YOGURT/YOGHURT

YOGURT/YOGHURT

YOGURT/YOGHURT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>YOGURT</strong>/<strong>YOGHURT</strong><br />

Garima Pande<br />

FDST 8120<br />

Summer 2010<br />

History<br />

Food historians generally agree the genesis of yogurt<br />

and other fermented milk products was discovered<br />

accidentally by Neolithic peoples living in Central<br />

Asia. These foods occurred naturally due to local<br />

climate and primitive storage methods (1). Yogurt<br />

first gained international prominence in the early<br />

1900s when Ilya Metchnikov, a Russian bacteriologist,<br />

observed that the long life span of Bulgarians<br />

was mainly due to their diet which included the<br />

consumption of large quantities of soured milk (2).<br />

The first industrialized production of yogurt is attributed<br />

to Isaac Carasso in 1919 in Barcelona – his<br />

company “Danone” was named for his son, “Little<br />

Daniel”. Turkish immigrants brought yogurt to<br />

North America in the 1700s but it really didn’t catch<br />

on until the 1940s when Daniel Carasso, the son of<br />

Danone founder Isaac, and Juan Metzger took over<br />

a small yogurt factory in the Bronx, New York – the<br />

company is now called Dannon in the United States<br />

(3). The word is derived from Turkish: yoğurt, and is<br />

related to yoğurmak ‘to knead’ and yoğun “dense” or<br />

“thick”.<br />

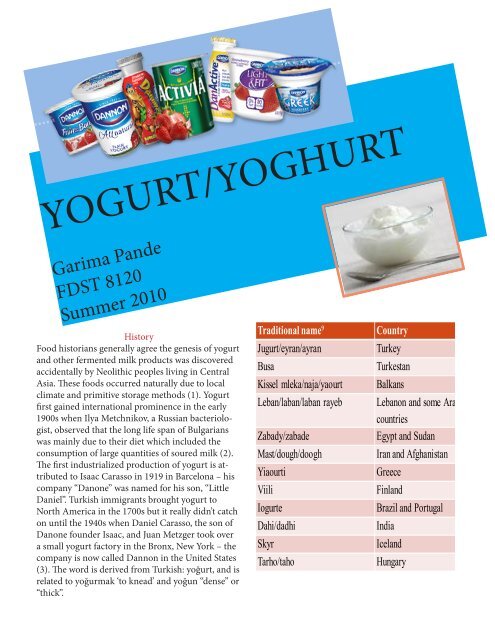

Traditional name 9<br />

Jugurt/eyran/ayran<br />

Busa<br />

Kissel mleka/naja/yaourt<br />

Leban/laban/laban rayeb<br />

Zabady/zabade<br />

Mast/dough/doogh<br />

Yiaourti<br />

Viili<br />

Iogurte<br />

Dahi/dadhi<br />

Skyr<br />

Tarho/taho<br />

Country<br />

Turkey<br />

Turkestan<br />

Balkans<br />

Lebanon and some Arab<br />

countries<br />

Egypt and Sudan<br />

Iran and Afghanistan<br />

Greece<br />

Finland<br />

Brazil and Portugal<br />

India<br />

Iceland<br />

Hungary

What is yogurt?<br />

According to the Code of Federal Regulations of the FDA (4), yogurt is defined as the “food produced by culturing<br />

one or more of the optional dairy ingredients (cream, milk, partially skimmed milk, and skim milk) with a<br />

characterizing bacteria culture that contains the lactic acid-producing bacteria, Lactobacillus delbrueckii subsp.<br />

bulgaricus and Streptococcus thermophilus”. “Yogurt, before the addition of bulky flavors, contains not less than<br />

3.25% milkfat and not less than 8.25% milk solids not fat, and has a titratable acidity of not less than 0.9%, expressed<br />

as lactic acid. Yogurt may be heat treated after fermenting to destroy viable microorganisms for a longer<br />

shelf life of the food”. Lowfat yogurt and nonfat yogurt are similar in description to yogurt but contain 0.5 to 2%<br />

and less than 0.5% milkfat, respectively (5, 6).<br />

National Yogurt Association proposed a yogurt standard that (i) requires a minimum level of active cultures of<br />

