Marking Technology Spezialmaschinenfabrik - Grün GmbH

Marking Technology Spezialmaschinenfabrik - Grün GmbH

Marking Technology Spezialmaschinenfabrik - Grün GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

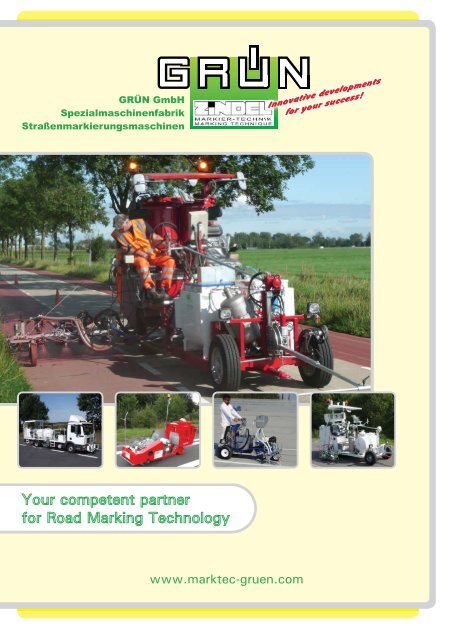

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

GRÜN <strong>GmbH</strong><br />

<strong>Spezialmaschinenfabrik</strong><br />

Straßenmarkierungsmaschinen<br />

<br />

www.marktec-gruen.com

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

Innovative systems and complete solutions for the<br />

production of high-quality markings<br />

Devices and machines for the spray application of HS-paint, watersoluble<br />

paint and cold spray plastic in AIRSPRAY- and in AIRLESSprocess.<br />

Hot spray application of thermoplastic.<br />

Devices and machines for thick-layer application of cold plastic and<br />

thermoplastic.<br />

Devices and machines for structure markings (defined or<br />

stochastic) / agglomerates made of cold plastic or thermoplastic.<br />

Complemental devices and products around marking:<br />

Milling machines for line removal Bead dispenser <strong>Marking</strong> material<br />

Road lane dryer<br />

Accessories<br />

2

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

Content<br />

1. Hand-guided devices for paint, cold spray plastic, cold plastic, Page 4 - 11<br />

thermoplastic and for the application of marking tape<br />

1.1 Air-Atomization technology (AIRSPRAY) for paint Page 4<br />

1.2 AIRLESS technology for paint and cold spray plastic Page 4 - 6<br />

1.3 Cold plastic application devices Page 7 - 8<br />

1.4 Thermoplastic application devices and pre-heaters Page 9 - 10<br />

1.5 Automatic Tape Applicator Page 11<br />

2. Self-propelled sit-on machines for paint, cold spray plastic 1:1/98:2, Page 12 - 18<br />

cold plastic 98:2 and thermoplastic<br />

2.1 Model range UNIZET Page 12<br />

2.2 Model range W 351 Page 13<br />

2.3 Model range COMBIZET Page 14<br />

2.4 Model range W 850 Page 15<br />

2.5 Model range GM-1000 Page 16<br />

2.6 Trucks and marking superstructures Page 17<br />

2.7 Machines with special equipment for airport- and bicycle lane marking Page 18<br />

3. Further tools, machines and accessories Page 19 - 22<br />

3.1 Machines for line removal Page 19 - 20<br />

3.2 Bead guns, bead dispensers Page 21<br />

3.3 Road lane dryer Page 21<br />

3.4 Accessories Page 22<br />

3.4.1 Pre-marking tools Page 22<br />

3.4.2 Spray guns Page 22<br />

3.4.3 <strong>Marking</strong> material Page 22<br />

3.5 Transport trailers Page 22<br />

4. Sales clerks Page 23<br />

Please note: This brochure shall give an overview on our wide product range. Please ask for detailed single<br />

