+' +HDY\'XW\N: )UHTXHQF\FRQYHUWHU 4XLFNUHIHUHQFH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>+'</strong><br />

<br />

<strong>+HDY\'XW\N</strong>:<br />

<br />

)<strong>UHTXHQF\FRQYHUWHU</strong><br />

<br />

<strong>4XLFNUHIHUHQFH</strong><br />

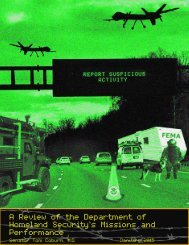

216mm<br />

<br />

CAN<br />

RS232<br />

HD 7500<br />

H1<br />

H2<br />

H3<br />

CLOSE<br />

COM<br />

OPEN<br />

GND<br />

Out1<br />

Out2<br />

Out3<br />

+24V<br />

In1<br />

In2<br />

306mm<br />

In3<br />

In4<br />

GND<br />

AGND<br />

+24V<br />

PWM Out<br />

PWM In<br />

Ana Out<br />

Ana In<br />

10V Ref<br />

U<br />

V<br />

W<br />

PE<br />

PE<br />

L+<br />

RB<br />

L-<br />

PE<br />

L1<br />

L2<br />

L3<br />

&$87,21<br />

Risk of Electric Shock.<br />

The electrical connection<br />

remain life for at least 5<br />

min. after main separation.<br />

PTC<br />

<br />

<br />

<br />

<br />

Version: 13.09.2005 - 1 -

7DEOHRIFRQWHQWV<br />

29(59,(: <br />

,QWURGXFWLRQ <br />

1.1.1 General 4<br />

1.1.2 Block diagram 4<br />

&KDUDFWHULVWLFV <br />

1.2.1 Major characteristics 5<br />

1.2.2 Capability characteristic 5<br />

1.2.3 Protection features 5<br />

7HFKQLFDOVSHFLILFDWLRQ <br />

,167$//$7,21 <br />

,QWURGXFWLRQ <br />

,QVWDOODWLRQRSWLRQV <br />

2.2.1 Installation thermal separated 7<br />

2.2.2 Installation with “Cold Plate“ 7<br />

(OHFWULFDOLQVWDOODWLRQ <br />

7HUPLQDODVVLJQPHQW <br />

2.4.1 Terminal description 8<br />

2.4.2 Pin description of X1 9<br />

2.4.3 Pin description of X2 9<br />

2.4.4 Pin description of X3 9<br />

2.4.5 Pin description of H1 – H4 10<br />

2.4.6 Pin description of T1 – T4 10<br />

2.4.7 Pin description of CAN 10<br />

2.4.8 Pin description of RS232 10<br />

(0&FRPSDWLEOHLQVWDOODWLRQ <br />

,1,7,$/67$5783 <br />

6HULDOLQWHUIDFHSURWRFRO <br />

3.1.1 Control operation 12<br />

3.1.2 Programming parameters 13<br />

3.1.3 Coding of variables 15<br />

<strong>+'</strong>7RRO6RIWZDUH <br />

3.2.1 Description 17<br />

3.2.2 Installation 17<br />

3.2.3 Start the program 17<br />

3.2.4 After start 18<br />

3.2.5 Communication with frequency converter 18<br />

3.2.6 Basic functions 19<br />

3.2.7 Input of new parameters 19<br />

3.2.8 Error messages 19<br />

Version: 13.09.2005 - 2 -

6

2YHUYLHZ<br />

,QWURGXFWLRQ<br />

This short reference describes the most important characteristics of the frequency<br />

converter HD7500 and should be read carefully before the first starting. It serves the<br />

learned user to the fast assembly and starting of the converter. In additionally, the<br />

function, the connections, the installation and the parameter settings are described.<br />

