Primal SB-200 -- Technical Data Sheet - The Dow Chemical Company

Primal SB-200 -- Technical Data Sheet - The Dow Chemical Company

Primal SB-200 -- Technical Data Sheet - The Dow Chemical Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

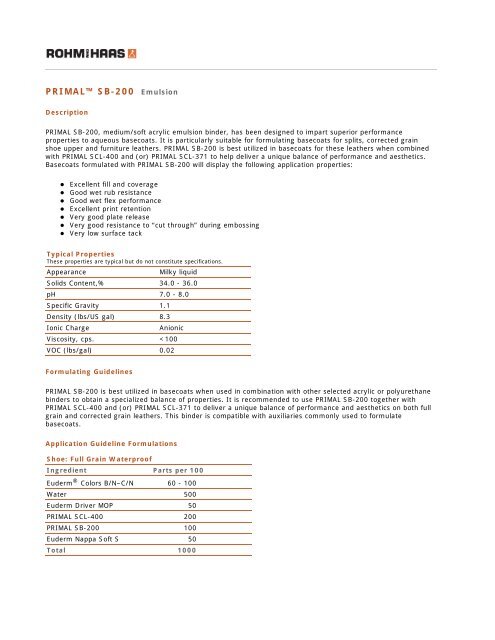

PRIMAL <strong>SB</strong>-<strong>200</strong> Emulsion<br />

Description<br />

PRIMAL <strong>SB</strong>-<strong>200</strong>, medium/soft acrylic emulsion binder, has been designed to impart superior performance<br />

properties to aqueous basecoats. It is particularly suitable for formulating basecoats for splits, corrected grain<br />

shoe upper and furniture leathers. PRIMAL <strong>SB</strong>-<strong>200</strong> is best utilized in basecoats for these leathers when combined<br />

with PRIMAL SCL-400 and (or) PRIMAL SCL-371 to help deliver a unique balance of performance and aesthetics.<br />

Basecoats formulated with PRIMAL <strong>SB</strong>-<strong>200</strong> will display the following application properties:<br />

• Excellent fill and coverage<br />

• Good wet rub resistance<br />

• Good wet flex performance<br />

• Excellent print retention<br />

• Very good plate release<br />

• Very good resistance to “cut through” during embossing<br />

• Very low surface tack<br />

Typical Properties<br />

<strong>The</strong>se properties are typical but do not constitute specifications.<br />

Appearance<br />

Milky liquid<br />

Solids Content,% 34.0 - 36.0<br />

pH 7.0 - 8.0<br />

Specific Gravity 1.1<br />

Density (lbs/US gal) 8.3<br />

Ionic Charge<br />

Anionic<br />

Viscosity, cps.

Corrected Grain Box Leather<br />

Ingredient Parts per 100<br />

Euderm Black B-N 100<br />

Water 70<br />

PRIMAL <strong>SB</strong>-371 250<br />

PRIMAL <strong>SB</strong>-<strong>200</strong> 170<br />

PRIMAL SCL-400 220<br />

Euderm Duller SN-01 120<br />

Euderm Nappa Soft S 60<br />

Total 1000<br />

Add sufficient ACRYSOL TT-935 thickener (1:3 ratio with<br />

water) to yield a #2 Zahn Cup viscosity of 20 - 25 seconds<br />

Full Grain Basecoat<br />

Ingredient Parts per 100<br />

Levaderm ® Dyes 30<br />

Water 500<br />

Euderm Driver MOP 80<br />

Euderm Colors B/N-C/N 30<br />

ROSILK 2229 10<br />

PRIMAL SCL-371 100<br />

PRIMAL SCL-400 <strong>200</strong><br />

PRIMAL <strong>SB</strong>-<strong>200</strong> 50<br />

Total 1000<br />

Furniture Colorcoat<br />

Ingredient Parts per 100<br />

Euderm Colors B-N/C-N 100 - 150<br />

Water 150<br />

PRIMAL <strong>SB</strong>-150 280<br />

PRIMAL <strong>SB</strong>-<strong>200</strong> 190<br />

Euderm Nappa Soft S 150<br />

Euderm Duller SN-01 80<br />

Total 1000<br />

Add 20 - 40 parts ACRYSOL RM-1020 rheology modifier<br />

(1:1 ratio with water) to yield a #2 Zahn Cup viscosity of<br />

20 seconds<br />

Safe Handling Information<br />

Rohm and Haas Material Safety <strong>Data</strong> <strong>Sheet</strong>s (MSDS) contain pertinent information that you may need to protect<br />

your employees and customers against any known health or safety hazards associated with our products.<br />

Under the OSHA Hazard Communication Standard, workers must have access to and understand MSDS on all<br />

hazardous substances to which they are exposed. Thus, it is important that you provide appropriate training and<br />

information to your employees and make sure they have available to them MSDS on any hazardous products in the<br />

workplace.<br />

Upon initial shipment of its products (including samples), Rohm and Haas sends MSDS on those items to the<br />

recipient. If you do not have access to one of these MSDS, please contact your local Rohm and Haas representative<br />

for a copy.

Updated MSDS are sent upon revision to all customers of record. In addition, MSDS are sent annually to all<br />

customers receiving products deemed hazardous under the Superfund Amendments and Reauthorization Act.<br />

MSDS should be obtained from your suppliers of other materials recommended in this bulletin.<br />

Rohm and Haas <strong>Company</strong> is a member of the American Chemistry Council and is committed to ACC’s Responsible<br />

Care ® Program.<br />

PRIMAL is a trademark of Rohm and Haas <strong>Company</strong>, or of its subsidiaries or affiliates.<br />

<strong>The</strong>se suggestions and data are based on information we believe to be reliable. <strong>The</strong>y are offered in good faith, but without<br />

guarantee, as conditions and methods of use of our products are beyond our control. We recommend that the prospective<br />

user determine the suitability of our materials and suggestions before adopting them on a commercial scale.<br />

Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specific patents in<br />

this publication should not be understood as recommending the use of our products in violation of any patent or as permission<br />

or license to use any patents of the Rohm and Haas <strong>Company</strong>.<br />

©Rohm and Haas, <strong>200</strong>8 All rights reserved. December <strong>200</strong>6