Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

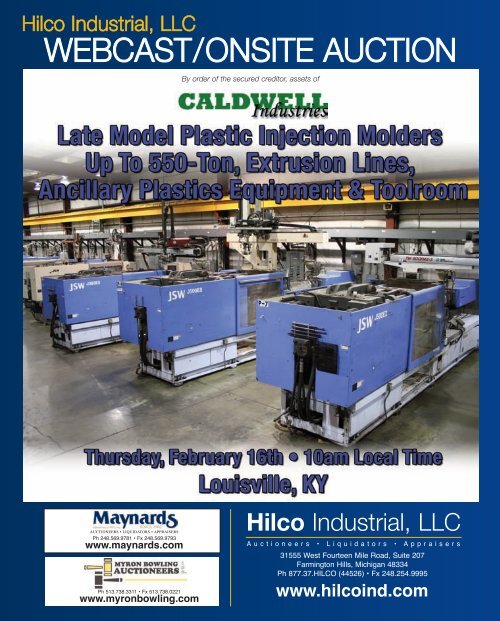

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

WebCast/OnsIte auCtIOn<br />

By order of the secured creditor, assets of<br />

Auctioneers • LiquidAtors • ApprAisers<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

Ph 513.738.3311 • Fx 513.738.0221<br />

www.myronbowling.com<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 877.37.HILCO (44526) • Fx 248.254.9995<br />

