Equipment Tune-Up Worksheet - Focus on Energy

Equipment Tune-Up Worksheet - Focus on Energy

Equipment Tune-Up Worksheet - Focus on Energy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

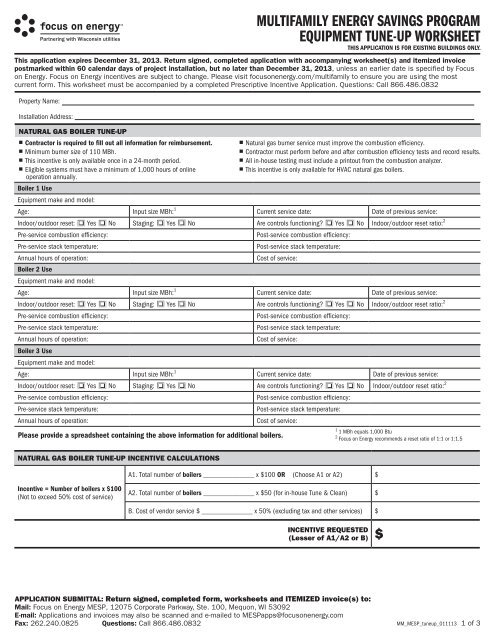

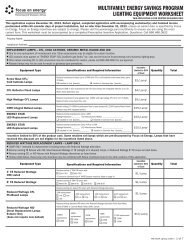

MultifaMily EnErgy SavingS PrograM<br />

EQuiPMEnt tunE-uP WorKSHEEt<br />

THIS APPLICATION IS FOR EXISTING BUILDINGS ONLY.<br />

This applicati<strong>on</strong> expires December 31, 2013. Return signed, completed applicati<strong>on</strong> with accompanying worksheet(s) and itemized invoice<br />

postmarked within 60 calendar days of project installati<strong>on</strong>, but no later than December 31, 2013, unless an earlier date is specified by <str<strong>on</strong>g>Focus</str<strong>on</strong>g><br />

<strong>on</strong> <strong>Energy</strong>. <str<strong>on</strong>g>Focus</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> incentives are subject to change. Please visit focus<strong>on</strong>energy.com/multifamily to ensure you are using the most<br />

current form. This worksheet must be accompanied by a completed Prescriptive Incentive Applicati<strong>on</strong>. Questi<strong>on</strong>s: Call 866.486.0832<br />

Property Name:<br />

Installati<strong>on</strong> Address:<br />

NATURAL GAS BOILER TUNE-UP<br />

n C<strong>on</strong>tractor is required to fill out all informati<strong>on</strong> for reimbursement.<br />

n Minimum burner size of 110 MBh.<br />

n This incentive is <strong>on</strong>ly available <strong>on</strong>ce in a 24-m<strong>on</strong>th period.<br />

n Eligible systems must have a minimum of 1,000 hours of <strong>on</strong>line<br />

operati<strong>on</strong> annually.<br />

Please provide a spreadsheet c<strong>on</strong>taining the above informati<strong>on</strong> for additi<strong>on</strong>al boilers.<br />

n Natural gas burner service must improve the combusti<strong>on</strong> efficiency.<br />

n C<strong>on</strong>tractor must perform before and after combusti<strong>on</strong> efficiency tests and record results.<br />

n All in-house testing must include a printout from the combusti<strong>on</strong> analyzer.<br />

n This incentive is <strong>on</strong>ly available for HVAC natural gas boilers.<br />

Boiler 1 Use<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> make and model:<br />

Age: Input size MBh: 1<br />

Current service date: Date of previous service:<br />

Indoor/outdoor reset: q Yes q No Staging: q Yes q No Are c<strong>on</strong>trols functi<strong>on</strong>ing? q Yes q No Indoor/outdoor reset ratio: 2<br />

Pre-service combusti<strong>on</strong> efficiency: Post-service combusti<strong>on</strong> efficiency:<br />

Pre-service stack temperature: Post-service stack temperature:<br />

Annual hours of operati<strong>on</strong>:<br />

Boiler 2 Use<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> make and model:<br />

Cost of service:<br />

Age: Input size MBh: 1<br />

Current service date: Date of previous service:<br />

Indoor/outdoor reset: q Yes q No Staging: q Yes q No Are c<strong>on</strong>trols functi<strong>on</strong>ing? q Yes q No Indoor/outdoor reset ratio: 2<br />

Pre-service combusti<strong>on</strong> efficiency: Post-service combusti<strong>on</strong> efficiency:<br />

Pre-service stack temperature: Post-service stack temperature:<br />

Annual hours of operati<strong>on</strong>:<br />

Boiler 3 Use<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> make and model:<br />

Cost of service:<br />

Age: Input size MBh: 1<br />

Current service date: Date of previous service:<br />

Indoor/outdoor reset: q Yes q No Staging: q Yes q No Are c<strong>on</strong>trols functi<strong>on</strong>ing? q Yes q No Indoor/outdoor reset ratio: 2<br />

