Volume 16 Number 4 - GEO Drilling Fluids, Inc.

Volume 16 Number 4 - GEO Drilling Fluids, Inc.

Volume 16 Number 4 - GEO Drilling Fluids, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Drilling</strong> <strong>Fluids</strong>, <strong>Inc</strong>.<br />

TECHNICAL SERVICES NEWSLETTER<br />

<strong>Volume</strong> XVI, <strong>Number</strong> 4 July 1, 2012<br />

WHAT DO YOU WANT IT TO BE?<br />

I<br />

VALLEY OF OIL<br />

n 1964 the Independent Petroleum Association<br />

of America and The Oildale News produced a<br />

slim volume commemorating 100 years of oil<br />

production in Kern County. There are many fascinating<br />

stories based mostly on published reports<br />

and stories from newspapers.<br />

One of the sections of this book traces the<br />

founding and development of the Tidewater Oil<br />

Company. The story begins in 1895 in Coalinga<br />

which is still an oil producing region of California.<br />

Colorful Charlie Canfield, one of the<br />

“fathers” of what is now Tidewater Oil<br />

Company (now part of ConocoPhillips),<br />

discovered San Joaquin Valley’s famous old<br />

“Oil City” field in 1895 because the fourhorse<br />

wagon that carried his drilling rig got<br />

bogged down and couldn’t be moved.<br />

Valley of Oil<br />

(Connued on page 2)<br />

“Hide not your talents. They for use<br />

were made. What’s a sundial in the<br />

shade?”― Benjamin Franklin<br />

American Statesman, Scienst, Philosopher,<br />

Printer, Writer and Inventor. 1706-1790<br />

1. If filtrate is pink after adding Phenolphthalein<br />

and your pH meter reads 8.2: a) replace your<br />

pH meter, b) replace you Phenolphthalein, c)<br />

add more Desco, d) your filtrate may be lightly<br />

buffered.<br />

2. When making large additions of Barite: a)<br />

don’t run mud cleaner, b) don’t run centrifuge,<br />

c) don’t run degasser, e) don’t run water.<br />

3. Wash the shaker screens: a) with soap and water,<br />

b) as rarely as practical, c) from back to<br />

front, d) from underneath.<br />

W<br />

ANSWERS ON PAGE 2<br />

SAFETY<br />

atch for a survey from Chuck Cartwright<br />

about insurance and employee content (or<br />

discontent). It is important that you take a moment<br />

to fill it out and return it to the office in Bakersfield.<br />

An additional safety award drawing will be held for<br />

those who respond by the date indicated on the<br />

questionnaire.<br />

Remember that if you have any sort of incident,<br />

whether an injury or vehicle accident, it must be<br />

reported to Chuck as soon as possible, 24/7/365.<br />

Waiting a few days is not acceptable.<br />

Pictures taken at a vehicle incident site should<br />

be of the non-<strong>GEO</strong> vehicle(s). As well as the general<br />

surroundings.<br />

"Lord, keep Your arm around my shoulder<br />

and Your hand over my mouth!"

