Untitled - IKS Messerfabrik Geringswalde GmbH

Untitled - IKS Messerfabrik Geringswalde GmbH

Untitled - IKS Messerfabrik Geringswalde GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

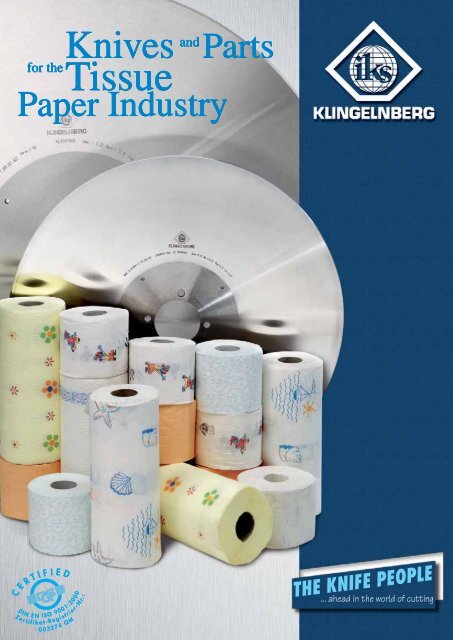

ABOUT US<br />

A long tradition signifies commitment.<br />

The history of our company can be<br />

traced back to 1814. The manufacturing<br />

of machine knives started in<br />

1908. Klingelnberg today is known<br />

as one of the oldest existing machine<br />

knife factories in the region called<br />

„Bergisches Land“.<br />

Over the decades, this region has<br />

built up a worldwide reputation.<br />

Our high competence, resulting<br />

from close cooperation with leading<br />

machine builders as well as intensive<br />

partnerships with innovative key<br />

customers, forms the basis for continuative<br />

development and successful<br />

growth of <strong>IKS</strong> Klingelnberg - The Knife<br />

People.<br />

<strong>IKS</strong> Klingelnberg <strong>GmbH</strong>, Remscheid<br />

The <strong>IKS</strong> Klingelnberg Group<br />

Rolf Meyer <strong>GmbH</strong>, Bargteheide<br />

Constantly expanding production<br />

facilities in Europe and overseas<br />

and their highly skilled employees<br />

provide fl exibility and a high quality<br />

level of production.<br />

<strong>IKS</strong> <strong>Messerfabrik</strong> <strong>Geringswalde</strong> <strong>GmbH</strong>, <strong>Geringswalde</strong><br />

Böhler·Miller Messer- u. Sägen <strong>GmbH</strong>, Böhlerwerk

QUALITY EXCEEDING CURRENT INDUSTRY STANDARDS<br />

In view of a permanent growing<br />

demand in high productivity, short<br />

delivery times and a high product<br />

quality level, Tissue Mills today<br />

are under severe pressure, always<br />

looking for optimization and costsaving<br />

improvements. Increasing<br />

operation speed of machines needs<br />

high performance cutting tools, today<br />

more than ever before. <strong>IKS</strong> Klingelnberg<br />

as manufacturer of such tools<br />

has specialized in this field, closely<br />

cooperating with many Tissue Mills<br />

all over the world.<br />

We optimize the cutting process<br />

in your converting section !!!<br />

Our highly skilled product specialists<br />

give technical advice, show room<br />

for improvements, help to find costeffi<br />

cient solutions of your cutting<br />

problems, hold seminars at your<br />

premises and keep you up-to-date<br />

about our latest product developments.<br />

Based on specially designed<br />

state-of-the-art machinery, best heat<br />

treatment and surface finish, our logsaw-blades<br />

have a consistently high<br />

product quality -<br />

The reliablity that you need !<br />

LOG SAW BLADES<br />

<strong>IKS</strong> Klingelnberg is well known for it‘s high quality Log Saw Blades. We produce<br />

knives for all existing Log Saw machines, e.g. PERINI, PCMC, Kawanoe<br />

Zoki and others.<br />

The following knife qualities are available:<br />

CHROMAVAN<br />

Chrome-Vanadium alloyed Tool Steel<br />

Economically priced Log Saw Blade<br />

CHROMALIT<br />

High Carbon High Chrome (HCHC) Steel<br />

Today´s most produced and sold quality.<br />

We developed a special execution for the use in combination with the<br />

Lubrication System<br />

DURITAN<br />

High Speed Steel (HSS)<br />

Best performance for the latest generation of fast running Log Saw machines<br />

with 3 or 4 logs. The lifetime of DURITAN is much longer than CHROMALIT.<br />

Apart from that, we recommend a special knife execution in combination<br />

with our lubrication system for the best performance.