brochures and quotations according to your requirements.<br />

The following table helps to find the suitable product:<br />

<strong>Marking</strong><br />

material<br />

City<br />

LineLazer<br />

LineLazer<br />

HS 130-2K<br />

HS 200-2K<br />

SmartLiner<br />

DUROZET<br />

5 / 11<br />

200<br />

DUROZET<br />

A50/150<br />

200<br />

WT 30 / WT 50<br />

THERMOLAZER<br />

Autom. Tape<br />

Applicator<br />

sit-on machines<br />

UNIZET/W 351/<br />

COMBIZET/W 850/<br />

GM-1000<br />

Tape<br />

<br />

HS-paint<br />

<br />

CSP 1:1/98:2<br />

<br />

CP 98:2<br />

Flat line <br />

CP 98:2<br />

Rib-line <br />

CP 98:2<br />

Structure <br />

Thermopl.<br />

Flat line <br />

Thermopl.<br />

Rib-line <br />

Thermopl.<br />

Structure <br />

Hot spray<br />

<br />

Page 4 4 – 6 6 7 - 8 7 - 8 9 11 12 – 16 17 - 18<br />

trucks<br />

3

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

1. Hand-guided devices for paint, cold spray plastic,<br />

cold plastic, thermoplastic and for the application<br />

of marking tape<br />

1.1 Air-atomization technology (AIRSPRAY) for paint<br />

Model range City<br />

Paint spraying devices of the model range City work according to the airatomization<br />

principle AIRSPRAY. They are suitable for application of<br />

high-solid marking paints on solvent or water base.<br />

Options as for example drive unit, hand spray gun and bead dispenser<br />

are available.<br />

Devices of the model range City are used with preference on<br />

car-parks, multi-storey car parks, at keep-out areas and for repair<br />

markings.<br />

City - 5<br />

_______________________________________________________________________________________<br />

1.2 AIRLESS – <strong>Technology</strong> (high-pressure spraying) for paint and<br />

cold spray plastic<br />

Model range LineLazer<br />

City - 100<br />

Paint spray devices of the model range LineLazer work with AIRLESS–<br />

technology (high-pressure-atomization-technique without air).<br />

In this case the paint is compressed in special pumps and sprayed by means<br />

of special AIRLESS – nozzles. The results are<br />

<br />

<br />

<br />

little overspray<br />

sharp-edged lines<br />

even paint distribution even at wide lines<br />

AIRLESS – technique is suitable especially for HS-paints on water base,<br />

because no hot compressor air for atomization is used. The spraying width can<br />

be adjusted very easily. Line widths up to 50 cm are possible with the wide line<br />

spraying unit (option)<br />

LineLazer IV 3900 G<br />

with 2 spray guns<br />

4

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

A wide model range with various equipment and pump capacity is<br />

available.<br />

For example, GRÜN offers the LineLazer IV 200 HS including compressor<br />

upgrade and optionally with bead gun, electronic skip-line control and hookup<br />

kit for spraying hardener/primer (“OnLine-System”).<br />

The wide range of accessories leaves nothing to be desired.<br />

LineLazer with<br />

AUTO-LAYOUT pre-marking system<br />

LineLazer IV 200 HS Kompressor<br />

with special equipment and upgraded for “OnLine-System”<br />

The LineDriver upgrades your LineLazer to a self-propelled sit-on machine.<br />

The units are connected by means of a ball valve coupling. Increased capacity<br />

and improved quality make the usage at big parking spaces, airports (taxi<br />

ways) and road construction sites profitable!<br />

Also available as LineDriver HD with centrifugal clutch.<br />

The LineDriver with compressor upgrading developed by GRÜN allows the<br />

operation of a skip-line control and a bead gun and turns each LineLazer to a<br />

