Advanced Technology, Engineered Solutions Ready for any challenge

Advanced Technology, Engineered Solutions Ready for any challenge

Advanced Technology, Engineered Solutions Ready for any challenge

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

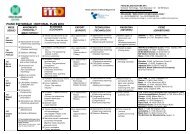

TRANSFLUID<br />

VAL-PO-CI<br />

WALVOIL<br />

ZEC<br />

NEW PRODUCTS<br />

MULTI PUMP DRIVES<br />

FOR INDUSTRIAL<br />

APPLICATIONS<br />

Transfluid – Italy has<br />

introduced a new line<br />

of multiple pump drives.<br />

Designed to be bolted directly<br />

to the engine fl ywheel<br />

housings, these devices are<br />

available in three different<br />

sizes – MPD 14, MPD 18 and<br />

MPD 22 - with SAE 3 to SAE<br />

0 housings. The cast casings<br />

are designed to house four<br />

heads that allow mounting<br />

of up to four pumps or eight<br />

units with the back–to–back<br />

confi guration. The MPD<br />

features an integral oil sump<br />

<strong>for</strong> the gear and bearings<br />

lubrication. According to<br />

the power fed to the PTOs,<br />

it is possible to mount a<br />

fl uid cooler heat exchanger<br />

inside the MPD casing or an<br />

external air-oil radiator. An<br />

elastic coupling from Reich<br />

Kupplungen is mounted on<br />

the power intake side in-line<br />

with the engine crankshaft<br />

axis to avoid torsion problems.<br />

On the output side, the SAE<br />

dummy wheel is capable of<br />

transmitting the whole engine<br />

power, a feature which is not<br />

common to all pump drives.<br />

Any make of coupling or<br />

PTO with SAE fl ange can be<br />

connected to the Transfl uid<br />

MPD, however the comp<strong>any</strong><br />

internally manufactures the<br />

line of KPTO variable fi ll<br />

fl uid couplings and HFO /<br />

HFR oil actuated PTOs. The<br />

MPD is suitable <strong>for</strong> mobile<br />

crushers thanks to the new<br />

Diesel engine generation as<br />

well as the increasing need<br />

of pump drives on machines.<br />

The simplicity and the<br />

compactness of the system<br />

is the key of MPD success.<br />

readerservice@fieramilanoeditore.it n.44<br />

PNEUMATIC FITTINGS<br />

AND TUBES<br />

Sang-a Pneumatic Co.<br />

produces high quality and<br />

reliable pneumatic fi ttings<br />

and tubes. It offers a<br />

complete range of products:<br />

automatic quick couplings,<br />

compact automatic quick<br />

couplings, fl ow controls,<br />

rotary joints, stop fi ttings,<br />

unidirectional valves, stop<br />

cocks, hand valves, plastic<br />

quick couplings, silencers,<br />

air guns, pneumatic tubes,<br />

assembly fi ttings and<br />

couplings. Sang-a products<br />

stand out because of their<br />

elliptical sleeve enabling,<br />

through light pressure, an<br />

easy disconnection of the<br />

tube in confi ned space. They<br />

can be used with operating<br />

pressures up to 20 bar and<br />

are vacuum tight up to 60<br />

°C. Pneumatic fi ttings are<br />

suitable <strong>for</strong> polyurethane,<br />

polyamide, polyethylene,<br />

nylon and rilsan plastic tubes<br />

having external diameters<br />

ranging from 3 to 16 mm with<br />

Tefl on (R)-metric tapered<br />

gas or O-ring (G) parallel<br />

gas threads, from M3 to ½...<br />

The body is made in brass,<br />

nickel-plated brass and<br />

technopolymers. In order<br />

to meet the requirements<br />

of a demanding market, the<br />

comp<strong>any</strong> delivers high quality<br />

products in compliance with<br />

Iso 9001 standard. Sang-a<br />

products are distributed<br />

in Italy by Val-Po-Ci, a<br />

comp<strong>any</strong> located in Mantello<br />

(Sondrio).<br />

readerservice@fieramilanoeditore.it n.45<br />

LOAD-SENSING<br />

PROPORTIONAL<br />

SECTIONAL VALVE<br />

Walvoil introduces the new<br />

proportional Load Sensing<br />

DPC200 valve suitable<br />

to obtain fl ow towards<br />

proportional usage to the<br />

spool position in <strong>any</strong> working<br />

condition irrespective of<br />

both charge and number of<br />

working sections (the only<br />

limit is in case of saturation<br />

in fl ow). Taking OEM needs<br />

into consideration, with the<br />

DPC200 and the Load Sensing<br />

system, users can benefi t<br />

from energy saving, longer<br />

component life, reduction of<br />

energy dissipation as well as<br />

the opportunity to develop<br />

elaborated circuits. Energy<br />

is especially saved when<br />

the DPC200 works together<br />

with Load Sensing variable<br />

displacement pumps. The<br />

sectional valve, supplied from<br />

1 to 10 working sections, can<br />

be used in applications with<br />

fi x displacement pumps (open<br />

centre confi guration - CA) or<br />

with variable displacement<br />

Load Sensing pumps (closed<br />

centre – CC). Main features<br />

include compensated /<br />

not compensated working<br />

sections and interchangeable<br />

spools with 22 mm diameter.<br />

DPC200 is supplied with<br />

manual control, proportional<br />

hydraulic control, electrohydraulic<br />

control and back<br />

operating electro-hydraulic<br />

control integrating diagnostic,<br />

safety and electronic<br />

functions. DPC200 can be<br />

used <strong>for</strong> several applications,<br />

especially <strong>for</strong> concrete boom<br />

pumps, backhoe loaders,<br />

drilling machines, wheel<br />

loaders.<br />

readerservice@fieramilanoeditore.it n.46<br />

NEW PRODUCTS<br />

LOW, MEDIUM AND<br />

HIGH PRESSURE<br />

THERMOPLASTIC<br />

HOSES<br />

With over <strong>for</strong>ty year<br />

experience in the sector<br />

of fl exible thermoplastic<br />

hoses at low, medium, high<br />

and very high pressure,<br />

ZEC offers a wide range of<br />

linear, single, multiple and<br />

spiral thermoplastic hoses,<br />

characterized by inside<br />

diameter from 2 to 40 mm,<br />

operating pressure from 5<br />

to 600 bar and operating<br />

temperatures from –60 °C to<br />

+260 °C. Different product<br />

lines are supplied: hoses <strong>for</strong><br />

low and medium pressure, in<br />

Rilsan PA11, Rilsan PA12, Ptfe,<br />

Pebax, Hytrel, Polyamide 6,<br />

Polyamide 6.6, Polyurethane<br />

and Polyethylene. They are<br />

offered in around 40 different<br />

diameters and 7 colours, even<br />

in single, doubling or multiple<br />

spiral versions, <strong>for</strong> application<br />

mainly in pneumatics and<br />

lubrication, depending on<br />

the specifi c requirements of<br />

the end user. High pressure<br />

thermoplastic hoses are made<br />

with raw materials used and<br />

tested on low and medium<br />

pressure hoses except <strong>for</strong><br />

specifi c applications requiring<br />

alternative products. Specifi c<br />

single or double plaits in<br />

polyester fi bers, aramide,<br />

high tensile steel, stainless<br />

steel, or mixed materials are<br />

placed to reach the pressures<br />

required by oil-hydraulics<br />

and pneumatics, lubrication,<br />

solvents and paints, gases<br />

and chemical products. These<br />

hoses are provided either in<br />

single, doubling or multiple<br />

versions.<br />

readerservice@fieramilanoeditore.it n.47<br />

31<br />

APRILE 2010