Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

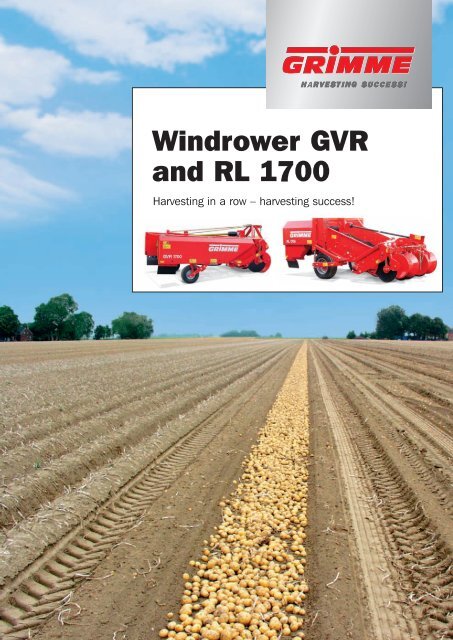

<strong>Windrower</strong> <strong>GVR</strong><br />

<strong>and</strong> <strong>RL</strong> <strong>1700</strong><br />

Harvesting in a row – harvesting success!

More efficient: windrowers<br />

from Grimme<br />

Wherever “clean <strong>and</strong> bright potato reliability, high output <strong>and</strong> low<br />

skins” <strong>and</strong> set skin potatoes are<br />

maintenance these machines are<br />

required by the farmer or the customer, ideal for harvesting large areas.<br />

NERVENSCHONUNG<br />

Grimme windrowers can be found. And The <strong>GVR</strong> <strong>and</strong> <strong>RL</strong> <strong>1700</strong> (with extended<br />

whoever thought that these machines main web) are generally used in fields<br />

are only for small acreages is wrong. where harvesting “by h<strong>and</strong>” is normal.<br />

Because: Both have harvest technology The <strong>RL</strong> <strong>1700</strong> (with haulm separation)<br />

taken from the Grimme 2-row<br />

is mainly used for the 2-stage harvest<br />

harvesters. And because of their<br />

system. The potatoes are windrowed<br />

into a 50 cm wide bed. After the drying<br />

period, where the potato skins set <strong>and</strong><br />

increase their resilience, a conventional<br />

potato harvester then lifts the crop.<br />

This system also increases the output<br />

of the potato harvester. – Together you<br />

are harvesting success!<br />

<strong>GVR</strong> <strong>1700</strong><br />

An effective machine:<br />

the <strong>GVR</strong> <strong>1700</strong> from Grimme<br />

Ideal for every day use:<br />

The fully mounted <strong>GVR</strong> <strong>1700</strong><br />

windrower from Grimme is<br />

impressive, not only because<br />

of its robust construction,<br />

but also because of its<br />

simple operation <strong>and</strong> gentle<br />

crop h<strong>and</strong>ling. A cross<br />

conveyor is available<br />

as an option.<br />

Compact. Robust. Powerful: At first glance<br />

you notice the short construction of the<br />

machine. During both road transport <strong>and</strong><br />

field working the <strong>GVR</strong> <strong>1700</strong> remains fully<br />

mounted on the tractor three-point linkage.<br />

This makes it extremely agile <strong>and</strong> soon<br />

pays for itself, especially on headl<strong>and</strong>s. At<br />

the second glance the machine impresses<br />

with it robust construction. Look behind<br />

the side panels <strong>and</strong> you see the proven<br />

technology from the 2-row harvester<br />

system. The complete intake unit is taken<br />

100 % from that proven technology.<br />

Another benefit is the very easy h<strong>and</strong>ling.<br />

Connect the <strong>GVR</strong> <strong>1700</strong> to the convenient<br />

three-point-linkage, set the diablo rollers to<br />

the ground conditions <strong>and</strong> off you go. The<br />

depth sensing of the share avoids cutting<br />

of the crop <strong>and</strong> optimised soil sieving. This<br />

improves the quality of the crop – even in<br />

tough conditions. Because: the extra drop<br />

created by having two short main webs<br />

produces efficient <strong>and</strong> gentle separating as<br />

well as a gentle delivery of the crop behind<br />

the machine. The <strong>GVR</strong> <strong>1700</strong> is a windrower<br />

which incorporates all the typical<br />

Grimme advantages: long life <strong>and</strong> high<br />

output at the same time as gentle<br />

h<strong>and</strong>ling of the crop. A real “Grimme”.<br />

Full width: First gentle<br />

separating then delivery<br />

across the full width<br />

behind the machine.<br />

1<br />

For tough conditions: Extra drop created<br />

by having two short main webs (1) for effective<br />

sieving – ideal for heavy <strong>and</strong> wet conditions.

