singapore engineer singapore engineer singapore engineer

singapore engineer singapore engineer singapore engineer

singapore engineer singapore engineer singapore engineer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

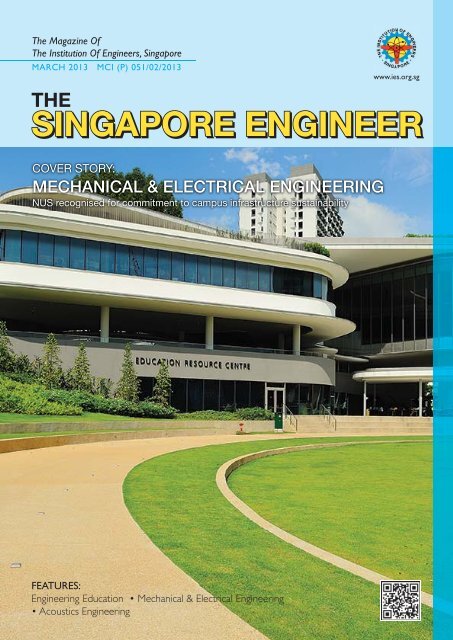

The Magazine Of<br />

The Institution Of Engineers, Singapore<br />

MARCH 2013 MCI (P) 051/02/2013<br />

THE<br />

www.ies.org.sg<br />

SINGAPORE ENGINEER<br />

COVER STORY:<br />

MECHANICAL & ELECTRICAL ENGINEERING<br />

NUS recognised for commitment to campus infrastructure sustainability<br />

FEATURES:<br />

Engineering Education • Mechanical & Electrical Engineering<br />

• Acoustics Engineering

CONTENTS<br />

FEATURES<br />

12 ENGINEERING EDUCATION:<br />

How young <strong>engineer</strong>s will mold the future<br />

Prof Calestous Juma, from Harvard Kennedy School, USA, summarises the current<br />

thinking on how <strong>engineer</strong>s should be trained so that they acquire the skills needed to<br />

solve the world’s problems.<br />

14 MECHANICAL & ELECTRICAL ENGINEERING: Cover Story:<br />

NUS recognised for commitment to campus infrastructure<br />

sustainability<br />

The National University of Singapore won a Green Mark Champion Award for the<br />

environment-friendly development of its facilities.<br />

20 MECHANICAL & ELECTRICAL ENGINEERING:<br />

The advantages of fabric ducting<br />

This method of air distribution offers higher productivity during installation as well as<br />

greater energy effi ciency and comfort levels, in operation.<br />

24 ACOUSTICS ENGINEERING:<br />

Aeroacoustics simulations for the aerospace industry<br />

Computer simulation techniques contribute to a better understanding of noise<br />

generation by aircraft in fl ight and thereby to its reduction.<br />

26 PROJECT APPLICATION:<br />

Innovative solutions for the power generation industry<br />

Engineering software facilitate the design of complex plants employing the latest technologies.<br />

28 PROJECT APPLICATION:<br />

Leveraging M2M technology to preserve the Amazon rainforest<br />

The use of machine-to-machine communication technology has helped to reduce<br />

illegal logging in Brazil.<br />

34 INTERVIEW:<br />

Moving towards the smart grid<br />

Mr Willie Chan, Director of Strategy, Schneider Electric Singapore, discusses some of<br />

the changes taking place in power generation and distribution.<br />

REGULAR SECTIONS<br />

02 IES UPDATE<br />

30 PRODUCTS & SOLUTIONS<br />

Chief Editor<br />

T Bhaskaran<br />

t_b_n8@yahoo.com<br />

Director, Marketing<br />

Roland Ang<br />

roland@iesnet.org.sg<br />

Marketing & Publications Executive<br />

Jeremy Chia<br />

jeremy@iesnet.org.sg<br />

CEO<br />

Angie Ng<br />

angie@iesnet.org.sg<br />

Publications Manager<br />

Desmond Teo<br />

desmond@iesnet.org.sg<br />

Published by<br />

The Institution Of Engineers, Singapore<br />

70 Bukit Tinggi Road<br />

Singapore 289758<br />

Tel: 6469 5000 Fax: 6467 1108<br />

Cover designed by Irin Kuah<br />

Cover image by National University<br />

of Singapore.<br />

The Singapore Engineer is published<br />

monthly by The Institution of Engineers,<br />

Singapore (IES). The publication is<br />

distributed free-of-charge to IES members<br />

and affi liates. Views expressed in this<br />

publication do not necessarily refl ect those<br />

of the Editor or IES. All rights reserved. No<br />

part of this magazine shall be reproduced,<br />

mechanically or electronically, without the<br />

prior consent of IES. Whilst every care is<br />

taken to ensure accuracy of the content<br />

at press time, IES will not be liable for any<br />

discrepancies. Unsolicited contributions<br />

are welcome but their inclusion in the<br />

magazine is at the discretion of the Editor.<br />

Design & layout by 2EZ Asia Pte Ltd<br />

Printed by Print & Print Pte Ltd.<br />

36 EVENTS<br />

38 NEWS<br />

March 2013 THE SINGAPORE ENGINEER<br />

01

IES UPDATE<br />

Message from the President<br />

The results of the United Nations Climate Change<br />

Conference that was held in Doha, Qatar, in<br />

December 2012, show that while international<br />

negotiations are moving steadily in the right direction,<br />

they are moving at too slow a pace, according to<br />

Ms Christiana Figueres, Executive Secretary of the<br />

United Nations Framework Convention on Climate<br />

Change. She points out that while the evolution of<br />

preferred energy sources has moved slowly over the<br />

centuries, from fi rewood, to coal and then to oil, the<br />

increasing incidence and severity of natural disasters, which are the consequences of<br />

climate change, have given an added urgency to the need to switch to renewable<br />

energy and to increase energy-effi ciency.<br />

For the building and construction industry, besides improving the energy-mix and<br />

increasing energy effi ciency, there is also a need to adopt a range of measures such<br />

as sustainable designs and materials.<br />

Recognising the importance of sustainability in the built environment, Singapore’s<br />

Building and Construction Authority (BCA) developed the Green Building Masterplan<br />

for greening 80% of all buildings in the republic, by 2030.<br />

The masterplan includes initiatives such as fi nancial incentives, capability building<br />

programmes, and regulatory and administrative policies. These have proven successful.<br />

From just 17 green building projects, when the BCA Green Mark scheme was<br />

launched in 2005, there are now about 1,400 such buildings now.<br />

At fi rst, mainly new buildings were Green Mark-certifi ed. Improving the sustainability of<br />

existing buildings came later. With recent enhancements to the Green Mark Incentive<br />

and mandatory measures in place, for existing buildings, Green Mark certifi cation for<br />

buildings under this category will increase. There is also a rising trend among building<br />

tenants to go for Green Mark certifi cation.<br />

This year, IES will be holding its Annual General Meeting at the NUSS Kent Ridge<br />

Guild House on Saturday, 18 May. A registration form for the AGM will be sent to all<br />