*HQHUDO<br />

The major task is the electronic speed setting of an asynchronous motor.<br />

%ORFNGLDJUDP<br />

Version: 13.09.2005 - 4 -

&KDUDFWHULVWLFV<br />

0DMRUFKDUDFWHULVWLFV<br />

• Rugged design<br />

• Vibration safe<br />

• Simple installation and startup<br />

• Parameter setting using a PC<br />

• Isolated control input:<br />

o serial interface (12V level, RS232, RS485, CAN, IrDA)<br />

o 4 digital outputs<br />

o 4 digital inputs<br />

o 1 PWM input up to 1,6kHz<br />

o 1 PWM output up to 1,6kHz<br />

o 1 Analog output 0-10V/8bit<br />

o 1 Analog input 0-10V/10 bit<br />

o Relay output<br />

• U/f- characteristic, acceleration and deceleration ramps<br />

• integrated brake chopper<br />

• Wide input voltage range: 340 - 520VAC / 47 - 63Hz<br />

&DSDELOLW\FKDUDFWHULVWLF<br />

• Overload 150% for 30 seconds<br />

3URWHFWLRQIHDWXUHV<br />

• Motor protection<br />

• Over current protection<br />

• Over temperature protection<br />

• Short-circuit-protection phase against phase and/or phase against earth<br />

• Over and under voltage monitoring<br />

• I²t - monitoring<br />

• Motor over temperature protection<br />

• phase loss detection<br />

• Status indication on 3 LEDs<br />

Version: 13.09.2005 - 5 -

7HFKQLFDOVSHFLILFDWLRQ<br />

Type<br />

Input voltage<br />

Rated input frequency<br />

Motor rating<br />

Output voltage<br />

Rated output current<br />

Output frequency<br />

Switching frequency<br />

Continuous brake<br />

power<br />

Pulse brake power<br />

HD7500<br />

400V -15% + 30%, 3ph<br />

47 – 63Hz<br />

7,5kW<br />

3 x 0..400V<br />

17A<br />

1 – 100Hz<br />

8kHz<br />

200W<br />

2kW für/for 1sec<br />

Storage temperature -40°C – 85°C<br />

Ambient humidity<br />

95% (non-condensing)<br />

Ambient temperature -20 – 50°C<br />

Maximum Altitude<br />

bis 2000m / up to 2000m<br />

Type<br />

Height<br />

Width<br />

Length<br />

Weight<br />

HD7500<br />

306mm<br />

216mm<br />

164mm<br />

~9kg<br />

Version: 13.09.2005 - 6 -

,QVWDOODWLRQ<br />

,QWURGXFWLRQ<br />

All installation operations shell be carried out after disconnection of the electrical<br />

supply. Risk of electrical shock. The frequency converter and the electrical<br />

connections remain life for up to 5min. after mains separation.<br />

Ensure correct earthing connection of the frequency converter. An inappropriate earth<br />

connection can destroy the frequency converter and causes risk of electrical shock for<br />

persons.<br />

<br />

,QVWDOODWLRQRSWLRQV<br />

,QVWDOODWLRQWKHUPDOVHSDUDWHG<br />

For thermal separated installation the standard heat sink is mounted in the<br />

installation wall.<br />

,QVWDOODWLRQZLWK³&ROG3ODWH³<br />

The HD 7500 frequency converters is available with „Cold Plate“ and can be mounted<br />

directly to an external heat sink or on an enclosure. The area of contact should be as<br />

