold (-320°F, -196°C, 77K) <strong>and</strong> can cause severe frostbite.<br />

Always use gloves <strong>and</strong> face protection when h<strong>and</strong>ling liquid nitrogen. Loose-fitting long<br />

sleeve clothing is recommended.<br />

Never use liquid nitrogen in a confined space. An oxygen-deficient atmosphere may<br />

occur.<br />

In case <strong>of</strong> skin contact, rinse with plenty <strong>of</strong> water. Do not remove clothes. Seek medical<br />

attention.<br />

In case <strong>of</strong> eye contact, rinse with plenty <strong>of</strong> water. Seek medical attention.<br />

In case <strong>of</strong> a major liquid spill, evacuate all personnel from the affected area. Do not enter<br />

the affected area without a self-contained breathing apparatus. Respirators WILL NOT<br />

function in an oxygen-deficient atmosphere.<br />

Transfer from tank to Dewar<br />

Place Dewar under dispensing line.<br />

Open valve on tank slowly.<br />

Fill Dewar slowly. Never fill completely to the top.<br />

Replace foam cap on Dewar.<br />

Transfer from Dewar to equipment<br />

Remove foam cap from Dewar.<br />

Pour slowly into equipment, using a funnel if necessary.<br />

Replace foam cap on Dewar when not in use.<br />

Ladder Use <strong>Guide</strong>lines<br />

Before using a ladder inspect it, place it properly, <strong>and</strong> use it appropriately.<br />

INSPECT IT<br />

Contact FIT facilities maintenance (321-674-8038 or x 8038) <strong>and</strong> have one <strong>of</strong> their<br />

ladder safety trained employees inspect your ladder.<br />

AND,<br />

Inspect ladders before using (make sure there are no breaks or cracks, all components<br />

must be in good working condition, no oil or grease on side rails or steps, no frayed or<br />

worn ropes, movable parts operate freely, no excessive wear, rungs securely attached to<br />

side rails, <strong>and</strong> are you using the proper ladder for the job?)<br />

Before using a ladder, consider any external hazards: overhead obstructions, presence<br />

<strong>of</strong> electrical equipment, congested area, uneven surfaces, weather conditions, etc.<br />

Page 15 <strong>of</strong> 23

Never use a ladder that is too long or too short for what you are going to work on, <strong>and</strong><br />

NEVER st<strong>and</strong> on a swivel chair, stool, desk, or other object when you need to reach<br />

something. Check the ladder’s load limits before putting it into service. Use this table to<br />

interpret the ladder rating that will be marked on the ladder somewhere:<br />

Category Weight Limit, Pounds Rating<br />

Type I-AA 375 Special Duty<br />

Type I-A 300 Heavy Duty Industrial<br />

Type I 250 Heavy Duty<br />

Type II 225 Medium Duty<br />

Type III 200 Light Duty<br />

Remove any defective ladder from service immediately, tag it (or better yet, break it so<br />

that it can not be used), <strong>and</strong> report it so that it can be replaced.<br />

PLACE IT<br />

Do not use ladders as a brace, platform, scaffold, plank, or lever, <strong>and</strong> do not use the<br />

rungs for storage.<br />

Never use a metal ladder near electrical sources, don’t use step ladders as straight<br />

ladders (i.e., leaned against the wall), <strong>and</strong> don’t tie ladders together to make a longer<br />

ladder.<br />

If you have to use a ladder near a doorway, take one or more <strong>of</strong> these precautionary<br />

steps to make sure nobody comes through the door <strong>and</strong> knocks you from the ladder:<br />

lock the door, put up barricades, secure the ladder, <strong>and</strong>/or have somebody st<strong>and</strong> watch<br />

to warn others that a ladder is in use.<br />

Set up straight ladders using the 4 to 1 rule: 1 foot from the wall for every 4 feet <strong>of</strong> the<br />

