Penicillin Production - DCU

Penicillin Production - DCU

Penicillin Production - DCU

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• Reasonable heat-transfer.<br />

• Prevention of aggregation without damaging microorganisms.<br />

• Good bulk-flow and mixing to prevent the creation of dead zones in the<br />

reactor.<br />

• Good nutrient transfer.<br />

Economic:<br />

• Easy to operate aseptically.<br />

• Reasonably flexible regarding process requirements.<br />

• Low power consumption.<br />

• Stable under fluctuating conditions.<br />

• Cheap, robust, simple and well understood for scale-up.<br />

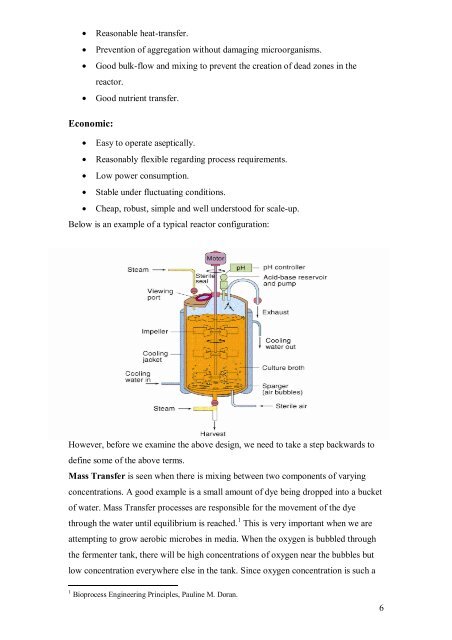

Below is an example of a typical reactor configuration:<br />

However, before we examine the above design, we need to take a step backwards to<br />

define some of the above terms.<br />

Mass Transfer is seen when there is mixing between two components of varying<br />

concentrations. A good example is a small amount of dye being dropped into a bucket<br />

of water. Mass Transfer processes are responsible for the movement of the dye<br />

through the water until equilibrium is reached. 1 This is very important when we are<br />

attempting to grow aerobic microbes in media. When the oxygen is bubbled through<br />

the fermenter tank, there will be high concentrations of oxygen near the bubbles but<br />

low concentration everywhere else in the tank. Since oxygen concentration is such a<br />

1 Bioprocess Engineering Principles, Pauline M. Doran.<br />

6