big as the cold plate of the frequency converter.<br />

Version: 13.09.2005 - 7 -

(OHFWULFDOLQVWDOODWLRQ<br />

7HUPLQDODVVLJQPHQW<br />

216mm<br />

CAN<br />

RS232<br />

HD 7500<br />

H1<br />

H2<br />

H3<br />

CLOSE<br />

COM<br />

OPEN<br />

GND<br />

Out1<br />

Out2<br />

Out3<br />

+24V<br />

In1<br />

In2<br />

;<br />

306mm<br />

;<br />

In3<br />

In4<br />

GND<br />

AGND<br />

+24V<br />

PWM Out<br />

PWM In<br />

Ana Out<br />

Ana In<br />

10V Ref<br />

U<br />

V<br />

W<br />

PE<br />

PE<br />

L+<br />

RB<br />

L-<br />

PE<br />

L1<br />

L2<br />

L3<br />

Risk of Electric Shock.<br />

The electrical connection<br />

remain life for at least 5<br />

min. after main separation.<br />

PTC<br />

+<br />

<br />

7<br />

<br />

7<br />

<br />

&$87,21<br />

7<br />

7 <br />

;<br />

7HUPLQDOGHVFULSWLRQ<br />

¢¡¤£¦¥ §¤¥©¨¤ <br />

X1<br />

X2<br />

X3<br />

H1 – H4<br />

T1 – T4<br />

CAN<br />

RS232<br />

power supply, motor and brake resistor terminal of the frequency converter<br />

control terminal of the frequency converter<br />

terminal for motor protection<br />

status indication<br />

control panel<br />

terminal for CAN connection<br />

terminal for serial interface<br />

Version: 13.09.2005 - 8 -

3LQGHVFULSWLRQRI;<br />

¢¡¤£¦¥ ¥©¤¥ §¤¥©¨¤ <br />

U, V, W - motor terminal, voltage output of the frequency converter<br />

PE - earth terminal of the frequency converter<br />

L+ - positive DC bus link<br />

RB - connection for brake resistor<br />

L- - negative DC bus link<br />

L1 - L3<br />

3 ~ AC,<br />

340..520V<br />

3LQGHVFULSWLRQRI;<br />

power supply terminal of the frequency converter<br />

CLOSE<br />

COM<br />

OPEN<br />

125 Vac / 0.3 A<br />

60 Vdc / 0.5A<br />

30 Vdc / 1 A<br />

relay closer<br />

relay common<br />

relay output opener<br />

¢¡¤£¦¥ ¥©¤¥ ¥¨ © <br />

GND 0V reference potential for digital outputs<br />

Out1<br />

Out2<br />

Out3<br />

Output Voltage:<br />

+5V, +15V or<br />

+24V<br />

max. 10mA<br />

digital I/O 1, internal pull up (10k<br />

digital I/O 2, internal pull up (10k<br />

digital I/O 3, internal pull up (10k<br />

+24V +20 .. 26V power supply for digital inputs<br />

In1<br />

digital input 1, internal pull up (10k<br />

In2<br />

In3<br />

HIGH(+10 ...<br />

+32V)<br />

LOW(0 ... +2V)<br />

digital input 2, internal pull up (10k<br />

digital input 3, internal pull up (10k<br />

In4<br />

digital input 4, internal pull up (10k<br />

GND 0V reference potential for digital inputs<br />

AGND 0V reference potential for analog inputs<br />

+24V +20 .. 26V power supply for digital inputs<br />

PWM out 0 .. +10V PWM output up to 1,6kHz<br />

PWM in 0 .. +10V PWM input up to 1,6kHz<br />

Ana out 0 .. +10V analog output<br />

Ana in 0 .. +10V analog input<br />

+10V Ref +10V Reference for analog Input<br />

3LQGHVFULSWLRQRI;<br />

PTC Resistive input for motor thermal protection device (PTC, Klixon)<br />

<br />

Version: 13.09.2005 - 9 -

3LQGHVFULSWLRQRI+±+<br />

H1 red warning or error<br />

H2 amber operation<br />

H3 green power on<br />

H4 - 7-segment Display<br />

3LQGHVFULSWLRQRI7±7<br />

T1 Ok select or Ok<br />

T2 ESC escape or delete<br />

T3 Up up or increment<br />

T4 Down down or decrement<br />

3LQGHVFULSWLRQRI&$1<br />

Pin1 +5V +5V power supply<br />

Pin2 CANL CAN low line<br />

Pin3 CANG Shield for CAN connection<br />

Pin4 NC Not connected<br />

Pin5 NC Not connected<br />

Pin6 GND Ground for CAN connection<br />

Pin7 CANH CAN high line<br />

Pin8 NC Not connected<br />

Pin9 +5V +5V power supply<br />

3LQGHVFULSWLRQRI56<br />

Pin1 +15V +15V power supply<br />

Pin2 TxD Transmit, 9600 baud, 8,N,1, start bit 10V<br />

Pin3 RxD Receive, 9600 baud, 8,N,1, start bit 10V<br />

Pin4 DTR power control for in circuit programming ICT Programming<br />

Pin5 GND reference potential<br />

Pin6 24V +24V power supply, Hardware selectable<br />

Pin7 NC Not connected<br />

Pin8 A Output A for RS485, optional 12V TTL serial output (Hardware selectable)<br />

Pin9 B Output B for RS485, optional 12V TTL serial input (Hardware selectable)<br />

Version: 13.09.2005 - 10 -

(0&FRPSDWLEOHLQVWDOODWLRQ<br />

Connect the frequency converter to the mounting plate with lock washer. If the<br />

mounting plate is varnished, remove the varnish in mounting area.<br />

Lay motor, power line and signal cables as far away from each other as possible and<br />

separately. Crossing of power cables and control cable should be at an angle of 90<br />

degree.<br />

It is recommended that the motor cable is screened. Connect the shielding on both<br />

sides.<br />

Lay the cable as close as possible to the reference potential.<br />

Version: 13.09.2005 - 11 -

,QLWLDOVWDUWXS<br />

6HULDOLQWHUIDFHSURWRFRO<br />

&RQWURORSHUDWLRQ<br />

+RVW)8<br />

¡ ©!© ¥ ¨¢<br />

" ¢§<br />

¥¤$%©¥ &¤' #<br />

¥¤$%©¥ &( #<br />

)¢¥¢*+¨%¤£<br />

10110100b B4h<br />

1xxxxxxxb<br />

xxxxxxx according to variable coding HD7500<br />

for normal operation coding is 10000000b<br />

FFFFFFFFb FFFFFFF, target frequency of the motor in 1 Hz steps<br />

FFFF000Rb<br />

FFFFFFF, target frequency of the motor in 1/16 Hz steps<br />

R direction of rotation (0..left, 1..right)<br />

xxxxxxxxb start byte + (coding rotate left 1) + (frequency1 rotate left 2) + (frequency2 rotate left 2)<br />

)8+RVW<br />

¨¢ ¡ ©!© ¥<br />

¢§ "<br />

¡, ©¨©-.¥,'<br />

01001011b<br />

0xxxxxxxb<br />

AAAAAAAAb<br />

4Bh<br />

xxxxxx according to variable coding HD7500<br />

for normal operation coding is 00000000b<br />

the requested coding will be answered<br />

¡ ©¨¢-.¥ ¢2 ¥¤$%¢¥©¨¢ ¥¤§3©§ "¦4 ¨¤¥¢¥657 '©7 5¤8<br />

////////10<br />

for normal operation with coding 00000000b, the answer is the Failflag register.<br />

