GEKKO METALLURGICAL LABORATORY - Gekko Systems

GEKKO METALLURGICAL LABORATORY - Gekko Systems

GEKKO METALLURGICAL LABORATORY - Gekko Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>GEKKO</strong><br />

<strong>METALLURGICAL</strong><br />

<strong>LABORATORY</strong><br />

CONCENTRATING ON THE FUTURE, NOW<br />

Specialist, world-class laboratory,<br />

backed by technical expertise

Experienced personnel<br />

working in conjunction<br />

with our world-class<br />

technical and sales team<br />

EQUIPPED AND SKILLED<br />

BACKGROUND<br />

<strong>Gekko</strong> <strong>Systems</strong> operates a fully equipped mineral processing laboratory located within a modern<br />

purpose-built facility at its Ballarat office. Additional laboratories are being established at other <strong>Gekko</strong><br />

centres to expand this service. The laboratory staff comprises a team of experienced personnel who<br />

work in conjunction with the world-class technical and sales team to develop and facilitate test work<br />

protocols for many ore types. <strong>Gekko</strong> is the world leader in the development of continuous gravity<br />

separation systems and its expertise in designing test work programs includes gravity separation,<br />

flotation, intensive cyanide leaching, electrowinning, sizing and various other metallurgical analytical<br />

procedures. Their specialty is in the recovery of precious metals and heavy minerals or gangue.<br />

APPLICATIONS<br />

The <strong>Gekko</strong> metallurgical facility has completed test work protocols on a vast array of minerals<br />

including, but not limited to, Au, Ag, Cu, W, Fe, Pb, Zn, Sn, S.<br />

THE <strong>GEKKO</strong> <strong>METALLURGICAL</strong> <strong>LABORATORY</strong> SPECIALISES IN:<br />

• Testing of pre-concentration and gangue rejection<br />

• Optimum mineral liberation<br />

• Optimum comminution and feed preparation<br />

• Alternative comminution methods and mineral liberation e.g. (HPGR, VSI)<br />

• Optimising feed size to enhance pre-concentration or gangue rejection<br />

• Continuous Gravity Recovery (CGR) – <strong>Gekko</strong> protocol<br />

• Gravity Recoverable Gold (GRG) – can be completed using single or three stage protocol<br />

• Combined gravity and flotation recovery<br />

• Scavenging of fine fractions via centrifugal gravity separation, and/or flotation<br />

• Intensive cyanide leaching of pre-concentrated ore<br />

• Optimum recovery of gold and silver from solution via Ion Exchange Resin (Aurix®100)<br />

and/or electrowinning

TEST WORK PROGRAMS<br />

SAMPLE PREPARATION AND GRINDING EQUIPMENT<br />

The <strong>Gekko</strong> Metallurgical laboratory is equipped with a 10kW Vertical Shaft Impactor, two sets of jaw<br />

crushers, rolls crusher, HPGR, rod and ball mills, LM1.5 pulverising machine and a hammer mill. <strong>Gekko</strong>’s<br />

sample preparation includes sizing and analysis equipment including shaker screens, riffle and rotary<br />

splitters and a cyclo-sizer. Also available are screens for coarse testing and fine sizing from 150mm down<br />

to 20 micron.<br />

FLOTATION<br />

Flotation equipment includes an Agitair and Denver flotation machines, with a range of float cells available.<br />

GRAVITY SEPARATION<br />

The laboratory has a range of batch centrifugal concentrators including the InLine Spinner, Knelson and<br />

Falcon Batch Concentrators. Also included is a lab scale dense media separation unit, Wilfley tables,<br />

Mozley Lab Separator and an InLine Pressure Jig (IPJ600) pilot plant.<br />

The IPJ pilot plant can treat material of 6mm in both open and closed circuit configurations – typically<br />

treating 200kg sample batches.<br />

GOLD LEACHING<br />

<strong>Gekko</strong> <strong>Systems</strong> is the world leader in gold and silver leaching test protocols. Intensive cyanidation can be<br />

performed using <strong>Gekko</strong>’s mini InLine Leach Reactor. Additional lab scale leach vessels are available for<br />

