OnLIne AuCtIOn - Hilco Industrial

OnLIne AuCtIOn - Hilco Industrial

OnLIne AuCtIOn - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

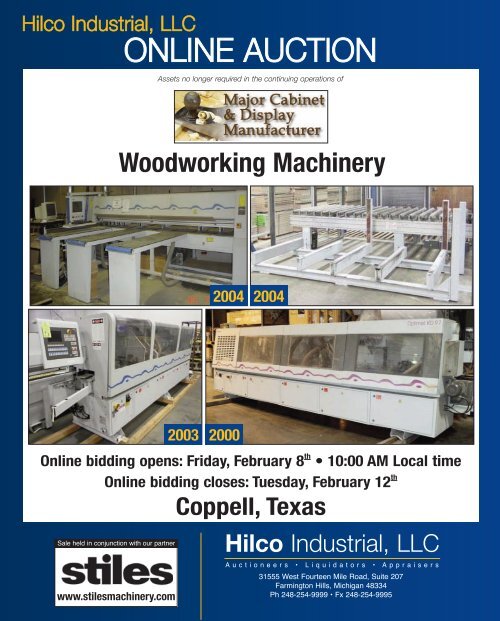

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

<strong>OnLIne</strong> <strong>AuCtIOn</strong><br />

Assets no longer required in the continuing operations of<br />

Woodworking Machinery<br />

2004<br />

2004<br />

Online bidding opens: Friday, February 8 th • 10:00 AM Local time<br />

Online bidding closes: Tuesday, February 12 th<br />

Coppell, Texas<br />

Sale held in conjunction with our partner<br />

www.stilesmachinery.com<br />

2003 2000<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248-254-9999 • Fx 248-254-9995

HILCO IndustrIAL, LLC <strong>OnLIne</strong> <strong>AuCtIOn</strong><br />

Assets no longer required in the continuing operations of<br />

<strong>OnLIne</strong> BIddIng Opens<br />

FrIdAy, FeBruAry 8 tH<br />

BegInnIng At 10Am et<br />

<strong>OnLIne</strong> BIddIng ends<br />

tuesdAy, FeBruAry 12 tH<br />

CheCk www.hilCoind.Com for Closing times<br />

prevIew dAtes<br />

FrIdAy, FeBruAry 8 tH<br />

9Am tO 4pm LOCAL tIme<br />

or eArlier by Appointment. ContACt<br />

tim pfister At 847-313-4747 or emAil<br />

tpfister@hilCoind.Com<br />

to sChedule A preview Appointment.<br />

prevIew LOCAtIOn<br />

600 rOyAL LAne, suIte 500<br />

COppeLL, tX 75019<br />

dIreCtIOns tO prevIew LOCAtIOn<br />

FrOm dALLAs FOrt wOrtH InternAtIOnAL AIrpOrt: eXIt AIrpOrt HeAd-<br />

Ing sOutH. tAke tHe rAmp OntO InternAtIOnAL pArkwAy (pArtIAL tOLL<br />

rOAd). gO 2.6 mILes And merge OntO tX-121 n. tAke tHe eXIt tOwArd BAss<br />

prO dr. keep rIgHt At tHe FOrk, FOLLOw sIgns FOr COppeLL/BetHeL rd<br />

And merge OntO BAss prO dr. COntInue OntO w BetHeL rd And turn<br />

LeFt OntO s rOyAL Ln. LOCAtIOn wILL Be On tHe rIgHt.<br />

FurtHer InFOrmAtIOn<br />

• An 18% buyer's premium will be chArged on All Assets. the<br />

buyer’s premium will be reduced to 15% for pAyments mAde<br />

by cAsh, compAny check or wire trAnsfer. Auction will be<br />

conducted in english, Accepting u.s. currency only.<br />

• remoVAl deAdline is februAry 22 with hours of remoVAl between<br />

8Am to 4pm mondAy thru fridAy. buyers with items left on site After<br />

deAdline Are subject to fines of $500 per dAy.<br />

• for further informAtion on mAchinery & equipment, pleAse<br />

contAct tim pfister At 847-313-4747 or emAil tpfister@hilcoind.com<br />

• for pAyments pleAse contAct lesiA joseph At 616.732.1800 x19<br />

or emAil ljoseph@hilcoind.com or hilco Accounts receiVAble<br />

At hin_Ar@hilcoind.com<br />

• for customer serVice, pleAse contAct sAndi neely At<br />

248.254.9999 x16 or emAil sneely@hilcoind.com<br />

Information contained herein deemed to be accurate at time of printing and subject to change.<br />