107 colony-forming units (CFU) per gram (g); (ii) requires an acidity of pH 4.6 or lower; (iii) requires a minimum<br />

level of total dairy ingredients of 51 percent; (iv) provides for pre-culture homogenization and pasteurization;<br />

(v) permits the use of reconstituted milk and whey protein concentrate as ``standard dairy ingredients;’’<br />

(vi) provides for the use of any milk-derived ingredients as optional dairy ingredients; (vii) permits the use of<br />

safe and suitable sweeteners, emulsifiers, and preservatives; (viii) permits the optional use of any safe and suitable<br />

ingredients added for nutritional or functional purpose; and (ix) makes provisions for lowfat and nonfat<br />

yogurts based on total fat content of the food per reference amount customarily consumed (7).<br />

smoked<br />

yogurt<br />

Yogurt Related Products 9<br />

Yogurt Production 9<br />

frozen<br />

yogurt<br />

drinking<br />

yogurt<br />

dried<br />

yogurt<br />

yogurt<br />

yogurt<br />

cheese<br />

yogurt<br />

butter<br />

or ghee<br />

strained<br />

yogurt<br />

Classification of Yogurt 9<br />

Yogurt<br />

Physical<br />

Set<br />

Stirred<br />

Drinking<br />

Chemical<br />

Full fat<br />

Medium fat<br />

Low fat<br />

Flavor<br />

Plain/natural<br />

Fruit<br />

single/mixed<br />

Miscellaneous<br />

Enzyme<br />

hydrolysis<br />

Vitamin<br />

fortification<br />

Vegetable oils<br />

Heat treatment<br />

INGREDIENTS<br />

• Milk: Whole milk, partially skimmed milk, skim milk or<br />

whole milk<br />

• Other Dairy Products: concentrated skim milk, nonfat dry<br />

milk, whey, lactose<br />

• Sweeteners: glucose or sucrose, high-intensity sweeteners<br />

(e.g. aspartame)<br />

• Stabilizers: gelatin, carboxymethyl cellulose, locust bean<br />

gum, guar, alginates, carrageenans, whey protein concentrate<br />

• Flavors<br />

• Fruit Preparations: including natural and artificial<br />

flavouring, colour

CHEMISTRY OF <strong>YOGURT</strong><br />

Yogurt is a cultured dairy product made by fermentation of heated milk with lactic<br />

acid bacteria, which convert lactose into lactic acid resulting in a reduction in pH.<br />

Casein micelles are the building blocks of acid milk gels, so the nature and type<br />

of casein interactions are very important for the properties of acid milk gels. The<br />

integrity of casein micelles is controlled by a localized balance between hydrophobic<br />

interactions and electrostatic repulsion (10). Yogurt mix is normally heated at<br />

a higher temperature and longer time than normal pasteurization, ranging from<br />

90 to 95 °C for 5 to 10 min, to help improve product consistency through whey<br />

protein denaturation (9). Whey proteins which participate in casein aggregation<br />

in yogurt are α- lactalbumin and β-lactoglobulin. The former has a denaturation<br />

temperature of 62 °C and the latter, 78 °C. During heat treatment there are two<br />

possible events depending on heat intensity; very high heat treatment such as 90<br />

°C for 10 min induces both α-LA and β-LG to participate in protein aggregation<br />

resulting in less susceptibility to syneresis in yogurt, but a lower heat treatment (vat<br />

pasteurization) causes β-LG to participate rather than α-LA because 80 to 90% of<br />

denatured α-LA is reversible after heating (10). Incorporation of β-LG at the micellar<br />

surface gives a long chain casein micelle linked by a finely flocculated protein<br />

resulting in a loose structure and an increase in syneresis (11). Finally, the lactic<br />

acid production during the fermentation step leads to the destabilization of the micellar<br />

system which results in the gelation of the proteins. As the isoelectric points<br />

of denatured whey proteins (pH 5.2), and caseins (pH 4.6) are reached, low-energy<br />

bonds, mainly hydrophobic, are progressively established between the proteins<br />