fully fledged small marking machine.<br />

LineLazer with LineDriver<br />

5

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

LineLazer IV 250sps – self-propelled<br />

airless marking device with standing platform in the rear.<br />

<br />

<br />

<br />

<br />

<br />

<br />

hydrostatic drive<br />

foldable standing platform in the rear<br />

hydraulic pump drive, pump capacity max. 9.5 l/min.<br />

big material tank, capacity 95 litres<br />

automatic skip-line control<br />

Auto-Layout System<br />

LineLazer HS 130-2K, LineLazer HS 200-2K<br />

Hand-pushed devices for the application of<br />

2-component cold spray plastic with mixing ratio 1:1.<br />

<br />

<br />

<br />

<br />

<br />

powerful, hydraulically driven GRACO airless pumps,<br />

capacity each pump max. ca. 7.5 l/min.<br />

good line quality, little overspray<br />

no flushing procedure necessary because of<br />

external mixing<br />

easy to transport, immediately ready for use<br />

hand spray gun and bead dispensing unit are available<br />

as option<br />

SmartLiner<br />

Professional airless marking machine for processing airless paint and<br />

2-component cold spray plastic, mixing ratio 1:1,<br />

with internal mixing.<br />

<br />

<br />

<br />

<br />

hydrostatic drive unit<br />

powerful, hydraulically driven GRACO airless pumps<br />

internal mixing 1:1, flushing system via pressured<br />

solvent tank<br />

powerful compressor, for connection of pneumatic<br />

operated bead gun and electronic skip-line control<br />

6

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

1.3 Cold plastic application devices<br />

Model range DUROZET<br />

DUROZET – 5 G<br />

DUROZET – 11 GPP<br />

DUROZET – A50<br />

The DUROZET model range allows efficient processing of cold<br />

plastic (CP).<br />

DUROZET – 5 G for flat lines up to 3 mm coating thickness.<br />

Standard line width 10 – 30 cm resp. up to 50 cm as option.<br />

DUROZET – 5 G<br />

DUROZET – 11 GPP for flat lines and profile markings.<br />

The device is equipped serially with a roller bead dispenser<br />

with electrically driven accelerator roller.<br />

Standard line width 10 – 30 cm.<br />

Special widths on request.<br />

DUROZET - 11 GPP<br />

The DUROZET – A50 is a device for producing structure<br />

markings (agglomerates) up to 50 cm width. The sophisticated<br />

design with battery driven structure roller and laterally<br />

positioned application unit allows e.g. near-edge marking or<br />

the production of angle keep-out areas in one go.<br />

DUROZET - A 50<br />

7

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

DUROZET – 150<br />

DUROZET – 200<br />

The DUROZET-150 allows to apply open structure markings<br />

(agglomerates) up to 50 cm line width.<br />

The device is as standard equipped with drive unit and bead<br />

roller dispenser.<br />

DUROZET – 150<br />

The DUROZET-200 is, depending on the equipment, suitable for<br />

the application of flat lines, rib-lines and open structure<br />

markings (agglomerates).<br />

The standard configuration includes already gasoline engine,<br />

compressor, hydraulic drive, cold plastic material tank<br />

(capacity ca. 30 litres), hardener tank and mixing unit. In<br />

addition, one screed box for flat lines 12 cm as well as a bead<br />

gun for a spreading with up to 30 cm is included in the scope<br />

of supply.<br />

Available as option:<br />

Screed boxes for flat lines, structure markings* and rib-lines*<br />

for line widths 12 cm, 15 cm, 25 cm, 30 cm,<br />

electronic skip-line control, upgrading kits for structure<br />

markings resp. rib-lines<br />

(* use in combination with the appropriate upgrading kits for<br />

structure markings and rib-lines)<br />