00000000b -> no error<br />

¡, ©¨©-.¥, (<br />

////////10 ¡ ©¨¢-.¥ ¢2 ¥¤$%¢¥©¨¢ ¥¤§3©§ "¦4 ¨¤¥¢¥657 '©7 5¤8<br />

AAAAAAAAb for normal operation with coding 00000000b, the answer is the Failflag register.<br />

00000000b -> no error<br />

xxxxxxxxb start byte + (coding rotate left 1) + (answer1 rotate left 2) + (answer2 rotate left 2)<br />

)¢¥¢*+¨%¤£<br />

Version: 13.09.2005 - 12 -

3URJUDPPLQJSDUDPHWHUV<br />

'DWD+RVW)8<br />

¨¢ ¡ ©!© ¥<br />

¡¤§§ ¥¨¢¨<br />

11010xxxb<br />

xxxxxxxxb<br />

xxxxxxxxb<br />

11011010b<br />

D3h – WRITE<br />

D4h – READ<br />

D5h – ERASE<br />

WRITE xxxxxx according to parameter address<br />

READ xxxxxx according to parameter address<br />

address for ERASE E²PROM<br />

¡© ¡,'<br />

xxxxxxxxb<br />

00000000b<br />

01011011b<br />

WRITE – data for address high<br />

READ<br />

ERASE<br />

¡© ¡¢(<br />

xxxxxxxxb<br />

00000000b<br />

01011011b<br />

WRITE – data for address low<br />

READ<br />

ERASE<br />

xxxxxxxxb start byte + (address rotate left 1) + (data1 rotate left 2) + (data2 rotate left 2)<br />

)¢¥¢*+¨%¤£<br />

'DWD)8±+RVW<br />

00101100b<br />

xxxxxxxxb<br />

2Ch<br />

WRITE xxxxxx according to parameter address<br />

¨¢ ¡ ©!© ¥<br />

xxxxxxxxb<br />

11011010b<br />

READ xxxxxx according to parameter address<br />

address for ERASE E²PROM<br />

¡¤§§ ¥¨¢¨<br />

xxxxxxxxb<br />

xxxxxxxxb<br />

WRITE – data for address high<br />

READ – data for address high<br />

¡© ¡,'<br />

00000000 ERASE<br />

xxxxxxxxb<br />

WRITE – data for address low<br />

¡© ¡¢(<br />

xxxxxxxxb<br />

0000000x<br />

READ – data for address low<br />

ERASE<br />

0 erasing ok<br />

1 error at erasing<br />

xxxxxxxxb start byte + (address rotate left 1) + (data1 rotate left 2) + (data2 rotate left 2)<br />