of our corporate members soon and I look forward to seeing you there!<br />

Prof Chou Siaw Kiang<br />

President<br />

The Institution of Engineers, Singapore (IES)<br />

IES COUNCIL MEMBERS<br />

2012/2013<br />

President<br />

Prof Chou Siaw Kiang<br />

Vice Presidents<br />

Er. Chong Kee Sen<br />

Er. Edwin Khew<br />

Dr Kwok Wai Onn, Richard<br />

Mr Neo Kok Beng<br />

Er. Ong Geok Soo<br />

Er. Ong See Ho<br />

Honorary Secretary<br />

Dr Boh Jaw Woei<br />

Honorary Treasurer<br />

Mr Kang Choon Seng<br />

Assistant Honorary Secretary<br />

Er. Koh Beng Thong<br />

Assistant Honorary Treasurer<br />

Er. Seow Kang Seng<br />

Immediate Past President<br />

Er. Ho Siong Hin<br />

Past Presidents<br />

Er. Dr Lee Bee Wah<br />

Er. Tan Seng Chuan<br />

Honorary Council Member<br />

Er. Ong Ser Huan<br />

Council Members<br />

Prof Chau Fook Siong<br />

Er. Dr Chew Soon Hoe<br />

Ms Fam Meiling<br />

Er. Dr Ho Kwong Meng<br />

Dr Ho Teck Tuak<br />

Mr Lee Kwok Weng<br />

Mr Lim Horng Leong<br />

Mr Ng Sing Chan<br />

Mr Oh Boon Chye, Jason<br />

Er. Tan Shu Min, Emily<br />

Mr Tan Boon Leng, Mark<br />

Er. Toh Siaw Hui, Joseph<br />

Er. Wong Fee Min, Alfred<br />

Dr Zhou Yi<br />

02 THE SINGAPORE ENGINEER March 2013

04 THE SINGAPORE ENGINEER March 2013

March 2013 THE SINGAPORE ENGINEER<br />

05

IES UPDATE<br />

Creativity & Innovation showcased at IES<br />

Design Awards 2013<br />

by Leon Leong<br />

Five polytechnics, 15 teams, and one objective - to win this<br />

year’s IES Design Awards competition which was held on<br />

22 March 2013. Teams from Singapore Poly, Ngee Ann Poly,<br />

Republic Poly, Temasek Poly and Nanyang Poly, had to base<br />

their innovative design creations on the theme ‘Devices of<br />

Assistive, Rehabilitative and Therapeutic Applications’.<br />

The organising committee’s objective for this year’s IES<br />

Design Awards was very clear - to inculcate in the younger<br />

generation, the importance of community service, and<br />

encourage them to think more for the handicapped and the<br />

less-fortunate, and help them improve their lifestyles.<br />

The scope of the projects covered the creative design of<br />

gadgets/equipment that would enhance the lives of the<br />

handicapped or old folks. The students were divided into<br />

groups, to design and fabricate a device within a stipulated<br />

budget which was capped at S$ 2,000, that would help<br />

handicapped or elderly people.<br />

Due to the high level of creativity demonstrated by the students<br />

in coming up with the innovative products, the panel of judges<br />

had a hard time in deciding the top three winners. At the end<br />

of the day, the top prize went to Temasek Polytechnic for its<br />

H-Frame Walking Stick. The team impressed the judges with its<br />

presentation, usability and cost-effectiveness.<br />

A total of eight winners (three top prizes and fi ve merit awards)<br />

emerged from the 15 participating teams.<br />

A highlight of this year’s event was the presentation by Dr Jeffrey<br />

Nicholson, Brand Ambassador for 3M Technology, on the topic<br />

‘The Keys to Innovation’. (His full presentation is available on<br />

http://www.ies.org.sg/temp/keysinnovation.pdf). Dr Nicholson is<br />

The judging criteria were based on the optimisation of<br />

material and equipment, as well as value-added features to<br />

the Homes. The judges were IES members Dr Lock Kai Sang<br />

(Chief Judge), Dr Richard Kwok and Dr Ho Teck Tuak, from<br />

IES, and Ms Winnie Koh, from the Home of the Aged Sick.<br />

Judges deliberating on the designs presented.<br />

Judges seeking clarifi cations from one of the teams.<br />

The winner was Temasek Polytechnic.<br />

A team explaining and emonstrating its creative design.<br />

Dr Nicholson sharing his thoughts on ‘The Keys to Innovation’.<br />

06 THE SINGAPORE ENGINEER March 2013

March 2013 THE SINGAPORE ENGINEER<br />

07

IES UPDATE<br />

the man behind the successful Post-It Notes. All the students<br />

present were awed by his presentation.<br />

Two other speakers, Dr Bernard Leong, Technology Manager of<br />

Vistaprint, and Mr Leslie Loh, Managing Director of Red Dot<br />

Ventures also shared interesting tips and experiences with the<br />

students. Their lively presentations also fi red up the students’<br />

interest in innovation and entrepreneurialism. Dr Leong’s<br />

topic ‘Start from the User - Lean Lessons Learned on Design,<br />

Content & Experience’ can be found on http://www.slideshare.<br />

net/bleongcw/start-fromtheuser, while Mr Loh’s presentation on<br />

‘Learn to be a Technopreneur & Create your Tech Startup’ can<br />

be read on http://www.ies.org.sg/temp/iesstartup.pdf.<br />

The presentation of prizes to the top three winners will be held<br />

during the IES Annual General Meeting at NUSS Kent Ridge<br />

Guild House on 18 May 2013.<br />

Guest speaker Dr Leong receiving a token of appreciation from<br />

Er. Seow Kang Seng, Chairman of Community Services Committee, IES.<br />

Courtesy visits by overseas professional groups<br />

IES warmly welcomed a group<br />

of delegates from The Board<br />

of Architects, Professional<br />

Engineers and Quantity<br />

Surveyors, Brunei Darussalam,<br />

on 28 February 2013, and<br />

another group from Engineers<br />

Australia, on 1 March 2013.<br />

The group of delegates from<br />

Brunei Darussalam, with Dato<br />

Prof Chou Siaw Kiang and Dato<br />

Paduka Haji Suhaimi bin Haji Gafar.<br />

Paduka Haji Suhaimi bin Haji Gafar as the Head of Delegation,<br />

was received by IES President Prof Chou Siaw Kiang, Vice<br />

President Er. Chong Kee Sen, Past President Er. Ong Ser Huan,<br />

Council Member Er. Emily Tan, and CEO Ms Angie Ng.<br />

The meeting was held over a hearty lunch. A brief introduction of<br />

IES and a description of the types of activities that are organised<br />

for IES members, were provided, for the benefi t of the visitors.<br />

A discussion was also held with the delegates on IES’s efforts to<br />

promote <strong>engineer</strong>ing to students and how IES contributes to<br />

<strong>engineer</strong>ing education in Singapore. An invitation was extended<br />

to the delegation to join IES at the World Engineers’ Summit<br />

2013 (WES 2013) in September this year.<br />

Engineers Australia National President Dr Marlene Kanga<br />

and her delegation were received by IES Past President and<br />

Chairman of the WES 2013 Steering Committee, Er. Tan Seng<br />

Chuan; Chairman for WES 2013 Ambassadorial Committee, Er.<br />

Ng Say Cheong; and IES CEO, Ms Angie Ng.<br />

During the meeting, ways of collaboration were discussed, such<br />

as looking at how both organisations can tap on their resources<br />

to run courses in Singapore. Engineers Australia will be bringing<br />

a delegation to Singapore for WES 2013 and will also be holding<br />

their International Meeting here during that time.<br />

Er. Tan updating the delegates on WES 2013.<br />

Group photo taken with the delegates fromThe Board of Architects, Professional<br />

Engineers and Quantity Surveyors, Brunei Darussalam.<br />

Group photo taken with Dr Marlene Kanga (4 th from right) and<br />

Er. Tan Seng Chuan (2 nd from right)<br />

08 THE SINGAPORE ENGINEER March 2013

IES UPDATE<br />

Joint Accreditation Committee organises RE /<br />

RTO Networking and Awards Night 2013<br />

IES President, Prof Chou Siaw Kiang giving his Welcome Speech.<br />

ACES President, Er. Koh Boon Liang<br />

giving his Welcome Speech.<br />

Er. Shee Siu Ming, BCA<br />

Mr Marcus Wee, CPIB<br />

Mr Winston Yew, MOM<br />

The participants enthusiastically engagied in questions-and-answers sessions.<br />

From left to right, Mr Lee Kwee How (RTO), Mr Thiagarajan Subramanian (RE), Er.<br />

Chew Keat Chuan, Er. Chong Kee Sen, Mdm Hoe Swee Seng (RE), Mr Koh Ah Chek<br />

(RTO), Mr Chin Sin Yee (RTO), and Mr Fernando Jr Mendoza Dematera (RTO).<br />

The Joint Accreditation Committee (JAC) of the Institution of<br />

Engineers, Singapore (IES) and the Association of Consulting<br />

Engineers Singapore (ACES) recently honoured Resident<br />

Engineers (REs) and Site Supervisors (RTOs) responsible for<br />

extraordinary achievements at construction worksites. The<br />

second awards ceremony took place on 22 February 2013 at<br />

the RE & RTO Networking and Awards Night, held at the Matrix<br />

Auditorium @ Biopolis. Er. Chew Keat Chuan, Group Director,<br />

Building Engineering Group, Building and Construction Authority<br />

(BCA), graced the event as the Guest-of-Honour.<br />

More than 413 REs and RTOs, and 20 guests attended the event,<br />

at which three speakers also addressed pertinent topics in the<br />

construction industry. The three speakers were Er. Shee Siu Ming<br />

from BCA, who talked about supervisory duties of accredited<br />

site supervisors; Mr Marcus Wee from the Corrupt Practices<br />

Investigation Bureau (CPIB), who talked about corrupt practices<br />

in the construction industry; and Mr Winston Yew from the<br />

Ministry Of Manpower (MOM), who spoke on workplace safety<br />

and health issues.<br />

Exemplary Resident Engineer Awards<br />

and Exemplary Site Supervisor Awards<br />

Er. Chew Keat Chuan presented the Exemplary Resident<br />

Engineer Awards and Exemplary Site Supervisor Awards to<br />

three REs and four RTOs, respectively. One of the REs who won<br />

the award was absent. The winners were commended for their<br />

dedication and contribution towards making a difference in the<br />

industry. Each of the winners received a S$ 300 cash cheque<br />

and a certifi cate.<br />

Set up by the JAC, the Exemplary Site Supervisor Award<br />

recognises the exceptional dedication and contributions of<br />

site supervisors (RTOs) in ensuring that the construction of<br />

structural works is carried out in accordance with the building<br />

regulations, and the signifi cant effort and contribution made by<br />

them towards achieving construction safety and productivity in<br />

the projects they have handled or are handling.<br />

One of the winners of the Exemplary Site Supervisor Award,<br />

Mr Lee Kwee How, Senior Technical Offi cer, HCE Engineers and<br />

Architects 61, said, “I am very happy to receive this award after<br />

27 years in the construction line. Through these years, I have<br />

learnt a lot from Qualifi ed Personnel (QPs) and my colleagues<br />

about building quality and construction safety and also from the<br />

IES courses I attended to upgrade myself. I hope that JAC will<br />

continue organising this award to encourage all RTOs to achieve<br />

high standards in safety and quality”.<br />

A winner, in the RE category, Mdm Hoe Swee Seng, Technical<br />

Manager, Welltech Construction Pte Ltd, said, “Receiving this<br />

award is defi nitely a recognition of my years of hard work. Even<br />

so, it is important for us to remember that we have the duty<br />

and responsibilities to ensure that all works entrusted to us are<br />

carried out accordingly”.<br />

10 THE SINGAPORE ENGINEER March 2013

Sustainable design combines aesthetics<br />

and functionality<br />

RSP Architects Planners & Engineers (Pte)<br />

Ltd (RSP) is providing, on a pro bono<br />

basis, the architectural as well as the civil &<br />

structural <strong>engineer</strong>ing design for the new<br />

annexe to the IES Building at Bukit Tinggi.<br />

Being built in the car park space adjacent<br />

to the existing IES Building, the new annexe<br />

will be a green building. It is scheduled for<br />

completion during the fi rst quarter of 2014.<br />

IES UPDATE<br />

The lower level of the new annexe will<br />

house the IES Secretariat whilst the upper<br />

level will accommodate a members’ area,<br />

training rooms and an open terrace.<br />

IES is extending land use and expanding its premises to cater to<br />

membership growth and to better support <strong>engineer</strong>s in their<br />

contribution to Singapore’s economic and societal developments.<br />

Design considerations<br />

According to RSP, the main idea that has gone into the design<br />

of the building is that it should provide a functional demarcation<br />

between the secretariat offi ce and the members’ area, so that<br />

at any time of the day, the functioning of either would not affect<br />

the other.<br />

The development of the design then began with the creation of<br />

two distinct zones, one for the members and the other for the<br />

secretariat offi ce. The secretariat is on the lower fl oor since its<br />

staff meet members and visitors regularly. A primary service core<br />

fronts the neighbouring German European Secondary School,<br />

a 4-storey building, thereby also providing some privacy for the<br />

annexe. Lining the service core is a rain garden on one side, and<br />

on the inner side, a feature landscape provides a green interface<br />

to the members area and secretariat offi ce. On the upper storey,<br />

an open courtyard, in the middle, provides an ideal venue for<br />

outdoor functions. Rooms on the upper storey have fl exible<br />

partitions that allow the interior spaces to be combined, and even<br />

for the rooms to open out into the courtyard when necessary.<br />

The design of the new annexe has been inspired by the lush<br />

environment of the area. It has sought to bring some elements<br />

of the natural surroundings into the development through, for<br />

example, a series of perforated fi ns adorning the facade of the<br />

building, which create a tree-canopy-like effect from within and<br />

from the outside.<br />

There is also a desire for a distinct <strong>engineer</strong>ing expression, to<br />

highlight the core knowledge of the institution. Accordingly,<br />

the upper storey has been designed to also provide a deep,<br />

cantilevered sheltered area below, for vehicular drop-off activity .<br />

It was a considerable <strong>engineer</strong>ing challenge to design a large<br />

overhang of 6 m for the sheltered drop-off, while minimising<br />

the number of columns on plan to ensure maximum clear-span<br />

spaces. In order to achieve this, much of the suspended fl oor<br />

plates has been substituted with hollow-core slabs, in order to<br />

With the new annexe, IES is extending land use and expanding its premises.<br />

MEMBERS ZONE<br />

SECRETARIAT<br />

OFFICE<br />

MAIN SERVICE CORE<br />

LANDSCAPE INTERFACE<br />

FUNCTION<br />

COURTYARD<br />

CANTILEVERED<br />

SHELTER DROP-OFF<br />

POTENTIAL SEAMLESS<br />

CONNECTION TO<br />

EXISTING BUILDING<br />

RSP’s design for the new annexe to the IES Building seeks to create a functional<br />

demarcation between the secretariat offi ce and the members’ area. It also<br />

emphasises distinct <strong>engineer</strong>ing expression, to highlight the core knowledge of IES.<br />

All images by<br />

RSP Architects Planners & Engineers (Pte) Ltd.<br />

keep the plates strong but light.<br />

Further, the inclusion of an elevator in the proposed annexe<br />

ensures barrier-free connection between the annexe and the<br />

existing building.<br />

March 2013 THE SINGAPORE ENGINEER<br />

11

ENGINEERING EDUCATION<br />

How young <strong>engineer</strong>s will mold the future<br />

by Prof Calestous Juma<br />

In a provocative article, the Economist recently asked whether<br />

new technology had stopped driving the world economy. The<br />

article challenged innovation pessimists by providing several<br />

examples of technologies that mold future economies.<br />

The most urgent question, however, is how to train a new<br />

generation of young <strong>engineer</strong>s who will be capable of combining<br />

technical excellence with a deeper appreciation of societal<br />

needs and values.<br />

This was the theme of a recent meeting that brought together<br />

educators interested in <strong>engineer</strong>ing at the Harvard Kennedy<br />

School. The focus of the meeting was to identify ways in which<br />

universities and high schools can work together to train the next<br />

generation of <strong>engineer</strong>s who can help solve the world’s most<br />

pressing economic and environmental challenges.<br />

It is not that the world is short of <strong>engineer</strong>ing solutions.<br />

The Economist lists a few: ‘Pattern-recognition software is<br />

increasingly good at performing the tasks of entry-level lawyers,<br />

scanning thousands of legal documents for relevant passages.<br />

Algorithms are used to write basic newspaper articles on<br />

sporting outcomes and fi nancial reports….In Japan, where<br />

labour to care for an ageing population is scarce, innovation in<br />

robotics is proceeding by leaps and bounds’.<br />

The real <strong>engineer</strong>ing challenge may be integrating those<br />

solutions into societies. This will involve linking education to<br />

production and manufacturing as well as incorporating real<br />

world experiences into <strong>engineer</strong>ing education.<br />

The meeting brought together representatives from Boston<br />

University, Harvard University, Kent School, MIT, and the<br />

University of Hong Kong to explore how to advance <strong>engineer</strong>ing<br />

education in high schools. It also included the One Laptop per<br />

Child Association.<br />

Training a new generation of <strong>engineer</strong>s demands leadership. “It<br />

takes getting into things early and we are ready to promote this<br />

cause through our pre-<strong>engineer</strong>ing program”, said Fr Richardson<br />

Schell, head of Kent School, which includes grades 9–12.<br />

“Our pre-<strong>engineer</strong>ing program seeks to challenge students to<br />

explore their potential for achievement by nurturing their critical<br />

thinking, increasing scientifi c literacy, and enabling innovation”, he<br />

explained. Kent School is working to create an applied learning<br />

center that will integrate with the local community.<br />

Kent School will conduct a one-week (June 10–14, 2013)<br />

summer program on ‘Global Development: Grand Challenges<br />

for Engineering’ to inspire students to explore how to leverage<br />

the power of <strong>engineer</strong>ing in solving global economic challenges.<br />

“We are delighted with the involvement of professionals from<br />

Harvard University, MIT, Boston University, One Laptop per<br />

Child Association, and other institutions”, Fr Schell noted.<br />

The program will cover themes such as energy, education,<br />

health, and nutrition. It will be conducted through lectures,<br />

hands-on activities, fi eld visits, and roundtable discussions with<br />

practitioners.<br />

The meeting was inspired by the Grand Challenges for<br />

Engineering report produced by a committee of the US<br />

National Academy of Engineering (NAE). The committee was<br />

chaired by former US Secretary of Defense William Perry,<br />

and members included leading <strong>engineer</strong>s and thinkers such as<br />

Alec Broers, Wesley Harris, Bernadine Healy, Dean Kamen, Ray<br />

Kurzweil, Robert Langer, Jane Lubchenco, Mario Molína, Larry<br />

Page, Robert Socolow, Craig Venter, and Jackie Ying.<br />

The world is indeed forging ahead with a new age of integrated<br />

<strong>engineer</strong>ing. This approach is being promoted through new<br />

educational approaches adopted by high education institutions<br />

such as the Olin College of Engineering. In 2013 Olin’s founding<br />

academic leaders received NAE’s prestigious Bernard M<br />

Gordon Prize for their pioneering ‘experiments in education<br />

that develop effective <strong>engineer</strong>ing leaders’.<br />

In recognition of the importance of the fi eld, Chinese, US, and<br />

UK <strong>engineer</strong>ing academies are co-sponsoring the Global Grand<br />

Challenges Summit in London in March 2013. The summit<br />

will showcase ‘leading international <strong>engineer</strong>ing thinkers and<br />

innovators sharing ideas with the next generation of <strong>engineer</strong>s<br />

and policy-makers on how to solve the world’s most pressing<br />

challenges’.<br />

A few days after the summit, the UK Royal Academy of Engineering<br />

will announce the Queen Elizabeth Prize for Engineering, the<br />

world’s largest honor of its type. The £1 million prize aims to<br />

reward and celebrate individuals who have made ground-breaking<br />

innovations that have global benefi ts to humanity.<br />

MIT Associate Provost Professor Wesley Harris stressed to the<br />

Harvard meeting the importance of integrating <strong>engineer</strong>ing<br />

education across disciplines and leveraging the energy and<br />

creativity of students from a variety of majors. Without such<br />

integration, he noted, a dichotomy is created whereby some<br />

people focus on technology for its own sake, while others<br />

navigate an increasingly complex world without any technological<br />

background or appreciation.<br />

One of the challenges facing the <strong>engineer</strong>ing profession today is<br />

retention. According to Dr Sujata Bhatia of the Harvard School<br />

12 THE SINGAPORE ENGINEER March 2013

ENGINEERING EDUCATION<br />

of Engineering and Applied Sciences, students will not sustain<br />

their interest in the rigor of <strong>engineer</strong>ing courses if they do not<br />

see their role in solving practical problems. To do this, she said,<br />

<strong>engineer</strong>ing must integrate with other liberal arts subjects such<br />

as language, philosophy, ethics and literature. “Similarly, women<br />

are more likely to study <strong>engineer</strong>ing if the fi eld focuses on<br />

solving real world problems,” she added.<br />

Indeed, NAE President Charles Vest has rightly called for the<br />

integration of the liberal arts with <strong>engineer</strong>ing. The real challenge,<br />

according to Professor Muhammad Zaman of Boston University,<br />

is to focus on how <strong>engineer</strong>ing can help solve the world’s most<br />

pressing development challenges. “This requires integration of<br />

fi elds such as medicine and <strong>engineer</strong>ing while taking into account<br />

ethical considerations,” he emphasized at the meeting.<br />

Professor Zaman has been active in promoting new biomedical<br />

<strong>engineer</strong>ing courses in Africa. In his judgment, developing<br />

countries offer unique opportunities to foster integrated<br />

approaches to <strong>engineer</strong>ing education. The same applies to<br />

starting at the pre-<strong>engineer</strong>ing or pre-medicine levels in high<br />

schools.<br />

Dr Wai Leung Tang of the University of Hong Kong also stressed<br />

the importance of integrating the disciplines around problemsolving.<br />

“The training of young people must include <strong>engineer</strong>ing<br />

principles, techniques, and knowledge as well as integration<br />

with other disciplines. So <strong>engineer</strong>s need a wide spectrum of<br />

knowledge,” he noted.<br />

OLPC’s Dr Redouane Megateli said we had come full circle.<br />

First the world was concerned with improving education. But<br />

to do that it had to <strong>engineer</strong> the development of new laptops<br />

whose design criteria refl ected how people learn. But with the<br />

proliferation of access to such devices, the world is back to the<br />

beginning: thinking about education.<br />

“This is the rationale behind the creation of OLPC academies<br />

around the world”, he said.<br />

Devices will come and go, but the demand for impact assessment<br />

will always remain. Professor Harris challenged the participants<br />

to establish metrics for assessing the impact of new high school<br />

pre-<strong>engineer</strong>ing programs.<br />

For me the fi nest idea came from Dr Bhatia: “Give me a young<br />

person who is excellent in anything and I can turn him or her<br />

into an excellent <strong>engineer</strong>. It is about discipline. Those who have<br />

it in any fi eld, including athletics, can excel in any other fi eld”.<br />

Professor Harris noted that the focus on excellence and other<br />

attributes should provide a basis for evaluating the impact of<br />

new <strong>engineer</strong>ing programs for high school students.<br />

“It is important to provide metrics for setting goals and assessing<br />

impact”, he emphasized.<br />

The training of future <strong>engineer</strong>s will need to integrate diverse<br />

disciplines so they can mold economies that promise prosperity<br />

for all.<br />

As the Economist aptly concluded, ‘The main risk…may not be<br />

that the pace of innovation is too slow, but that institutions have<br />

become too rigid to accommodate truly revolutionary changes’.<br />

According to Fr Schell, this is where learning becomes an<br />

applied fi eld aimed at integrating the disciplines to solve the<br />

world’s pressing challenges. That is how young <strong>engineer</strong>s can<br />

mold the future.<br />

(Calestous Juma is Professor of the Practice of International<br />

Development at Harvard Kennedy School and author of The New<br />

Harvest: Agricultural Innovation in Africa (Oxford University Press,<br />

2011). He was a member of the Grand Challenges for Engineering<br />

Committee of the US National Academy of Engineering and serves<br />

on the selection jury of the Queen Elizabeth Prize for Engineering.<br />

Professor Juma is currently writing a book on <strong>engineer</strong>ing for<br />

global development. This article is reprinted with the permission<br />

of the Harvard Kennedy School Belfer Center for Science and<br />

International Affairs).<br />

Winners of the inaugural Queen<br />

Elizabeth Prize for Engineering<br />

announced<br />

Five <strong>engineer</strong>s who created the Internet and the World<br />

Wide Web have together won the inaugural £ 1 million<br />

Queen Elizabeth Prize for Engineering for their innovations<br />

which have revolutionised the way people communicate<br />

and enabled the development of whole new industries.<br />

Today, a third of the world’s population use the Internet<br />

and it is estimated to carry around 330 Petabytes of<br />

data per year - enough to transfer every character ever<br />

written in every book ever published 20 times over.<br />

Engineers Robert Kahn, Vinton Cerf, Louis Pouzin, Tim<br />

Berners-Lee and Marc Andreessen were announced as<br />

the winners, by Lord Browne of Madingley in the presence<br />

of HRH The Princess Royal, at the Royal Academy of<br />

Engineering which administers the prize.<br />

The winners will come to London in June for the formal<br />

presentation of the prize by Her Majesty The Queen.<br />

The art of <strong>engineer</strong>ing lies in the effi cient combination<br />

of technologies to deliver the most meaningful results<br />

for society. The international team of judges for the Prize<br />

consider that these fi ve outstanding <strong>engineer</strong>s epitomise<br />

this approach in the way that they designed and built the<br />

Internet and the Web.<br />

March 2013 THE SINGAPORE ENGINEER<br />

13

COVER STORY<br />

NUS recognised for commitment to campus<br />

infrastructure sustainability<br />

In 2012, the National University of Singapore became the fi rst educational institution in the<br />

republic to receive the prestigious Green Mark Champion Award, conferred by the Building<br />

and Construction Authority.<br />

INTRODUCTION<br />

The National University of Singapore (NUS) strives to deliver<br />

transformative education and high-impact research. Its campus<br />

community, which comprises over 37,000 students and about<br />

9,700 staff, study, work, live and play on three campuses.<br />

NUS is committed to integrating sustainability into its<br />

operations, planning, education, research and public service, and<br />

aims to develop an excellent campus infrastructure through the<br />

adoption of sustainable principles for master planning, design<br />

and construction.<br />

To-date, NUS has received 16 Green Mark building and district<br />

awards, including the inaugural Green Mark District Gold Plus Award<br />

(in 2009) and fi ve Green Mark Platinum Awards for Buildings.<br />

To qualify for the Green Mark Champion Award, building owners<br />

need to have at least 10 projects rated Green Mark Gold and<br />

above, including at least three projects rated Gold Plus and at least<br />

three projects rated Platinum.<br />

District / Building<br />

BCA Green Mark Award<br />

University Town<br />

Gold Plus (District)<br />

Education Resource Centre Platinum<br />

EduSports Building Platinum<br />

Yong Loo Lin School of Platinum<br />

Medicine Block MD1<br />

Ventus<br />

Platinum<br />

Kent Vale 2 Staff Housing Platinum<br />

A selection of NUS’s BCA Green Mark Award-winning projects.<br />

MASTER PLANNING<br />

NUS’s master plan is anchored in a vision of a vibrant campus<br />

that provides an integrated sustainable living-learning experience<br />

for its students and staff. The master plan consists of a series of<br />

systems plans addressing building and land use, landscape structure,<br />

access and circulation, and housing and sustainability strategies.<br />

The sustainability strategies, in particular, recommend balancing<br />

integrative design and effi cient use of space; optimising architectural<br />

designs for daylighting while minimising solar heat; as well as<br />

leveraging natural ventilation for circulation and open communal<br />

spaces. Other best practices and green features include enhancing<br />

the natural systems through existing slope and habitat preservation,<br />

implementing best management practices to introduce water by<br />

fi ltration, and improving alternative means of access.<br />

“Higher education is more than imparting knowledge and life<br />

skills. It has the potential of instilling a sense of responsibility in<br />

the students to create a healthy environment to be enjoyed<br />

by future generations. By building the NUS campus as a living<br />

laboratory for sustainability, our students can learn to be better<br />

stewards of the environment” - Mr Joseph Mullinix, Deputy<br />

President (Administration) of NUS.<br />

“Building and infrastructure sustainability is more than just<br />

designing facilities to save energy and resources. To be truly<br />

successful, it must meet the numerous expectations placed on it<br />

by the occupants and create a perfect blend of form and function.<br />

Through the innovative engagement of the NUS students and<br />

staff, NUS buildings have become vibrant environments that<br />

encourage creativity, innovation and community. At NUS, we are<br />

committed to sustaining a green future, beyond Green Mark<br />

buildings and infrastructure” - Prof Yong Kwet Yew, NUS Vice<br />

President (University Campus Infrastructure).<br />

The master planning process emphasises respect for natural<br />

resources by adapting to climatic conditions, and sets new<br />

standards for building performance. By living and learning in an<br />

environment-conscious setting, the NUS staff and students learn<br />

to consider the impact of everyday decisions, and carry the<br />

principles of sustainability beyond the confi nes of the university<br />

campus and into their lives as global citizens.<br />

COMMITMENT TO REDUCE CARBON<br />

EMISSIONS<br />

NUS has set a target of reducing its carbon emissions by 23%<br />

below business-as-usual, by 2020. The approach is to identify<br />

emission trends and areas of growth, and suggest spheres of<br />

infl uence and activities where emission reductions and energy<br />

effi ciency increases can have the greatest impact. This, in turn,<br />

provides a sound basis for formulating a strategic climate action<br />

programme, particularly in the area of energy management.<br />

UNIVERSITY TOWN - A SUSTAINABLE<br />

CAMPUS PRECINCT<br />

The NUS University Town (UTown) is a 19 hectare, mixed-use<br />

residential, sports, educational and research development along<br />

Clementi Road. It is connected to the main Kent Ridge campus<br />

by a vehicular, bicycle and pedestrianised bridge over the Ayer<br />

Rajah Expressway. In addition to its receiving the Green Mark<br />

District Gold Plus Award, UTown also has all fi ve buildings within<br />

its boundaries certifi ed Green Mark Gold and above (two<br />

Platinum, two Gold Plus and one Gold).<br />

14 THE SINGAPORE ENGINEER March 2013

COVER STORY<br />

Nestled within a lush tropical landscape, UTown supports a<br />

vibrant community of undergraduate and graduate students,<br />

staff and researchers, who work, live, learn and play. It exemplifi es<br />

NUS’s holistic and integrated approach to a sustainable campus,<br />

incorporating sustainable design principles into its master plan<br />

and building design, as well as emphasising strategies for energy<br />

and water effi ciencies, material and waste management, and<br />

environmental quality and protection.<br />

This vision of a sustainable campus precinct is guided by three<br />

key objectives - to strive towards a low carbon campus, to<br />

encourage the growth of an ecologically biodiverse habitat, and<br />

to create a pedagogical sustainable environment that would be<br />

enjoyed by the campus community. There are several design<br />

strategies that enabled NUS to achieve its objectives in the area<br />

of sustainability.<br />

LOW CARBON CAMPUS<br />

• Minimising carbon emissions before construction and after<br />

completion of the campus, through computation of carbon<br />

sequestration.<br />

• Designing north-south-facing buildings, to reduce exposure<br />

of interiors to direct sunlight, and encouraging natural cross<br />

ventilation into buildings.<br />

• Designing a mixed mode of naturally ventilated and airconditioned<br />

spaces, emphasising the use of fans and natural<br />

ventilation over air-conditioning, for most buildings.<br />

• Specifying natural ventilation for all major circulation areas.<br />

• Introducing an innovative ‘Pay-As-You-Use’ system for airconditioning<br />

in student residences, to encourage prudent use<br />

of energy.<br />

• Designing shaded outdoor interactive and circulation spaces<br />

and specifying hardscape materials with high Solar Refl ection<br />

Index (SRI) and green roofs for buildings.<br />

• Creating sheltered interconnected walkways and safe<br />

dedicated bicycle lanes to reduce dependence on automobiles.<br />

• Specifying effi cient external task lighting for energy effi ciency<br />

and reduction of light pollution and glare.<br />

ECOLOGICALLY BIODIVERSE HABITAT<br />

• Conserving the natural topography and hydrology.<br />

• Preserving the existing green buffer (leaving them ‘wild’)<br />

around the campus, to encourage the growth of fl ora<br />

and fauna.<br />

• Extensively using a wide variety of native plant species, to<br />

promote fl oral biodiversity.<br />

• Incorporating the ‘Active Beautiful Clean’ stormwater<br />

management system.<br />

• Causing minimal disturbance to the site through the use of the<br />

‘cut and fi ll’ construction approach.<br />

PEDAGOGICAL SUSTAINABLE ENVIRONMENT<br />

• Incorporating passive sustainable design principles for tropical<br />

climates into the living and learning environment.<br />

• Creating a shaded interconnected pedestrian pathway<br />

network, thereby encouraging a healthy lifestyle.<br />

• Ensuring optimal external thermal comfort in outdoor activity<br />

areas through shading and selection of hardscape materials.<br />

• Encouraging the adoption of a sustainable lifestyle by providing<br />

a convenient integrated waste management infrastructure.<br />

• Minimising exhaust heat from cooling tower/condenser units<br />

near occupants of buildings and reducing energy costs through<br />

use of a District Cooling Plant.<br />

By integrating sustainability into planning, construction and<br />

operations, UTown is expected to achieve electricity savings of<br />

up to 3.8 million kWh and water savings of about 44,800 m 3 .<br />

More importantly, demonstration of sustainable precinct master<br />

The curved forms of the ERC are covered by a facetted, high performance facade using double-glazed fritted glass and horizontal sunshades to achieve a highly energyeffi<br />

cient building envelope.<br />

March 2013 THE SINGAPORE ENGINEER<br />

15

COVER STORY<br />

planning and building construction serves as the basis for future<br />

projects throughout the entire university.<br />

SUSTAINABLE BUILDINGS FOR TEACHING<br />

AND LEARNING<br />

EDUCATION RESOURCE CENTRE<br />

The Education Resource Centre (ERC), a 24/7 collaborative<br />

learning hub at the heart of UTown, exemplifi es the design<br />

principles deployed for the UTown precinct. It has been<br />

designed around existing mature Tembusu trees and the natural<br />

topography of the site, resulting in an organic arrangement of<br />

clusters that house the educational facilities. Its curved forms<br />

are covered by a facetted, high performance facade using<br />

double-glazed fritted glass and horizontal sunshades to achieve<br />

a highly energy-effi cient building envelope. Built with multiple<br />

entrances, outdoor study areas and lush green spaces, the ERC<br />

is a highly porous building with natural cross ventilation to all the<br />

circulation spaces. The building has three levels with the Learning<br />

Café terrace spilling onto the Town Green. ERC received the<br />

Green Mark Platinum Award in 2011.<br />

Sustainable features of ERC<br />

Building designed around existing trees<br />

ERC has been designed to wrap around several large and<br />

mature trees.<br />

Topography<br />

Integration of the fi rst storey ground plate with the natural<br />

contours of the site enabled existing trees to be conserved.<br />

ERC has been designed to wrap around several large and mature trees.<br />

Natural ventilation<br />

The design of study areas as individual clusters scattered around<br />

the ERC fl oor plate has created a network of naturally ventilated<br />

pedestrian circulation spaces throughout the building.<br />

Micro-climate<br />

The cooling effect within the circulation spaces is provided by<br />

the conserved trees which draw cool air down through open<br />

courtyards.<br />

Daylight maximisation<br />

Key spaces are provided with double-glazed, low-E fritted<br />

glass panels, to maximise visual transparency into the building.<br />

Large sun-shading canopies and vertical green screens are used<br />

extensively around ERC.<br />

Green roof<br />

Roof plantings provide additional roof insulation.<br />

Recycled materials<br />

Sustainable materials such as recycled timber, have been used<br />

for construction.<br />

Other factors<br />

A chilled ceiling at the Study Cluster at Level 1 maximises<br />

comfort, and the use of a total lighting management system<br />

in all study areas enables controlled dimming/light level tuning,<br />

scene zone control, occupancy and vacancy sensing, automatic<br />

daylight harvesting, solar-adaptive shading and scheduling, and<br />

personalised light control.<br />

EDUSPORTS<br />

EduSports, recently named the Stephen Riady Centre, is the<br />

focal point for the student community at UTown. Under one<br />

roof are education facilities (lecture theatres, seminar rooms and<br />

auditorium), cultural and performing arts spaces (performance<br />

and practice theatres, dance studios, a music library and individual<br />

practice rooms), sports facilities (swimming pool, gymnasium,<br />

rock climbing wall, as well as training and competition halls), an<br />

array of dining and retail outlets and a sheltered open space which<br />

is an attractive venue for performances, fairs and interactions.<br />

Sprinkled throughout the building are small gathering nodes to<br />

facilitate informal group learning opportunities.<br />

EduSports has been designed to optimise the building envelope and mitigate heat gain and cooling loads.<br />

16 THE SINGAPORE ENGINEER March 2013

COVER STORY<br />

EduSports has been designed to optimise the building envelope<br />

and mitigate heat gain and cooling loads. Daylight spaces were<br />

included to further reduce energy demands and provide a<br />

comfortable, sustainable environment for the user community.<br />

EduSports received the Green Mark Platinum Award in 2012.<br />

Sustainable features of EduSports<br />

Mitigating solar heat gain<br />

Extensive self-shading has created large, naturally ventilated,<br />

semi-exterior north-south corridors. Setbacks, overhangs,<br />

spandrels and high-performance glazing, at selected facades,<br />

further enhance shading and signifi cantly reduce solar heat gain.<br />

Highly insulated or vertical green walls, a green roof and large<br />

pockets of greenery, further improve the performance of the<br />

entire building envelope.<br />

Encouraging natural ventilation<br />

Spacing and layout have been optimised to funnel in air through<br />

public spaces and enhance breezes. Common areas that require<br />

a larger air velocity and lower radiant temperature, are fi tted<br />

with low-energy features such as high-volume low-speed fans,<br />

to improve thermal comfort during ‘still air’ weather conditions.<br />

Saving energy<br />

The air-conditioning system utilises variable speed drives on<br />

the Air Handling Units (AHUs), Fan Coil Units (FCUs) and<br />

motors, ensuring energy effi ciency. Motion sensors in toilets and<br />

corridors provide further energy savings.<br />

SUSTAINABLE BUILDING FOR RESEARCH<br />

NUS YONG LOO LIN SCHOOL OF MEDICINE BLOCK<br />

The NUS Yong Loo Lin School of Medicine Block (MD1) houses<br />

both wet and dry laboratories, teaching spaces and offi ces.<br />

Designed with cutting-edge research and learning facilities and<br />

located adjacent to the National University Hospital, it allows<br />

students, researchers and clinicians the opportunity to interact<br />

in a seamless bed-to-bench environment. MD1 received the<br />

Green Mark Platinum Award in 2012.<br />

Sustainable features of MD1<br />

Energy effi ciency features<br />

Laboratory-type facilities are energy intensive compared to<br />

normal offi ce settings, due to the use of a single pass ventilation<br />

system. To achieve the energy effi ciency within MD1, the façade<br />

thermal performance has been maximised with the use of low<br />

E-coated double glazing, shading, and an effi cient chiller plant<br />

with variable speed control for pumps and cooling towers. For<br />

the ventilation system, the AHU is equipped with a heat pipe<br />

and heat recovery unit that harnesses energy which is utilised<br />

to maintain the desired temperature and relative humidity.<br />

The resulting Envelope Thermal Transmittance Value (ETTV)<br />

outperforms the national standards by 50%.<br />

Similarly, energy-effi cient lighting such as T5 and LED lights are<br />

installed in the laboratories, lobbies and common areas. Motion<br />

sensors are also deployed in laboratories and toilets to reduce<br />

energy wastage.<br />

SUSTAINABLE BUILDINGS FOR<br />

ADMINISTRATION AND HOUSING<br />

VENTUS<br />

Ventus comprises offi ce, meeting and communal spaces for<br />

the four administrative offi ces within the University Campus<br />

Infrastructure cluster. The building is intended to exemplify both<br />

sustainable and passive design, complementing its surroundings.<br />

Ventus received the Green Mark Platinum Award in 2012.<br />

Ventus exemplifi es both sustainable and passive design, complementing its surroundings.<br />

March 2013 THE SINGAPORE ENGINEER<br />

17

COVER STORY<br />

Sustainable features of Ventus<br />

Responding to the site<br />

Removal of existing trees and excavation were minimised as the<br />

building was designed around the natural site elements, using<br />

trees as markers for the architectural form. As a result, there was<br />

a reduction in energy consumption and water contamination<br />

during the construction period, natural biodiversity is preserved,<br />

and thermal comfort conditions are provided for outdoor<br />

spaces.<br />

Wind scoop feature<br />

The wind scoop (integrated with the central spine of the<br />

building) is a key feature of the design, that takes advantage<br />

of the predominant wind for natural ventilation, through the<br />

venturi effect. The building is shaped such that the ends have<br />

large openings that capture high volumes of air and the middle<br />

portion narrows and accelerates the air through. This space also<br />

provides a thermal zone between the air-conditioned spaces<br />

and outdoor environment, minimising the associated transitional<br />

discomfort.<br />

Innovative structural design<br />

The shape of the central spine and the spacing in between the<br />

three offi ce blocks are tailored such that the blocks provide<br />

shading for one another, and the central spine provides overall<br />

shading for the circulation and activities housed within. This<br />

translates to a signifi cant reduction in the solar radiation profi le.<br />

KENT VALE 2<br />

Kent Vale 2 (KV2) comprises one 25-storey and two 24-storey<br />

residential blocks for staff, and a podium block housing communal<br />

facilities such as swimming pool, gym and lounge. Offering a<br />

good mix of apartment types, KV2 offers fl exible on-campus<br />

accommodation for families, couples or singles, in 3-bedroom,<br />

2-bedroom and 1-bedroom units. The intent is to provide an<br />

environment that encourages social interaction and crosscultural<br />

exchanges, whilst forging a strong sense of community.<br />

KV2 received the Green Mark Platinum Award in 2011.<br />

Sustainable features of Kent Vale 2<br />

Mitigation of solar heat gain<br />

Solar gain through the façade is minimised via optimum building<br />

orientation; strategic sunshading provided by modular green walls,<br />

balconies, fi xed and sliding screens on the east and west facing<br />

facades; and horizontal sunshading to all facades. Considered<br />

positioning of ventilation openings allows for adequate light and<br />

ventilation, without additional solar glazing systems.<br />

Off-form concrete and construction effi ciency<br />

The entire building façade, lobbies and common areas have<br />

concrete fi nishes, hence eliminating the need for external<br />

plastering or skim coat and external painting. The module design<br />

of the apartment blocks also encourages the use of standardised<br />

formwork, minimising on-site wet trade works. This resulted in<br />

a 25% improvement in productivity and signifi cant savings on<br />

fi nishing, without compromising building aesthetics.<br />

Kent Vale 2 comprises residential blocks for staff and a podium block housing<br />

communal facilities.<br />

Integrated building management system<br />

An Integrated Building Management System (IBMS) monitors<br />

and controls the consumption of electricity and water.<br />

User-controlled operable windows and screens<br />

The sliding screens deployed on the eastern and western<br />

facades are user-controllable and offer greater reduction in solar<br />

radiation. The onus is then shifted to the residents to optimise<br />

the use of these screens and the air-conditioning within the<br />

apartments, for thermal comfort.<br />

ACTIVE LEADERSHIP AND ENGAGEMENT<br />

A strong and active NUS management, together with the<br />

support of its student and staff community, ensures effective<br />

environmental stewardship that goes beyond the construction<br />

and operation of sustainable buildings. The NUS community<br />

is also constantly engaged in various outreach and education<br />

programmes to bring about greater awareness of and interest<br />

in being environmentally responsible.<br />

NUS believes that as a leading educational institution, it should<br />

contribute to efforts in tackling climate change and play an<br />

active role in incorporating sustainable development concepts<br />

in its activities and operations so as to reduce the university’s<br />

overall environmental impact.<br />

All images by the National University of Singapore.<br />

18 THE SINGAPORE ENGINEER March 2013

March 2013 THE SINGAPORE ENGINEER<br />

19

MECHANICAL & ELECTRICAL ENGINEERING<br />

The advantages of fabric ducting<br />

by David Mackerness, General Manager, The LGM Group<br />

As an air distribution option, it is an alternative to a steel ducting and diffuser system.<br />

Fabric ducting is a common ACMV (Air-Conditioning &<br />

Mechanical Ventilation) component used all over the world. It<br />

offers great improvements in productivity as well as in energy<br />

effi ciency and thermal comfort.<br />

The heat load calculations and equipment sizing for fabric<br />

ducting remains the same as for traditional systems, but instead<br />

of using metal ducts to transport the air, patented fabric is used.<br />

fabric ducts can operate at signifi cantly reduced static pressure<br />

requirements as compared to steel ducting systems. This results<br />

in energy savings of up to 25%, as the AHU/FCU fans do not<br />

need to work as hard to push the air through the system.<br />

To cite one example, fabric ducting has enabled an offi ce in<br />

Singapore to generate energy savings and obtain a BCA Green<br />

The three main benefi ts of fabric ducting are a vast reduction<br />

in labour costs required to install the system (achieving up to<br />

80% reduction in man-hours), energy effi ciency (generating up<br />

to 25% savings), and better comfort.<br />

Productivity<br />

Fabric ducting systems are mounted on aluminium rails which<br />

hold the fabric ducts in place. This simple and reliable mounting<br />

system allows contractors to reduce installation times by up to<br />

80% and the lightweight characteristics of the system allow it to<br />

be installed on any ceiling (including false ceilings).<br />

Energy efficiency<br />

Fabric ducting systems should be custom designed with the<br />

help of local suppliers who understand the energy effi ciency<br />

and performance goals of the project. If designed correctly,<br />

The use of fabric ducting in this factory at Tuas reduced installation times by 73%.<br />

Steel Ducting and Diffusers<br />

Fabric Ducting<br />

27 AHUs<br />

1 m 2 of steel duct requires 0.5 man hours to install<br />

Each diffuser requires 0.5 man hours to install<br />

SAD = 250 m 2 per AHU = 125 man hours x 27 = 3,375<br />

RAD = 250 m 2 per AHU = 125 man hours x 27 = 3,375<br />

Diffusers = 864 in total = 0.5 man hours x 864 = 432<br />

TOTAL = 7,182 Man Hours<br />

27 AHUs<br />

2.5 m 2 of fabric duct requires 0.5 man hours to install<br />

Each diffuser requires 0.5 man hours to install<br />

SAD = 180 m 2 per AHU = 72 man hours x 27 = 1,944<br />

RAD = 0 m 2 per AHU = 0<br />

Diffusers = 0<br />

TOTAL = 1,944 Man Hours<br />

Comparison between installation times required for conventional ducting systems and for fabric ducting systems.<br />

20 THE SINGAPORE ENGINEER March 2013

MECHANICAL & ELECTRICAL ENGINEERING<br />

Mark Platinum rating. The original ACMV design for this offi ce<br />

used three FCUs and a traditional ducting and diffuser system.<br />

During the fi t-out stage, fabric ducting was retrofi tted to the<br />

existing FCUs and it reduced the fan motor power requirements<br />

by 23%.<br />

Better comfort<br />

Fabric ducts are custom-made for every project, ensuring optimal<br />

air distribution throughout the space. This allows designers to<br />

accommodate any temperature or velocity requirements and<br />

results in a good indoor environment.<br />

Given the challenge of cooling a 15 m by 35 m space with sidewall<br />

diffusers, an advertising agency opted for a custom designed<br />

fabric ducting system. The design incorporates three different<br />

throw lengths and angles to achieve uniform air distribution<br />

and temperatures throughout the space with no draughts<br />

or hotspots.<br />

Types of fabric ducting<br />

The technology for fabric ducting is not new. Fabric ducts have<br />

been used in Europe and the US for the past three decades.<br />

Most manufacturers can offer fi breglass-based, PVC-coated<br />

ducts but these are not recommended for use in Asia as<br />

they are not permeable and condensation may form on the<br />

outside of the ducts, due to the humid conditions here. This<br />

could result in dripping water which can damage equipment in<br />

the space.<br />

To prevent the condensation problem, fabric ducting systems for<br />

Asian markets must be permeable.<br />

Until recently, none of the permeable fabric ducts could<br />

comply with the Class ‘O’ fi re certifi cation standards required<br />

by Singapore.<br />

Recent advances in technology have now enabled some of the<br />

fabric ducting manufacturers, in Europe and the US, to produce<br />

permeable ducts which meet the Class ‘O’ fi re certifi cation<br />

standards.<br />

And now, there are local suppliers who offer design, supply and<br />

installation services for this type of fabric ducting, for projects in<br />

any Asian environment.<br />

Such ducting has already been installed in over 30 high profi le<br />

projects in Singapore.<br />

Fabric ducting can be used in any project and there are examples<br />

of fabric ducts being used in warehouses, sports halls, offi ces and<br />

even a sound stage.<br />

For installations that require a high indoor air quality, the ducts<br />

can be taken down and washed. To ensure that warranties are<br />

Fabric ducting has enabled this BCA Green Mark Platinum-rated offi ce in<br />

Singapore to generate energy savings of 23%.<br />

FCU Parameters Steel Ducting Fabric<br />

and Diffusers Ducting<br />

Airfl ow 7001 7001<br />

Static Pressure 218 195<br />

Fan Motor Power each 2.0 1.55<br />

No. of Fan Motors 3 3<br />

in Operation<br />

Total Power in Operation 6.0 4.7<br />

Annual Operation Hour 2,730 2,730<br />

Annual Energy 16,380 12,695<br />

Consumption<br />

Annual Energy Savings = 3,686 kWh<br />

% of Annual Energy Savings = 23%<br />

Comparison between energy consumption of offi ce with conventional ducting<br />

systems and with fabric ducting systems.<br />

maintained, the manufacturer’s guidelines for washing must<br />

be followed.<br />

In Europe and the US, fabric duct installations have shown no<br />

signs of deterioration or damage during the 30 years that they<br />

have been in service.<br />

More information on fabric ducting may be obtained from the author<br />

(Tel: 6586 9015. Email: david.mackerness@thelgmgroup.com)<br />

March 2013 THE SINGAPORE ENGINEER<br />

21

MECHANICAL & ELECTRICAL ENGINEERING<br />

2<br />

1<br />

3<br />

A research and development facility with fabric ducting - (1) Equipment sizing remains unchanged. (2) Cool air leaves the Air Handling Unit (AHU) / Fan Coil Unit (FCU)<br />

and is transported along the fabric duct. (3) Once the duct is infl ated and pressurised (in 5 sec to 10 sec), cool air enters the space through the permeable fabric as well<br />

as custom designed, laser-cut holes.<br />

Advertising agency using side-wall mounted fabric ducting.<br />

Fabric ducting installed in the sports hall of an international school in Singapore.<br />

A Green Mark Platinum-rated engine assembly plant that uses a custom designed fabric ducting system.<br />

22 THE SINGAPORE ENGINEER March 2013

March 2013 THE SINGAPORE ENGINEER<br />

23

ACOUSTICS ENGINEERING<br />

Aeroacoustics simulations for the aerospace industry<br />

by Fred Mendonça & Deborah Eppel, CD-adapco<br />

The article presents two case studies, one on the airframe noise simulation of a complex nose landing<br />

gear, and the other on the aeroacoustics analysis of an avionic cooling rack in an Airbus cockpit.<br />