DUROZET - 200<br />

8

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

1.4 Thermoplastic application devices and pre-heaters<br />

THERMOLINER WT 30 / WT 50<br />

THERMOLAZER/THERMOLAZER PROMELT<br />

The Thermoliner WT 30 is the useful hand device for small<br />

construction sites. The special screed box, equipped with<br />

radiant heater and hard-metal gliding skids, is available for<br />

line widths 10 – 30 cm.<br />

Delivery including hand torch, hose and gas pressure<br />

regulator.<br />

Optionally, the device is available as version WT 30-EP<br />

with bead tank and path-dependent roller bead dispenser<br />

with electrically driven accelerator roller.<br />

Spreading width: 10 – 15 cm and 20 – 30 cm.<br />

The Thermoliner WT 50 allows the application of<br />

50 cm wide lines.<br />

WT 30<br />

The THERMOLAZER impresses with user-friendly<br />

performance, big tank capacity and innovative SmartDiescreed<br />

box technology.<br />

Those who want to avoid the use of a separate pre-heater<br />

should decide for the THERMOLAZER PROMELT. The<br />

economic ProMelt-system allows to melt the thermoplastic<br />

directly in the application device.<br />

The infrared heated SmartDie-screed boxes are available<br />

for line widths 10 - 30 cm and also for double lines.<br />

A bead dispensing unit for single lines is delivered serially<br />

with the machine, bead dispensers for double lines are<br />

available as accessories.<br />

The THERMOLAZER and THERMOLAZER PROMELT can<br />

be combined with the drive unit LineDriver.<br />

WT 30-EP<br />

THERMOLAZER with LineDriver<br />

THERMOLAZER PROMELT<br />

9

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

Thermoplastic pre-heaters<br />

Hand torches<br />

GRÜN offers a wide range of various thermoplastic pre-heaters.<br />

The experience gained over decades in the production of boilers<br />

for different materials from bitumen up to mastic asphalt has<br />

been used for the construction and production of the<br />

thermoplastic pre-heaters.<br />

The range:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

"vertical" boilers up to 800 litres<br />

"horizontal" boilers up to 2,400 litres, also bigger on<br />

request<br />

direct or indirect heating; a special heating technology<br />

allows a quasi-direct gentle heating without thermal oil<br />

optionally propane gas- or diesel oil heating<br />

high heating efficiency by optimized heating chambers<br />

fully automatic temperature control<br />

stationary versions for installation on carrier vehicles or<br />

completely mounted on high-speed trailer chassis;<br />

double boilers for especially effective operation<br />

RTK 800 stationary<br />

At each thermoplastic construction site<br />

a hand torch has to be available. GRÜN<br />

offers a wide range of these products, too.<br />

RK 550 on high-speed trailer chassis<br />

RTDK 1000 stationary<br />

TKO 2 x 1200<br />

10

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

1.5 Automatic Tape Applicator FVM 700G / ATA<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

fully hydraulic machine<br />

integrated hydraulic tape pressing device for one-man-operation according to<br />

3M-specification<br />

cutter with automatic trigger, skip line control by PLC<br />

hydraulically operated lifting device for turning the machine<br />

mechanic steering unit for small application radius<br />

near-edge application<br />

optimised ergonomics<br />

optionally: video-monitor-aiming system<br />

optionally: application data registration (temperature/dampness, location, applied quantity)<br />

and transfer to <strong>Grün</strong>-Data Server (subject to the availability of appropriate networks)<br />

Our solution for safe loading and transportation of the<br />

Automatic Tape Applicator:<br />

special transport trailer with lowerable platform<br />

11

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

Self-propelled sit-on machines for paint, cold spray plastic<br />

1:1 / 98:2, cold plastic 98:2 and thermoplastic<br />

2.1 Model range UNIZET<br />

The UNIZET is the compact, manoeuvrable and high-performance<br />

universal machine.<br />

The separable machine frame allows a field-tested quick<br />

change of the application aggregate. The machine can be<br />

equipped with all common application techniques.<br />

hydrostatic drive on both rear wheels with continuous speed<br />

control<br />

powerful wheel rotor motors for steep inclines and high<br />

constant load<br />

turbo diesel engine with electronic control for optimized<br />

engine operation at all load conditions; on request available<br />

with particulate filter<br />

UNIZET with paint spray technique<br />

rotary compressor with high air flow and low noise and<br />

vibration<br />

well-dimensioned cooler for reliable operation also at<br />

extreme conditions of temperature and load<br />

mechanical precision steering<br />

UNIZET with cold plastic technique<br />

UNIZET with cold plastic technique<br />

UNIZET with airless technique<br />

12

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

2.2 Model range W 351<br />

The model range W 351 convinces by strong diesel engines,<br />

compressors with high air capacity and generously<br />

dimensioned material tanks at compact design and high<br />

efficiency.<br />

The proven design with the separable machine frame allows<br />

also for the W 351 the quick change of the application<br />

technique and the competitive use of several application<br />

modules with one drive module.<br />

The machine can of course be equipped with all common<br />

application techniques.<br />

13

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

2.3 Model range COMBIZET<br />

The COMBIZET is the machine for daily usage on all kinds of<br />

construction sites. Its dimension combines high-performance<br />

with flexibility.<br />

By means of interchangeable aggregate pallets available as<br />

<br />

<br />

<br />

<br />

paint machine with atomizing air- or airless<br />

spray technology<br />

paint and cold spray plastic machine with 1:1- or<br />

98:2-system and airless spray technology<br />

cold plastic application machine with closed<br />

98:2 – system<br />

thermoplastic application machine with screed box or<br />

extruder, WHSS-System for structure markings<br />

or with hot spray technology<br />

COMBIZET – 3S with airless technique 1:1<br />

GRÜN offers a practice-related, economic solution with the idea<br />

to equip basic machines with interchangeable pallets. The<br />

COMBIZET can carry different marking technologies. The<br />

particular aggregates are mounted on quick-exchange-palettes.<br />

The conversion (changing from one pallet to another) requires<br />

only short time. All necessary energy supplies as hydraulics,<br />

pneumatics and electrics are connected via quick hitches.<br />

Advantages:<br />

When buying a machine you do not determine one<br />

application technique in every case. By means of buying an<br />

interchangeable palette for conversion (later) you are<br />

competitive at any time with low investments.<br />

A basic machine with several interchangeable palettes saves<br />

money.<br />

COMBIZET – 2 with 1-component airless technique<br />

COMBIZET – 2 with hot spray technique<br />

COMBIZET – 2 with thermoplastic technique<br />

14

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

2.4 Model range W 850<br />

The model W 850 is the perfect choice, also for big marking<br />

jobs. The machine offers large tank capacity and is of course<br />

equipped with generously dimensioned drive power.<br />

Naturally, the W 850 can also be equipped with all common<br />

application techniques.<br />

WKP 850 with cold plastic technique<br />

WP 850 with paint spray technique<br />

WTE 850 with thermoplastic technique with extruder<br />

WKSP 850 with cold spray plastic technique<br />

15

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

2.5 Model range GM-1000<br />

Universell<br />

The GM-1000<br />

einsetzbare<br />

is the modern, high-performance marking<br />

Markierungsmaschine, machine also for large marking jobs durch on highways or airports.<br />

The big tank capacities enable high application performance.<br />

Wechselpalettentechnik ausrüstbar mit allen<br />

gängigen On the robust Markierungssystemen<br />

machine chassis all established marking<br />

techniques can be mounted, like<br />

<br />

<br />

<br />

<br />

<br />

paint spray technique<br />

1- or 2- component airless technique<br />

cold plastic technique<br />

hot spray technique<br />

thermoplastic technique, also with extruder unit.<br />

Besides, the GM-1000 can also be delivered with combined<br />

aggregates, e.g. thermoplastic/airless or hot spray/<br />

thermoplastic.<br />

GM-1000 Airless<br />

GM-1000 Thermo<br />

GM-1000 Thermo/Airless<br />

16

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

2.6 Truck machines and marking superstructures<br />

Model range UNI<br />

Under the model name UNI GRÜN delivers all marking technologies<br />

on MERCEDES-BENZ trucks or on the vehicle you desire. Also so<br />

called communal vehicles (MULTI-CAR, X-Series and others) are<br />

suitable as carrier vehicle.<br />

Here also applies:<br />

Superstructures for all marking systems are available.<br />

Furthermore we equip and/or modify marking machines of all<br />

manufacturers – used or new - with our systems.<br />

We produce complete superstructures with power station for selfinstallation<br />

on available carrier vehicles according to your individual<br />

requirements.<br />

A particularly attractive version is the<br />

RoadLazer<br />

Three pumps allow a high application capacity or the (simultaneous)<br />

processing of three colours!<br />

The equipment can easily be installed on nearly every loading<br />

platform, e.g. on pick-ups, small lorries or big trucks and converts<br />

every suitable vehicle to a marking machine.<br />

17

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

2.7 Machines with special equipment for airport- and<br />

bicycle lane marking<br />

ll<br />

The competent team of GRÜN develops individual, customized<br />

machine solutions, based on the wide range of proven machine<br />

models and application techniques.<br />

Special requirements on the machine equipment do e.g. apply<br />

for professional marking jobs on airports or bicycle lanes.<br />

Usual features of such machines are e.g. several material tanks<br />

and/or paint pumps for the simultaneous application of several<br />

colours (e.g. for taxi ways), as well as special marking units for<br />

extremely wide lines up to 160 cm or more.<br />

18

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

3. Further tools, machines and accessories<br />

3.1 Machines for line removal<br />

Model range LineEx<br />

For professional line removal GRÜN offers currently 5 models within<br />

the LineEx range:<br />

LineEx 10:<br />

Floor Grinder, working width 290 mm, with electric motor<br />

LineEx 15:<br />

Milling machine, working width up to 200 mm,<br />

with gasoline engine<br />

<br />

LineEx 20 – Diamond:<br />

Milling machine with gasoline engine and electric feeder, working<br />

width up to 200 mm, with diamond tool or standard milling tool<br />

LineEx 30:<br />

Milling machine, working width up to 340 mm, with gasoline<br />

engine<br />

<br />

LineEx EP:<br />

Shotblaster, working width 200 mm, with electric motor<br />

The machines are designed for economic operation, gentle to the<br />

surface, and are suitable for removing paint, cold spray plastic, cold<br />

plastic and thermoplastic – depending on the tool configuration.<br />

LineEx 20 – Diamond<br />

LineEx 10<br />

LineEx 15<br />

LineEx EP<br />

LineEx 30<br />

19

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

Model range GrindLazer<br />

For professional line removal GRÜN offers currently three<br />

milling machines within the GRACO GrindLazer range:<br />

GrindLazer 270<br />

GrindLazer 390<br />

GrindLazer 480<br />

Line Removing Machine GRACO GRINDLAZER TM 270<br />

Typical Applications:<br />

max. working width:<br />

Traffic paint removal<br />

Thermoplastic removal<br />

Smoothing uneven surfaces<br />

20.5 cm<br />

average removal rate<br />

at ca. 3 mm milling depth: ca. 55 m²/h (hand-guided)<br />

ca. 120 m²/h (with LineDriver)<br />

Line Removing Machine GRACO GRINDLAZER TM 390<br />

Typical Applications:<br />

max. working width:<br />

Traffic paint removal<br />

Thermoplastic removal<br />

Epoxy coating removal<br />

Smoothing uneven surfaces<br />

25.5 cm<br />

GRINDLAZER 270<br />

GRINDLAZER 390<br />

average removal rate<br />

at ca. 3 mm milling depth: ca. 75 m²/h (hand-guided)<br />

ca. 160 m²/h (with LineDriver)<br />

Line Removing Machine GRACO GRINDLAZER TM 480<br />

Typical Applications:<br />

max. working width:<br />

Traffic paint removal<br />

Thermoplastic removal<br />

Epoxy coating removal<br />

Smoothing uneven surfaces<br />

Inlay<br />

Grooving<br />

25.5 cm<br />

average removal rate<br />

at ca. 3 mm milling depth: ca. 195 m²/h<br />

GRINDLAZER 480<br />

The GrindLazer 480 with Reverse/ “Up-Cut” cutting direction<br />

requires the use of a LineDriver drive unit!<br />

20

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

3.2 Bead guns, bead dispensers<br />

Different application systems for reflective beads are available:<br />

<br />

<br />

<br />

<br />

<br />

Hand bead dispenser<br />

pneumatic bead guns, as hand gun or for installation on machines<br />

Bead roller dispenser for installation on marking machines, including accelerator roller and metering roller;<br />

for constant or path-dependent application of drop-on material; mechanically driven via ground wheel or with<br />

electric drive. The delivery rate of the dispenser can be adjusted.<br />

Bead dispensing trolley without metering roller<br />

Bead dispensing trolley with metering roller and electrically driven accelerator roller<br />

3.3 Road lane dryer<br />

The powerful road lane dryer GST is ideally suitable for all<br />

drying jobs around road marking.<br />

Furthermore the removal of marking tapes is much easier<br />

and faster after warming up the tapes with the road lane dryer<br />

GST with especially extended burner head.<br />

The road lane dryer GST, equipped with the appropriate addon<br />

kit, can be combined with the drive unit LineDriver and<br />

thus allows comfortable operation while seating.<br />

road lane dryer GST with LineDriver<br />

21

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

3.4 Accessories<br />

3.4.1 Pre-marking tools<br />

Pre-marking units for marking machines<br />

Pre-marking rope<br />

Pre-marking paint<br />

3.4.2 Spray guns<br />

Hand spray guns<br />

Mixing heads<br />

Automatic guns<br />

3.4.3 <strong>Marking</strong> material<br />

High-Solid paint<br />

Cold plastic material<br />

2-component cold spray plastic<br />

Thermoplastic<br />

Reflective beads<br />

GRÜN offers a wide range of tools and accessories for road marking. Please ask for detailed quotations!<br />

3.5 Transport trailers<br />

GRÜN delivers various trailer models, according to your individual requirements. Please ask for detailed quotations!<br />

22

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

4. Sales clerks:<br />

4.1 Sales clerks office<br />

Mr. Tessfom Zemichael<br />

Phone: +49 (0)271/3988-156<br />

Fax: +49 (0)271/3988-159<br />

+49 (0)271/3988-26156<br />

E-mail:<br />

t.zemichael@gruen-gmbh.de<br />

Homepage: www.marktec-gruen.com<br />

Mrs. Melanie Stahl<br />

Phone: +49 (0)271/3988-101<br />

Fax: +49 (0)271/3988-159<br />

+49 (0)271/3988-26101<br />

E-mail:<br />

m.stahl@gruen-gmbh.de<br />

Homepage: www.marktec-gruen.com<br />

4.2 Field service<br />

Mr. Frank Lohse<br />

Mobile: +49 (0)170/8689999<br />

Phone: +49 (0)271/3988-156<br />

Fax: +49 (0)271/3988-159<br />

E-mail:<br />

f.lohse@gruen-gmbh.de<br />

Homepage: www.marktec-gruen.com<br />

23

<strong>Marking</strong> <strong>Technology</strong><br />

<br />

< Dortmund<br />

Siegen<br />

A45<br />

Wilnsdorf-<br />

Niederdielfen<br />

Anschlussstelle<br />

Wilnsdorf<br />

L723<br />

<br />

<br />

<strong>Spezialmaschinenfabrik</strong> Straßenmarkierungsmaschinen<br />

Siegener Straße 81-83<br />

57234 Wilnsdorf / GERMANY<br />

Phone +49 (0) 2 71 39 88 - 0<br />

Fax +49 (0) 2 71 39 88 - 1 59<br />

E-mail: info@marktec-gruen.com<br />

www.marktec-gruen.com