OPTIONS<br />

Option for the <strong>GVR</strong> <strong>1700</strong><br />

Exp<strong>and</strong> your possibilities: With the hydraulically driven <strong>and</strong> infinitely speed adjustable cross conveyor the<br />

<strong>GVR</strong> <strong>1700</strong> becomes the ideal windrower. For a distinct increase in output of a 2-row Grimme potato harvester.<br />

Option for the <strong>RL</strong> <strong>1700</strong><br />

Better harvest without pressure: Reduced clod creation <strong>and</strong> reduced crop damage with the mechanical<br />

ridge pressure relief system – ideal for s<strong>and</strong>y soil or in heavy conditions.<br />

Option for the <strong>GVR</strong> <strong>and</strong> <strong>RL</strong> <strong>1700</strong><br />

A worthwhile option: You do not only save time with the infinite electronic adjustment of the rotary<br />

agitator intensity but have also more peace of mind.

<strong>RL</strong> <strong>1700</strong><br />

More developed:<br />

the <strong>RL</strong> <strong>1700</strong> from Grimme<br />

Simply connect the three-point-linkage of<br />

the <strong>RL</strong> <strong>1700</strong> to your tractor. The machine<br />

is semi-mounted so the tractor only lifts<br />

half of its weight, both during road<br />

transport <strong>and</strong> when digging. This unique<br />

development makes it possible for small<br />

tractors (from 55 HP) to h<strong>and</strong>le the<br />

machine. As with the <strong>GVR</strong> <strong>1700</strong>, the<br />

<strong>RL</strong> <strong>1700</strong> is equipped with the proven<br />

technology from the Grimme 2-row<br />

harvester system. The complete intake<br />

system with share, share frame, spring<br />

loaded <strong>and</strong> pulled discs, diablo rollers <strong>and</strong><br />

haulm intake rollers are taken 100 % from<br />

that harvester technology. This ensures<br />

high reliability <strong>and</strong> high output. Additionally<br />

the <strong>RL</strong> <strong>1700</strong> also has an extracting roller<br />

<strong>and</strong> counter-rotating hedgehog web to<br />

separate the haulm from the potatoes.<br />

The haulm is deposited separately from the<br />

potatoes on the ground. The <strong>RL</strong> <strong>1700</strong> is<br />

ideal for the 2-stage harvest system.<br />

As an option a longer main web can be<br />

chosen, which makes the <strong>RL</strong> <strong>1700</strong> perfect<br />

for high output in light soils. And the best<br />

is: The gentle but effective sieving, together<br />

with the small drop height at the end of<br />

the long main web ensures a gentle delivery<br />

of the crop – a most gentle harvest with<br />

maximum output!<br />

More sieving. More<br />

agility. More for your money:<br />

the compact windrower<br />

<strong>RL</strong> <strong>1700</strong> with three-point-linkage<br />

<strong>and</strong> long main web, high quality<br />

processed <strong>and</strong> robust constructed<br />

1<br />

2<br />

2<br />

3<br />

Trash-free separation without any losses: haulm<br />

extracting roller (1), counter-rotating hedgehog<br />

web (2) <strong>and</strong> cross conveyor (3) is st<strong>and</strong>ard<br />

equipment on the <strong>RL</strong> <strong>1700</strong>.<br />

Minimum soil. Most gentle harvest: the long main<br />

web (1) with angled end (2) for optimum sieving<br />

<strong>and</strong> gentle, wide deposit behind the machine as<br />

an option on the <strong>RL</strong> <strong>1700</strong>.<br />

1<br />

Simple, but resourceful: the<br />

unique construction of the<br />

<strong>RL</strong> <strong>1700</strong> from Grimme. With<br />

haulm extracting roller, diablo<br />

rollers <strong>and</strong> counter-rotating<br />

hedgehog web this version of<br />

the <strong>RL</strong> <strong>1700</strong> ensures maximum<br />

haulm separation during digging.<br />

Clean option: The <strong>RL</strong> <strong>1700</strong> is<br />

available with a long main web<br />

<strong>and</strong> angled end – ideal in those<br />

areas where the potatoes are<br />

later picked by h<strong>and</strong>. Another<br />

valuable option: A single wide<br />

diablo roller ensures that the<br />

crop is delivered centrally at<br />

the rear of the machine.

BASIC EQUIPMENT<br />

Proved a thous<strong>and</strong> times: the original Grimme<br />

harvest technology of the <strong>GVR</strong> <strong>and</strong> <strong>RL</strong> <strong>1700</strong><br />

1<br />

2<br />

You can count on that: The intake units of the <strong>GVR</strong> <strong>1700</strong> <strong>and</strong> <strong>RL</strong> <strong>1700</strong> are taken 100 % from the<br />

successful 2-row harvest technology from Grimme. Two diablo rollers (1), ensure even depth control <strong>and</strong><br />

4 spring loaded disc coulters (2) including haulm intake roller, guarantee a blockage free crop intake:<br />

simple harvest – <strong>and</strong> harvesting success!<br />

High st<strong>and</strong>ards: All windrowers are equipped<br />

as st<strong>and</strong>ard with a rotary agitator with intensity<br />

adjustment – ideal for heavy conditions.<br />

It held. And held. And held: Original Grimme<br />

overlapping technology on the web joiners. – For<br />

a long life of the main web.<br />

1<br />

2<br />

2<br />

The more intelligent give way: The spring loaded<br />

disc coulters can be very beneficial, especially<br />

in stony <strong>and</strong> heavy conditions. They adjust<br />

themselves to the respective soil conditions<br />

without altering the digging depth.<br />

No more blockages: The large haulm intake<br />

rollers (1) at the side minimize haulm blockages.<br />

Regardless of whether you have 2- or 3-piece<br />

shares (2) – both ensure an optimum crop<br />

intake.

Technical data<br />

Measurements<br />

Length<br />

Width<br />

Height<br />

Weight<br />

Tyres<br />

Drawbar<br />

Row width<br />

Intake<br />

Share depth<br />

control<br />

Main webs<br />

Agitator<br />

Separator<br />

Potato discharge<br />

<strong>GVR</strong> <strong>1700</strong> <strong>RL</strong> <strong>1700</strong><br />

3.80 m<br />

2.05 m<br />

1.20 m<br />

1,500 kg<br />

5.00-8<br />

Three-point hydraulic<br />

Category 2<br />

75– 90 cm<br />

4 disc coulters (spring loaded <strong>and</strong> pulled) with<br />

2 big haulm intake rollers at the side<br />

Shares: 2- or 3-pieces<br />

With diablo rollers<br />

1 st main web 1.64 m wide, 1.10 m long<br />

2 nd main web 1.64 m wide, 1.40 m long<br />

Driven rotary agitator in 2 nd main web<br />

Option: electrically adjustable agitator<br />

No haulm separation<br />

Centre discharge at the rear of the machine<br />

Option: hydraulically driven cross conveyor to one side<br />

With haulm cross conveyor: 5.60 m;<br />

With extended main web: 4.60 m<br />

2.28 m<br />

1.65 m<br />

With haulm web: 2,350 kg<br />

With extended main web: 2,100 kg<br />

10.0/75-15<br />

Three-point hydraulic<br />

Category 2<br />

75– 90 cm<br />

4 disc coulters (spring loaded <strong>and</strong> pulled) with<br />

2 big haulm intake rollers at the side<br />

Shares: 2- or 3-pieces<br />

With diablo rollers<br />

With haulm web: main web 1.64 m wide, 2.70 m long <strong>and</strong><br />

counter-rotating hedgehog web 1.64 m wide, 0.85 m long<br />

With extended main web: main web 1.64 m wide, 3.40 m long<br />

Driven rotary agitator in 1 st main web<br />

Option: electrically adjustable agitator<br />

Option: two rotary agitators in 1 st main web<br />

With haulm web: haulm discharge over extracting roller <strong>and</strong> counterrotating<br />

hedgehog web to the l/h-side of the discharged potatoes<br />

With extended main web: no haulm separation<br />

With haulm web: centre discharge at the rear of the machine<br />

in with soil scraper <strong>and</strong> pressure roller shaped beds<br />

With long main web: wide centre discharge at the rear<br />

of the machine<br />

Option: soil scraper <strong>and</strong> pressure roller for shaped beds<br />

Your Grimme Partner for advice <strong>and</strong> service:<br />

Grimme L<strong>and</strong>maschinenfabrik GmbH & Co. KG · Hunteburger Straße 32 · D-49401 Damme<br />

Phone +49 5491 666-0 · Fax +49 5491 666-298<br />

grimme@grimme.de · www.grimme.com<br />

We reserve the right of alterations. L05.0811.EN 10/08/2000