Carbon-In-Pulp (CIP), Carbon-In-Leach (CIL) and Resin-In-Pulp (RIP) test protocols. Bottle roll devices<br />

are available for smaller scale leaching tests when sample availability is minimal. Heated leaching tests are<br />

available where required and is applicable to whole-ore gravity, flotation and gravity/float concentrates.<br />

DETOX OF CN SOLUTIONS<br />

<strong>Gekko</strong> has recently added cyanide detox test work services at their facilities in both Australia and Canada<br />

using the latest technologies available in the mining industry. Detailed test work programs using S02/Air,<br />

peroxide or Caro’s Acid are developed from client requirements. The test work protocols used ensure<br />

metal and cyanide discharge limits meet permit levels or company standards. <strong>Gekko</strong> is able to test both<br />

slurries and solutions for Greenfields and Brownfields projects. Through consultation with <strong>Gekko</strong>’s own<br />

Cyanide Detox Group throughout the testwork program <strong>Gekko</strong> can provide solutions for your cyanide detox<br />

circuit.<br />

LEACH PILOT PLANT EQUIPMENT<br />

Pilot plant equipment available includes a lab scale InLine Leach Reactor that processes up to 110Kg of<br />

feed solids at 10-50kg per hour. There is also a larger scale ILR that can be used for high sample loads.<br />

ELECTROWINNING<br />

A lab scale electrowinning cell is available to determine the recovery of gold and silver from solution in<br />

conventional or <strong>Gekko</strong> electrowinning cells. <strong>Gekko</strong>’s electrowinning systems was developed for highvolume<br />

silver concentrate which incorporate auto-sludge harvesting. In combination with the high efficiency<br />

of the ILR, a substantially high overall recovery is obtained.<br />

RESIN<br />

Preliminary bench-scale testwork can be carried out with AuRIX 100 using leach solutions to determine<br />

the technical viability of the resin for gold/silver recovery and to provide process design parameters for the<br />

prelim RIS solution.<br />

GRAVITY SEPARATION SPECIALISTS<br />

Gravity separation by its very nature provides opportunities to both reduce costs and improve the<br />

environmental profile of mineral processing. Maximising recovery through gravity separation by creating a<br />

high-grade stream of concentrates for preferential treatment is a significant conceptual platform to help<br />

achieve these objectives. Gravity separation also has an important function in the efficient removal of<br />

waste. The following are specialised tests utilised by <strong>Gekko</strong>’s metallurgical laboratory:<br />

VIKING CONE<br />

The Viking Cone simulates single pass recoveries only. It utilises a ferro-silicon slurry to float or sink coarse<br />

rocks, based on slurry density. It has been proven to be effective for testing particles >5mm.<br />

DENSE MEDIA SEPARATION (DMS)<br />

The Dense Media Cyclone is a recent addition to the family of tests. Results of DMS align with the<br />

Viking testwork. Dense media separation plants can be configured to follow gravity circuits, multi-gravity<br />

separation and/or flotation on particles between >1mm and

TEST WORK PROGRAMS<br />

SAMPLE PREPARATION AND GRINDING EQUIPMENT<br />

The <strong>Gekko</strong> Metallurgical laboratory is equipped with a 10kW Vertical Shaft Impactor, two sets of jaw<br />

crushers, rolls crusher, HPGR, rod and ball mills, LM1.5 pulverising machine and a hammer mill. <strong>Gekko</strong>’s<br />

sample preparation includes sizing and analysis equipment including shaker screens, riffle and rotary<br />

splitters and a cyclo-sizer. Also available are screens for coarse testing and fine sizing from 150mm down<br />

to 20 micron.<br />

FLOTATION<br />

Flotation equipment includes an Agitair and Denver flotation machines, with a range of float cells available.<br />