Pre-service combusti<strong>on</strong> efficiency: Post-service combusti<strong>on</strong> efficiency:<br />

Pre-service stack temperature: Post-service stack temperature:<br />

Annual hours of operati<strong>on</strong>: Cost of service:<br />

NATURAL GAS BOILER TUNE-UP INcENTIvE cALcULATIONS<br />

Incentive = Number of boilers x $100<br />

(Not to exceed 50% cost of service)<br />

A1. Total number of boilers ______________ x $100 OR (Choose A1 or A2) $<br />

A2. Total number of boilers ______________ x $50 (for in-house <str<strong>on</strong>g>Tune</str<strong>on</strong>g> & Clean) $<br />

B. Cost of vendor service $ ______________ x 50% (excluding tax and other services) $<br />

APPLICATION SUBMITTAL: Return signed, completed form, worksheets and ITEMIZED invoice(s) to:<br />

Mail: <str<strong>on</strong>g>Focus</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> MESP, 12075 Corporate Parkway, Ste. 100, Mequ<strong>on</strong>, WI 53092<br />

E-mail: Applicati<strong>on</strong>s and invoices may also be scanned and e-mailed to MESPapps@focus<strong>on</strong>energy.com<br />

Fax: 262.240.0825 Questi<strong>on</strong>s: Call 866.486.0832<br />

1 1 MBh equals 1,000 Btu<br />

2 <str<strong>on</strong>g>Focus</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> recommends a reset ratio of 1:1 or 1:1.5<br />

INcENTIvE REqUESTEd<br />

(Lesser of A1/A2 or B) $<br />

MM_MESP_tuneup_011113 1 of 3

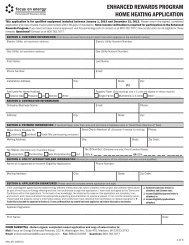

MultifaMily EnErgy SavingS PrograM<br />

EQuiPMEnt tunE-uP WorKSHEEt<br />

This applicati<strong>on</strong> expires December 31, 2013. Return signed, completed applicati<strong>on</strong> with accompanying worksheet(s) and itemized invoice<br />

postmarked within 60 calendar days of project installati<strong>on</strong>, but no later than December 31, 2013, unless an earlier date is specified by <str<strong>on</strong>g>Focus</str<strong>on</strong>g><br />

<strong>on</strong> <strong>Energy</strong>. <str<strong>on</strong>g>Focus</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> incentives are subject to change. Please visit focus<strong>on</strong>energy.com/multifamily to ensure you are using the most<br />

current form. This worksheet must be accompanied by a completed Prescriptive Incentive Applicati<strong>on</strong>. Questi<strong>on</strong>s: Call 866.486.0832<br />

STEAM TRAP REPAIR/REPLAcEMENT<br />

THIS APPLICATION IS FOR EXISTING BUILDINGS ONLY.<br />

n Steam trap repair incentives must be accompanied by a completed log sheet.<br />

n Repair incentives are <strong>on</strong>ly available for the repair or replacement of traps that have malfuncti<strong>on</strong>ed and are leaking steam. Repair incentives are not available for traps<br />

that are failed closed or are plugged.<br />

n A copy of the paid invoice must be submitted with this worksheet. Repair incentives will not exceed invoice cost.<br />

n These incentives are available <strong>on</strong>ly <strong>on</strong>ce per steam system per 12-m<strong>on</strong>th period.<br />

n Municipal steam systems (i.e., “city steam”) are not a qualifying utility.<br />

n Mass Replacement: For mass replacement of steam traps incentive is <strong>on</strong>ly available for 20% of the repaired traps.<br />

n Log Sheet: Steam trap repair work must be recorded and attached to the applicati<strong>on</strong> in order to be eligible for incentives. Vendor must create and fill in the log as work is<br />

completed. Required fields (minimum):<br />

n ID Tag Number n Indicate C<strong>on</strong>diti<strong>on</strong> (check ONE): n Survey Date/Repair Date<br />

n Locati<strong>on</strong> Descripti<strong>on</strong> q Functi<strong>on</strong>ing Properly n Survey/Repair Technician Name<br />

n Nominal Steam Pressure q Malfuncti<strong>on</strong>ing - Not Leaking Steam n Orifice Size (if repaired or replaced)<br />

n Trap Type q Malfuncti<strong>on</strong>ing - Leaking Steam n Notes<br />

STEAM TRAP REPAIR/REPLAcEMENT INcENTIvE cALcULATIONS<br />

Number of radiator traps ______________ x $25 $<br />

Number of all other traps ______________ x $50 $<br />

A1. Total incentive for traps (radiator + all other) OR (Choose A1 or A2) $<br />

