Auction: Thursday January 28, 2010, 10 am

Auction: Thursday January 28, 2010, 10 am

Auction: Thursday January 28, 2010, 10 am

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

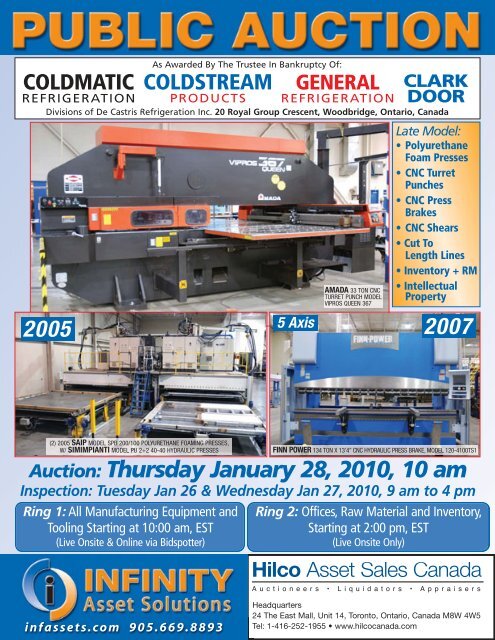

COLDMATIC<br />

REFRIGERATION<br />

2005<br />

As Awarded By The Trustee In Bankruptcy Of:<br />

COLDSTREAM<br />

PRODUCTS<br />

5 Axis<br />

GENERAL<br />

REFRIGERATION<br />

AMADA 33 TON CNC<br />

TURRET PUNCH MODEL<br />

VIPROS QUEEN 367<br />

CLARK<br />

DOOR<br />

Divisions of De Castris Refrigeration Inc. 20 Royal Group Crescent, Woodbridge, Ontario, Canada<br />

Late Model:<br />

• Polyurethane<br />

Fo<strong>am</strong> Presses<br />

• CNC Turret<br />

Punches<br />

• CNC Press<br />

Brakes<br />

• CNC Shears<br />

• Cut To<br />

Length Lines<br />

• Inventory + RM<br />

• Intellectual<br />

Property<br />

2007<br />

(2) 2005 SAIP MODEL SPB 200/<strong>10</strong>0 POLYURETHANE FOAMING PRESSES,<br />

W/ SIMIMPIANTI MODEL PU 2+2 40-40 HYDRAULIC PRESSES<br />

<strong>Auction</strong>: <strong>Thursday</strong> <strong>January</strong> <strong>28</strong>, <strong>20<strong>10</strong></strong>, <strong>10</strong> <strong>am</strong><br />

Inspection: Tuesday Jan 26 & Wednesday Jan 27, <strong>20<strong>10</strong></strong>, 9 <strong>am</strong> to 4 pm<br />

Ring 1: All Manufacturing Equipment and<br />

Tooling Starting at <strong>10</strong>:00 <strong>am</strong>, EST<br />

(Live Onsite & Online via Bidspotter)<br />

FINN POWER 134 TON X 13’4” CNC HYDRAULIC PRESS BRAKE, MODEL 120-4<strong>10</strong>0TS1<br />

Ring 2: Offices, Raw Material and Inventory,<br />

Starting at 2:00 pm, EST<br />

(Live Onsite Only)<br />

infassets.com 905.669.8893<br />

Headquarters<br />

24 The East Mall, Unit 14, Toronto, Ontario, Canada M8W 4W5<br />

Tel: 1-416-252-1955 • www.hilcocanada.com

2005<br />

POLYURETHANE F<br />

(2) 2005 SAIP<br />

Model SPB 200/<strong>10</strong>0<br />

Polyurethane<br />

Fo<strong>am</strong>ing Presses, w/<br />

SIMIMPIANTI Model<br />

PU 2+2 40-40<br />

Hydraulic Presses,<br />

Each with (4) 13’ x 13’<br />

Shuttle Tables,<br />

Hydraulic Power Pack,<br />

Fo<strong>am</strong>ing Dispenser,<br />

Euro Cold Cooling<br />

System, Light Curtains,<br />

Pro-Face DRO Fo<strong>am</strong><br />

Dispensing Controller,<br />

Max 650 Bar, 600V, 80<br />

KVA, 60 Cycles, SAIP<br />

s/n 1631,<br />

SIMMIMPIANTI s/n’s<br />

2041392 & 2041393<br />

State of the Art MANNI Presses – Available for Prior Sale<br />

$6 Million New Cost<br />

Delivered New in 2005<br />

2<br />

(2) 2005 MANNI SAP Models 2+2 & 2+0 Polyurethane Molding Presses w/ (14) 55” x 46’ long platens, (4) Main Fr<strong>am</strong>e Super Structures,<br />