For updated information, please visit our website at www.hilcoind.com for any<br />

date, sale process, terms and conditions and list of available assets.<br />

2004<br />

LOADER / STACKER<br />

1 – HOLZMA/BARGSTEDT O TBP 220/QX/36/16/88 LOADER/STACKER, (2004), With Bridge Crane, Automated Vacuum Lifting<br />

Attachment, 5’ x 12’ Sheet Capacity, 4-Zone Lifting, (10) Vacuum Cups, Powered Infeed Conveyor, PC Control<br />

2<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

LOAder/stACker • edgeBAnders • pAneL sAw<br />

2004<br />

PANEL SAW<br />

1 – HOMAG CHF-325/38/38 COMPUTERIZED HORIZONTAL PANEL<br />

SAW, S/N 0-341-07-6719, (2004), With Maximum Cutting Height 60<br />

mm (2-3/8”), Saw Blade Projection 72 mm (2-7/8”), Auto-Cutting<br />

Height Presets, 5 mm Steps, Grooving Height Up to 30 mm, Program<br />

Fence Advance Speed 25 meters/min, Program Fence Return Speed<br />

80 meters/min, Main Saw Blade Diameter 350 x 75 mm, Scoring Saw<br />

Blade Diameter 200 x 45 mm, Main Saw Blade Speed 4750 RPM,<br />

Scoring Saw Blade Speed 5100 RPM, Main Saw Motor 12 HP,<br />

Scoring Saw Motor 1.5 HP, Saw Carriage Advance Speed 0 to 197<br />

FPM (0 – 60 m/min), Saw Carriage Return Speed Standard 197 FPM<br />

(60 m/min)<br />

2007 2000<br />

EDGEBANDERS<br />

1 – BRANDT KDN 530-C SINGLE-SIDED<br />

EDGEBANDER, (2007), With Edgeband<br />

Thickness 0.4 - 8 mm (.016” - .250”)<br />

(5/16”), Coil Cutoff Maximum 0.8 x 55<br />

mm 3.0 x 45 mm (PVC), Edgeband<br />

Height 12 - 55 mm (1/2” – 2-3/16”), Panel<br />

Length min. 160 mm (6-3/8”), Panel<br />

Width min. 65 mm (2-3/8”), Panel<br />

Thickness - min. - max. 8 mm (5/16”) 50<br />

mm (2”), Feed Speed 11/14 m/min (36<br />

FPM when Contour Trimming, otherwise<br />

46 FPM), Feed Motor 3 HP, Pressure<br />

Section First Roller Driven, Two Rollers<br />

Idle, End Trim Unit, Two Motors 1/4 HP,<br />

Cutting Speed 12,000 RPM, Straight Cut<br />

Max 8 x 50 mm (5/16” x 2”) 12,000 RPM,<br />

2003<br />

2000<br />

Contour Trimming Unit, Cutting Speed 1/2 HP, 12,000 RPM, Electronic Frequency Inverter, Power Control PC20+<br />

1 – BRANDT OPTIMAT KDN 650 SINGLE-SIDED EDGEBANDER, (2003), With Edgeband Thickness 0.4 – 12 mm (0.016” - 1/2”), Coil<br />

Cutoff Maximum 0.8 x 45 mm, 3.0 x 45 mm (PVC), Edgeband Height 12 - 60 mm (1/2” – 2-3/8 “), Panel Length min. 160 mm (6-3/8”),<br />

Panel Width min. 65 mm (2-3/8”), Panel Thickness 8 mm - 55 mm, Two Speeds 36 FPM & 46 FPM, 3 HP Feed Motor, End Trim Unit,<br />

12,000 RPM Cutting Speed, Fine Trimming Unit, Tilting Range, Top & Bottom Profile Trimming<br />

1 – BRANDT OPTIMAT KD 77-C CONTOUR EDGEBANDER, S/N 0-261-02-7671, (2000), With NC-02 Control, Quickmelt Gluing System,<br />

Straight & Chamfer End Trimming, Top & Bottom Fine Trimming, Combo Cutters, (2) Contour Trim Motors, Scrape, Buff, 8 mm Edge<br />

