Annex XV report PROPOSAL FOR IDENTIFICATION OF A ... - ECHA

Annex XV report PROPOSAL FOR IDENTIFICATION OF A ... - ECHA

Annex XV report PROPOSAL FOR IDENTIFICATION OF A ... - ECHA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

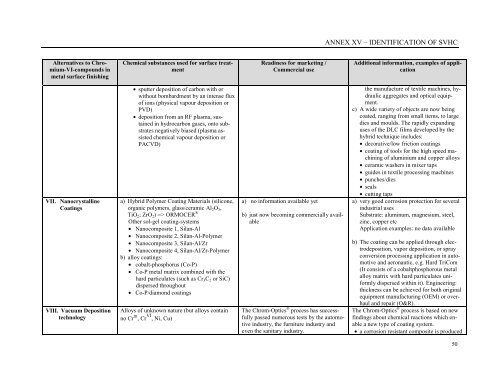

ANNEX <strong>XV</strong> – <strong>IDENTIFICATION</strong> <strong>OF</strong> SVHC<br />

Alternatives to Chromium-VI-compounds<br />

in<br />

metal surface finishing<br />

Chemical substances used for surface treatment<br />

Readiness for marketing /<br />

Commercial use<br />

Additional information, examples of application<br />

VII. Nanocrystalline<br />

Coatings<br />

VIII. Vacuum Deposition<br />

technology<br />

• sputter deposition of carbon with or<br />

without bombardment by an intense flux<br />

of ions (physical vapour deposition or<br />

PVD)<br />

• deposition from an RF plasma, sustained<br />

in hydrocarbon gases, onto substrates<br />

negatively biased (plasma assisted<br />

chemical vapour deposition or<br />

PACVD)<br />

a) Hybrid Polymer Coating Materials (silicone,<br />

organic polymers, glass/ceramic Al 2 O 3 ,<br />

TiO 2 ; ZrO 2 ) => ORMOCER ®<br />

Other sol-gel coating-systems<br />

• Nanocomposite 1, Silan-Al<br />

• Nanocomposite 2, Silan-Al-Polymer<br />

• Nanocomposite 3, Silan-Al/Zr<br />

• Nanocomposite 4, Silan-Al/Zr-Polymer<br />

b) alloy coatings:<br />

• cobalt-phosphorus (Co-P)<br />

• Co-P metal matrix combined with the<br />

hard particulates (such as Cr 3 C 2 or SiC)<br />

dispersed throughout<br />

• Co-P/diamond coatings<br />

Alloys of unknown nature (but alloys contain<br />

no Cr III , Cr VI , Ni, Cu)<br />

a) no information available yet<br />

b) just now becoming commercially available<br />

The Chrom-Optics ® process has successfully<br />

passed numerous tests by the automotive<br />

industry, the furniture industry and<br />

even the sanitary industry.<br />

the manufacture of textile machines, hydraulic<br />

aggregates and optical equipment.<br />

c) A wide variety of objects are now being<br />

coated, ranging from small items, to large<br />

dies and moulds. The rapidly expanding<br />

uses of the DLC films developed by the<br />

hybrid technique includes:<br />

• decorative/low friction coatings<br />

• coating of tools for the high speed machining<br />

of aluminium and copper alloys<br />

• ceramic washers in mixer taps<br />

• guides in textile processing machines<br />

• punches/dies<br />

• seals<br />

• cutting taps<br />

a) very good corrosion protection for several<br />

industrial uses<br />

Substrate: aluminum, magnesium, steel,<br />

zinc, copper etc<br />

Application examples: no data available<br />

b) The coating can be applied through electrodeposition,<br />

vapor deposition, or spray<br />

conversion processing application in automotive<br />

and aeronautic, e.g. Hard TriCom<br />

(It consists of a cobaltphosphorous metal<br />

alloy matrix with hard particulates uniformly<br />

dispersed within it). Engineering:<br />

thickness can be achieved for both original<br />

equipment manufacturing (OEM) or overhaul<br />

and repair (O&R).<br />

The Chrom-Optics ® process is based on new<br />

findings about chemical reactions which enable<br />

a new type of coating system.<br />

• a corrosion resistant composite is produced<br />

50