(2) AGIP Model PMC 376 T Control Panels, s/n 0504009, (3) CANNON / AFROS Model A Sys 200 STD Fo<strong>am</strong> Applicator Systems, w/<br />

Transfer Pumps, s/n <strong>28</strong>024, <strong>28</strong>0242 & <strong>28</strong>0243, SIEMENS Model Simatic Digital Read-Out Control Stations, Safety Fencing, Hydraulic<br />

Power Packs w/ (2) Overhead Craneways Consisting of: (6) 26’ Wide Cranes, (16) Sections 32” x 38’ Runways, (8) 20’ High Free Standing<br />

Uprights, (2) 20’ Long Steel Storage Shipping Containers, Hydraulic Power Packs. Units are dismantled, in secure storage and ready for<br />

shipping. For Further Details Please Contact Leslie Amoils @ 905-669-8893<br />

For full details and photos please visit hilcocanada.com and infassets.com

OAMING PRESSES<br />

2005<br />

1of 2<br />

PARTIAL VIEW<br />

OF TOOLING<br />

Other Fo<strong>am</strong> Plugs available:<br />

(3) Assorted Hydraulic Fo<strong>am</strong> Plugs: 32” x 15” x<br />

72”, 26” x 36” x <strong>10</strong>0”, 29” x 37” x 80”<br />

3 Ch<strong>am</strong>ber Fo<strong>am</strong> Plug, Approx: 34” x 30” x 60”<br />

Ch<strong>am</strong>bers, Hydraulic Power Pack<br />

4 Ch<strong>am</strong>ber Fo<strong>am</strong> Plug, Approx 22” x 20” x 32”<br />

Ch<strong>am</strong>bers, Hydraulic Power Pack<br />

(2) 2005 SAIP Model SPB 200-<strong>10</strong>0 Polyurethane Fo<strong>am</strong>ing Presses, w/ 2005 SIMIMPIANTI Model PU 2+2 15-135 Hydraulic Presses, Each<br />

with (4) 5’11” x 44’ Shuttle Tables, AURO Cold Cooling System, Carpenter Chemical Co and Mahle Filtration System, Twin Head Hydraulic<br />

Pumps, Dual Fo<strong>am</strong> Injectors, Controls, and Related Support Equipment, 170/600V, 80 KVA, 60 Cycles, s/n’s 1604 & 1605. PLUS: 20 Carts<br />

of Assorted Fo<strong>am</strong>ing Press Dies and Tooling.<br />

2007<br />

CON-TEK FOAMING PLUG, 4<br />

ZONE, <strong>10</strong>’ X 6’ CAPACITY, <strong>10</strong> HP<br />

HYDRAULIC POWER PACK, CON AIR<br />

THERMOLATOR MODEL TW, 575V,<br />

S/N 072396<br />

UP TO 15 SIZE CONFIGURATIONS<br />

New Cost $500K<br />

SIMIMPIANTI MODEL<br />

G2-12-17.5-35 FOUR POST<br />

HEATED PLATEN PRESS, 5' X<br />

12' BED, HYDRAULIC POWER<br />

PACK, S/N 84152<br />

PERROS FOAMING PLUG,<br />

MODEL GENERAL, 30” X 60”<br />

CAPACITY, W/ SETUP DIES,<br />

CONTROL PANEL, 575V, S/N A-130<br />

SIMIMPIANTI 5’ X 13’<br />

COOLER DISPLAY CABINET<br />

PLUG, 40” X 30” X 13’ BASE,<br />

HYDRAULIC POWER PACK,<br />

TIMER, CURING CAPACITY,<br />

FOAM SHOT, 600V<br />

3

CNC TURRET PUNCHES<br />

1997<br />

4<br />

AMADA 33 TON CNC TURRET PUNCH MODEL VIPROS QUEEN 367<br />

SIEMENS SINUMERIK<br />

CNC CONTROLS<br />

FINN POWER 33 TON CNC TURRET PUNCH, & 27.5 TON CNC SHEAR, MODEL SHEAR GENIUS TR-S6<br />

AMADA 33 TON CNC TURRET PUNCH MODEL VIPROS 357<br />

PARTIAL VIEW OF TOOLING<br />

This brochure is meant merely as a guide. Infinity Assets & Hilco Asset Sales Canada<br />