UNIQUE KNIFE QUALITY CERTIFICATION<br />

Axial and radial<br />

runout on every<br />

blade<br />

GRINDING STONES<br />

Always the right choice to suit your<br />

knives! We offer grinding wheels for<br />

machines like PERINI, PCMC, Italconverting,<br />

and others. Special grinding<br />

wheels have been designed in use<br />

with our high performance knives<br />

and lubrication system, providing<br />

• less sparks<br />

• best cutting edge of the knife<br />

• longer life time<br />

• less pollution of tissue material

LUBRICATION SYSTEM AND LUBR<strong>IKS</strong>-05<br />

The lubrication system with it‘s new developed lubricant Lubr<strong>IKS</strong>-05 of<br />

<strong>IKS</strong> Klingelnberg supports the idea of a perfect cut along with a fast<br />

cutting speed.<br />

The water based lubricant (95% water) is atomised onto the blade<br />

surface by high-tech spray-nozzles.<br />

But the water evaporates, leaving a coating on the blade preventing<br />

from glue deposit and decreasing friction between knife and tissue to a<br />

minimum.<br />

Advantages are:<br />

• no crushed cores<br />

(in particular when using the special blade design)<br />

• no fires<br />

(security improvement - regular cleaning of the machine presumed)<br />

• no glue on the blade<br />

• considerably decreased spray-intervals compared to a common<br />

spray-system<br />

• less cleaning of the grinding wheels<br />

• less dirt on the blade<br />

• less dirt in the machine<br />

• less pollution of tissue material<br />

The <strong>IKS</strong> Klingelnberg Log Saw<br />

Blade, grinding stones and lubrication<br />

system in combination<br />

lead to the highest efficiency of<br />

your Log Saw Machine.

PERFORATION BLADES<br />

All our blades, either made from<br />

tool steel, solid HSS or tipped as<br />

bi-metal and even solid TC anvil<br />

blades are being made in high<br />

precision and perforation slots are<br />

perfectly ground.<br />

Perforation blades can be supplied<br />

for every common machine and<br />

others, of course.<br />

CREPING BLADES<br />

Creping blades, e.g. used on the<br />

„Yankee Dryer“, are made from<br />

hardened and tempered carbon<br />

steel with a blue-grey surface.<br />

Other steel grades for special<br />

applications are also available<br />

(stainless steel, Bronze and<br />

others). The specially ground<br />

edges and excellent straightness<br />

guarantee a superior run on the<br />

machine. We produce creping<br />

blades acc. to customers‘ requirements,<br />

every size and bevel is<br />

possible.<br />

MISCELLANEOUS<br />

In completion of our product range we also manufacture a variety of knives, band knives, perforation blades<br />

etc. for machines like:<br />

PACKAGING<br />

(foil wrapping)<br />

TMC<br />

Casmatic<br />

Wrapmatic<br />

SHEET<br />

PRODUCTION<br />

(napkins, handkerchiefs, towels)<br />

Winkler + Dünnebier<br />

Bretting<br />

Senning<br />

Hobema<br />

SPECIAL TISSUE<br />

PRODUCTS<br />

(industrial towels, non-wovens)<br />

OMET<br />

Hobema<br />

Dixon

RELIABILITY<br />

The constant modernization of manufacturing<br />

equipment over the last<br />

10 years has lead to an increase in<br />

capacity, which has clearly reduced<br />

the delivery time in favour of our customers.<br />

Today, most common knives<br />

are available from stock.<br />

We aim for our customers‘ satisfaction.<br />

Since 1995 we have been certified<br />

to DIN EN ISO 9001 (issue 1994)<br />

and obtained the registration under<br />

No. 003274 QM from DQS in July<br />

2002, according to DIN EN ISO<br />

9001:2000.

THE <strong>IKS</strong> KLINGELNBERG GROUP<br />

<strong>IKS</strong> KLINGELNBERG <strong>GmbH</strong><br />

Industriegebiet Bergisch-Born<br />

In der Fleute 18<br />

42897 Remscheid/Germany<br />

Tel.: +49- (0)2191 / 969-0<br />

Fax: +49- (0)2191 / 969-111<br />

BFC-72-DD0804