(10). Hydrophilic colloids bind water and consequently increase the viscosity of<br />

yoghurt; they also help prevent the separation of whey from the yoghurt, a problem<br />

known as syneresis. Common stabilisers are, gelatin, pectin, agar, starch.<br />

MICROBIOLOGY OF <strong>YOGURT</strong><br />

Early investigators of yogurt microorganisms found rod and coccal-shaped bacteria, yeasts and molds in yogurt<br />

(9). Yogurt bacteria are now characterized as lactic acid bacteria belong to the Lactobacillaceae and<br />

Streptococcaceae genera. Generally, yogurt cultures are L. delbrueckii subsp. bulgaricus and S. thermophilus.<br />

Some other strains such as L. helveticus, L. jugurti, L. acidophilus and Bifidobacterium spp. are also sometimes<br />

used as adjuncts. S. thermophilus is a Gram-positive, facultative anaerobic homofermentative bacterium<br />

with a spherical or ovoid shape, a diameter

CHEMICAL AND PHYSICAL ANALYSIS OF <strong>YOGURT</strong><br />

Analysis of the qualitative parameters of yogurt can be divided into two parts as chemical and structural analysis.<br />

The former includes yogurt flavor analysis (taste/aroma compounds), milk constituents analysis (e.g., carbohydrates,<br />

fat, total nitrogen, free amino acids, proteins, and antibiotics), and assays for chemical indices (e.g., Zeta<br />

potential of casein micelles and enzymes activity). Structural analysis includes textural and rheological as well as<br />

microstructural analysis. Textural and rheological analysis is associated with the methods evaluating gel (set-type<br />

yogurt) and liquid (stirred-type yogurt) properties of yogurts. Microstructural analysis consists of two parts:<br />

microstructural images (studying detail structure) and microstructural assays (such as those obtained by EPS,<br />

exopolysaccarides secreted by bacteria, and those for the determination of the mean diameter of fat globules/<br />

particles) (15). Yogurt is a typical non-Newtonian fluid, exhibiting a shear-thinning, yield stress, viscoelasticity,<br />

and thixotropic (time-dependency) flow behavior. The rheological properties of yogurt are indicative of gel formation<br />

and are important in the design of flow processes, quality control, processing and storage, and predicting<br />

the texture of yogurt. Textural properties for yogurt include viscosity, firmness and syneresis. Viscosity of yogurt<br />

is affected by composition, type of starter cultures, heat treatment and stabilizer (15).<br />

MICROSTRUCTURE OF <strong>YOGURT</strong><br />

Microstructure of yogurt is usually studied by transmission electron microscopy (TEM) of thin section and<br />

scanning electron microscopy (SEM) (16). Sample preparation for TEM is time consuming but it allows for the<br />

visualization of casein aggregation, whereas with SEM sample preparation is easier and aids in the study of gel<br />

structure (16). Heat treatment of a yogurt mix causes changes in the microstructure of finished product. As<br />

previously mentioned, denaturation of whey proteins is responsible for the changes in gel formation. Protein<br />

micelles in yogurt mix when heated at 90 °C for 10 min have appendages which are complexes of whey proteins<br />

and κ- casein, but without casein fusion (9). During the fermentation process, these appendages inhibit casein<br />

fusion resulting in a loose structure (9). In a recent development, confocal scanning laser microscopy was used<br />

to study the microstructure of yogurt during fermentation in real time without sample preparation (16). Microstructure<br />

studies on yogurt gels have demonstrated that these gels consist of a coarse particulate network of<br />

casein particles linked together in clusters, chains, and strands (16). The network has pores or void spaces where<br />

the aqueous phase is confined.<br />

4X 10X<br />

<strong>YOGURT</strong> MICROSTRUCTURE BY<br />

LIGHT MICROSCOPY<br />

20X 40X

EFFECT OF MILK SOLID % (LEFT TO RIGHT,10, 15, 20% ) ON <strong>YOGURT</strong> MICROSTRUCTURE<br />

http://www.magma.ca/~pavel/science/Yogurt.htm<br />

Microstructure of yogurt obtained from milk bases enriched with SMP, WPC, NaCn, and CaCn (in clockwise<br />

order), and heated at 90 °C for 5 min. Bar—20 mm (17).<br />

SEM image of yogurt. Left upper corner and right lower corner show the protein matrix<br />

of yogurt made by the action of bacteria: streptococci (yellow) and lactobacilli (blue).<br />

http://www.magma.ca/~pavel/science/Yogurt.htm<br />

Transmission electron microscopy of sheep's milk labneh:<br />

Fat particles (yellow - small arrows) are encapsulated in<br />

aggregated protein particles (dark structures - large<br />

arrows). Bar: 1 µm.