Thickness Capacity, 36 FPM Feed Speed<br />

1 – BRANDT OPTIMAT KD 97-C SINGLE-SIDED EDGEBANDER, S/N 0-261-02-7951, (2000), With Edgeband Thickness 0.4 - 20 mm,<br />

Edgeband Height 12 - 60 mm (1/2” - 2-3/8”), Panel Length min. 160 mm (6-3/8”), Panel Width min. 65 mm (2-1/2”), Panel Thickness 10<br />

mm - 55 mm, 52 FPM Feed, 3 HP Feed Motor, Two-Motor End Trim Unit, 1 HP, 12,000 RPM Cutting Speed, 2 HP Fine Trimming Unit,<br />

Tilting 0 - 25°, Top & Bottom Contour Trimming, 10 mm x 50 mm Straight Cut Capacity<br />

1 – HOLZ-HER ACCORD 1442 SINGLE-SIDED EDGEBANDER, S/N 2009-12, (1988), With 1” Edgebanding Capacity, 5-1/2” Min. Panel<br />

Length, 2-1/2” Max. Panel Thickness, Automatic Feed Magazine, Cartridge Gluing System, HD Guillotine for 3 mm PVC, Pressure<br />

Section with (1) Large Diameter Driven Roller, (4) Idle Rollers, Pneumatic Pressure Control, Powered First Roller, Electronic Speed<br />

Control, Double Motor End Trim, 12,000 RPM, Profile Edge Sanding Head, Top & Bottom Buffing Unit<br />

1 – BRANDT KD 54 SINGLE-SIDED EDGEBANDER, S/N 0-260-01-4600, (1993), With End Trim, Top & Bottom Trim, Scrape and Buffing<br />