make no guarantee, expressed or implied, as to the accuracy of the information in<br />

this brochure. Buyers should inspect the goods prior to bidding.<br />

AMADA 30 TON CNC TURRET PUNCH,<br />

MODEL OCTO 30.30.40<br />

Foster Refrigeration<br />

Assets for Sale in Montreal<br />

2005 SAIP Model SPB 200/<strong>10</strong>0 Panel Press, s/n<br />

1606<br />

LOCKFORMER 60” Wide Cut-To Length Line C/W<br />

Uncoiler, Feeder, Rollformer, Shear, Transfer Tables &<br />

Controls (Cost $800,000)<br />

AMADA Model Vp35072 Vipros Queen Turret Punch,<br />

s/n 3573020<br />

AMADA Model Hfbo 125 Press Brake, s/n HFBO-<br />

125-30-H-50905<br />

ALLSTEEL Model <strong>10</strong>g-12 Shear, s/n S-2577<br />

CHICAGO Model 8<strong>10</strong>l Press Brake, s/n L19519<br />

ALLSTEEL ¼” X <strong>10</strong>’ Long Bed Shear, s/n Mp-14170<br />

AZTECH Model C50-<strong>10</strong> Press Brake, s/n 0069<br />

All Support Equipment Consisting Of: Intellectual<br />

Property, Plugs, Fo<strong>am</strong> Applicators, Air Compressors,<br />

Shop Equipment, Forklift, Press Brake Dies, Office<br />

Equipment, Raw Materials, Inventory Etc.<br />

PLUS:<br />

2002 CURVATUBI Model SMI Silver 2, <strong>10</strong> Axis Tube<br />

Bending Machine, s/n 26402954<br />

OAK Model CFCL M4-5<strong>28</strong> Cut-To Length Hair Pin<br />

Bender, s/n Vbhbm8-63rh072401<br />

OAK Model STOOS-M2-14 Cut-To Length Tube Machine<br />

TRIDAN Model RLB45E-30-22-4 High Speed Fin Die<br />

Punch Press, s/n E95488<br />

NIAGARA Model PD2-35-36 High Speed Punch Press,<br />

s/n 49164<br />

(Please Contact Odd Knudsen @ 1-647-991-6905)<br />

CNC TURRET PUNCHES<br />

1997 AMADA 33 Ton CNC Turret Punch Model Vipros<br />

Queen 367, 60” Throat, 60” x 144” Max Sheet Size,<br />

45 Station Turret , 2 Auto Index , Fanuc 0-4P-C CNC<br />

Control, s/n 36730057, Plus Huge Selection of Tooling<br />

1996 FINN POWER SG6 – Hydraulic Punch / Right<br />

Angle Shear Center, Model TRS6 BIF3-21-AM, 33 Ton<br />

CNC Turret Punch, 21 Turret Station, 60” Throat, Max.<br />

Punch Di<strong>am</strong>eter 3.5”, Max. Punching Material<br />

Thickness 0.314”, X-<strong>10</strong>1.73” & Y-61.4”, Integrated<br />

Right Angle 27.5 Ton Shear, Model TR-6 Shear<br />

Genius, Max. Shearing Material Thickness Alum.<br />

0.196”, 31.5” x 60.15 Full Stroke Shear, Max. Sheet<br />

Axis Traverse: X-3150 IPM, Y-2362 IPM, Siemens<br />

Sinumerik 880N CNC Controller, Finn-Power Jetc<strong>am</strong><br />

Software With Automatic Nesting & Loading System,<br />

s/n 8.1-TRS612496<br />

1994 AMADA 33 Ton CNC Turret Punch Model Vipros<br />

357, 50” x 144” Max Sheet Size, 50” Throat, 4.5” Max<br />

Hole Di<strong>am</strong>eter, Max Sheet Thickness ¼”, 58 Station<br />

Turret, 2 Auto Index, Fanuc O4PC CNC Control, s/n<br />

357<strong>10</strong>688, Plus Huge Selection of Tooling<br />

AMADA 30 Ton CNC Turret Punch, Model OCTO<br />

30.30.40, Fanuc O Control, 40” Throat, 8 Station<br />

Turret, 1 Auto Index, 30” x 80” Max Sheet Size, Max<br />

Sheet Thickness ¼”, s/n: 3340683<br />

STRIPPIT 30 Ton Punch, Model Custom 91880/300<br />

Fabricator, 30 Ton Capacity w/ Tooling, s/n:<br />

093122773

2007 2006<br />

5 Axis 5 Axis<br />

FINN POWER 134 TON X 13’4” CNC HYDRAULIC PRESS BRAKE, MODEL 120-4<strong>10</strong>0TS1<br />