Ref:18<br />

REFERENCES:<br />

(1) Brothwell, D.; Brothwell, P., Food in Antiquity: A Survey of the Diet of Early Peoples, expanded ed.; Johns Hopkins University<br />

Press, Baltimore, MD, 1997.<br />

(2) Whitman, J., Craig Claiborne’s The New York Times Food Encyclopedia,Times Books,New York, 1985 (p. 489)<br />

(3) Mariani, J. F., Encyclopia of American Food and Drink, Lebhar-Friedman, New York, 1999 (p. 355).<br />

(4) FDA. 1996c. Yogurt. 21 CFR 131.200, Code of Federal Regulations. U.S. Dept. of Health and Human Services, Washington,<br />

DC.<br />

(5) FDA. 1996a. Lowfat yogurt. 21CFR 131.203, Code of Federal Regulations. U.S. Dept. of Health and Human Services,<br />

Washington, DC.<br />

(6) FDA. 1996b. Nonfat yogurt 21 CFR 131.206, Code of Federal Regulations. U.S. Dept. of Health and Human Services,<br />

Washington, DC.<br />

(7) http://aboutyogurt.com/index.asp?sid=1<br />

(8) International Dairy Foods Association, (2008), “Dairy facts2008”, International Dairy Foods Association Publications,<br />

Washington DC, USA.<br />

(9) Tamine A.Y.; Robinson, R.K., Yoghurt science and technology. 2nd ed.; CRC Press LLC, Boca Raton, FL,1999.<br />

(10) Lucey, J. A., Formation and physical properties of milk protein gels. J. Dairy Sci. 2002, 85,281–294.<br />

(11) Wong, N. P.; Jenness, R.; Keeney, M.; Marth, E. H., Fundamentals of Dairy Chemistry. 3rd ed.; Van Nostrand Reinhold<br />

Co. Inc., New York, NY, 1998.<br />

(12) Chandan R. C., Manufacturing of yogurt and fermented milks. 1st ed.; Blackwell Publishing Professional, Ames, Iowa,<br />

2006.<br />

(13) Lee W.J.; Lucey J. A., Rheological properties, whey separation and microstructure in set type yogurt: effects of heating<br />

temperature and incubation temperature, J. Texture Studies. 2004, 34, 515-536.<br />

(14) Ozer B., Destructive effects of classical viscometers on the microstructure of yoghurt gel, Turkish J. Agri. For. 2004, 28,<br />

19-23.<br />

(15) Mortazavian, A.M; Karamatollah, R.; Sohrabvandi, S., Application of Advanced Instrumental Methods for Yogurt<br />

Analysis. Crit. Rev. Food Sci. Nutr. 2009, 49, 153-163.<br />

(16) Kalab, M.; Allen-Wojtas, P.; and Phipps-Todd, B. E., Development of microstructure in setstyle nonfat yoghurt - a<br />

review. Food Microstruct. 1983, 2, 51-66.<br />

(17) Sandoval-Castillaa, O.; Lobato-Callerosa, C.; Aguirre-Mandujanoa, E.; Vernon-Carterb, E. J., Microstructure and texture<br />

of yogurt as influenced by fat replacers. Intl. Dairy J. 2004,14,151–159<br />

(18) Hassan, A. N.; Frank, J. F.; Farmer, M. A.; Schmidt, K. A.; Shalabi, S. I. Formation of yogurt microstructure and threedimensional<br />

visualization as determined by confocal scanning laser microscopy. J. Dairy Sci. 1995, 78,2629-2636