)¢¥¢*+¨%¤£<br />

<br />

Version: 13.09.2005 - 13 -

Version: 13.09.2005 - 14 -

&RGLQJRIYDULDEOHV<br />

¤" ¡, §¥¨ © <br />

¢,§ ¤¡, ¥<br />

b15 stop motor<br />

b14 not used<br />

b13 rectifier temperatur alarm<br />

b12 power module temperature alarm<br />

b11 motor temperatur alarm<br />

b10 Brake overload<br />

b9 I²t error<br />

0 Failflag<br />

b8 over current<br />

b7 DC Line error<br />

b6 Phase error<br />

b5 input voltage high<br />

b4 input voltage low<br />

b3 fault high side<br />

1 SystemStartUp<br />

2 SystemWarning<br />

3<br />

Reset Status<br />

Register<br />

b2 fault phase W<br />

b1 fault phase V<br />

b0 fault phase U<br />

b15 not used<br />

b14 not used<br />

b13 not used<br />

b12 not used<br />

b11 not used<br />

b10 not used<br />

b9 Ventilation On<br />

b8 Brake On<br />

b7 StartUpOk<br />

b6 RectifierOn<br />

b5 UzkLoadOk<br />

b4 UzkHOk<br />

b3 UzkOk<br />

b2 ElkoLoad<br />

b1 PhaseOk<br />

b0 HardwareOk<br />

b15 not used<br />

b14 not used<br />

b13 not used<br />

b12 SerialTimeout<br />

b11 I²tCount<br />

b10 CurrentReferencWarning<br />

b9 Current overrated<br />

b8 GLTempWarning<br />

b7 IPMTEmpWarning<br />

b6 MotorTempWarning<br />

b5 UzkHOutofRange<br />

b4 UzkOutofRange<br />

b3 L3Fail<br />

b2 L2Fail<br />

b1 L1Fail<br />

b0 Varistor Fail<br />

.7 power On reset (POR)<br />

.6 external reset (Pin)<br />

.5 watchdog (COP)<br />

.4 illegal opcode (ILOP)<br />

.3 illegal address reset (ILAD)<br />

.1 low voltage inhibit reset (LVI)<br />

4 Version Software Version xx.xx<br />

5 Bulid Bulid<br />

Version: 13.09.2005 - 15 -

6 GLTemp Rectifier Temperature measurement point in °C<br />

7 IPMTemp IPM Temperature measurement point in °C<br />

8 MTemp Resistance of motor temperature sensor<br />

9 Uzk main DC voltage 1bit ~ 4V<br />

10 UzkH half main DC voltage 1bit ~ 4V<br />

11 Izk main DC current 1bit ~ 20mA<br />

12 IzkR Reference 128bit<br />

13 IzkM Main DC Current with reference 128bit<br />

14 AnaIn Analog input value in bit<br />

15 - Not used<br />

16 I²t high<br />

17 I²t low byte<br />

maximum load integral<br />

18 BrakeI²t high<br />

19 BrakeI²t low Brake load integral<br />

20 Brake PWM<br />

21 SerialTarget target output frequency serial<br />

22 CANTarget target output frequency CAN<br />

23 DigitalTarget target output frequency digital<br />

24 PWMTarget target output frequency PWM<br />

25 AnalogTarget target output frequency analog<br />

26 TastTarget target output frequency switches<br />

27 SerTimeOutCounter serial timeout counter<br />

28 CANTimeOutCounter CAN timeout counter<br />

29 PWMPeriode period of PWM signal<br />

30 PWMPuls width of PWM signal high<br />

31 PWMBuffer buffer for PWM signal<br />

32 coding serial interface coding<br />

33 Notstop emergency stop active<br />

34 target frequency target output frequency<br />

35 actual frequency actual output frequency<br />

36 Direction direction of rotation<br />

37 motor voltage output voltage to motor<br />

38 SinStep step width in sin table<br />

39 Pout output power<br />

40 BootTime bootstrap timer<br />

41 GenTime time of dynamic operation<br />

42 StopTime timer for emergency stop or brake<br />

43 L1FailTime time of operation without L1<br />

44 L2FailTime time of operation without L1<br />

45 L3FailTime time of operation without L1<br />

46 VFailTime time of operation without varistor<br />

47 MainFlag main loop timer<br />

48 Flag flag variable<br />

49 CycleTime cycle timer<br />

50 CountTime counter<br />

51 MTempADC ADC value of motor resistor<br />

52 GLTempADC ADC value of temp sensor<br />

53 IPMTempADC ADC value of temp sensor<br />

54 IOMode<br />

bit 15 – 12 Digital Inputs, bit 11 – 8 button inputs,<br />

low byte port output<br />

55 Uzkload main DC voltage at turn on<br />

56 BrakeGLI overload line brake<br />

Version: 13.09.2005 - 16 -

<strong>+'</strong>7RRO6RIWZDUH<br />

'HVFULSWLRQ<br />

The PC software “HD7500Tool” supports the parameter setting. This graphic user<br />

interface offers fast and simple access to the FU-parameters. With the software the<br />

parameter lists can be stored or loaded from disk.<br />

,QVWDOODWLRQ<br />

Insert the “HD7500Tool CD” into CD-Rom drive. The Setup program starts<br />

automatically. If this should not be the case, start the setup file in the root directory of<br />

the CD and follow the instructions at the screen. During the installation, a directory C:\<br />

HD7500Tool with parameter lists is created.<br />

6WDUWWKHSURJUDP<br />

Start “HD7500Tool” in your start menu.<br />

Version: 13.09.2005 - 17 -

$IWHUVWDUW<br />

&RPPXQLFDWLRQZLWKI<strong>UHTXHQF\FRQYHUWHU</strong><br />

For correct communication between frequency converter and PC the frequency<br />

converter must be connected to mains voltage. The serial connection between PC and<br />

frequency converter must be made either by the options print or a peripheral interface<br />

adapter. Select the COM port on the user interface.<br />

Version: 13.09.2005 - 18 -

%DVLFIXQFWLRQV<br />

New<br />

Open File<br />

Save File<br />

Print<br />

DOWNLOAD<br />

UPLOAD<br />

Clear FU<br />

The existing parameter list is replaced by empty default table.<br />

Opens a saved parameter list.<br />

ATTENTION: parameter lists are “.csv” files.<br />

Saves the parameter list.<br />

ATTENTION: parameter lists are “.csv” files.<br />

Prints the parameter list.<br />

Downloads the parameter list of the connected frequency converter.<br />

ATTENTION: Works only if frequency converter is cleared.<br />

Uploads the parameter list to the connected frequency converter.<br />

Clears the parameter in connected frequency converter.<br />

EXIT<br />

Terminates the program.<br />

&20±LQWHUIDFHEXWWRQ<br />

Define the serial communication port to be used.<br />

,QSXWRIQHZSDUDPHWHUV<br />

The area DESCRITPION, COSTUMER and PROJEKT are for additional definitions of<br />

the parameter list. The additional information is stored in the “.csv” file. To the<br />

frequency converter only changes in column value become operative. This column<br />

value is updated at download and is sent to the frequency converter at upload.<br />