FINN POWER 1<strong>10</strong> TON X <strong>10</strong>’ SERVO ELECTRIC PRESS BRAKE, MODEL E BRAKE <strong>10</strong>0-3<strong>10</strong>0<br />

1994 NC9 EX II Control<br />

ACCURPRESS 175 TON X 14’ HYDRAULIC PRESS BRAKE, MODEL 717514<br />

AMADA 1<strong>10</strong> TON X <strong>10</strong>’ HYDRAULIC PRESS BRAKE, MODEL RG-<strong>10</strong>0<br />

NC9 EX Control<br />

AMADA 1<strong>10</strong> TON X 13’ HYDRAULIC PRESS BRAKE, MODEL RG-<strong>10</strong>0L<br />

1994<br />

ACCURPRESS 130 TON X 12’ HYDRAULIC PRESS BRAKE, MODEL 713012<br />

AMADA 1<strong>10</strong> TON X 13’ HYDRAULIC PRESS BRAKE, MODEL RG-<strong>10</strong>0<br />

ALLSTEEL 70 TON X 8’ HYDRAULIC PRESS BRAKE,<br />

MODEL 70-8<br />

PRESS BRAKES<br />

2007 FINN POWER 134 Ton x 13’4” CNC Servo-Hydraulic Press<br />

Brake, Model H-Brake 120-4<strong>10</strong>0 TS1, 5 Axis CNC Back Gauge,<br />

161.4” Working Length, 11.02" Max. Stroke, Max. Bending<br />

Speed 0.39”/Sec, <strong>10</strong> HP, Delem 65W CNC Control, CNC<br />

Crowning, Wila Tooling, Light Curtains, s/n K4196<br />

2006 FINN POWER 112 Ton x <strong>10</strong>’ CNC Mechatronic-Hydraulic<br />

Press Brake, Model E-Brake <strong>10</strong>0-3<strong>10</strong>0 TS1, 5 Axis CNC Back<br />

Gauge, 122" Working Length, 11.02" Max. Stroke, Max. Bending<br />

Speed 0.39”/Sec, <strong>10</strong> HP, Delem 65W CNC Control, s/n: M<strong>10</strong><strong>28</strong><br />

1994 ACCURPRESS 175 Ton x 14’ Hydraulic Press Brake, Model<br />

717514, 12’4” Distance Between Uprights, 8” Stroke, 14” Open<br />

Height, Automec CNC 99 2 Axis Back Gauge, s/n 2735<br />

1989 AMADA 1<strong>10</strong> Ton x <strong>10</strong>’ Hydraulic Press Brake, Model RG-<br />

<strong>10</strong>0, <strong>10</strong>0.5 Distance Between Uprights, 3.94” Stroke, 14.58”<br />

Open Height, 118.2” Table Length, 122.1” Max. Bending Length,<br />

15.76” Throat depth, NC9-EX II CNC Controller, 3 Axis CNC<br />

Back Gauge, s/n <strong>10</strong>3755<br />

5

6<br />

AMADA <strong>10</strong>’ X 1/4" HYDRAULIC SHEAR, MODEL H3065T<br />

1998<br />

1994<br />

ACCURSHEAR 12’ X 1/4" HYDRAULIC SHEAR, MODEL 625012<br />

ALLSTEEL 12’ X <strong>10</strong> GAUGE HYDRAULIC SHEAR<br />

ALLSTEEL 70 TON X <strong>10</strong>’ HYDRAULIC PRESS BRAKE, MODEL 70-<strong>10</strong><br />

