ttm2/100es - Gerco

ttm2/100es - Gerco

ttm2/100es - Gerco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Gerco</strong> Kunststofftechnik Trocknen, Fördern und mehr …<br />

Produkt - Information<br />

Two – Chamber – Desiccant - Dryer 2/100 ES; TTM 2/50 ES<br />

Application Area<br />

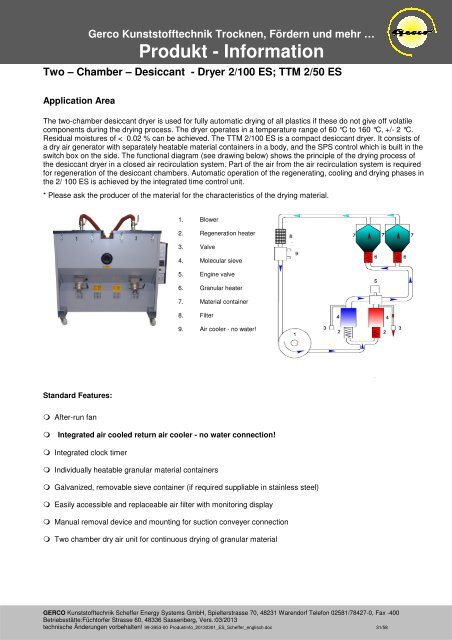

The two-chamber desiccant dryer is used for fully automatic drying of all plastics if these do not give off volatile<br />

components during the drying process. The dryer operates in a temperature range of 60 °C to 160 °C, +/- 2 °C.<br />

Residual moistures of < 0.02 % can be achieved. The TTM 2/100 ES is a compact desiccant dryer. It consists of<br />

a dry air generator with separately heatable material containers in a body, and the SPS control which is built in the<br />

switch box on the side. The functional diagram (see drawing below) shows the principle of the drying process of<br />

the desiccant dryer in a closed air recirculation system. Part of the air from the air recirculation system is required<br />

for regeneration of the desiccant chambers. Automatic operation of the regenerating, cooling and drying phases in<br />

the 2/ 100 ES is achieved by the integrated time control unit.<br />

* Please ask the producer of the material for the characteristics of the drying material.<br />

1. Blower<br />

2. Regeneration heater<br />

3. Valve<br />

4. Molecular sieve<br />

5. Engine valve<br />

6. Granular heater<br />

7. Material container<br />

8. Filter<br />

9. Air cooler - no water!<br />

Standard Features:<br />

After-run fan<br />

<br />

Integrated air cooled return air cooler - no water connection!<br />

Integrated clock timer<br />

Individually heatable granular material containers<br />

Galvanized, removable sieve container (if required suppliable in stainless steel)<br />

Easily accessible and replaceable air filter with monitoring display<br />

Manual removal device and mounting for suction conveyer connection<br />

Two chamber dry air unit for continuous drying of granular material<br />

GERCO Kunststofftechnik Scheffer Energy Systems GmbH, Spielterstrasse 70, 48231 Warendorf Telefon 02581/78427-0, Fax -400<br />

Betriebsstätte:Füchtorfer Strasse 60, 48336 Sassenberg, Vers.:03/2013<br />

technische Änderungen vorbehalten! 99-3953-00 Produktinfo_20130301_ES_Scheffer_englisch.doc 31/58

Technical data<br />

<strong>Gerco</strong> Kunststofftechnik Trocknen, Fördern und mehr …<br />

Produkt - Information<br />

TTM 2/100 ES (TTM 2/50 ES*)<br />

Mechanical data<br />

Electrical data<br />

Dimensions H/W/D) mm 1500 x 1630 x 910 Connected load V / Hz 3 x 400 / 50<br />

Weight kg 280 Power consumption kW 11.8<br />

Capacity liters 2x100 (2x50*) Current consumption A 29,5<br />

Fan capacity m ³ /hr 168 Regenerating heater kW 3.5<br />

Drying temperature °C 60 - 160 Granular material heater kW 2 x 3,5<br />

Residual moisture % < 0.02 Fan power kW 0.9<br />

Drying capacity kg/hr 22 to 65 (11 to 36*)<br />

Two chamber desiccant dryer<br />

TTM 2 / 100 ES Item number 631-000104<br />

TTM 2 / 50 ES Item number 631-000105<br />

The dryer is equipped with RAL 7004 light gray textured paint and the equipment cabinet and cover RAL 7016<br />

(dark gray finish.<br />

Other color shades can be selected at an additional charge if required. The main voltage can be changed at an<br />

additional charge if required.<br />

OPTIONAL FEATURES<br />

Type<br />

Item no.<br />

Single suction tube ES 2 065 - 042525<br />

Made of galvanized steel for sucking<br />

material from the dryer to the processing machine.<br />

Vacuum conveyer GKS 50 071 - 000110<br />

Single component conveyer<br />

with 230 V fan<br />

Vacuum conveyer VSF 101 071 - 000117<br />

Single component conveyer<br />

with 230 V fan<br />

Double Bolt Opening 641 – 047306<br />

to connect two conveyors to the chamber<br />

We reserve the right to make technical changes!<br />

GERCO Kunststofftechnik Scheffer Energy Systems GmbH, Spielterstrasse 70, 48231 Warendorf Telefon 02581/78427-0, Fax -400<br />

Betriebsstätte:Füchtorfer Strasse 60, 48336 Sassenberg, Vers.:03/2013<br />

technische Änderungen vorbehalten! 99-3953-00 Produktinfo_20130301_ES_Scheffer_englisch.doc 32/58