www.hilcoind.com

HILCO InDustrIaL, LLC WebCast/OnsIte auCtIOn<br />

by order of the secured creditor, assets of<br />

auCtIOn Date<br />

tHursDay, February 16 tH<br />

begInnIng at 10am LOCaL tIme<br />

PrevIeW Dates<br />

LOuIsvILLe, Ky LOCatIOn:<br />

WeDnesDay, February 15 tH<br />

8am tO 4Pm LOCaL tIme<br />

granD raPIDs, mI LOCatIOn:<br />

by aPPOIntment OnLy<br />

To schedule an appoinTmenT, please conTacT BrenT Bonham<br />

aT 616.732.1800 or email BBonham@hilcoind.com<br />

auCtIOn LOCatIOn<br />

2351 neW mILLennIum Dr.<br />

LOuIsvILLe, Ky 40216<br />

PrevIeW LOCatIOns<br />

2351 neW mILLennIum Dr. • LOuIsvILLe, Ky 40216<br />

1134 Freeman ave. sW • granD raPIDs, mI 49503<br />

DIreCtIOns<br />

FrOm LOuIsvILLe InternatIOnaL aIrPOrt: exIt aIrPOrt OntO<br />

I-264 West. traveL West 2.5 mILes tO exIt # 9, tayLOr bLvD. nOrtH<br />

On tayLOr bLvD 1.3 mILes tO CentraL ave. turn LeFt On CentraL<br />

ave, .7 mILes tO enD at s 7tH st. turn LeFt On s 7tH st., gO<br />

.2 mILes tO 1st rIgHt OntO WatHen Lane, CrOss Over raILrOaD<br />

traCKs, PLant Is On LeFt.<br />

FurtHer InFOrmatIOn<br />

• an 18% buyer's PremIum WILL be CHargeD On aLL assets. tHe<br />

buyer’s PremIum WILL be reDuCeD tO 15% FOr Payments maDe by<br />

CasH, COmPany CHeCK Or WIre transFer. auCtIOn WILL be<br />

COnDuCteD In engLIsH, aCCePtIng u.s. CurrenCy OnLy.<br />

• REMOVAL DEADLINE IS FRIDAy, MARch 2ND, WITh hOURS OF REMOVAL<br />

BETWEEN 8AM TO 4PM MONDAy ThRU FRIDAy. BUyERS WITh ITEMS LEFT<br />

ON SITE AFTER DEADLINE ARE SUBjEcT TO FINES OF $500 PER DAy.<br />

• FOr FurtHer InFOrmatIOn On maCHInery & equIPment, PLease<br />

COntaCt tOm KInsey at 248.207.3108 Or emaIL tKInsey@HILCOInD.COm<br />

• FOr Payments PLease COntaCt LesIa JOsePH at 616.732.1800 x19 Or<br />

emaIL LJOsePH@HILCOInD.COm Or HILCO aCCOunts reCeIvabLe at<br />

HIn_ar@HILCOInD.COm<br />

• FOr CustOmer servICe, PLease COntaCt sanDI neeLy at<br />

248.254.9999 x16 Or emaIL sneeLy@HILCOInD.COm<br />

EXTRUSION LINES<br />

*NOTE: Extrusion Lines May Be Offered In Bulk Subject To Piecemeal Bids<br />

1 – NRM 36" SHEET EXTRUSION LINE, INcLUdINg:<br />

1 – NRM MOdEL 2-1/2 VANgUARd RL EXTRUdER, S/N 10307, 2-1/2",<br />

9.75/1 Ratio, 3-Zone Air Cooled, Reliance DC Drive Motor With Fincor<br />

Class 3000 DC Motor Controller, 75 KVA Transformer, Control Panel,<br />

Feed Hopper<br />

1 – NRM 36" POLISH ROLL STANd, S/N 12459, 3-Roll Vertical Roll Stack,<br />

(2) Chromed Rolls, (1) Finish Roll, 12" Roll Diameter x 42" Overall Face<br />

Width, Liquid Temperature Controlled Rolls, With 36" x 9' Long Gravity<br />

Run-Out Conveyor, S/N 12460, Recirculation Pumps, Travelling Frame Base<br />

1 – NRM 36" dRAW ROLL STANd, S/N 12461, 7" Diameter x 42" Overall<br />

Face Width Rubber Coated Pull Rolls, DC Speed Control, Travelling Base<br />

1 – NRM 36" TURRET WINdER, S/N 12480<br />

*NOTE: No Sheet Die Is Being Offered With This Line<br />

1 – 1 3/4" EXTRUdER LINE, INcLUdINg:<br />

1 – AKRON MOdEL MK1500 1-3/4" EXTRUdER, S/N NA, 15-HP,<br />

36" Barrel Length, 4-Zone Electric Heaters, Water Cooled, Delta VFD-B<br />

Drive, Feed Hopper With Una Dyn Additive Feeder<br />

1 – cONAIR FRANKLIN dUST BEATER VAcUUM LOAdER<br />

1 – WATER BATH TABLE, 8' Length, 14" x 8" Top & Bottom Stainless Steel<br />

Water Tanks, Recirculation Pump, With 12' Aft Tank, 4" x 4" Tank Size,<br />

Control Panel With Digital Temperature Controllers<br />

1 – FARRIS MOdEL c500VT BELT PULLER, S/N 4785, 4-1/2" x 28",<br />

Digital Display, Programmable AC Vector Drive<br />

1 – AUTOMATEd MANUFAcTURINg SYSTEMS IN-LINE ROTARY cUTTER<br />

2<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

extrusIOn LInes • PLastIC InJeCtIOn mOLDIng maCHInes<br />

(17) PLASTIC INJECTION MOLDING MACHINES<br />

1 – VAN dORN dEMAg MOdEL 550HP60 PLASTIc INJEcTION MOLdINg MAcHINE, S/N 500HP60-0879<br />

(1996), LOT # 106, 550-Ton Clamp Force, 60 Oz. Shot Size, Hydraulic Clamp, Tie Bar Spacing<br />

36.5" H x 31.89" V, Daylight 11.5"-62.0", Clamp Stroke 38.0", Pathfinder 4500 Microprocessor<br />

Control, 100-HP Main Hydraulic Pump<br />

2 – JSW MOdEL J500EII PLASTIc INJEcTION MOLdINg MAcHINES, S/Ns 298725601, 298725301,<br />

(1999), 500-Ton Clamp Force, 101.3 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing 31.89" H x<br />

31.89" V, Mold Thickness 14.96"-29.53", Daylight Opening 61.02", Clamp Stroke 31.50", Syscom<br />

1000 Microprocessor Control<br />

1 – cINcINNATI MILAcRON MOdEL VT440-41 PLASTIc INJEcTION MOLdINg MAcHINE,<br />

S/N T39A0398039, (1998), 440-Ton Clamp Force, 41 Oz. Shot Size, Toggle Clamp, Tie Bar Spacing<br />

29" H x 29" V, CAMAC 486C Microprocessor Control<br />

1 – cINcINNATI MILAcRON MOdEL VH400-54 PLASTIc INJEcTION MOLdINg MAcHINE,<br />

S/N H04A0195057, (1995), 400-Ton Clamp Force, 54 Oz. Shot Size, Hydraulic Clamp, Tie Bar<br />

Spacing 29" H x 29" V, Daylight 7.1"- 44.7", Clamp Stroke 37.0", CAMAC 486 Microprocessor Control<br />

1 – JSW MOdEL J385EII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 299712107545 (2000),<br />

385 Clamp Force, Toggle Clamp, Tie Bar Spacing 28.74" H x 28.74" V, Mold Thickness 12.6"-26.38",<br />

Daylight Opening 53.94", Clamp Stroke 27.56", Syscom 1000 Microprocessor Control<br />

1 – JSW MOdEL J385E-c5 PLASTIc INJEcTION MOLdINg MAcHINE, S/N 292012017, (1992),<br />

385 Clamp Force, Toggle Clamp, Tie Bar Spacing 28.74" H x 28.74" V, Mold Thickness 12.6"-26.38",<br />

Daylight Opening 53.94", Clamp Stroke 27.56", Microprocessor Control Terminal, Machine<br />

3 – JSW MOdEL J245E-c5 PLASTIc INJEcTION MOLdINg MAcHINES, S/Ns 293008061,<br />

292008005, 293008039, (As New as 1994),245 Clamp Force, 33.87 Cu. In. Shot Size, Toggle<br />

Clamp, Tie Bar Spacing 22.83" H x 22.83" V, Mold Thickness 9.06"-19.69", Daylight Opening 41.34",<br />

Clamp Stroke 21.65", Microprocessor Control Terminal<br />

1 – JSW MOdEL J200ELII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 298765004, (1999),<br />

200-Ton Clamp Force, 18.3 Cu. In. Shot Size, Electric Servo Drive Clamp, Tie Bar Spacing 20.9" H x<br />

20.9" V, Mold Thickness 8.7"-19.7", Daylight Opening 37.0", Clamp Stroke 17.3", Microprocessor Control<br />

1 – cINcINNATI MILAcRON MOdEL VT-165-11 PLASTIc INJEcTION MOLdINg MAcHINE,<br />

S/N T36A0397020, (1997), 165-Ton Clamp Force, 11 Oz. Shot Size, Toggle Clamp, Tie Bar Spacing<br />