HACO 12’ X 1/4" HYDRAULIC SHEAR, MODEL HSLX 3606<br />

PROMECAM 82 TON X<br />

<strong>10</strong>’ HYDRAULIC PRESS<br />

BRAKE, MODEL RG 75/30<br />

2003<br />

AMADA <strong>10</strong>’ X 3/16” MECHANICAL SHEAR, MODEL M-3045<br />

CINCINNATI 12’ X <strong>10</strong> GAUGE HYDRAULIC SHEAR<br />

HYDRAULIC FOLDING BRAKE 12’ X 3/16” CAP. MODEL PBPF3750<br />

CINCINNATI 225 TON X 16’ MECHANICAL PRESS BRAKE, MODEL #9<br />

Bid on-line at<br />

1989<br />

PRESS BRAKES (con’t)<br />

1986 AMADA 1<strong>10</strong> Ton x 13’ Hydraulic Press Brake,<br />

Model RG-<strong>10</strong>0L, 122.1 Distance Between Uprights,<br />

3.94” Stroke, 14.85” Open Height, 157.6” Table<br />

Length, 161.5” Max. Bending Length, 15.76” Throat<br />

depth, NC9-EX CNC Controller, 3 Axis CNC Back<br />

Gauge, s/n <strong>10</strong>3080<br />

1986 AMADA 1<strong>10</strong> Ton x 13’ Hydraulic Press Brake,<br />

Model RG-<strong>10</strong>0L, 22.1 Distance Between Uprights,<br />

3.94” Stroke, 14.85” Open Height, 157.6” Table<br />

Length, 161.5” Max. Bending Length, 15.76” Throat<br />

depth, Hurco Autobend CNC Controller, 2 Axis CNC<br />

Back Gauge, s/n <strong>10</strong>3137<br />

1994 ACCURPRESS, 130 Ton x 12’ Hydraulic Press<br />

Brake, Model 713012, <strong>10</strong>’4” Distance Between<br />

Uprights, 8” Stroke, 14” Open Height, Automec Model<br />

CNC 99 2 Axis CNC Back Gauge, Light Curtains<br />

ALLSTEEL, 70 Ton x 8’ Hydraulic Press Brake, Model<br />

70-8, 6’ 6” Distance Between Uprights, 15” Open<br />

Height, 0 to 6” Stroke, Light Curtains, Automec CNC 99<br />

2 Axis CNC Back Gauge, s/n 485<br />

ALLSTEEL 70 Ton x <strong>10</strong>’ Hydraulic Press Brake, Model<br />

70-<strong>10</strong>, 8’6” Distance Between Uprights, 0 to 6”<br />

Stroke, 15” Open Height, s/n: 184<br />

HYDRAULIC FOLDING BRAKE, Model PBPF3750, 12'<br />

x 3/16” Mild Steel Capacity, s/n PBPF3750/2/2GG/387<br />

CINCINNATI 225 Ton x 16’ Mechanical Press Brake,<br />

Model #9, <strong>10</strong>’ 6” Distance Between Uprights, 4' Horn,<br />

Triad Safety Lights, Power R<strong>am</strong> Adjustment, Air Trip<br />

Clutch, Floor Mount, s/n 3<strong>28</strong>14<br />

PROMECAM 82 Ton x <strong>10</strong>’ Hydraulic Press Brake,<br />

Model RG 75/30, 8’ 3” Distance Between Uprights,<br />

Autobend IV CNC Back Gauge<br />

BROWN BOGGS (CHICAGO) 60 Ton x <strong>10</strong>’ Mechanical<br />

Press Brake, Model 6<strong>10</strong>, Light Curtains, s/n 6947<br />

PROMECAM 4' Hydraulic Press Brake, Model RG25-12<br />

SHEARS<br />

1998 AMADA <strong>10</strong>’ x 1/4" Hydraulic Shear, Model<br />

H3065T, CNC Back Gauge, Squaring Arm, (2) Material<br />

Support Arms, s/n 759<br />

2003 HACO 12’ x 1/4" Hydraulic Shear, Model HSLX<br />

3606, Haco Model SC7 CNC Control, Back Gauge, s/n<br />

67133<br />

1994 ACCURSHEAR, 12’ x 1/4" Hydraulic Shear,<br />

Model 625012, Progr<strong>am</strong>mable Back Gauge, Squaring<br />

Arm, Support Arms, s/n 1889<br />

1989 AMADA, <strong>10</strong>’ x 3/16” Mechanical Shear, Model<br />

M-3045, Progr<strong>am</strong>mable Back Gauge, Squaring Arm,<br />

Support Arms, s/n 3045088<br />