TECHNICAL SERVICES NEWSLETTER VOLUME XVI NUMBER 4 July 1, 2012<br />

Canfield and a man named J. A. Chanslor,<br />

both former gold miners, had formed a partnership<br />

and after drilling some wells in the<br />

Los Angeles area, they shipped their rig to<br />

Coalinga where Canfield loaded it on a wagon<br />

and headed back into the hills to wildcat. A<br />

few miles from town the wagon sank down to<br />

its axles in an alkali dry-bog.<br />

After working furiously for several hours<br />

to get the wagon free, Canfield gave up in<br />

disgust and exclaimed, “Hell! This is just as<br />

good a place as any to drill.” He unloaded the<br />

old “fiddle rig” and put it to work right by the<br />

side of the road. The hole had barely been<br />

drilled to a depth of 400 feet when Charlie<br />

had himself an oil well that flowed light crude<br />

at the rate of 25 barrels a day.”<br />

Four years later, in 1899, a man named J. M.<br />

Ellwood discovered oil in the Kern River section of<br />

the San Joaquin Valley (about 7 miles north of Bakersfield)<br />

… at a depth of 75 feet. The shallow production<br />

was inexpensive to develop. This started<br />

such a rush of drilling that within a short time production<br />

of oil in California had tripled. Prices fell<br />

rapidly, and for some time crude oil could be<br />

bought for as little as 10 cents a barrel.<br />

THE MUD MAN’S CORNER<br />

Near Miss (or is it a Near Hit?)<br />

T<br />

he photograph below of a retort kit shows a<br />

problem with the power cord. There are several<br />

issues here. First and most obvious is that the insulation<br />

is badly broken. This can allow water to<br />

penetrate into the cord and plug causing a short circuit.<br />

It can also lead to bare wires presenting the<br />

possibility of a shock. Any time that a power cord<br />

develops a break in the insulation it should be replaced<br />

or repaired.<br />

The second problem shown here is not as clear.<br />

The reason the power cord insulation broke is that it<br />

was wrapped tightly around the unit while still<br />

plugged in whenever it was not in use. The stress of<br />

being tightly kinked right next to the plug led to the<br />

equipment failure. Power cords should be stored<br />

rolled into loops.<br />

ANSWERS TO WHAT DO YOU WANT IT TO BE?<br />

1. d) your filtrate may be lightly buffered<br />

2. a) don’t run mud cleaner<br />

3. c) from back to front<br />

PAGE 2<br />

Retort Etiquette<br />

If the retort results indicate a solids content that<br />

is unbelievably high there are several potential<br />

problems that have caused this effect. Perhaps the<br />

Retort<br />

(Connued on page 3)

TECHNICAL SERVICES NEWSLETTER VOLUME XVI NUMBER 4 July 1, 2012<br />

Retort<br />

(Connued from page 2)<br />

most common cause is that the Tube (see the photograph<br />

below) is plugged with oily residue. This can<br />

happen with oil base mud when the fatty acids<br />

cause the problem or in mud with crude oil in it<br />

where the asphaltenes and paraffins cool in the tube<br />

Exposed Wires<br />

Tube<br />

Condenser<br />

Threads<br />

Cell<br />

and harden. Clean the tube regularly with a pipe<br />

cleaner, drill or special wire brush. PetroDrill solvent<br />

should be used to rinse out the tube after every<br />

few tests.<br />

Thermostat<br />

High solids may be the result of the thermostat<br />

suddenly not working and the temperature not getting<br />

to the required 950° F. The thermostat usually<br />

fails catastrophically, with the retort not heating at<br />

all. Rarely does it go out of adjustment suddenly.<br />

Adjusting the thermostat should only be done when<br />

a 1000° F thermometer is available. Just guessing<br />

at how far to turn the adjusting screw can lead to<br />

overheating and serious damage.<br />

ball that is 50% larger than the cell diameter works<br />

well.<br />

Is the Mud Cleaner Throwing Out Barite?<br />

The recommended screen size to allow Barite to<br />

return to the mud system is anything coarser than<br />

200 API. Be sure to use the API size, not the part<br />

number or other mesh designations.<br />

In order to determine the content of the solids<br />

going to the sump you should catch a sample and<br />

measure the density (specific gravity) with the mud<br />

balance. If the material is too dry to get a good<br />

weight a small amount of water may be added. This<br />

in no way effects the results. Be sure not to add<br />

enough water that separation starts to occur.<br />

Take the same material from the mud scale and<br />

fill a retort. With the retort results you can determine<br />

the percent barite. This can be done on the<br />

<strong>GEO</strong> <strong>Drilling</strong> <strong>Fluids</strong> mud report by simply substituting<br />

the mud weight and retort results from the<br />

mud cleaner for the mud test results in the mud<br />

checks section. The Daily Mud Report will show<br />

the amount of barite being discarded for every bbl<br />

of material going off the slide.<br />

North Dakota Dewatering<br />

This picture shows a rig in North Dakota. In the<br />

foreground is a dewatering unit. This equipment is<br />

used to remove the finest solids from drilling mud.<br />

When the horizontal section is drilled with salt water<br />

the dewatering unit can maintain the corrected<br />

solids content at or near 0%.<br />

Steel Wool<br />

Steel wool is used in the retort to keep the boiling<br />

mud from getting to the tube before it is converted<br />

to steam. The steel wool should be designated<br />

000 or 0000 in order to be fine enough to provide<br />

a proper barrier. The amount of steel wool to<br />

use is learned by experience, but if you use too<br />

much it will restrict the flow of steam while using<br />

too little will allow whole mud to pass over to the<br />

condenser and into the graduated cylinder. A soft<br />

PAGE 3<br />

<strong>GEO</strong> ZERO-LW Dewatering Unit.

TECHNICAL SERVICES NEWSLETTER VOLUME XVI NUMBER 4 July 1, 2012<br />

THERMAL EXPANSION<br />

Effect of Temperature on Mud Weight<br />

in PetroDrill Systems<br />

By Aaron Philips<br />

W<br />

ith few exemptions, materials expand when<br />

they are heated. As the temperature rises in<br />

our PetroDrill oil base mud system, both the oil and<br />

the salt water in the fluid expand. This expansion<br />

can be observed when the mud weight at the flow<br />

line is lower than at the suction. As the mud cools in<br />

the surface pits the liquids contract resulting in increased<br />

mud weight. When precise mud weight<br />

control is critical it is important to be able to calculate<br />

the expected change in mud weight as the temperature<br />

of the fluid changes.<br />

PetroDrill has three main components: LVT-200<br />

enheit. With LVT-200 more data is available and a<br />

range of expansion rates may me used for various<br />

temperatures and pressures (See Table 1). These<br />

expansion coefficients are useful when calculating<br />

volume changes in the hole but for surface density<br />

changes the only coefficient needed for most situations<br />

is 0.000374. This formula is for surface mud:<br />

MW 2 =<br />

MW 1<br />

(S + W x (1 + 0.000358 x ΔT) + O x (1 + 0.000374 x ΔT))<br />

Other Uses<br />

Due to the contraction of the fluid as it cools<br />

after a long trip the mud weight in the pits can be<br />

very elevated. By using the above equation one can<br />

demonstrate what the mud weight will be once the<br />

system has returned to the normal operating temperature.<br />

The expansion of mud in the well bore as<br />

it heats up can cause a small amount of flow when<br />

pumps are turned off. This can lead to the incorrect<br />

assumption that the well is flowing if only very<br />

short flow checks are taken. For the expansion of<br />

mud in the well bore the expansion coefficients utilized<br />

to determine the expected change in volume<br />

depend on the bottom hole temperatures and pressures<br />

and are calculated using Table 1.<br />

oil, CaCl 2 water, and solids (including clays, drill<br />

solids and Barite). Even over the most extreme temperature<br />

range that PetroDrill goes through the solids<br />

do not expand to any measurable degree. The<br />

liquids, LVT-200 and CaCl 2 water, do expand significantly<br />

over the same temperature range.<br />

Calculations<br />

To calculate the mud weight at a different temperature<br />

(MW 2 ) the following information is used:<br />

1. Change in temperature = ∆T<br />

2. Known mud weight = MW 1<br />

3. Percent oil from retort = O<br />

4. Corrected percent solids = S<br />

5. Corrected percent water = W<br />

CaCl 2 water expands 0.0358% per degree Fahr-<br />

PAGE 4<br />

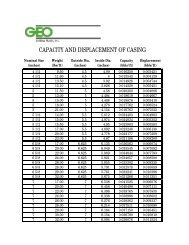

Pressure<br />

(PSI)<br />

Expansion per °F<br />

75 °F to 200 °F<br />

Expansion per °F<br />

200 °F to 300 °F<br />

0 0.000374 0.000417<br />

1,500 0.000354 0.000380<br />

3,000 0.000336 0.000351<br />

4,500 0.000331 0.000342<br />

6,000 0.000321 0.000328<br />

7,500 0.000306 0.000308<br />

9,000 0.000294 0.000292<br />

10,500 0.000283 0.000278<br />

12,000 0.000272 0.000268<br />

13,500 0.000263 0.000259<br />

15,000 0.000255 0.000251<br />

Table 1: Change in volume of LVT-200 as temperature<br />

is changed over normal operang temperatures and<br />

pressures of wells.

TECHNICAL SERVICES NEWSLETTER VOLUME XVI NUMBER 4 July 1, 2012<br />

RELIEF ETIQUETTE<br />

How you would like it to be.<br />

Don Boulet, Operations Manager, Northern California<br />

B<br />

ack in the old days (in the 1970’s—1980’s)<br />

relieving a mud engineer was rare as most<br />

jobs were done by a single person without days off.<br />

Now we relieve each other as often as every week.<br />

What you do to make the job seamless from the<br />

customer’s perspective is critical to a good job with<br />

rave reviews.<br />

Simplify Your Communication<br />

It’s not about big words or long explanations.<br />

It’s about keeping it simple. When you start telling<br />

the story of what has been happening make the beginning<br />

exciting so you get his attention. Start with<br />

the remarkable success or disaster. Then go over the<br />

meat of the matter, discussing relations with the<br />

hands, product consumption, and how the wind is<br />

blowing with the DSM/Company Man. Finish up<br />

with a review of the current activity.<br />

Look Them in the Eye<br />

Talking face to face is effective. Cell phone to<br />

cell phone is NOT as effective and should only be<br />

used as a last resort. Communication has to be a<br />

two way street. When you are seeing the reactions<br />

of the other person you can tell if they are getting<br />

the importance of what you are saying. If they are<br />

staring out the window just waiting for you to drive<br />

off so they can go about their business without your<br />

You may be wondering why it’s<br />

always the mud man’s fault…<br />

there are two thing that go in the<br />

hole, there’s steel and there’s<br />

mud… and it’s prey hard to screw<br />

up steel.<br />

input they may need to be jolted back to reality.<br />

Tell the Truth!<br />

There is no better way to establish your credibility<br />

than to tell the truth. Come on… he’s going to<br />

check it after you leave. Regardless of what the official<br />

line is you gain nothing by failing to fully disclose<br />

the current situation. It may be in the process<br />

of being changed or fixed but your relief still needs<br />

to know.<br />

Get a Response<br />

One person doing all the talking is NOT the<br />

form of communication that makes for good relief.<br />

Respond to what you are hearing. Ask questions.<br />

Become a part of the process, not just an empty<br />

vessel being filled with information.<br />

Count the Material<br />

Daily counting of the material on location is the<br />

only accurate way to determine what is being used.<br />

Relief day gives you a chance to have two sets of<br />

eyes on the process to catch mistakes. Those hidden<br />

sacks of GeoZan that are laying on a partial pallet<br />

of sawdust. Or the pallet of Desco with 10 sacks<br />

missing from the far side. The last thing you want is<br />

to finish a well and be way off on the inventory.<br />

Customers don’t like those surprises, whether in<br />

their favor or not.<br />

One Final Thought<br />

Keep this in mind as you interact with each other<br />

as well as with the roughnecks. This is a quote<br />

from Charles Schwab, 1870-1939, who was the<br />

head of Bethlehem Steel. “I have yet to find the<br />

man, however exalted his station, who did<br />

not do better work and put forth greater effort<br />

under a spirit of approval than under a<br />

spirit of criticism.”<br />

Barite Ore<br />

PAGE 5