18" H x 16-1/2" V, CAMAC 486 Microprocessor Control<br />

1 – JSW MOdEL J165EII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 297302513, (1997), 165-Ton<br />

Clamp Force, 18.3 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing 20.08" H x 20.08" V, Mold<br />

Thickness 8.66"-17.72", Daylight Opening 35.04", Clamp Stroke 17.32", Syscom Microprocessor Control<br />

1 – JSW MOdEL J85EII PLASTIc INJEcTION MOLdINg MAcHINE, S/N 296704420, (1997), 85-Ton<br />

Clamp Force, 9.21 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing 14.17" H x 14.17" V, Mold<br />

Thickness 7.09"-13.78", Daylight Opening 25.59", Clamp Stroke 11.81", Syscom Microprocessor Control<br />

2 – JSW MOdEL J85E-c5 PLASTIc INJEcTION MOLdINg MAcHINES, S/Ns 293019001,<br />

293767305, (1994), 85-Ton Clamp Force, 9.21 Cu. In. Shot Size, Toggle Clamp, Tie Bar Spacing<br />

14.17" H x 14.17" V, Mold Thickness 7.09"-13.78", Daylight Opening 25.59", Clamp Stroke 11.81",<br />

Microprocessor Control<br />

1 – ARBURg ALLROUNdER MOdEL 320M (750-210) PLASTIc INJEcTION MOLdINg MAcHINE,<br />

S/N 156189, (1992), Clamping Force 750 kN (84.3 Ton), 5.18 Cu. In. Shot Size, Tie Bar Spacing<br />

12" x 12", Not In Service<br />

For more information, please visit us on the web at www.hilcoind.com 3

vertICaL CLamP PLastIC InJeCtIOn mOLDIng maCHInes • rObOts<br />

(5) VERTICAL CLAMP PLASTIC INJECTION MOLDING MACHINES<br />

1 – ENgEL MOdEL 2000 / 450 VHSH VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINg<br />

MAcHINE, S/N 3970-400-91, 450-Ton Clamp Force, 48.9 Oz. Shot Size, Toggle Clamp, R-L Shuttle<br />

Table, Table Size 33" x 108", Upper Platen Size 47.2 " x 47.2", Tie Bar Clearance 33.5" x 33.5", Clamp<br />

Stroke 27.5", 56" Maximum Daylight, 9.02"-29.02" Mold Height, Engel CC90 Microprocessor Control,<br />

*NOTE: This Machine Is Located In Grand Rapids, MI; *NOTE: Battenfield Airmould, Tu-Pac Hydraulic &<br />

Conair Vacuum Load Equipment Shown In Photo's Not Included With Machine<br />

1 – cINcINNATI MILAcRON MOdEL VEcTOR cH-150-S VERTIcAL cLAMPINg PLASTIc INJEcTION<br />

MOLdINg MAcHINE, S/N 3958A01/94-6, 150-Ton Clamp Force, 16 Oz. Shot Size, Hydraulic Clamp,<br />

R-L Shuttle Table, Overall Table Area 16" x 121", Upper Platen Size 16" x 40", 28" Maximum Daylight,<br />

CAMAC VST Microprocessor Control, 40-HP Self-Contained Hydraulic Unit, *NOTE: This Machine Is<br />

Located In Grand Rapids, MI; *NOTE: AEC Whitlock Vacuum Loader/Hopper Shown In Photo's Not<br />

Included With Machine<br />

1 – PH TRUEBLOOd MOdEL PH150A-9 VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINg<br />

MAcHINE, S/N 70012, 125-Ton Clamp Force, 8.5 Oz. Shot Size, Hydraulic Clamp, R-L Shuttle Table,<br />

Overall Table Area 14" x 45", Upper Platen Size 14" x 21", 27" Maximum Daylight, Barber Colman<br />

Microprocessor Control, Self-Contained Hydraulic Unit, *NOTE: This Machine Is Located In Grand<br />

Rapids, MI<br />

1 – gLUcO MOdEL VS30 VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINg MAcHINE, S/N<br />

98670, 30-Ton Clamp Force, Shot Size NA, Hydraulic Clamp, R-L Shuttle Table, Overall Table Area 10"<br />

x 35", Upper Platen Size 16" 21", 16.5" Maximum Daylight, Allen Bradley Panel View 900 Microprocessor<br />

Control, 15-HP Self-Contained Hydraulic Unit, *NOTE: This Machine Is Located In Grand Rapids, MI<br />

1 – AUTOJEcTOR MOdEL HA50-5 VERTIcAL cLAMPINg PLASTIc INJEcTION MOLdINg MAcHINE,<br />

S/N 44409589-0687, 30-Ton Clamp Force, 8.8 Cu. In. Shot Size, Indexing Table, Not In Service<br />