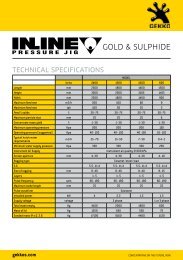

GRAVITY SEPARATION<br />

The laboratory has a range of batch centrifugal concentrators including the InLine Spinner, Knelson and<br />

Falcon Batch Concentrators. Also included is a lab scale dense media separation unit, Wilfley tables,<br />

Mozley Lab Separator and an InLine Pressure Jig (IPJ600) pilot plant.<br />

The IPJ pilot plant can treat material of 6mm in both open and closed circuit configurations – typically<br />

treating 200kg sample batches.<br />

GOLD LEACHING<br />

<strong>Gekko</strong> <strong>Systems</strong> is the world leader in gold and silver leaching test protocols. Intensive cyanidation can be<br />

performed using <strong>Gekko</strong>’s mini InLine Leach Reactor. Additional lab scale leach vessels are available for<br />

Carbon-In-Pulp (CIP), Carbon-In-Leach (CIL) and Resin-In-Pulp (RIP) test protocols. Bottle roll devices<br />

are available for smaller scale leaching tests when sample availability is minimal. Heated leaching tests are<br />

available where required and is applicable to whole-ore gravity, flotation and gravity/float concentrates.<br />

DETOX OF CN SOLUTIONS<br />

<strong>Gekko</strong> has recently added cyanide detox test work services at their facilities in both Australia and Canada<br />

using the latest technologies available in the mining industry. Detailed test work programs using S02/Air,<br />

peroxide or Caro’s Acid are developed from client requirements. The test work protocols used ensure<br />

metal and cyanide discharge limits meet permit levels or company standards. <strong>Gekko</strong> is able to test both<br />

slurries and solutions for Greenfields and Brownfields projects. Through consultation with <strong>Gekko</strong>’s own<br />

Cyanide Detox Group throughout the testwork program <strong>Gekko</strong> can provide solutions for your cyanide detox<br />

circuit.<br />

LEACH PILOT PLANT EQUIPMENT<br />

Pilot plant equipment available includes a lab scale InLine Leach Reactor that processes up to 110Kg of<br />

feed solids at 10-50kg per hour. There is also a larger scale ILR that can be used for high sample loads.<br />

ELECTROWINNING<br />

A lab scale electrowinning cell is available to determine the recovery of gold and silver from solution in<br />

conventional or <strong>Gekko</strong> electrowinning cells. <strong>Gekko</strong>’s electrowinning systems was developed for highvolume<br />

silver concentrate which incorporate auto-sludge harvesting. In combination with the high efficiency<br />

of the ILR, a substantially high overall recovery is obtained.<br />

RESIN<br />

Preliminary bench-scale testwork can be carried out with AuRIX 100 using leach solutions to determine<br />

the technical viability of the resin for gold/silver recovery and to provide process design parameters for the<br />

prelim RIS solution.<br />

GRAVITY SEPARATION SPECIALISTS<br />

Gravity separation by its very nature provides opportunities to both reduce costs and improve the<br />

environmental profile of mineral processing. Maximising recovery through gravity separation by creating a<br />

high-grade stream of concentrates for preferential treatment is a significant conceptual platform to help<br />

achieve these objectives. Gravity separation also has an important function in the efficient removal of<br />

waste. The following are specialised tests utilised by <strong>Gekko</strong>’s metallurgical laboratory:<br />

VIKING CONE<br />

The Viking Cone simulates single pass recoveries only. It utilises a ferro-silicon slurry to float or sink coarse<br />

rocks, based on slurry density. It has been proven to be effective for testing particles >5mm.<br />

DENSE MEDIA SEPARATION (DMS)<br />

The Dense Media Cyclone is a recent addition to the family of tests. Results of DMS align with the<br />

Viking testwork. Dense media separation plants can be configured to follow gravity circuits, multi-gravity<br />

separation and/or flotation on particles between >1mm and