ALLSTEEL, 12’ x <strong>10</strong> Gauge Hydraulic Shear, Model<br />

<strong>10</strong>G-12, Front Operated Motorized Back Gauge, 50"<br />

Squaring Arm, Support Arms, 15HP, <strong>10</strong> Gauge Mild<br />

Steel & 14 Gauge Stainless Steel Cap., Rake Angle<br />

Inch/Foot 1/8"-3/8", s/n S2525<br />

CINCINNATI 2’ x <strong>10</strong> Gauge Mechanical Shear, Model<br />

<strong>10</strong>12, 15 HP, 24” Hand Crank Back Gauge, s/n 19087<br />

CUT TO LENGTH LINES<br />

IOWA PRECISION Model SLEAR 2 Sheet Metal Forming<br />

Line Consisting of: LITTELL Model 90-48 Auto<br />

Centering Reel / Uncoiler, <strong>10</strong>,000 lb Capacity, 48”<br />

Width Capacity, 60” OD Capacity on Roll or Coil, 20-<br />

24” ID Capacity, s/n S-1855-75, IOWA PRECISION<br />

Model SLR6014, 14 Gauge Shearing Capacity Flying<br />

Cutoff Shear, 5 Slits Slitting Capacity, s/n 67926, IOWA<br />

PRECISION Model AN60 Feeder, Straightener w/<br />

Pneumatic Notchers, Feeder Roll and Groover, s/n<br />

AN7912, Complete w Hydraulic System and 4 Post, <strong>10</strong>’<br />

Mezzanine, IOWA PRECISION 56” x 36’ Powered<br />

Conveyor, LOCKFORMER 9 Station Roll Former, 24<br />

Gauge Capacity, 46” Capacity, s/n 9D-<strong>10</strong>1<strong>28</strong>, FELD-<br />

MAN Hydraulic Conveyor, 60” x 30’ Powered<br />

Conveyor, FELDMAN 4 Post Forming Machine, s/n 930<br />

Hydraulic, 63” Capacity, Hydraulic Power Pack, FELD-<br />

MAN Hydraulic Conveyor, 60” x 30’ Powered<br />

Conveyor, s/n 931<br />

GRIEBEL Model BRH 8D Cut-To Length Blanking Line,<br />

51” Width w/ <strong>10</strong>,000 lb Capacity Uncoiler, Film<br />

Applicator, Model BRA 50” x ¼” Capacity, s/n 403/83<br />

BROWN BOGGS 60 TON X <strong>10</strong>’ MECHANICAL<br />

PRESS BRAKE, MODEL 6<strong>10</strong>

COMPLETE IOWA PRECISION SLEAR 2 48” CUT TO LENGTH LINE<br />

GRIEBEL MODEL BRH 8D CUT-TO LENGTH BLANKING LINE<br />

KEYSTONE MODEL A2-ECO VINYL CORNER WELDER<br />

Onsite & Online<br />

Webcast<br />

Powered By<br />

BidSpotter.com<br />

AMADA MODEL CSHW-220<br />

CORNER NOTCHER<br />

2003<br />

AMADA MODEL TOGU-11US TOOL<br />

GRINDER<br />

PROXY BIDDING:<br />

We will be happy to bid on your<br />

behalf if you are unable to attend<br />

our auction. Please call our<br />

offices at 416-252-1955 or<br />

1-866-669-8893.<br />

Visit our websites<br />

www.hilcocanada.com or<br />

www.infassets.com<br />

to submit a proxy bid.<br />

SAMPSON MODEL V NOTCHER<br />

ROLLFORMERS<br />

(16) Station Double Sided Rollformer 1.5" cap.<br />

(<strong>10</strong>) Station Double Sided Rollformer<br />

LOCKFORMER 22 Gauge 9 Station Roll<br />

Former, s/n D-1<strong>20<strong>10</strong></strong>1<br />

LOCKFORMER Adjustable Table Roll Former<br />

REINHART Machine Model 22.60 #<strong>10</strong>/3 Roll<br />

Former<br />

FABRICATION<br />

AMADA Model CSHW-220 Corner Notcher, ¼”<br />

Capacity, 8-5/8” x 8-5/8” Blades, 1.02”<br />

Stroke, 42 SPM, 5 HP, 4,000 lbs, 2 Axis DRO,<br />

s/n 22000329<br />

SAMPSON Model V Notcher and Square Notcher, Hydraulic<br />

KEYSTONE Model A2-ECO Vinyl Corner Welder, s/n <strong>10</strong>0<strong>28</strong><br />