(11) ROBOTS<br />

*NOTE: Robots May Be Offered Separately From Machine<br />

They Are Mounted On<br />

1 – WITTMANN MOdEL W633 3-AXIS ROBOT, S/N<br />

5106/084, Servo Drive Linear Slides, Stroke; X-500,<br />

Y-1600, Z-2500<br />

1 – STAR AUTOMATION MOdEL TW-800FM III-3 3-AXIS<br />

ROBOT, S/N 80GXK16-0022, Servo Drive Linear Slides,<br />

STEC-450 Hand Held Pendant Control<br />

1 – INSOL / IcHIKOH MOdEL WB2-15115 SYNcRO-ARM<br />

dUAL HEAd 3-AXIS ROBOT, S/N M-990024, Servo<br />

Drive Linear Slides, Console Control With 5-Axis Hand<br />

Held Pendant<br />

1 – WITTMANN MOdEL W631 3-AXIS ROBOT, S/N 5157<br />

(2001), Servo Drive Linear Slides, Stroke: X-900, Y-1200,<br />

Z-2000, Hand Held Pendant Control<br />

1 – INSOL MOdEL ISP-950W SPRUE PIcKER ROBOT,<br />

S/N P000173-2, Hand Held Pendant Control<br />

1 – cONAIR HARMO MOdEL EX-450 SPRUE PIcKER<br />

ROBOT, S/N 011761, Harmo PC-EIID Remote Controller<br />

1 – cONAIR HARMO MOdEL EX-350 SPRUE PIcKER<br />

ROBOT, S/N 011235, No Control<br />

1 – YUSHIN MOdEL HOP-IIIM-750 SPRUE PIcKER<br />

ROBOT, S/N 986395-09, Hand Pendant Controller<br />

1 – YUSHIN MOdEL HOP-III-750 SPRUE PIcKER ROBOT,<br />

S/N 976509-11, Hand Pendant Controller<br />

1 – YUSHIN MOdEL HOP-III-550 SPRUE PIcKER ROBOT,<br />

S/N NA, Hand Pendant Controller<br />

1 – cONAIR HARMO MOdEL NA SPRUE PIcKER<br />

ROBOT, S/N NA, Harmo PC-RX1 Hand Pendant Control<br />

(14) VACUUM LOADERS<br />

*NOTE: Vacuum Loaders May Be Offered Separately From The Machine They Are<br />

Mounted On<br />

8 – cONAIR FRANKLIN MOdEL dUST BEATER dB12 VAcUUM LOAdERS, With<br />

Loader Control, Collector Hopper<br />

4 – cONAIR FRANKLIN MOdEL dUST BEATER VAcUUM LOAdERS, With<br />

Loader Control, Collector Hopper<br />

1 – BUdgET MOLdER MOdEL NA VAcUUM LOAdER, S/N NA, With Collector<br />

Hopper, Separator Magnet<br />

1 – cONAIR FRANKLIN MOdEL 7000600401 VAcUUM LOAdER, S/N B47420<br />

(22) TEMPERATURE CONTROL UNITS<br />

*NOTE: Temperature Control Units May Be Offered Separately From The Machine<br />

They Are Connected To<br />

8 – cONAIR TEMPRO MOdEL MIcRO TRAc 2 THERMOLATOR TEMPERATURE<br />

cONTROL UNITS<br />

6 – THERMAL cARE MOdEL RA122004 TEMPERATURE cONTROL UNITS<br />

2 – BUdZAR MOdEL BWA-1WT-12-2-50-dS-460 TEMPERATURE cONTROL<br />

UNITS, S/Ns 200711-13148, 200608-11359-2<br />

4- THERMAL cARE MOdEL Rd090804 TEMPERATURE cONTROL UNITS<br />

2 – THERMAL cARE MOdEL RA0920042 TEMPERATURE cONTROL UNITS<br />

Quantity Of Temperature Control Units Including: Conair, Thermal Care, Budzar,<br />

Additional Units, Stored<br />

4<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Dryers • HOPPers • granuLatOrs • bLenDIng statIOn<br />