One of the greatest challenges facing the aerospace industry<br />

is improving the aeroacoustic noise generation of its products<br />

to meet today’s more stringent noise pollution standards. As<br />

fl ow-induced noise makes a signifi cant contribution to the overall<br />

decibel output, it is essential to fi nd out how aircraft design can be<br />

optimised in order to minimise the fl ow-induced noise without<br />

impairing the general performance of the air vehicle.<br />

Sources of fl ow-induced noise are varied. Typically,<br />

for commercial aircraft, they are mainly associated with<br />

high-lift devices, landing gear, jet nozzles, and cabin and cockpit<br />

climate control devices. For military air vehicles, structural and<br />

aerodynamic instabilities of weapons and weapon bays are<br />

additional issues that need to be addressed.<br />

Case Study 1<br />

Case Study 1 was implemented as part of Problem 4 of the First<br />

AIAA Workshop on Benchmark problems for Airframe Noise<br />

Computations (BANC-I), which was held in Stockholm, Sweden,<br />

on 10 and 11 June 2010. The geometry is a simplifi cation of<br />

the Gulfstream G550 nose landing gear, confi gured as Partially-<br />

Dressed Cavity-Closed (PDCC). Experiments on a quarter-scale<br />

model were performed in the NASA-BART acoustic tunnel and<br />

at the University of Florida.<br />

The computational model contained complete component details<br />

and resolved the geometry down into the laminar sub-layer<br />

(nominally y+ < 1). The mesh comprised trimmed hexahedra<br />

with extruded prisms in the normal-to-wall direction, totalling 39<br />

million cells. In the vicinity of all the landing gear components and<br />

wheel, uniform cubic cells of 0.75 mm were used.<br />

In addition, a mesh coarsening exercise was performed. Two<br />

coarse meshes were successively run, in which the cell size in<br />

the core fl ow region was increased from 0.75 mm (fi ne) to 1.00<br />

mm (medium mesh, resulting in 22 million cells) and 1.25 mm<br />

(coarse mesh, 13 million cells).<br />

First, a steady-state simulation was performed in order to<br />

determine where volume mesh refi nements were needed, as<br />

well as calculate the mesh frequency cut-off measure to size<br />

the cells. The applied mesh was well able to capture frequencies<br />

up to 5 kHz in the vicinity of the landing gear components, as<br />

shown in the accompanying images.<br />

The results from the transient compressible simulation, using<br />

DES and applying non-refl ective treatments at the infl ow and<br />

outfl ow boundaries, delivered a high level of confi dence that<br />

both the mean and fl uctuating fl ow fi elds were well predicted.<br />

The total computational time for 0.25 seconds of simulated time<br />

on the fi ne mesh was approximately 16000 CPU-hours on a<br />

modern 3.0 GHz Linux platform.<br />

This corresponds to just over 5 days on 128 CPUs. Likewise, the<br />

coarse 13 million cell case took just under 2 days.<br />

1/4-scale model of<br />

the Partially-Dressed<br />

Cavity-Closed (PDCC)<br />

Gulfstream G550 nose<br />

landing gear.<br />

Mesh Frequency<br />

Cut-Off estimator along<br />

the model centre-line.<br />

Uniform cubic cells were used in the vicinity of the<br />

nose-gear components: 0.75 mm (left), 3.0 mm (centre),<br />

6.0 mm (right).<br />

Transient Mean<br />

Static Pressure<br />

Coefficeint on the<br />

Wheel.<br />

Mean two dimensional (x-y)<br />

turbulent kinetic energy<br />

- STAR-CCM+ prediction (top)<br />

and PIV results (below)<br />

(Mean) transient (DES k-ω-SST) (left) and steady-state k-ω-SST (right).<br />

Case Study 1: Aeroacoustics of a complex nose landing gear.<br />

24 THE SINGAPORE ENGINEER March 2013

ACOUSTICS ENGINEERING<br />

Case Study 2<br />

Case Study 2 demonstrated the up-front use of the steadystate<br />

turbulence synthesisation method to improve the<br />

noise signature of an avionics cooling rack. The electronics<br />

sit on shelves which are actively cooled by air channels<br />

within the shelving, supplied by ducts which are fed from the<br />

Environmental Control System (ECS).<br />

[2] ‘Effi cient CFD Simulation Process for Aeroacoustic Driven<br />

Design’, Mendonça et al, presented at the II SAE Brazil<br />

International Noise and Vibration Congress, 17-19 October<br />

2010, Florianopolis, Brazil, SAE-2010-36-0545.<br />

(More information about methodologies and best practices for<br />

aeroacoustics simulations in the automotive and aerospace sectors<br />

can be obtained from Reference [2]).<br />

Debatin’s technique [1] was used to modify the original<br />

designs of the plenum and shelf fl ow restrictor. The effects of<br />

the modifi cations were then assessed by quantifying the noise<br />

reduction through CFD simulation and comparing the results<br />

with the measured noise reduction. A DES simulation was used<br />

for the transient fl ow-fi eld predictions. Microphones were placed<br />

in arbitrary locations in the plenum and in the shelf restrictor.<br />

It was found that the modifi ed plenum design signifi cantly<br />

reduces the volume of fl ow recirculation, and consequently the<br />

shear-noise generating mechanisms. The result was a reduction<br />

of noise levels across the full range of the human hearing<br />

spectrum. The DES simulation succeeded in predicting the level<br />

of noise reduction correctly (approximately 3 dB in the range<br />

300-10,000 Hz), but over-predicted the improvement in the<br />

lower frequency range.<br />

The fl ow turbulence through the shelf restrictor was found to<br />

be greatly reduced, resulting in a 2-5 dB reduction is noise levels<br />

between 100 Hz and 10,000 Hz. The predicted levels of noise<br />

reduction were excellent across this full range.<br />

The total model size was approximately 1.5 million cells.<br />

Calculations in steady state and transient state (DES) were<br />

performed by a graduate intern student and completed within a<br />

period of three months, using computer resources limited to a<br />

maximum of eight CPUs.<br />

Acoustic Pressure (Pa) at the driver’s ear location for the three different materials.<br />

Conclusion<br />

As part of its close working relationship with the transport<br />

industry, CD-adapco provides validated tools to predict and<br />

design against aeroacoustical effects early in the design process.<br />

From among a multitude of possible applications in the<br />

aerospace industry, two industrial aeroacoustics case studies<br />

have been briefl y described in this article.<br />

Plenum noise reduction due to modified design<br />

(vertical grading corresponds to 2 dB).<br />

The results proved to be accurate and the study helped illustrate<br />

how a deeper understanding of acoustical phenomena can be<br />

gained through the use of CD-adapco’s STAR-CCM+, thereby<br />

enabling a higher degree of <strong>engineer</strong>ing value to be added while<br />

reducing costs and timescales in the CAE process.<br />

Aeroacoustics best practices are now included in the<br />

STAR-CCM+ online documentation.<br />

References<br />

[1] ‘Chasing Noise with Simulation’, Debatin, ECOMAS CFD<br />

2006, The Netherlands, 5-8 September 2006.<br />

Shelf restrictor noise reduction due to modified design<br />

(vertical grading corresponds to 1 dB).<br />

Case Study 2: Noise signature from an Airbus cockpit avionics cooling rack.<br />

March 2013 THE SINGAPORE ENGINEER<br />

25

PROJECT APPLICATION<br />

Innovative solutions for the power<br />

generation industry<br />

Intergraph provides enterprise <strong>engineer</strong>ing software for the process, power, and marine<br />

industries, through its integrated SmartPlant Enterprise suite.<br />

Intergraph is a top <strong>engineer</strong>ing design solution provider for<br />

the power industry globally, supplying CAD and information<br />

management technology for over 30 years. Intergraph’s solutions<br />

address the complete life cycle of large fossil fuel, hydroelectric, or<br />

nuclear plants involved in generating power for commercial and<br />

residential use. By better understanding the information about the<br />

plant, owners can maximise their return on investment to bring a<br />

large plant online, improve plant effi ciency, and lower power plant<br />

operating costs. Across a range of activities, from new power plant<br />

design and construction to nuclear plant maintenance, owners<br />

can benefi t from a consolidated and managed source of asset<br />

information, in terms of, for example, maintaining effective change<br />

control over their valuable plant data.<br />

Intergraph is part of Hexagon, a leading global provider of<br />

design, measurement, and visualisation technologies that enable<br />

customers to design, measure and position objects, and process<br />

and present data.<br />

The power of 3D design<br />

In Southeast Asia, Indonesia represents a huge market for the<br />

development and construction of power plants and related<br />

network infrastructure to meet the rising demand for electricity,<br />

in line with the increasing momentum of the country’s economic<br />

growth. PT Rekadaya Electrika (Rekadaya) was established to<br />

respond to market demand for the development of electric<br />