2003 AMADA Model TOGU-11US Tool Grinder, s/n<br />

3023-0523<br />

SUPPORT EQUIPMENT<br />

COLCHESTER 15” x 50” Gap Bed Lathe, Model Triumph<br />

2000<br />

(<strong>10</strong>) Asst. LINCOLN, CANOX & MILLER Mig & Tig Welders<br />

WELDOMATIC & RWC Spot Welders, ARO Gun Welder<br />

ROUSSELLE Model 4 Punch Press, s/n 14097<br />

TALI APRASATE Model PR-80 Punch Press, s/n #111-21-FB<br />

STRONGARM 60 Ton H Fr<strong>am</strong>e Press<br />

BEVERLY Hand Shear<br />

CHICAGO 3' Finger Brake<br />

(2) FIRST & MILLTECH Vertical Mills, 9" x 42" Table, 2<br />

Axis DRO<br />

(4) BUFFALO, CRAFTEX & JET Drill Presses<br />

RIGID Model 300 Pipe Threader<br />

(3) CRAFTEX Dust collector<br />

NORDSON Dura Blue Glue Gun<br />

SAWS<br />

2005 MEP 14” Chop Saw, Model Cobra 350, s/n 151362R112<br />

HYD-MECH Model S20 Horizontal Bandsaw<br />

JAESPA Horizontal Metal Cutting Bandsaw<br />

TRENNJAEGER Model VC-32016" cold cut caw<br />

KAR-MANN Roll-In Band Saw<br />

JESPA Band Saw<br />

(2) GENERAL <strong>10</strong>' Table Saws<br />

ROCKWELL & DEWALT Radial Arm Saws<br />

AIR COMPRESSORS<br />

GARDNER DENVER <strong>10</strong>0 HP Model Electra Saver II<br />

Rotary Screw Type<br />

GARDNER DENVER 50 HP<br />

INGERSOLL RAND 30 HP Model SSR<br />

DOMINIK HUNTER T305 DHA air line dryer<br />

FORKLIFTS<br />

(2) LINDE 6,000 lb Capacity Diesel Forklift Model H30D,<br />

3 Stage Mast, Outdoor Tires<br />

HYSTER 6,000 lb Capacity Electric Forklift Model E<strong>10</strong>0A,<br />

3 Stage Mast, Indoor / Outdoor Tires<br />

YALE 6,000 lb Capacity Electric Forklift, Model<br />

ERC060RFN36SV084, 2 Stage Mast<br />

CATERPILLAR 5,000 lb Capacity Propane Forklift Model<br />

T50D, 3 Stage Mast, Side Shift, Indoor / Outdoor Tires<br />

NISSAN 4,700 lb Capacity Propane Forklift Model<br />

GPH02A25V, 3 Stage Mast, Indoor Tires<br />

MITSUBISHI 4,000 lb Capacity Propane Forklift, Model<br />

FGC 20, 3 Stage Mast, Indoor / Outdoor Tires<br />

CLARK 3,650 lb Capacity Propane Forklift, Model<br />

GPX25E, 3 Stage Mast, Outdoor Tires<br />

RAYMOND 3,000 lb Capacity, Reach Lift,<br />

Model 214DR40TT Electric, s/n 021-801956<br />

TRUCK<br />

1989 INTERNATIONAL Model 4600 Truck w/<br />

Roll-Off Deck<br />

LOCKFORMER ADJUSTABLE<br />

TABLE ROLL FORMER<br />

<strong>10</strong> STATION DOUBLE<br />

SIDED ROLLFORMER<br />

7

PARTIAL VIEW OF 9 FORKLIFTS<br />

1989<br />

INTERNATIONAL MODEL 4600 ROLL OFF TRUCK<br />

INVENTORY &<br />

RAW MATERIALS<br />

Over $1 Million in Cost Including: Huge Selection of<br />

Assorted Raw Materials, Aluminum Rolls, Steel and<br />

Stainless Steel Sheets, Copper Tubing, Windows,<br />

Refrigerator Compressors, Trim, Wiring, Assembly<br />

Components. Coldmatic 20' x 50' Two Door Walk-In<br />

Cooler For Test Purposes w/ Testing Equipment.<br />

(20) Assorted Reach-In Coolers<br />

(25) Foster WIP Coolers & Freezers<br />

MISCELLANEOUS<br />

ORION Packaging Pallet Wrapper Model H44B3RX, 6’<br />

Rotary Table, s/n 705386<br />

200' Roll Top Conveyor, Assorted Straight and Corner<br />

Sections<br />

1995 CLARK Model Vision 34 Ride-On Sweeper, s/n 15680<br />

Pallet Jacks, 20 Sections of Pallet Racking, 20 Sections<br />

Cantilever Racking<br />

Assorted Metal Shelving, Work Tables, Rolling Work<br />