A2. If mass replacement, Total incentive for traps $______________ x 20% $<br />

B. Cost of vendor service $______________ x 50% (excluding tax and other services) $<br />

INcENTIvE REqUESTEd<br />

(Lesser of A1/A2 or B) $<br />

MM_MESP_tuneup_011113 2 of 3

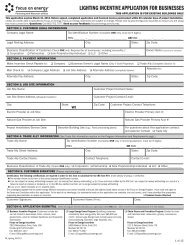

MultifaMily EnErgy SavingS PrograM<br />

EQuiPMEnt tunE-uP WorKSHEEt<br />

THIS APPLICATION IS FOR EXISTING BUILDINGS ONLY.<br />

This applicati<strong>on</strong> expires December 31, 2013. Return signed, completed applicati<strong>on</strong> with accompanying worksheet(s) and itemized invoice<br />

postmarked within 60 calendar days of project installati<strong>on</strong>, but no later than December 31, 2013, unless an earlier date is specified by <str<strong>on</strong>g>Focus</str<strong>on</strong>g><br />

<strong>on</strong> <strong>Energy</strong>. <str<strong>on</strong>g>Focus</str<strong>on</strong>g> <strong>on</strong> <strong>Energy</strong> incentives are subject to change. Please visit focus<strong>on</strong>energy.com/multifamily to ensure you are using the most<br />

current form. This worksheet must be accompanied by a completed Prescriptive Incentive Applicati<strong>on</strong>. Questi<strong>on</strong>s: Call 866.486.0832<br />

cOOLING EqUIPMENT TUNE-UP<br />

n This incentive is available <strong>on</strong>ly <strong>on</strong>ce in a 24-m<strong>on</strong>th period.<br />

n An individual chiller is c<strong>on</strong>sidered <strong>on</strong>e unit. A rooftop unit is c<strong>on</strong>sidered <strong>on</strong>e unit.<br />

n A copy of the paid invoice (or work order and annual service agreement) must be included with this worksheet.<br />

n Cooling service must include the following normal maintenance items (as applicable):<br />

n Air-cooled c<strong>on</strong>denser coil cleaning<br />

n System pressure check and adjust<br />

n Filter inspect or replace<br />

n Belt inspect or replace<br />

n Ec<strong>on</strong>omizer c<strong>on</strong>diti<strong>on</strong> check & repair<br />

n C<strong>on</strong>tactors c<strong>on</strong>diti<strong>on</strong><br />

n Evaporator c<strong>on</strong>diti<strong>on</strong><br />

UNIT 1<br />

UNIT 2<br />

UNIT 3<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> Type:<br />

q Unitary/Rooftop Unit A/C<br />

q Split System A/C<br />

q Air-Cooled Chiller<br />

q Water-Cooled Chiller<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> Type:<br />

q Unitary/Rooftop Unit A/C<br />

q Split System A/C<br />

q Air-Cooled Chiller<br />

q Water-Cooled Chiller<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> Type:<br />

q Unitary/Rooftop Unit A/C<br />

q Split System A/C<br />

q Air-Cooled Chiller<br />

q Water-Cooled Chiller<br />

n Compressor amp draw<br />

n Supply motor amp draw<br />

n C<strong>on</strong>densor fan(s) amp draw<br />

n Liquid line temperature<br />

n Subcooling & superheat<br />

n Sucti<strong>on</strong> pressure & temperature<br />

n Oil level & pressure<br />

Manufacturer: Model #:<br />

n Low pressure c<strong>on</strong>trols<br />

n High pressure c<strong>on</strong>trols<br />

n Crankcase heater operati<strong>on</strong><br />

n Water-cooled chiller c<strong>on</strong>denser tube cleaning<br />

n Water-cooled chiller evaporator tube cleaning<br />

Date of Previous Service: Current Service Date:<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> Capacity in T<strong>on</strong>s:<br />

Describe work performed:<br />

Manufacturer: Model #:<br />

Date of Previous Service: Current Service Date:<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> Capacity in t<strong>on</strong>s:<br />

Describe work performed:<br />

cOOLING EqUIPMENT TUNE-UP INcENTIvE cALcULATIONS<br />

Manufacturer: Model #:<br />

Date of Previous Service: Current Service Date:<br />

<str<strong>on</strong>g>Equipment</str<strong>on</strong>g> Capacity in T<strong>on</strong>s:<br />

Describe work performed:<br />

Did you indicate equipment type for each unit above? (required to receive incentive) q Yes<br />

A. Total of equipment capacity of all units above in t<strong>on</strong>s _____ x $2.00/t<strong>on</strong> $<br />

B. Cost of service = $_________________ x 50% $<br />

INcENTIvE REqUESTEd<br />

(Lesser of A or B) $<br />

TOTAL INcENTIvE REqUESTEd<br />

(all line items pages 1-3): $<br />

MM_MESP_tuneup_011113 3 of 3