(UURUPHVVDJHV<br />

9DOXHRXWRIUDQJH<br />

<br />

During download this area shows the index of the value which is out of range. If a<br />

value is out of range during uploading the parameter is replaced with a standard<br />

value.<br />

Recommended system requirements:<br />

Pentium III, Celeron 600 MHz or equivalent, 256MB RAM, 1024x768 pixel resolutions,<br />

16 Bit color depth, 30MB free disk space<br />

Microsoft Windows 98/ME/2000/NT 4.0 with SP 6/XP<br />

Version: 13.09.2005 - 19 -

6\VWHPSDUDPHWHUV<br />

3DUDPHWHUWDEOHDQGGHVFULSWLRQ<br />

¤§¤¥©9 ¢¡ ¡£:¥© ¥; ©¡£:¥ ¡,,,7 %, ¡, ¢"¥ ¡¤"¤¥<br />

0.0 line input voltage minimum Uinmin [V] 400 - 560 480 0,257<br />

0.1 line input voltage maximum Uinmax [V] 560 – 750 735 0,257<br />

0.2 line input voltage hysteresis Uinhys [V] 0-10 2 0,257<br />

for control of line input voltage the sine peak voltage is used<br />

for DC input use the corresponding values.<br />

0.3 Rated DC link voltage Uzksoll [V] 400 – 750 560 0,257<br />

Rated value of DC link voltage reference for motor control<br />

(This value is only a reference for motor control and should be 560V)<br />

0.4 DC link voltage minimum Uzkmin [V] 400 – 560 480 0,257<br />

0.5 DC link voltage maximum Uzkmax [V] 560 – 750 735 0,257<br />

0.6 DC link voltage hysteresis Uzkhyst [V] 0-10 4 0,257<br />

¢= ¤©¡, ¡£¦¥ ¥,2 =%©,%©%, ¥, ©<br />

1.0 Rated current Inenn [A] 0-50 17 0,64<br />

1.1 Over current Iover [A] 0-50 25 0,64<br />

1.2 Reduction factor Ired [%] 101-130 105 1<br />

1.3 Maximum load integral GLI [A²s] 0 0<br />

(Iover*0,64)² -<br />

(Inenn*0,64)²<br />

Set rated motor current (Inenn) and over current (Iover) should be maximum 150% of rated current.<br />

From rated current and over current the maximum load integral is calculated.<br />

The reduction factor gives the recovery time when overshooting the rated current. As shown in the diagram, with a<br />

reduction factor of 1,05 the frequency converter recovers in approximately 700 seconds from an overshooting<br />

during 30 seconds with Over current.<br />

Version: 13.09.2005 - 20 -

¢ ©¤¢¡ ¡£:¥© ¥2 %©? 2)¢¡ ¡¢@ ¥, ¨¢ <br />

2.0 U/f – characteristic IxR (eff) IxR [V] 0-50 20 0,64<br />

2.1 U/f – characteristic fx fx [Hz] 0-100 25 1<br />

2.2 U/f – characteristic Ux (eff) Ux [V] 0-400 200 0,64<br />

2.3 U/f – characteristic feck feck [Hz] 0-100 50 0,64<br />

2.4 U/f – characteristic Ueck(eff) Ueck [V] 0-400 400 0,64<br />

2.5 U/f – characteristic fmax fmax [Hz] 0-100 50 1<br />

2.6 U/f – characteristic Umax (eff) Umax [V] 0-400 400 0,64<br />

2.7 U/f – characteristic ramp + Ramp1+ [Hz/s] 1-100 5 1,28<br />

2.8 U/f – characteristic ramp - Ramp- [Hz/s] 1-100 5 1,28<br />

2.9 U/f – characteristic ramp + Ramp2+ [Hz/s] 1-100 5 1,28<br />

2.10 U/f – characteristic fxramp fxramp [Hz] 1-100 5 1<br />

2.11 U/f – characteristic fmin fmin [Hz] 1-100 0 1<br />

Ramp1 + for frequencies between 0 Hz and fxramp, Ramp2+ for frequencies between fxramp and fmax.<br />

fmin is the minimal frequency at startup.<br />

¢ © ¢¢¡, ¡£:¥© ¥,2 ¡*@¥<br />

3.0 DC link voltage, brake on Uzkbon [V] 700 – 800 750 0,257<br />

3.1 DC link voltage, brake off Uzkboff [V] 700 – 800 740 0,257<br />

3.2 Brake resistor value Rbrake [Ohm] 60 – 500 150 1<br />

3.3 Brake resistor nominal power Pbrake [W] 50 – 1000 300 1<br />

3.4 Brake resistor peak power Ppeakbrake [W] 100 – 5000 1000 1<br />

3.5 Time to mean nominal Pb Tbrakenom [s] 10 – 240 10 1<br />

Version: 13.09.2005 - 21 -

©= ©¤©¡, ¡¤£¦¥© ¥,2 2 ¥ §:-.¥©¡,*+¥, "A ¡ ¤"¥<br />

4.0 Pout max in field weakening range Poutmax [W] 100-2000 500 1<br />

4.1<br />

P-part of controller in field weakening<br />

[10 -<br />

Kp<br />

range<br />

Hz/W]<br />

0-50 7,9 2,52<br />

4.2<br />

I-part of controller in field weakening<br />

[10 -<br />

Ki<br />

range<br />

Hz/Ws]<br />

0-1000 396,5 0,013<br />

At operation in field weakening range (feck to fmax) the output power is regulated to Poutmax.<br />

¢ © ¢¢¡, ¡£:¥© ¥,2 ¥©9¢ ¥ ¤§¥¢§¦2%, ¤@ = ¨<br />

5.0 Maximum time for dynamic operation tgen [ms] 0-1000 500 0,2<br />

Maximum time for dynamic operation during deceleration.<br />

5.1 Duration of stop brake tstop [ms] 0-5000 2500 0,2<br />

A stop brake with IxR for tstop after deceleration. To deactivate set to 0.<br />

5.2 On-time emergency stop brake Tnotstop [s] 0-10 5 200<br />

5.3 DC brake power for emergency stop Pnotstop [W] 0-500 260 25<br />

¢ © ¤¢¡, ¡£:¥© ¥¤2 ¤ ¥¢ B2 ¥¢¡©% ¥¨<br />

6.0<br />

Motor temperature monitoring<br />

(0..MotorPTC, 1..switch contact)<br />

Mschutz [sel] 0-1 0 1<br />

6.1 Minimum PTC resistance Rptcmin [Ohm] 0-500 0 1<br />

6.2 Maximum PTC resistance Rptcmax [Ohm] 10-10000 747 1<br />

6.3 Warning PTC resistance Rptcwarn [Ohm] 10-10000 500 1<br />

6.4 Hysterics PTC resistance PTChys [%] 0-20 2 2,56<br />

Parameter for monitoring of motor PTC. With Mschutz a motor PTC monitoring or switching contact can be selected<br />

6.5 Minimum electronic temperature Etmin [°C] -20-20 0 1<br />

6.6 Maximum electronic temperature Etmax [°C] 30-100 78 1<br />

6.7 Warning electronic temperature Ewarn [°C] 30-100 70 1<br />

6.8 Hysterics electronic temperature Ethys [%] 0-20 0,8% 2,56<br />

Parameter for monitoring of electronic temperature.<br />

Version: 13.09.2005 - 22 -

¢ © ¢¢¡, ¡£:¥© ¥,2 ¥¤$%¢¥, ¢©!6¨¤¥ ¢"<br />

9.0 Target frequency Sollvor [sel] 0-3 0 1<br />

0.. target frequency using serial communication<br />

1.. target frequency using CAN<br />

2.. target frequency using digital I/Os<br />

3.. target frequency using PWM I/Os<br />

4.. target frequency using Analog I/Os<br />

5.. target frequency using tastatur<br />

¢= ¤©¡, ¡£¦¥ ¥,2 ¨¢¥ ¡©¢,£3£A%, , ©¡© =<br />

10.0 communication timeout Timeout [ms] 10 – 10000 100 0,2<br />

10.1 enable IrDA communication IrDA [sel] 0-1 0 1<br />

After communication Timeout the motor is turned off.<br />

If IrDA is set to 1, the IR communication port is enabled.<br />

¢= ¤©¡, ¡£¦¥ ¥,2 =C /ED ¢,£3£A%, ©¡© =<br />

11.0 CANMode CANMode [sel] 0-1 0 1<br />

11.1 CANSpeed CANSpeed [sel] 0-3 0 1<br />

11.2 CANAddress CANAdd [sel] 0-63 0 1<br />

CANMode<br />

0.. inactive<br />

1.. active<br />

CANSpeed<br />

0.. 125kbit/s<br />

1.. 250kbit/s<br />

2.. 500kbit/s<br />

3.. 1Mbit/s<br />

CANAddress (Node_ID)<br />

Version: 13.09.2005 - 23 -

¢= ¤©¡, ¡£:¥© ¥,2 ;; " ¡,©F ? G¨<br />

12.0 digital mode Digmode [sel] 0-3 0 1<br />

12.1 fix frequency f0 f0 [Hz] 0-100 0 256<br />

12.2 fix frequency f1 f1 [Hz] 0-100 0 256<br />

12.3 fix frequency f2 f2 [Hz] 0-100 0 256<br />

12.4 fix frequency f3 f3 [Hz] 0-100 0 256<br />

12.5 fix frequency f4 f4 [Hz] 0-100 0 256<br />

12.6 fix frequency f5 f5 [Hz] 0-100 0 256<br />

12.7 fix frequency f6 f6 [Hz] 0-100 0 256<br />

12.8 fix frequency f7 f7 [Hz] 0-100 0 256<br />

12.9 output voltage Uout [sel] 0-3 0 1<br />

12.10 Output mode Outmode [sel] 0-1 0 1<br />

Digital mode:<br />

0.. fix frequency with In4 = start/stop<br />

1.. fix frequency with In3 = left/right, In4 = start/stop<br />

2.. digital potentiometer with In3 = left/right, In4 = start/stop, In1 = up, In2 = down<br />

