2CRBR000 - INSTALLATION

2CRBR000 - INSTALLATION

2CRBR000 - INSTALLATION

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

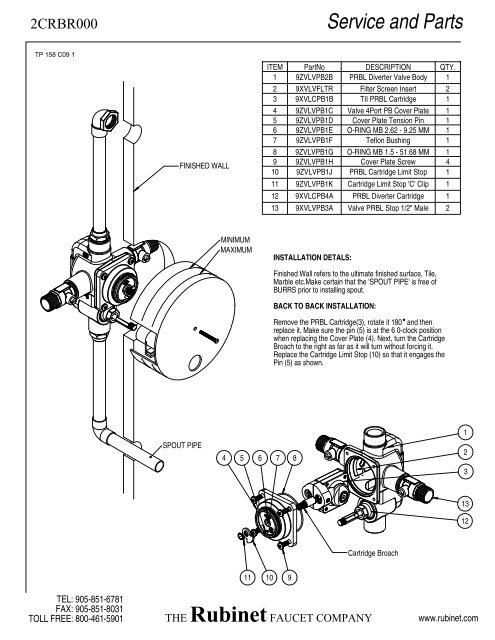

<strong>2CRBR000</strong><br />

Service and Parts<br />

TP 158 C09 1<br />

FINISHED WALL<br />

ITEM PartNo DESCRIPTION QTY.<br />

1 9ZVLVPB2B PRBL Diverter Valve Body 1<br />

2 9XVLVFLTR Filter Screen Insert 2<br />

3 9XVLCPB1B TII PRBL Cartridge 1<br />

4 9ZVLVPB1C Valve 4Port PB Cover Plate 1<br />

5 9ZVLVPB1D Cover Plate Tension Pin 1<br />

6 9ZVLVPB1E O-RING MB 2.62 - 9.25 MM 1<br />

7 9ZVLVPB1F Teflon Bushing 1<br />

8 9ZVLVPB1G O-RING MB 1.5 - 51.68 MM 1<br />

9 9ZVLVPB1H Cover Plate Screw 4<br />

10 9ZVLVPB1J PRBL Cartridge Limit Stop 1<br />

11 9ZVLVPB1K Cartridge Limit Stop 'C' Clip 1<br />

12 9XVLCPB4A PRBL Diverter Cartridge 1<br />

13 9XVLVPB3A Valve PRBL Stop 1/2" Male 2<br />

MINIMUM<br />

MAXIMUM<br />

<strong>INSTALLATION</strong> DETALS:<br />

Finished Wall refers to the ultimate finished surface, Tile,<br />

Marble etc.Make certain that the 'SPOUT PIPE' is free of<br />

BURRS prior to installing spout.<br />

BACK TO BACK <strong>INSTALLATION</strong>:<br />

Remove the PRBL Cartridge(3), rotate it 180 and then<br />

replace it. Make sure the pin (5) is at the 6 0-clock position<br />

when replacing the Cover Plate (4). Next, turn the Cartridge<br />

Broach to the right as far as it will turn without forcing it.<br />

Replace the Cartridge Limit Stop (10) so that it engages the<br />

Pin (5) as shown.<br />

1<br />

SPOUT PIPE<br />

4<br />

5 6 7<br />

8<br />

2<br />

3<br />

13<br />

12<br />

Cartridge Broach<br />

11<br />

10<br />

9<br />

TEL: 905-851-6781<br />

FAX: 905-851-8031<br />

TOLL FREE: 800-461-5901<br />

THE Rubinet<br />

FAUCET COMPANY<br />

www.rubinet.com

Filter Screen Removal and Cleaning<br />

PLEASE NOTE: SHUT OFF BOTH HOT AND COLD WATER SUPPLIES BEFORE SERVICING THE VALVE.<br />

The Pressure Balance valve contained in this kit has filter screens that prevent debris from obstructing the pressure balancing cartridge. If excessive in-line debris accumulates in the filter<br />

screen you will notice a decrease in flow from the valve.<br />

1<br />

The filter screens are attached to an insert<br />

that is fitted into the valve body inlets. With the<br />

cartridge removed the 2 inserts and filter<br />

screens can be easily removed from the valve<br />

body.<br />

3<br />

There is a place on either side of the filter insert<br />

where you can get your finger nail underneath<br />

the filter screen. By pulling the filter screen away<br />

from the insert it will “pop” out.<br />

All debris can now be easily removed from the<br />

filter screen. Replace the filter screen into the<br />

insert and push together gently until it clicks into<br />

place.<br />

2<br />

Remove the insert by pressing the top corner.<br />

This will rotate the insert allowing easy<br />

removal from the valve body.<br />

4<br />

Place the insert back into the valve body, making<br />

sure the angled edge of the insert faces out. Be<br />

careful that the O-Ring stays in place, applying a<br />

little grease (vaseline) will help. The insert<br />

should sit flush against the wall of the valve body<br />

when properly installed.<br />

TEL: 905-851-6781<br />

FAX: 905-851-8031<br />

TOLL FREE:800-461-5901 THE Rubinet FAUCET COMPANY www.rubinet.com<br />

TP 158 C09 1