Carts, Racks<br />

Assorted Office Equipment: Computers, Tables, Chairs,<br />

Executive Office Furniture, Boardrooms, Cafeterias Etc.<br />

Bid on-line at<br />

PARTIAL VIEW OF REACH IN FREEZERS<br />

PARTIAL VIEW OF CANTILEVER RACKING AND RAW MATERIALS<br />

INTELLECTUAL PROPERTY<br />

PARTIAL VIEW OF RAW MATERIAL<br />

ALUMINUM ROLL STOCK<br />

GENERAL REFRIGERATION WALK IN REFRIGERATOR<br />

TERMS OF SALE<br />

Payment: All payments must be in Cash, Certified Funds, Visa, MasterCard<br />

or Interac, Wire Transfers or Company Cheques must be accompanied with a bank<br />

letter guaranteeing irrevocable payment to Hilco Asset Sales Canada.<br />

A 2% surcharge will apply on all payments made by credit card.<br />

A 13% buyers premium will be added to all onsite purchases (16% Online).<br />

A $500 refundable security deposit is required upon registration.<br />

A 25% deposit is required at time of purchase, balance due by 2 pm,<br />

Friday <strong>January</strong> 29, <strong>20<strong>10</strong></strong>. NO EXCEPTIONS.<br />

All goods are sold "As Is, Where Is", ALL SALES ARE FINAL.<br />

All subject to prior sale. Sale to be conducted in Canadian Funds.<br />

Complete terms and conditions including removal procedures, are available on our<br />

websites, and will be posted at the auction site, and provided at the time of registration.<br />

REMOVAL TIMES<br />

All Small Items By Wednesday February 3, <strong>20<strong>10</strong></strong><br />

All Other Items By Friday February 12, <strong>20<strong>10</strong></strong><br />

Hours: Monday – Friday between 8 <strong>am</strong> – 4 pm.<br />

No items may be removed during auction. NO EXCEPTIONS.<br />

ACOMMODATIONS<br />

Holiday Inn Express: 6<strong>10</strong>0 Highway 7, Vaughan, Ontario, Canada, L4H 0R2<br />

Reservations: 1-877-851-1599 or 905-851-15<strong>10</strong> (1 Min From <strong>Auction</strong>)<br />

Comfort Hotel Airport North: 445 Rexdale Boulevard, Toronto, ON M9W 6K5,<br />

Canada - (416) 740-9500 (5 Mins From <strong>Auction</strong>)<br />

Hilton Toronto Airport: 5875 Airport Road, Mississauga, ON L4V 1N1, Canada<br />

(905) 677-9900, (18 Mins From <strong>Auction</strong>)<br />

DIRECTIONS: 20 Royal Group Crescent, Woodbridge,<br />

Ontario, Canada L4H 1X9<br />

Directions from Airport (Approx. 18 Mins):<br />

Exit Airport and Take the Hwy 427 North (9.2 km), Take the Hwy 7 Exit Br<strong>am</strong>pton/Vaughan,<br />

Turn Right at Hwy 7, Turn Right on Hwy 27, Turn Right at W Royal Gate Blvd (0.2 km),<br />

Right at Royal Group Crescent, Destination will be on the left.<br />

Members In Good<br />

Standing Of:<br />

All IP Including But Not Limited To: Trademarks, Patents, License<br />

Agreements, Technical Designs, Client Lists, Telephone Numbers<br />

For The Following Entities:<br />

COLDMATIC Refrigeration<br />

COLDMATIC Building Supplies<br />

COLDSTREAM Products<br />

GENERAL Refrigeration<br />

CLARK Door<br />

FOSTER Refrigeration<br />

ORYX Fixtures<br />

Visit websites for full details<br />

Printed in Canada<br />

infassets.com 1.866.669.8893<br />

Headquarters<br />

24 The East Mall, Unit 14, Toronto, Ontario, Canada M8W 4W5<br />

Tel: 1-416-252-1955 • www.hilcocanada.com