In3 In2 In1 frequency<br />

0 0 0 f0<br />

0 0 1 f1<br />

0 1 0 f2<br />

0 1 1 f3<br />

1 0 0 f4<br />

1 0 1 f5<br />

1 1 0 f6<br />

1 1 1 f7<br />

3.. Test mode Out1 = In1, Out2 = In2, Out3 = In3, Relay = In4<br />

Output voltage: 0.. 24V, 1..15V, 2..5V, 3..PullUp inactive (logic inverted)<br />

Output mode: 0.. Out1 = H1, Out2 = H2, Out3 = H3<br />

1.. Out1 = under voltage warning<br />

Out2 = H2, Out3 = H1<br />

¢ © ¢¢¡, ¡£:¥© ¥,2 H,IKJLF ? G1¨<br />

13.0 PWM mode PWMmode [sel] 0-1 0 1<br />

For duty cycles from 0 to 100% set PWMmode to 0 and for 10% to 90% to 1.<br />

©= ¤©¡, ¡¤£¦¥© ¥,2 ¡, ©¡, ,"3F ? G¨<br />

14.0 analog input mode Anainmode [sel] 0-3 0<br />

0.. input 0-5V<br />

1.. input 0 -10V<br />

2.. input 0-20mA<br />

3.. input 4-20mA<br />

14.1 analog output mode Anaoutmode [sel] 0-1 0<br />

0.. output 0-5V<br />

1.. output 0 -10V<br />

Version: 13.09.2005 - 24 -

M<br />

5<br />

¥¢¥, ¦N,O "<br />

M<br />

(<br />

¡£A¢¥,NO<br />

M<br />

'<br />

¥¤§AN,O <br />

<br />

<br />

(UURUGLDJQRVWLFVDQGIDLOXUHHOLPLQDWLRQ<br />

2SHUDWLQJVWDWXVLQGLFDWLRQ<br />

§¤¥©¨ <br />

off<br />

on<br />

off off no supply or error<br />

X on in circuit programming is active<br />

off<br />

off<br />

not ready for operation<br />

on<br />

Error (see Error table)<br />

off<br />

motor runs<br />

blink blink motor runs, Warning (see Warning table)<br />

on<br />

motor runs, Error (see Error table)<br />

off<br />

ready for operation<br />

on<br />

blink ready for operation, Warning (see Warning table)<br />

on<br />

ready for operation, Error (see Error table)<br />

<br />

(UURUWDEOH<br />

M=P<br />

§¥¨ © <br />

1 no parameter setting<br />

2 electronic temperature<br />

3 motor temperature<br />

4 brake overload<br />

5 I²t overload<br />

6 over current<br />

7 DC Line<br />

8 phase error<br />

9 input voltage to high<br />

10 input voltage to low<br />

11 high side fail<br />

12 phase W fail<br />

13 phase V fail<br />

14 phase U fail<br />

<br />

:DUQLQJWDEOH<br />

M=P<br />

§¥¨ © <br />

1 output current over rated<br />

2 electronic temperature goes high<br />

3 motor temperature goes high<br />

4 varistors are not more connected<br />

Version: 13.09.2005 - 25 -

6DIHW\DQGRSHUDWLQJLQVWUXFWLRQV<br />

To ensure safe and faultless operation of the frequency converter, appropriate<br />

transport, correct storage, assembly and installation as well as careful handling is<br />

required.<br />

In operation the frequency converter has life unisolated parts, as well as hot surfaces.<br />

In case of improper use, wrong installation or maloperation, there is the danger of<br />

serious personal injury and damage to property.<br />

All operations are to be carried out by skilled technical personnel. For proposes of<br />

these basic safety instructions, “skilled technical personnel” means persons who are<br />

familiar with the installation, mounting, commissioning and operation of the product<br />

and have the qualifications need for such installation.<br />

After disconnection of the frequency converter from the voltage supply, live appliance<br />

parts and power terminals must not be touched immediately because of possible<br />

energized capacitors. Wait at least 5min before touching the frequency converter.<br />

Version: 13.09.2005 - 26 -

![55721335-d6fe09eb5ffdcc87dbf6c3f0b5bbda07d2261e98[1]](https://img.yumpu.com/56533583/1/186x260/55721335-d6fe09eb5ffdcc87dbf6c3f0b5bbda07d2261e981.jpg?quality=85)