For more information, please visit us on the web at www.hilcoind.com 3

sAnders • drAwer CLAmp unIts • wOOdwOrkIng<br />

2002<br />

2006<br />

SANDERS<br />

1 – BUTFERING SUPER 213 ML 53” PLANER SANDER, S/N 75116, (2002),<br />

With 54” Belt Width, 75” Belt Length, 1/8” - 5-1/2” Work Piece Thickness,<br />

8-43 FPM Feed Speeds, 3 HP Feed Motor, 40 HP Planer Head, 32 HP<br />

Combi-Head<br />

1 – TIMESAVERS 137-1HD 36” WIDE-BELT SANDING MACHINE,<br />

S/N 18146T, With Power Table Adjustment, 20 HP<br />

1 – JET JWB-37P 36” WIDE-BELT SANDING MACHINE, S/N 7024116, With<br />

Power Table Adjustment, Accurate Pro Scale, 20 HP<br />

1 – ROBERT R PARKS 8” EDGE SANDER, With Adjustable Tables, 7.5 HP<br />

BORING / DRILLING<br />

MACHINES<br />

4 – BLUM M51P1005 USMI AUTOMATIC<br />

BORING / DRILLING MACHINES, S/Ns<br />

2006<br />

FA03174, FA02432, FA03092, FA02368,<br />

(ALL 2006), With Power Hold-down<br />

Clamps, Table Mounted<br />

Bid online at<br />

www.hilcoind.com<br />

DRAWER CLAMP UNITS<br />

1 – DODDS C-48 CNC-K DODDS C-48 CNC-K<br />

DRAWER CLAMP UNIT, S/N C07024-270, (2006),<br />

Allen Bradley Logix 5555 PLC With Panel View 600<br />

Interface, Servo Drives, Mounted On Pneumatic<br />

Scissors Lift Table<br />

1 – DODDS C-48 CNC-K DODDS C-48 CNC-K<br />

DRAWER CLAMP UNIT, S/N C07025-271, (2006),<br />

Allen Bradley Logix 5555 PLC With Panel View 600<br />

Interface, Servo Drives, Mounted On Pneumatic<br />

Scissors Lift Table<br />

WOODWORKING<br />

1 – PISTORIUS MN-302S 12” 90° TOE-NOTCHING<br />

SAW, S/N 300615, With Dual 12” Blades<br />

1 – EVANS ROTORK 1030 TEE MOLDING<br />

APPLICATOR, S/N 080011, With 110 Volt, Single<br />

Phase Electrics<br />

1 – MINI MAX SC-10 10 “ TILTING ARBOR TABLE<br />

SAW S/N 1U/000184 , With 50” Rip Fence<br />

1 – MAR-BEL LS-1 PLASTIC LAMINATE SLITTER,<br />

S/N 4126, With 110 Volt, Single Phase Electrics<br />

1 – RITTER 32 MM LINE BORING MACHINE,With<br />

14-Spindles, 3/4 HP, Work Table, (4) Adjustable<br />

Gauging Stops<br />

1 – WALCO 82-C-1M-62-6 49” FILM APPLICATOR,<br />

S/N 00-8375-7270, With Extra Roll of 24” W Film,<br />

110 Volt<br />

1 – ORBIT OR-1458F PEDESTAL DRILL PRESS,<br />

S/N 15670, With 3/4 HP, 5/8” Chuck<br />

1 – ROYAL PEDESTAL DRILL PRESS, S/N 16-19001,<br />

With 1/2 HP, Jacobs Chuck<br />

1 – EVANS ROTORK 650 POCKET HOLE MACHINE,<br />

S/N 24684103, With Work Table<br />

1 – MOD-EEZ CLIP DRILL MACHINE, With Drills,<br />

Router, One Operation for Drilling & Routing Pockets<br />

for Mod-eez Fasteners, 230 Volt, 3 Phase, 1/2 HP<br />

1 – DELTA 36-540 10” BENCH TABLE SAW,<br />

S/N K9428<br />

4<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

FOrkLIFts • dust COLLeCtOrs<br />

FORKLIFTS<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 217, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 215, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 214, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 216, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 218, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 213, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

1 – HK SYSTEMS CBF-3 AUTOMATIC GUIDED FORKLIFT<br />

VEHICLE, S/N 219, (2006), Capacity 1360 Kg. @ 1.5m, Lift<br />

Height 1.5m, Weight Unloaded Less Battery 2653 Kg., Speed 1.0<br />

m/sec., 48 Volt System, 48” Fork Length, Touch Screen Panel,<br />

(*Note - Battery Removed From Vehicle, Vehicle Being Sold<br />

Without Battery)<br />

2006<br />

DUST COLLECTORS<br />

1 – DISA INDOOR DUST COLLECTION<br />

SYSTEM, With (4) 55-Gallon Barrels,<br />

32 Canisters, 15 HP Blower, 230/460<br />

Volt, 3 Phase<br />

1 – DELTA 50-181 2 HP BARREL DUST<br />

COLLECTOR, With 1100 CFM<br />

1 – DELTA 50-181 2 HP BARREL DUST<br />

COLLECTOR, With 1100 CFM (No<br />

Barrel)<br />

LIMOUSINE<br />

1 – LINCOLN STRETCH LIMOUSINE<br />

For more information, please visit us on the web at www.hilcoind.com 5

sHOp suppOrt equIpment<br />

2006 2006<br />

SHOP SUPPORT EQUIPMENT<br />

1 – FULTON VMP-150 NATURAL GAS HOT WATER<br />

BOILER, S/N 102309 (2006), Natural Gas Fired, BTUH<br />

Output 5175, SH-3/8, HD-1/2, HS-352, MWP-60,<br />

Maximum BTUH Input At 0-2999 Ft. Altitude 5978000,<br />

Fulton Programmable Digital Burner Control, With Bell &<br />

Gossett Size 1510 BF 11 4E Hot Water Recirculation<br />

Pump, Max. WP 175 PSI, GPM-585, Ft.-105, 25-HP,<br />

1800 RPM<br />

1 – FULTON VMP-150 NATURAL GAS HOT WATER<br />

BOILER, S/N 10235, (2006), Natural Gas Fuel, BTUH<br />

Output 2678, SH 1/2, HD 5/8, HS 209, MWP 60,<br />

Maximum BTUH Input At 0-2999 Ft. Altitude 3188000,<br />

Fulton Programmable Digital Burner & Temperature<br />

Controls, w/ 2) Bell & Gossett Size 1531 BF 8.75 Hot<br />

Water Pumps, 175 Max. WP PSI, 144 GPM, 74 FT, 7.5<br />

HP, 1800 RPM<br />

1 – FABRICATED MANUAL CABINET TURNER, With 8’<br />

Inline Conveyor<br />

1 – 4’ x 4’ x 8’ FORKLIFT PLATFORM SAFETY CAGE<br />

1 – DAYTON 3XK82 18” HIGH VOLUME HIGH VELOCITY<br />

FAN, With 1/4 HP, Mounted on Rolling Cart<br />

1 – FOSTORIA CH-624-3A SUN-MITE INFRARED HEATER<br />

1 – SQUARE D 600 AMP ELECTRICAL CONTROL CABINET<br />

1 – MARATHON 50HP ELECTRIC MOTOR, With<br />

Disconnect Panel, 1760 RPM, TEFC Enclosure, 326T<br />

Frame, 230/460 Volt, 3-Phase<br />

1 – MARATHON 50HP ELECTRIC 3 PHASE MOTOR WITH<br />

DISCONNECT PANEL<br />

1 – VACUUM LIFTING HEAD, For Overhead Material Lifting<br />

and Stacking, (4) Vacuum Cups<br />

1 – 3M POLY GUN II HOT GLUE GUN With Stand<br />

1 – WHIRLPOOL TU8000XRP0 TRASH COMPACTOR, S/N<br />

D55094442<br />

1 – SOUTHERN STAPLER MANUAL FLOOR STANDING<br />

BOX STAPLER<br />

1 – CONTAINER STAPLING COR 344-L MANUAL FLOOR<br />

STANDING BOX STAPLER<br />

1 – NICOLETTI NAB-NT CORRUGATED FASTENER<br />

SYSTEM, S/N 00637, (1998), For Fastening Face<br />

Frames & Picture Frames<br />

1 – SL LASER SL 4002-05 GBPU LASER PROJECTION<br />

SYSTEM, S/N 2104, 2005<br />

LARGE QUANTITY OF ROLLING MATERIAL SUPPLY<br />

CARTS, Pallet Racking, Fans, AGV Parts & Hardware,<br />

RAFFAELLO MEGALINE ESPRESSO MACHINES, WIRE<br />

DISPLAY RACKS, With Four Sides, Casters, Adjustable Bins<br />

(UNASSEMBLED)<br />

6<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong (Greater China) •<br />

Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 2655<br />

Forwarding Service Requested<br />

HILCO <strong>OnLIne</strong> <strong>AuCtIOn</strong><br />

2006<br />

Woodworking Machinery<br />

2002<br />

Assets no longer required in the continuing operations of<br />

Online bidding opens: Friday, February 8 th • 10:00 AM Local time<br />

Online bidding closes: Tuesday, February 12 th<br />

Coppell, Texas<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters 5 revere drive, ste. 206 • northbrook, IL 60062 • All rights reserved<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC texas License #16842 • IL License #444.000215<br />

printed in usA • pIn026 • please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

An 18% buyer's premium will be charged on all assets. the<br />

buyer’s premium will be reduced to 15% for payments<br />

made by cash, company check or wire transfer. everything<br />

will be sold online to the highest bidder for cash, in accordance<br />

with the Auctioneer’s customary “terms of sale”,<br />

copies of which will be posted online. All items will be sold<br />

“as is, where-is” without any warranties, expressed or<br />

implied. Although obtained from sources deemed reliable,<br />

the Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained. bidders are<br />

encouraged to thoroughly inspect the items on which they<br />

intend to bid prior to sale. Absolutely no items will be<br />

removed until the day after the conclusion of the sale and<br />

payment is made in full. subject to additions, deletions and<br />

prior sale. for updated information, please visit our website<br />

at www.hilcoind.com for any date, sale process, terms and<br />

conditions and list of available assets.<br />

Payment: All purchAses must be pAid in full on<br />

the dAy of the Auction. if you intend to pay by wire<br />

transfer, we will accept payment the day after the sale<br />

only if a deposit of 25% of total purchases is made on<br />

the day of the sale. contact our office for wire transfer<br />

instructions. only cash, wire transfer or certified check,<br />

payable to hilco industrial, llc will be accepted. company<br />

checks payable to hilco industrial, llc will be accepted<br />

only if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales tax.<br />

purchasers claiming exemptions from taxes must provide<br />

proof satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(bank name) unconditionally guarantees payment to<br />

hilco industrial, llc from (company name). this<br />

guarantee will be valid for purchases made at the<br />

Auction of a major cabinet & display manufacturer on<br />

february 8-12, 2013.<br />

Follow<br />

Us on: