Key highlights - BOMAFA Armaturen

Key highlights - BOMAFA Armaturen

Key highlights - BOMAFA Armaturen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

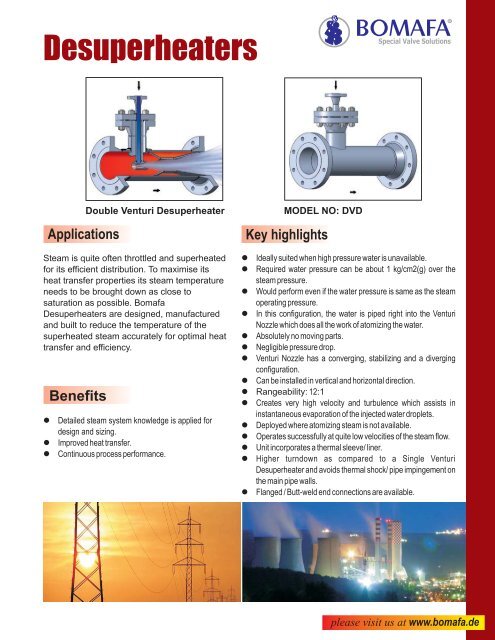

Desuperheaters<br />

Applications<br />

Steam is quite often throttled and superheated<br />

for its efficient distribution. To maximise its<br />

heat transfer properties its steam temperature<br />

needs to be brought down as close to<br />

saturation as possible. Bomafa<br />

Desuperheaters are designed, manufactured<br />

and built to reduce the temperature of the<br />

superheated steam accurately for optimal heat<br />

transfer and efficiency.<br />

Benefits<br />

Double Venturi Desuperheater MODEL NO: DVD<br />

�Detailed steam system knowledge is applied for<br />

design and sizing.<br />

�Improved heat transfer.<br />

�Continuous process performance.<br />

<strong>Key</strong> <strong>highlights</strong><br />

Special Valve Solutions<br />

�Ideally suited when high pressure water is unavailable.<br />

�Required water pressure can be about 1 kg/cm2(g) over the<br />

steam pressure.<br />

�Would perform even if the water pressure is same as the steam<br />

operating pressure.<br />

�In this configuration, the water is piped right into the Venturi<br />

Nozzle which does all the work of atomizing the water.<br />

�Absolutely no moving parts.<br />

�Negligible pressure drop.<br />

�Venturi Nozzle has a converging, stabilizing and a diverging<br />

configuration.<br />

�Can be installed in vertical and horizontal direction.<br />

�Rangeability: 12:1<br />

�Creates very high velocity and turbulence which assists in<br />

instantaneous evaporation of the injected water droplets.<br />

�Deployed where atomizing steam is not available.<br />

�Operates successfully at quite low velocities of the steam flow.<br />

�Unit incorporates a thermal sleeve/ liner.<br />

�Higher turndown as compared to a Single Venturi<br />

Desuperheater and avoids thermal shock/ pipe impingement on<br />

the main pipe walls.<br />

�Flanged / Butt-weld end connections are available.<br />

please visit us at www.bomafa.de<br />

R

Desuperheater<br />

(size in mm)<br />

80-150<br />

200-300<br />

350-450<br />

450-500<br />

Main Steam Pipe<br />

(size in mm)<br />

100-200<br />

200-350<br />

350-500<br />

500-600<br />

Bomafa is a<br />

leading global<br />

supplier of<br />

Severe Service<br />

Valves and<br />

products that<br />

improves<br />

productivity and<br />

quality in Utility<br />

and Process<br />

Industries. For<br />

the closest<br />

location and<br />

contact, visit our<br />

website:<br />

www.bomafa.de<br />

Dimensions (size in mm)<br />

A B C D<br />

80<br />

100<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

550<br />

600<br />

1000<br />

1000<br />

1000<br />

1200<br />

1200<br />

1400<br />

1400<br />

1600<br />

1600<br />

1800<br />

1800<br />

1800<br />

400<br />

425<br />

475<br />

550<br />

600<br />

650<br />

700<br />

750<br />

800<br />

850<br />

900<br />

950<br />

15,20<br />

15, 20, 25<br />

15, 20, 25<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40, 50<br />

15, 20, 25, 40, 50<br />

15, 20, 25, 40, 50<br />

15, 20, 25, 40, 50<br />

Notes:-<br />

1. Material of construction:<br />

a. Desuperheater Pipe: SA 106 Gr. B, SA 335 P11, SA 335 P22, SA 335 P91.<br />

b. Thermal Sleeve/ Liner: SA 106 Gr. B, SA 335 P11, SA 335 P22, SA 335 P91.<br />

c. Nozzle: AISI SS 304/ 316/ DIN 1.4122.<br />

d. Injection Water Pipe: SA 106 Gr. B, SA 335 P11, SA 335 P22, SA 335 P91.<br />

e. Flanges: SA 105, SA 182 F11, SA 182 F22, SA 182 F91.<br />

2. Dimensions can be engineered to fit existing piping/ flange requirements.<br />

3. Dimensions are subject to change without notice.<br />

4. For higher sizes consult factory.<br />

Contact us:<br />

<strong>BOMAFA</strong> <strong>Armaturen</strong> GmbH Hohensteinstrabe 52<br />

44866 Bochum / Deutschland<br />

Tel: +49(0)2327-9920 Fax:+49(0)2327-31443 eMail: info@bomafa.de<br />

Internet: www.bomafa.de<br />

R

Desuperheaters<br />

Fixed Nozzle Desuperheater (Hollow Cone) MODEL NO: FND<br />

Steam is quite often throttled and superheated for its efficient<br />

distribution. To maximise its heat transfer properties its<br />

steam temperature needs to be brought down as close to<br />

saturation as possible. Bomafa Desuperheaters are<br />

designed, manufactured and built to reduce the temperature<br />

of the superheated steam accurately for optimal heat transfer<br />

and efficiency.<br />

�<br />

�<br />

�<br />

Applications<br />

Benefits<br />

Detailed steam system knowledge is applied for<br />

design and sizing.<br />

Improved heat transfer.<br />

Continuous process performance.<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

�<br />

<strong>Key</strong> <strong>highlights</strong><br />

Special Valve Solutions<br />

One of the most simplest forms of desuperheaters and<br />

is also termed as a mechanical desuperheater.<br />

The basic principle of operation is to desuperheat the<br />

steam by introducing water droplets through a spraying<br />

nozzle and breaking the water droplets into a fine mist at<br />

the point of exit.<br />

The performance of this desuperheater corresponds<br />

directly to the design of the spray nozzle. This unit can<br />

handle low turndown requirements usually upto 3:1.<br />

Offers negligible pressure drop across the system.<br />

Requires typical superior water pressure than the steam<br />

operating pressure [recommended superior water<br />

pressure is 5 bar (g)].<br />

Due to this simple construction it is one of the most<br />

economical desuperheater available in the market.<br />

Flanged / Butt-weld end connections are available.<br />

please visit us at www.bomafa.de<br />

R

Desuperheater<br />

(size in mm)<br />

40-80<br />

40-100<br />

40-150<br />

40-150<br />

Main Steam Pipe<br />

(size in mm)<br />

100-200<br />

150-350<br />

250-500<br />

350-600<br />

Bomafa is a<br />

leading global<br />

supplier of<br />

Severe Service<br />

Valves and<br />

products that<br />

improves<br />

productivity and<br />

quality in Utility<br />

and Process<br />

Industries. For<br />

the closest<br />

location and<br />

contact, visit our<br />

website:<br />

www.bomafa.de<br />

Dimensions (size in mm)<br />

A B C D<br />

80<br />

100<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

550<br />

600<br />

1000<br />

1000<br />

1000<br />

1000<br />

1200<br />

1200<br />

1300<br />

1300<br />

1500<br />

1500<br />

1500<br />

1500<br />

400<br />

425<br />

475<br />

550<br />

600<br />

650<br />

700<br />

750<br />

800<br />

850<br />

900<br />

950<br />

15,20<br />

15, 20, 25<br />

15, 20, 25<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40<br />

15, 20, 25, 40, 50<br />

15, 20, 25, 40, 50<br />

15, 20, 25, 40, 50<br />

15, 20, 25, 40, 50<br />

Notes:-<br />

1. Material of construction:<br />

a. Desuperheater Pipe: SA 106 Gr. B, SA 335 P11, SA 335 P22, SA 335 P91.<br />

b. Nozzle: SS 304/ 316/ DIN 1.4122.<br />

c. Injection Water Pipe: SA 106 Gr. B, SA 335 P11, SA 335 P22, SA 335 P91.<br />

d. Flanges: SA 105, SA 182 F11, SA 182 F22, SA 182 F91.<br />

2. Dimensions can be engineered to fit existing piping/ flange requirements.<br />

3. Dimensions are subject to change without notice.<br />

4. For higher sizes consult factory.<br />

5. Different grades of material also available as an option.<br />

Contact us:<br />

<strong>BOMAFA</strong> <strong>Armaturen</strong> GmbH Hohensteinstrabe 52<br />

44866 Bochum / Deutschland<br />

Tel: +49(0)2327-9920 Fax:+49(0)2327-31443 eMail: info@bomafa.de<br />

Internet: www.bomafa.de<br />

R