DRYERS / HOPPERS<br />

1 – NOVATEc dRYER / HOPPER cOMBO, With Model MDM-50 Dryer, S/N<br />

10-121-0221, 200-Lb. Capacity Drying Hopper, Conair Dust Beater<br />

Vacuum Loader, Portable Base<br />

1 – NOVATEc dRYER / HOPPER cOMBO, With Model MD-50 Dryer, S/N<br />

10A1732-0520, 200-Lb. Capacity Drying Hopper, Novatec Vacuum<br />

Loader, Portable Base<br />

1 – cONAIR dRYER / HOPPER cOMBO, With Model SC60 Dryer, S/N<br />

99776, Model CH24-8 Drying Hopper, S/N 93106, Portable Base<br />

1 – dRYER / HOPPER cOMBO, With Conair Franklin Model CD-100 Dryer,<br />

S/N 9D0807, Thoreson McCosh 360-Lb. Capacity Drying Hopper, S/N<br />

303977, Conair Franklin Dust Beater Vacuum Loader, Portable Base<br />

1 – cONAIR dRYER / HOPPER cOMBO, With Model SC-30 Small<br />

Carousel Dryer, S/N 80110, Model CH16-6 Drying Hopper, S/N 71617,<br />

Conair Dust Beater Vacuum Loader, Portable Base<br />

1 – cONAIR dRYER / HOPPER cOMBO, With Model Compu-Dry CD-30<br />

Dryer, S/N D50735, Drying Hopper, Stationary Stand<br />

DRYERS<br />

4 – cONAIR FRANKLIN MOdEL cS 201 dRYERS, S/Ns D41722, D41721,<br />

2D0496, D31255, Portable<br />

1 – cONAIR FRANKLIN MOdEL cS 101 dRYER, S/N D51338, Portable<br />

1 – cONAIR FRANKLIN MOdEL cd 200 dRYER, S/N 9D1256, Portable<br />

1 – cONAIR FRANKLIN MOdEL cd 100 dRYER, S/N 0D0500, Portable<br />

DRYING HOPPERS<br />

1 – cONAIR FRANKLIN MOdEL 1805390400 dRYINg HOPPER, S/N NA,<br />

Est. 400-Lb., Stationary<br />

4 – cONAIR FRANKLIN MOdEL 1805390300 dRYINg HOPPERS, S/Ns<br />

D41633, 201994, D044xx, 2D1772, Est. 300-Lb., With Conair Dust<br />

Beater Vacuum Loader, (3) Portable, (1) Stationary<br />

1 – cONAIR FRANKLIN MOdEL 1805390200 dRYINg HOPPER, S/N<br />

D44010, Est. 200-Lb., With Conair Dust Beater Vacuum Loader, Portable<br />

1 – cONAIR FRANKLIN MOdEL cH24-18 dRYINg HOPPER, S/N 192198,<br />

With Vacuum Loader, Stationary<br />

OVER 15 GRANULATORS<br />

4 – NELMOR MOdEL g1012M1 gRANULATORS, S/Ns 84-11-21617,<br />

76-12-9733, 70-02-3338, 68-06-1721, 7.5-HP, Top Load, Portable<br />

1 – NELMOR MOdEL g810M1 gRANULATOR, S/N 80-01-1520, 5-HP, Portable<br />

1 – NELMOR MOdEL cF819 gRANULATOR, S/N 390.109, 5.5 KW, Portable<br />

1 – cUMBERLANd MOdEL 14x16 gRANULATOR, S/N 21230-6494, HP NA,<br />

Portable<br />

1 – cUMBERLANd MOdEL SIZE 10x12 gRANULATOR, S/N 25086-6554,<br />

20-HP, Stationary<br />

1 – cUMBERLANd MOdEL SIZE 4gRAN 3KN gRANULATOR, S/N 221370-<br />

754-R, HP NA, Top Load, Portable<br />

2 – RAPId MOdEL 912c gRANULATORS, S/Ns 305334, 305359, 7.5-HP, Top<br />

Load, Portable<br />

1 – POLYMER MOdEL 912SPL gRANULATOR, S/N 3000791N, 7.5-HP, Top &<br />

Side Load, Portable<br />

1 – IMS MOdEL LP120Sc gRANULATOR, S/N LP120SC-0260,<br />

7.5-HP, Portable<br />

1 – cONAIR MOdEL Jc814 gRANULATOR, S/N 67319, 5-HP, Portable<br />

1 – cONAIR MARTIN MOdEL cP611 gRANULATOR, S/N 240498, 3-HP, Top<br />

Load, Portable<br />

1 – BELOIT MOdEL M-88 gRANULATOR, S/N 7376-H/C-6099, Portable<br />

Quantity of Granulators Stored, Some Not In Service, Including: Nelmor, Conair,<br />

Rapid, Polymer, & Others<br />

BLENDING STATION<br />

1 – cONAIR cONOMIX MOdEL cMX2 BLENdINg STATION, S/N 9A0248, With<br />

(2) Additive Hoppers, Each With Una Dyn Vacuum Loaders & Screw Auger<br />

Discharge, (1) Blending Auger, Stationary Steel Stand With Conomix Main<br />

Control, Central Auger Control, Vacuum Loader Controls<br />

HOT RUNNER TEMPERATURE CONTROLLERS<br />

1 – dME MOdEL MPP126 24-ZONE HOT RUNNER TEMPERTAURE<br />

cONTROLLER, (2) 12 Zone Units, S/Ns 1C41230, 1C41229<br />

1 – INcOE 15-ZONE HOT RUNNER TEMPERATURE cONTROLLER<br />

Additional DME & INCOE Hot Runners, Some Incomplete<br />

For more information, please visit us on the web at www.hilcoind.com 5

seCOnDary equIPment • DIe CuttIng Press • tOOLrOOm<br />

SECONDARY EQUIPMENT<br />

2 – BRANSON MOdEL cV-12 ORBITAL WELdERS, S/Ns<br />

02R493591, 97R308678 (As New as 2002), Hydraulic,<br />

Programmable Control, Working Bed Area 19" x 19",<br />

12" Maximum Daylight<br />

1 – BRANSON MOdEL 9101W ULTRASONIc WELdER,<br />

S/N VE30074C<br />

1 – cUSTOM BUILT FOAM STRIP SPLITTER, Programmable<br />

Keypad<br />

1 – SHARP cELL cUTTER, Custom<br />

1 – HOLLINgER MOdEL KPSM-H-11 EXTRUSION SHARP<br />

cELL MANUAL WELdER, S/N 8028 (2003), Digital Electric<br />

Heater Controls<br />

1 – SYN-TEc MOdEL OMEgA-8100 EXTRUSION SHARP<br />

cELL AUTO WELdER, S/N W-004 (2004)<br />

1 – LASER MIKE MOdEL 700 IN-LINE MEASUREMENT<br />

gAUgE, S/N 5-1117, With Model 182 Dual Axis<br />

Programmable Control<br />

1 – VERSA cOMBINATION PULLER / cUTTER, With Versa<br />

Feed Model C-22 2" x 12" Belt Puller, S/N 22724, Rotary<br />

Knife Cutter With 45-Degree Angle Adjustment, Length<br />

Run-Out Meters, Commander SE Variable Drive Control<br />

1 – cONVEYORIZEd WATER BATH TABLE, Stainless Steel<br />

Tank Size 10" x 12" x 20' Long, 6" Wide Plastic Mesh<br />

Conveyor Belt With Variable Speed Drive, Water Spray Pump<br />

1 – WATER BATH TABLE, Stainless Steel Tank Size 14" x 8" x<br />

9' Long, Not In Service<br />

DIE CUTTING PRESS<br />

1 – ATOM MOdEL HSP-588/3 HYdRAULIc dIE cUTTINg<br />

PRESS, S/N 10021961-5 (2004), Working Bed Area 63-1/2"<br />

LR x 19-1/2" FB, Die Platen Size 19-1/4" x 19-1/4", Power<br />

R-L Die Head Adjustment, With Model AL-81 Backgauge,<br />

S/N 10019988<br />

2004<br />

TOOLROOM / MAINTENANCE EQUIPMENT<br />

1 – LEAdWELL MOdEL McV-610AP cNc VERTIcAL MAcHININg cENTER, S/N L19306026, Fanuc Series<br />

O-M Control, Table Size 15-1/2" x 30-1/2", 40-Taper, 20-Position ATC, Coolant<br />

1 – SHARP MOdEL HMV-3 VERTIcAL MILLINg MAcHINE, S/N 70401056, 3-HP, Variable Speeds 60-4500<br />

RPM, 10" x 51" Table With Power Feed, Kurt Power Drawbar, Newall DRO<br />

1 – BRIdgEPORT VERTIcAL MILLINg MAcHINE, S/N BR-266337, 2-HP, Variable Speeds 60-4200 RPM,<br />

9" x 42" Table, 4" Column Riser, Kurt Power Drawbar, Newall DRO<br />

2 – TRI-ONIcS VERTIcAL MILLINg MAcHINES, S/Ns 0235, 0194, 3-HP, Variable Speeds 60-4200, 9" x 49"<br />

Table, 1 with Newall DRO<br />

1 – SHARP MOdEL Rd 820 RAdIAL dRILL, S/N 13136, 3' Arm x 8" Column, (6) Spindle Speeds 88-1500 RPM,<br />

Plain Box Table, Coolant<br />

1 – TOOLMEX MOdEL TUM-35 ENgINE LATHE, S/N 3687, 14" Swing x 42" Centers, Spindle Speeds 28-2500<br />

RPM, Threading, Taper Attachment, 1-7/16" Hole Thru Spindle, Coolant, Newall Topaz DRO<br />

1 – OKAMOTO MOdEL Acc-1224ST HYdRAULIc SURFAcE gRINdER, S/N 83444, 12" x 24" Electromagnetic<br />

Chuck, External Coolant System With Paper Media Filtration<br />

2 – OKAMOTO MOdEL LINEAR 618 HANd FEEd SURFAcE gRINdERS, S/Ns 4895, 4577U, 6" x 18"<br />

Permanent Magnetic Chuck, Coolant, Newall DRO<br />

1 – OKAMOTO MOdEL PFg-618 HANd FEEd SURFAcE gRINdER, S/N 8567U, 6" x 18" Permanent Magnetic<br />

Chuck, Coolant, AcuRite DRO<br />

1 – cLAUSINg MOdEL cS-618c HANd FEEd SURFAcE gRINdER, S/N 02C-5870, 6" x 18" Permanent<br />

Magnetic Chuck<br />

1 – cHEVALIER MOdEL Ed-252 RAM TYPE EdM, S/N 0022272, CD-Bipulse 50 Amp Power Supply, 23-1/2" x<br />

11-3/4" T-Slotted Work Table With 6" x 12" Permanent Magnetic Chuck, 31" x 20" x 12" Deep Work Tank,<br />

System 3R Rotary Chuck, Anilam Wizard 900E DRO, Self-Contained Dielectric Fluid System<br />

1 – EXcELLO RAM TYPE EdM, Model & S/N NA, 7-1/2" x 15" T-Slotted Work Table With 6" x 10" Permanent<br />

Magnetic Chuck, Work Tank Size 21" x 13" x 12", Excello 25 Amp Power Supply, System 3R Work Chuck,<br />

Anilam MiniWizard DRO, Self-Contained Dielectric Fluid System<br />

1 – dOALL MOdEL c-916S HORIZONTAL METAL cUTTINg BANdSAW, S/N 503-95670, Coolant,<br />

Power Clamping<br />

1 – gROB MOdEL 4V-18 VERTIcAL BANdSAW, S/N 3803, 18" Throat, Power Table Feed, Blade Welder<br />

1 – MILLER MOdEL SYNcROWAVE 350 cONSTANT cURRENT Ac/dc WELdINg POWEER SUPPLY,<br />

S/N KC256001, With Coolmate 4 Water Cooling System, Tig Leads<br />

1 – MILLER MOdEL SYNcROWAVE 250 cONSTANT cURRENT Ac/dc WELdINg POWEER SUPPLY,<br />

S/N KD408913, With Radiator 1A Water Cooling System, Tig Leads<br />

1 – THERMAL SYSTEMS MOdEL TS20220U ELEcTRIc OVEN, S/N 9403, Upper & Lower Chambers, Chamber<br />

