Container Unloading using Robotized Palletizing

Container Unloading using Robotized Palletizing

Container Unloading using Robotized Palletizing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Container</strong> <strong>Unloading</strong> <strong>using</strong> <strong>Robotized</strong> <strong>Palletizing</strong><br />

Theoretical Framework<br />

In year 2009 the transportation by ship amounts to over 27 million TEUs [7], where one TEU<br />

is equal to one 20 foot container. In transportation of goods by ship the most common way is<br />

to use containers. A main advantage of <strong>using</strong> ships instead of trains is transportation volume,<br />

which are significantly higher for ships. Products not dependent on time are also beneficial to<br />

transport by ship. There are mainly three different types of standard containers, 20 foot, 40<br />

foot and 40 foot High Cube [8].<br />

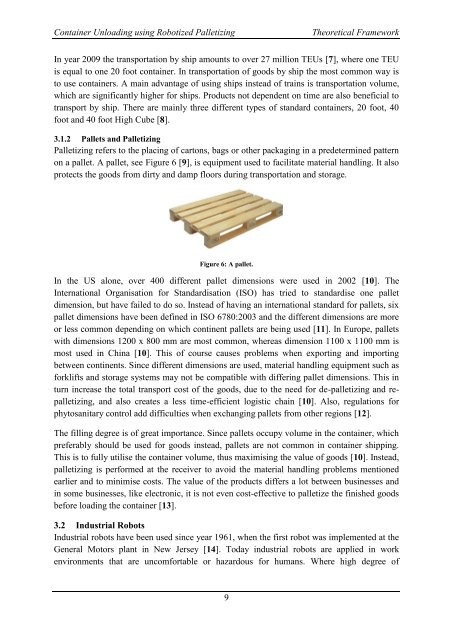

3.1.2 Pallets and <strong>Palletizing</strong><br />

<strong>Palletizing</strong> refers to the placing of cartons, bags or other packaging in a predetermined pattern<br />

on a pallet. A pallet, see Figure 6 [9], is equipment used to facilitate material handling. It also<br />

protects the goods from dirty and damp floors during transportation and storage.<br />

Figure 6: A pallet.<br />

In the US alone, over 400 different pallet dimensions were used in 2002 [10]. The<br />

International Organisation for Standardisation (ISO) has tried to standardise one pallet<br />

dimension, but have failed to do so. Instead of having an international standard for pallets, six<br />

pallet dimensions have been defined in ISO 6780:2003 and the different dimensions are more<br />

or less common depending on which continent pallets are being used [11]. In Europe, pallets<br />

with dimensions 1200 x 800 mm are most common, whereas dimension 1100 x 1100 mm is<br />

most used in China [10]. This of course causes problems when exporting and importing<br />

between continents. Since different dimensions are used, material handling equipment such as<br />

forklifts and storage systems may not be compatible with differing pallet dimensions. This in<br />

turn increase the total transport cost of the goods, due to the need for de-palletizing and repalletizing,<br />

and also creates a less time-efficient logistic chain [10]. Also, regulations for<br />

phytosanitary control add difficulties when exchanging pallets from other regions [12].<br />

The filling degree is of great importance. Since pallets occupy volume in the container, which<br />

preferably should be used for goods instead, pallets are not common in container shipping.<br />

This is to fully utilise the container volume, thus maximising the value of goods [10]. Instead,<br />

palletizing is performed at the receiver to avoid the material handling problems mentioned<br />

earlier and to minimise costs. The value of the products differs a lot between businesses and<br />

in some businesses, like electronic, it is not even cost-effective to palletize the finished goods<br />

before loading the container [13].<br />

3.2 Industrial Robots<br />

Industrial robots have been used since year 1961, when the first robot was implemented at the<br />

General Motors plant in New Jersey [14]. Today industrial robots are applied in work<br />

environments that are uncomfortable or hazardous for humans. Where high degree of<br />

9