ladder’s working length.<br />

When using a stepladder, open it fully, place it on a solid surface, <strong>and</strong> make sure the<br />

spreaders are locked into position. Do not st<strong>and</strong> on the top two rails, <strong>and</strong> never st<strong>and</strong> on<br />

the back section.<br />

When using a straight ladder or extension ladder, be sure the rails are supported equally<br />

at both the top <strong>and</strong> bottom. The bottom side rails must be on a firm surface. Also, extend<br />

the top at least 3 feet beyond the support point, make sure the upper section <strong>of</strong> an<br />

extension ladder overlaps the lower portion adequately, <strong>and</strong> check to be sure the rungs<br />

are locked in place.<br />

USE IT<br />

Do not st<strong>and</strong> on the top four rails when using a straight ladder.<br />

Face the ladder when ascending or descending. And remember, you will be farther from<br />

the wall as you descend the ladder. If you find it difficult to reach the wall as you near the<br />

bottom, you should be using a different ladder.<br />

Page 16 <strong>of</strong> 23

Grip the rails with both h<strong>and</strong>s whenever possible, <strong>and</strong> always use the 3-point contact<br />

rule (i. e., always have one h<strong>and</strong> <strong>and</strong> both feet in contact with the ladder, or one foot <strong>and</strong><br />

both h<strong>and</strong>s).<br />

Keep your belt buckle within the side rails to ensure against over-reaching. Move the<br />

ladder if you have to get to something beyond your normal reach.<br />

Never allow more than one person on the ladder at any given time.<br />

Hoist tools or other materials up to you, rather than carrying them up the ladder with you.<br />

Wear a tool belt so you don’t have to hold onto tools.<br />

Never paint wooden ladders. Paint will conceal cracks <strong>and</strong> defects.<br />

Do not try to move the ladder while you are still on it, <strong>and</strong> do not allow anyone else to<br />

move a ladder while it is still occupied.<br />

Be constantly aware <strong>of</strong> where you are <strong>and</strong> what you are doing. Many injuries have<br />

occurred because ladder users were not paying attention.<br />

Use slip resistant “shoes” on the bottoms <strong>of</strong> portable ladders. If a ladder can not be<br />

safely secured, have someone brace it at the bottom.<br />

If the top <strong>of</strong> a ladder must rest against a window or a corner, use a ladder stabilizer.<br />

Ladders longer than 8’ must be carried by two people.<br />

Store ladders safely <strong>and</strong> properly: step ladders in vertical, closed position; straight<br />

ladders horizontal, on ladder racks or wall brackets.<br />

Do not jump from the last rung to the ground.<br />

If you follow these guidelines, you should never have to worry about being injured in a<br />

ladder-related incident.<br />

General Machine Shop <strong>Safety</strong><br />

The head research pr<strong>of</strong>essor or shop supervisor is responsible for work done in lab<br />

areas. Detailed rules for the Machine Shop are in the “Basic Machine Tool Operations<br />

Policy".<br />

Student project work space is to be assigned by the Director <strong>of</strong> <strong>Lab</strong>oratories.<br />

See http://coe.fit.edu/srproject.html request form.<br />

All work orders are to be approved by the Director <strong>of</strong> <strong>Lab</strong>oratories.<br />

Equipment <strong>Safety</strong><br />

<strong>Lab</strong> equipment <strong>and</strong> machinery has the potential to produce large amounts <strong>of</strong> force <strong>and</strong><br />

potential injury. NEVER operate equipment unless you are trained to do so. Always<br />

follow the instruction or lab manual to prevent injury or damage to the equipment.<br />

Students working in the Machine shop are required to complete the training<br />

requirements outlined in the Basic Tool Manual.<br />

Page 17 <strong>of</strong> 23

Repairs <strong>of</strong> equipment are only to be performed under the direction <strong>of</strong> the Director <strong>of</strong><br />

<strong>Lab</strong>oratories. Employees <strong>and</strong> students working on equipment should always use the<br />

buddy system. Working alone on equipment will be viewed as unauthorized work <strong>and</strong><br />

will be subject to disciplinary action.<br />

Types <strong>of</strong> hazards present are dependant on the equipment design. Equipment may have<br />

the risk <strong>of</strong> an unexpected startup, energization, or release <strong>of</strong> stored energy.<br />

Types <strong>of</strong> energy that have the potential to cause injury include (but are not limited to):<br />

Electricity<br />

Trapped pressure<br />

Spring tension<br />

Components that could fall or shift position<br />

Hydraulic<br />

Pneumatic<br />

Piping <strong>and</strong> vessels<br />

Temperature extremes<br />

Any form <strong>of</strong> energy that could cause injury, whether on the above list or not, can cause<br />

injury. Follow written manuals when working on or with any equipment.<br />

Laser <strong>Safety</strong><br />

There are a great many lasers <strong>and</strong> laser-containing devices present in the <strong>College</strong> <strong>of</strong><br />

<strong>Engineering</strong> <strong>Lab</strong>oratories. Lasers have the potential to damage vision <strong>and</strong> skin. Always<br />

wear protective eyewear that is rated for the wave length <strong>of</strong> the laser. Never allow body<br />

parts to cross the laser’s path. For the University Policy <strong>and</strong> Procedure, Laser Use <strong>and</strong><br />

<strong>Safety</strong> Policy see the University <strong>Safety</strong> website or the University Laser <strong>Safety</strong> Officer<br />

(Stephanie Hopper X7349).<br />

Contact Information<br />

The below information is for reference only. Phone numbers can also be found on the<br />

posted yellow Emergency contact information placards or on the online directory at<br />

http://www.fit.edu/telecom/faculty_search.html<br />

Greg Peebles University <strong>Safety</strong> Officer X7715, Cell 917-5484<br />

Stephanie Hopper Dir. Of <strong>Lab</strong>s, University Laser Officer X7349, Cell 795-9440<br />

Julio Sanchez National Mgm’t Supervisor X7326<br />

Campus Security X8111<br />

Facilities X8038<br />

Page 18 <strong>of</strong> 23

Reference A –Yearly <strong>Safety</strong> Walk downs<br />

Page 19 <strong>of</strong> 23

Page 20 <strong>of</strong> 23

Page 21 <strong>of</strong> 23

Page 22 <strong>of</strong> 23

REFERENCE B<br />

Incident Review Report<br />

Name <strong>of</strong> person making the report: ______________________________________<br />

Title or Position; ____________________________________________________<br />

Supervisor;_________________________________________________________<br />

Person(s) involved in the incident:___________________________________________<br />

_______________________________________________________________________<br />

Date <strong>and</strong> Time <strong>of</strong> the incident:. _____________________________________________<br />

Building or location <strong>of</strong> incident _____________________________________________<br />

Task being done when the incident occurred:___________________________________<br />

_______________________________________________________________________<br />

_______________________________________________________________________<br />

_______________________________________________________________________<br />

Witnesses:______________________________________________________________<br />

_______________________________________________________________________<br />

Describe how the incident occurred.__________________________________________<br />

_______________________________________________________________________<br />

_______________________________________________________________________<br />

Describe physical injuries__________________________________________________<br />

_______________________________________________________________________<br />

_______________________________________________________________________<br />

Date <strong>and</strong> time medical attention was sought____________________________________<br />

Name <strong>of</strong> doctor <strong>and</strong> health care facility. _______________________________________<br />

_______________________________________________________________________<br />

Describe property damage__________________________________________________<br />

_______________________________________________________________________<br />

Estimate <strong>of</strong> property damage (if known) ______________________________________<br />

Describe what could have been done to prevent an incident <strong>of</strong> this type. _____________<br />

_______________________________________________________________________<br />

_______________________________________________________________________<br />

Signature; __________________________ Date_____________________<br />

Page 23 <strong>of</strong> 23