Your Ceramic Solutions Provider - Gigacomp

Your Ceramic Solutions Provider - Gigacomp

Your Ceramic Solutions Provider - Gigacomp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

!<br />

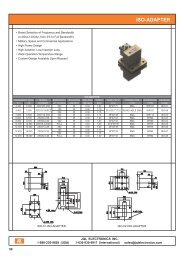

RM Resistor Series<br />

"<br />

Pad Dim. (2X)<br />

Dimensions in inches<br />

Tolerance +/- .005”<br />

unless otherwise stated<br />

Substrate Thickness<br />

and Material<br />

SEE -YY<br />

Flip Chip w/Back Metallization<br />

(Images for reference purposes only.)<br />

_<br />

RM 1005 ZZ XXXX W<br />

N<br />

_<br />

YY<br />

Flip Chip w/Back<br />

Metallization<br />

Example Size<br />

.100” x .050”<br />

(see table below)<br />

Pad Dim.<br />

L x W (Min.)<br />

RM 0202 .025" x .025" .007"<br />

RM 0302 .030" x .020" .005"<br />

RM 0402 .040" x .020" .010"<br />

RM 0502 .050" x .020" .009"<br />

RM 0503 .050" x .030" .010"<br />

RM 0505 .050" x .050" .009"<br />

RM 0603 .060" x .030" .008"<br />

RM 0605 .060" x .050" .010"<br />

RM 0802 .080" x .020" .018"<br />

RM 0805 .075" x .050" .015"<br />

RM 1005 .100" x .050" .010"<br />

RM 1010 .100" x .100" .015"<br />

RM 1206 .120" x .060" .025"<br />

RM 1505 .150" x .050" .015"<br />

RM 2010 .200" x .100" **<br />

RM 2335 .230" x .350" **<br />

RM 2510 .250" x .100" **<br />

RM 2512 .250" x .125" .020"<br />

RM 2525 .250" x .250" .045"<br />

RM 3725 .375" x .250" **<br />

RM 3737 .375" x .375" **<br />

** Varies : R eques t D ata Sheet-P ad D im ens io ns<br />

based on Substrate/M etallizatio n<br />

Termination<br />

Material and<br />

Finish<br />

.1 Ohms to 1 Gigohm<br />

(see examples below)<br />

0.5 .... R500<br />

1.......1R00<br />

10 ..... 10R0<br />

50 ..... 50R0<br />

100 ... 1000<br />

150 ... 1500<br />

1K ..... 1001<br />

10K .. 1002<br />

100K 1003<br />

470K 4703<br />

1M .... 1004<br />

Part Number Example:<br />

RM1005CB-50R0JN-90<br />

RoHS<br />

Tolerance<br />

F...... 1%<br />

G.....2%<br />

J......5%<br />

K.... 10%<br />

L....20%<br />

percent of rated power<br />

100<br />

75<br />

50<br />

25<br />

0<br />

Normal<br />

Inspection<br />

Derating Curve<br />

25 50 75 100 125 150<br />

mounting surface temperature - o C<br />

Substrates<br />

90 ...... .010” Alumina<br />

91 ...... .015” Alumina<br />

93 ...... .025” Alumina<br />

94 ...... .040” Alumina<br />

95 ...... .010” BeO<br />

96 ...... .015” BeO<br />

98 ...... .025” BeO<br />

99 ...... .040” BeO<br />

9F ...... .060” BeO<br />

2S ...... .025” AlN<br />

2T ...... .040” AlN<br />

9"0'()*"? >"? ,. >"? ,.<br />

@!181 9()1+"*/1.:"01,(AB"%1.:"01-(%:"0 ,. >"? >"? ,. >"? ,. ,.<br />

@9181 C*"? >"? ,. ,.<br />

2$D181 =.%/1EF#1G(