python brochure.indd - Gekko Systems

python brochure.indd - Gekko Systems

python brochure.indd - Gekko Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Step change<br />

benefits<br />

Unique technology<br />

Smart design<br />

Environomic Processing<br />

CONCENTRATING ON THE FUTURE, NOW

When you pre-concentrate ore in<br />

a modular plant, with a low energy<br />

processing system like the Python,<br />

you can count on substantial<br />

reductions in cost structures<br />

and environmental impact.<br />

Python Environomics<br />

Lowest environmental<br />

& life of mine costs<br />

= highest ROI<br />

GEKKO ILR<br />

BACKFILL<br />

TAILS<br />

ROCK CUTTING<br />

Underground processing<br />

reduces haulage by 70%<br />

DRILL AND BLAST<br />

STOPE<br />

BACKFILL<br />

PYTHON PLANT<br />

ORE PASS<br />

TAILS<br />

CONCENTRATE<br />

PYTHON PLANT

Potential total<br />

mine cost savings<br />

of 15% to 25%<br />

SUPERCHARGED RETURNS<br />

Welcome to Python’s Lean Mining concepts and higher<br />

operating margins. Fewer process steps, less stock<br />

piles, reduced handling, high upfront waste rejection<br />

and low power usage all result in greater profitability.<br />

ACCELERATED CASH FLOW<br />

The key to accelerated cash flow is fast environmental<br />

permitting and reduced infrastructure investment.<br />

Modular design, fast equipment build and ease of<br />

installation all support a quick pathway to cash<br />

flow and investment returns.<br />

ENVIRONMENTAL BENEFITS<br />

The concept of pre-concentration using gravity and<br />

flotation minimises or eliminates the use of chemicals<br />

on site and resident in tailing facilities. Check out the<br />

low power consumption per tonne treated and you’ll<br />

complete the picture of an environmentally improved<br />

processing strategy.<br />

Successful<br />

Python<br />

Installation<br />

Steps<br />

We want to make sure, as you<br />

do, that the Python provides<br />

the benefits you seek.<br />

Here’s our checklist;<br />

1. Mineral applications<br />

The equipment is primarily<br />

designed for free gold and<br />

sulphides. Applications and<br />

data is based on our experience<br />

within that sector, however<br />

logically other heavy mineral<br />

applications will be suitable.<br />

2. Ore mineralogy<br />

Typically, the coarser the mineral<br />

For pre-concentration by gravity and liberates, the higher the recovery<br />

flotation to work effectively in this and economic return on an ore.<br />

system, the ore body must undergo a For optimal Python performance:<br />

simple test work program. Liberation a) Gold/Sulphide Liberation > 250µm<br />

characteristics of mineral at various b) Recovery 80% - 100%<br />

grind sizes will determine if the Python c) Concentrate mass 0 - 30%<br />

will provide an economic return.<br />

Gold Recovery<br />

Yield Recovery Curve<br />

100%<br />

90%<br />

80%<br />

70%<br />

60%<br />

50%<br />

BGF (Gravity Only)<br />

40%<br />

RSA (Gravity and Flotation)<br />

30%<br />

OTHER (Gravity and Flotation)<br />

20%<br />

3. Test work<br />

A test work program is essential.<br />

<strong>Gekko</strong> can provide this service<br />

or key test work protocols to<br />

an independent laboratory<br />

at your request.<br />

Mineral characterisation test work<br />

that achieves recoveries in this<br />

zone are highly amenable to the<br />

Python processing system<br />

Plus 90% recoveries can be<br />

achieved in some ore bodies such<br />

as Ballarat Goldfields (BGF Gravity<br />

Only) and Witwatersrand ore<br />

(RSA Gravity and Flotation).<br />

10%<br />

Some ores may not be amenable<br />

0<br />

0<br />

20% 40% 60% 80% 100%<br />

Mass Yield<br />

to pre-concentration as shown by<br />

the yield curve denoted in grey.<br />

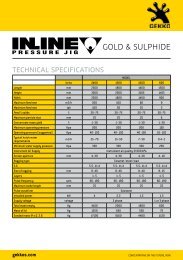

UNIQUE TECHNOLOGY: SMART DESIGN<br />

Low Profile Feeder<br />

Reduced height for use<br />

underground and easy<br />

transport<br />

Closed Circuit Jaw Crushing<br />

Dust & Spillage<br />

Management<br />

Vapour sprays essential<br />

for equipment use<br />

underground. Material<br />

runs wet in fines circuit<br />

2nd Stage Crushing<br />

Only 2 stages of<br />

crushing required to<br />

achieve target particle<br />

size distribution<br />

Closed Circuit, High<br />

Reduction Crushing<br />

Highly effective crushing<br />

design is a critical factor<br />

in the Python’s low<br />

power usage<br />

Low Profile Multi Stage IPJ Gravity Circuit<br />

The InLine Pressure Jig is a proven low<br />

cost proprietary continuous gravity device.<br />

Low profile due to its pressurisation<br />

High Capacity<br />

Coarse Flotation<br />

Flash flotation operates<br />

as a scavaging system<br />

to recover mineral from<br />

gravity tails<br />

Water Recycled to Plant<br />

Both the flotation and InLine<br />

Pressure Jig systems can<br />

operate effectively on<br />

recycled water<br />

Fully Automated<br />

Control System<br />

The Python has been<br />

designed with full<br />

automation for ease<br />

of operation

State of the Art Design<br />

High Efficiency Separation<br />

Computational Fluid Dynamics (CFD) and<br />

Discrete Element Method (DEM) modelling<br />

has been used to optimise InLine Pressure<br />

Jig design and performance.<br />

Structural Integrity<br />

Finite Element Analysis (FEA) has been<br />

utilised to ensure modules are structurally<br />

sound during operation.<br />

5m<br />

Turning Circle<br />

The Python 200 has the same turning<br />

circle as a 50 tonne underground truck.<br />

5m<br />

Static Stability Factors &<br />

Design Envelope<br />

The Python 200 in transport mode<br />

has a rollover safety factor of 0.80.<br />

BALLARAT–HQ<br />

T: +61 3 5339 5859<br />

F: +61 3 5339 5803<br />

E: gekkos@gekkos.com<br />

PERTH<br />

T: +61 8 9203 6950<br />

F: +61 8 9203 6951<br />

E: gekkos@gekkos.com<br />

gekkos.com<br />

JOHANNESBURG<br />

T: +27 (11) 448 1222<br />

F: +27 (11) 448 1230<br />

E: gekkos@gekkos.co.za<br />

VANCOUVER<br />

T: +1 604 681 2288<br />

F: +1 604 681 2220<br />

E: gekkos@gekkos.ca