Size 20"L x 12"W x 11"H, Digital Temperature Controls<br />

1 – PEXTO MOdEL 137g 36" FOOT OPERATEd SHEAR, S/N 4x41, Air Conversion<br />

1 – WESTHOFF MOdEL WM100-1 PREcISION HORIZONTAL dRILLINg MAcHINE, S/N 941218<br />

1 – KUHLMANN SINgLE LIP TOOL gRINdER, S/N NA<br />

1 – cYcLONE ABRASIVE dRY BLAST cABINET, S/N NA, 24" x 36"<br />

1 – AAF SYNdER gENERAL dUST cOLLEcTOR, (Outside)<br />

Quantity Of Toolroom Accessories Including: Double End Grinders, Drill Press, Workbenches, Kurt 6" & 8" Machine<br />

Vises, 40-Taper Toolholders, Shop Cabinets, Die Lift Tables, Etc.<br />

6<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

aIr COmPressOrs • Water system • materIaL HanDLIng • InsPeCtIOn<br />

AIR COMPRESSORS & DRYERS<br />

1 – INgERSOLL RANd MOdEL IRN25H-cc 25-HP ROTARY ScREW AIR<br />

cOMPRESSOR, S/N BN0347U07228, 94 CFM, 150 PSIG, Air Cooled,<br />

Enclosure Panels<br />

1 – INgERSOLL RANd MOdEL SSR-EP25 25-HP ROTARY ScREW AIR<br />

cOMPRESSOR, S/N JX1345U00049, 97 CFM, 125 PSIG, Air Cooled,<br />

Enclosure Panels<br />

1 – HANKISON MOdEL HPRP125MX-115 REFRIgERATEd cOMPRESSEd<br />

AIR dRYER, S/N RH0B3125A01A2NH07136, Rated 125 SCFM @ 100<br />

PSI @ 100-Deg. F<br />

1 – HANKISON MOdEL HPRP100-115 REFRIgERATEd cOMPRESSEd<br />

AIR dRYER, S/N H100A1150002045, Rated 100 SCFM @ 100 PSI @<br />

100-Deg. F<br />

1 – SILVAN INdUSTRIES 240 gALLON VERTIcAL cOMPRESSEd<br />

REcEIVER TANK<br />

PROCESS COOLING WATER SYSTEM<br />

1 – THERMAL cARE MOdEL PT1300 PROcESS cOOLINg WATER<br />

REcIRcULATION SYSTEM, S/N 46730010002, (2) 20-HP Process<br />

Pumps, (1) 7-1/2 HP Recirculation Pump, 60"x72"x72"H Carbon Steel<br />

Holding Tank, Steel Platform Base<br />

1 – APPLIcATION ENgINEERINg MOdEL gLAcIER SERIES NXgW25<br />

PORTABLE PROcESS WATER cHILLER, S/N 30H0432, 25-HP<br />

Compressor Pump, 7-1/2 HP Process Pump, 2-HP Recirculation Pump<br />

1 – THERMAL cARE MOdEL AccUcHILLER SERIES AQOW1004<br />

PORTABLE PROcESS WATER cHILLER, S/N 46710010002, 10-HP<br />

Compressor, 3-HP Process Pump<br />

1 – POLY HOLdINg TANK, Approx. 500 Gallon With Rack<br />

2 – THERMAL cARE WATER cOOLINg TOWERS<br />

1 – MARLEY WATER cOOLINg TOWER<br />

CRANES<br />

1 – KONE cRANES TOP RIdINg SINgLE gIRdER BRIdgE cRANE, S/N 5860030, 10-Ton<br />

Capacity, Estimated 45' Span, XL-400 Bottom Running Electric Cable Hoist, 2-Speed Hoist,<br />

2-Speed Bridge & Trolley, 6-Way Power Pendant Control, With Estimated 295' Runway Beams<br />

1 – 360-dEgREE FLOOR STANdINg JIB cRANE, 10' Height x 10' Reach, With Budgit 2-Ton<br />

Electric Chain Hoist<br />

MATERIAL HANDLING<br />

1 – NOVATEc MOdEL McS-132 BULK MATERIAL cONVEYINg SYSTEM, S/N 12-326-0647,<br />

32-Station Control Panel, 5-HP Vacuum Pump Unit, Disconnected – Not In Use<br />

18 – MAc MOdEL RB350 PORTABLE MATERIAL dISTRIBUTION HOPPERS, Est. 350-Lb. Capacity<br />

5 – VAcU-BIN MOdEL 500 PORTABLE MATERIAL dISTRIBUTION HOPPERS, Est. 500-Lb. Capacity<br />

1 – HYTROL MOTORIZEd HORIZONTAL BELT cONVEYOR, 36" Wide x 34' Long, Not In Use<br />

Quantity Of Aluminum Conveying Pipe, Disconnected, Stored and Assorted Motorized Belt Conveyors<br />

FORKLIFTS<br />

1 – NISSAN MOdEL cPH02A202V 3850-LB. cAPAcITY FORKLIFT, S/N CPH02-920701, LPG,<br />

Solid Tires, 169" Lift, Side Shift, 42" Forks<br />

1 – MITSUBISHI MOdEL Fgc20 3700-LB. cAPAcITY FORKLIFT, S/N AF82B-00232, LPG, Solid<br />

Tires, 189" Lift, Side Shift, 42" Forks<br />

1 – TOYOTA MOdEL 5FBE15 1500-LB. cAPAcITY FORKLIFT, S/N 34572, Electric, Sit Down<br />

Rider, 3- Wheel Chassis, 189" Lift, Side Shift, 42" Forks, 36 Volt<br />

1 – YALE MOdEL VE30S090 3000-LB. cAPAcITY WALK BEHINd ELEcTRIc FORKLIFT,<br />

S/N S277322, 163" Maximum Lift, Straddle Legs, Reach Forks<br />

WAREHOUSE<br />

1 – LANTEcH MOdEL Q300 SEMI-AUTOMATIc PALLET SHRINK WRAP MAcHINE, S/N QM013783<br />

1 – WEIgH-TRONIX MOdEL dSL-4848-05 ELEcTRONIc PLATFORM ScALE, S/N 38687, 5000-<br />

Lb. Capacity, 48" x 48" Platform, With Setra Super Count Electronic Counting Scale / Readout<br />

1 – PALLET JAcKS, MATERIAL cARTS<br />

1 – cARdINAL PALLET RAcKINg, Adjustable, Tear-Drop Style, 20' High Uprights, 42" Deep,<br />

9' Wide Cross Beams, Wire Mesh Deck Shelf Inlays, 3-Tier Cross Beams, (98 Sections Total),<br />

(11 Rows With 8 Sections, 5 Units With 2 Sections)<br />

Quantity of Adjustable Pallet Racking Including Interlake, Cardinal, & Other Mfg'rs, Assorted<br />

TRUCKS<br />

1 – 2005 INTERNATIONAL MOdEL 4300 SBA 4X2 SINgLE AXLE BOX VAN TRUcK, VIN:<br />

1HTMMAAL45H695440, DT466 Diesel, 6-Speed, Air Brakes, With Supreme 25' Aluminum Van<br />

Body, Roll-Up Door, Equalizer Systems Electric / Hydraulic Lift & Level System<br />

1 – 1996 cHEVROLET MOdEL 3500 cHEYENNE FLATBEd TRUcK, VIN:<br />

1GBJC34R3TE230469, V8 Gas, Automatic, Dual Rear Wheels, 12' Steel Deck Flatbed<br />

QUALITY CONTROL / INSPECTION<br />

1 – MIcRO VU MOdEL M436 VIdEO MEASURINg MAcHINE, S/N 4G10, Control Desk With<br />

Computer System & Joystick Pendant<br />

1 – TENSI TEcH MOdEL SSM-AJ-2000 TENSILE TESTER, S/N 102706<br />

1 – RAY-RAN MELT FLOW INdEXER, S/N RR01005/303<br />

1 – AccUPRO ROcKWELL HARdNESS TESTER, S/N 1815<br />

Quantity Of Misc. Gauges & Inspection Room Equipment<br />

OFFICES<br />

Quantity Of Computer Equipment & Office Furniture, Including Servers, PC's, Laptops, Monitors,<br />

Printers, Office Suites, Conference Room Table & Chair Sets, Cubicle Stations, Receptionist Station,<br />

General Office Furniture<br />

For more information, please visit us on the web at www.hilcoind.com 7

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong (Greater China) •<br />

Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAId<br />

Detroit, Mich.<br />

Permit No. 2655<br />

Forwarding Service Requested<br />

HILCO WebCast/OnsIte auCtIOn<br />

By order of the secured creditor, assets of<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters 5 revere Drive, ste. 206 • northbrook, IL 60062 • all rights reserved<br />

Printed in usa • CaLD0037 • Kentucky auctioneer & License: Myron C. Bowling, License #RP 7079 • IL License #444.000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

An 18% buyer's premium will be charged on all assets. The<br />

buyer’s premium will be reduced to 15% for payments<br />

made by cash, company check or wire transfer. Everything<br />

will be sold to the highest bidder for cash, in accordance<br />

with the Auctioneer’s customary “Terms of Sale”, copies of<br />

which will be posted on the premises of the sale and subject<br />

to additional terms announced the day of sale. All items<br />

will be sold “as is, where-is” without any warranties,<br />

expressed or implied. Although obtained from sources<br />

deemed reliable, the Auctioneer makes no warranty or<br />

guarantee to the accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the<br />

items on which they intend to bid prior to sale. Absolutely<br />

no items will be removed until the day after the conclusion<br />

of the sale and payment is made in full. Subject to additions,<br />

deletions and prior sale.<br />

Payment: ALL PURchASES MUST BE PAID IN FULL ON<br />

ThE DAy OF ThE AUcTION. If you intend to pay by wire<br />

transfer, we will accept payment the day after the sale<br />

ONLy IF a deposit of 25% of total purchases is made on<br />

the day of the sale. contact our office for wire transfer<br />

instructions. Only cash, wire transfer or certified check,<br />

payable to hilco <strong>Industrial</strong>, LLc will be accepted. company<br />

checks payable to hilco <strong>Industrial</strong>, LLc will be accepted<br />

only if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales tax.<br />

Purchasers claiming exemptions from taxes must provide<br />

proof satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees payment to<br />

hilco <strong>Industrial</strong>, LLc from (company Name). This<br />

guarantee will be valid for purchases made at the<br />

Auction of caldwell Industries on February 16, 2012.<br />

Follow<br />

Us on: