? Save Energy for the Benefit of Self and Nation ? - Gujarat Electricity ...

? Save Energy for the Benefit of Self and Nation ? - Gujarat Electricity ...

? Save Energy for the Benefit of Self and Nation ? - Gujarat Electricity ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

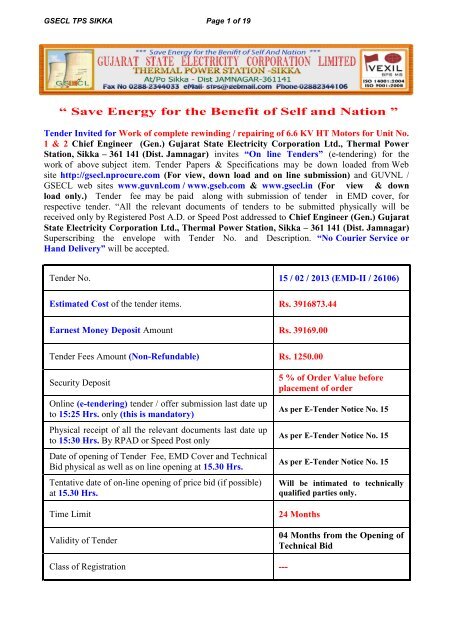

GSECL TPS SIKKA Page 1 <strong>of</strong> 19<br />

“ <strong>Save</strong> <strong>Energy</strong> <strong>for</strong> <strong>the</strong> <strong>Benefit</strong> <strong>of</strong> <strong>Self</strong> <strong>and</strong> <strong>Nation</strong> ”<br />

Tender Invited <strong>for</strong> Work <strong>of</strong> complete rewinding / repairing <strong>of</strong> 6.6 KV HT Motors <strong>for</strong> Unit No.<br />

1 & 2 Chief Engineer (Gen.) <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd., Thermal Power<br />

Station, Sikka – 361 141 (Dist. Jamnagar) invites “On line Tenders” (e-tendering) <strong>for</strong> <strong>the</strong><br />

work <strong>of</strong> above subject item. Tender Papers & Specifications may be down loaded from Web<br />

site http://gsecl.nprocure.com (For view, down load <strong>and</strong> on line submission) <strong>and</strong> GUVNL /<br />

GSECL web sites www.guvnl.com / www.gseb.com & www.gsecl.in (For view & down<br />

load only.) Tender fee may be paid along with submission <strong>of</strong> tender in EMD cover, <strong>for</strong><br />

respective tender. “All <strong>the</strong> relevant documents <strong>of</strong> tenders to be submitted physically will be<br />

received only by Registered Post A.D. or Speed Post addressed to Chief Engineer (Gen.) <strong>Gujarat</strong><br />

State <strong>Electricity</strong> Corporation Ltd., Thermal Power Station, Sikka – 361 141 (Dist. Jamnagar)<br />

Superscribing <strong>the</strong> envelope with Tender No. <strong>and</strong> Description. “No Courier Service or<br />

H<strong>and</strong> Delivery” will be accepted.<br />

Tender No. 15 / 02 / 2013 (EMD-II / 26106)<br />

Estimated Cost <strong>of</strong> <strong>the</strong> tender items. Rs. 3916873.44<br />

Earnest Money Deposit Amount Rs. 39169.00<br />

Tender Fees Amount (Non-Refundable) Rs. 1250.00<br />

Security Deposit<br />

Online (e-tendering) tender / <strong>of</strong>fer submission last date up<br />

to 15:25 Hrs. only (this is m<strong>and</strong>atory)<br />

Physical receipt <strong>of</strong> all <strong>the</strong> relevant documents last date up<br />

to 15:30 Hrs. By RPAD or Speed Post only<br />

Date <strong>of</strong> opening <strong>of</strong> Tender Fee, EMD Cover <strong>and</strong> Technical<br />

Bid physical as well as on line opening at 15.30 Hrs.<br />

Tentative date <strong>of</strong> on-line opening <strong>of</strong> price bid (if possible)<br />

at 15.30 Hrs.<br />

Time Limit<br />

Validity <strong>of</strong> Tender<br />

5 % <strong>of</strong> Order Value be<strong>for</strong>e<br />

placement <strong>of</strong> order<br />

As per E-Tender Notice No. 15<br />

As per E-Tender Notice No. 15<br />

As per E-Tender Notice No. 15<br />

Will be intimated to technically<br />

qualified parties only.<br />

24 Months<br />

04 Months from <strong>the</strong> Opening <strong>of</strong><br />

Technical Bid<br />

Class <strong>of</strong> Registration ---

GSECL TPS SIKKA Page 2 <strong>of</strong> 19<br />

01. All <strong>the</strong> relevant documents as per requirement <strong>of</strong> <strong>the</strong> Tender must also be submitted<br />

physically along with <strong>the</strong> Tender Fee in EMD sealed cover so that <strong>the</strong> same is received in<br />

this <strong>of</strong>fice on OR be<strong>for</strong>e <strong>the</strong> due date <strong>and</strong> time. All such documents should be<br />

strictly submitted by RPAD / speed post only. O<strong>the</strong>rwise <strong>the</strong> <strong>of</strong>fer will not be<br />

considered <strong>and</strong> no any fur<strong>the</strong>r communication in <strong>the</strong> matter will be entertained.<br />

02. Any deviation found in Data / Details / Documents between on line <strong>of</strong>fer (etendering)<br />

<strong>and</strong> physically submitted documents (Tender document fee, bidder, <strong>of</strong>fer<br />

<strong>of</strong> <strong>the</strong> same bidder) will not be considered <strong>and</strong> no any fur<strong>the</strong>r communication<br />

in <strong>the</strong> matter will be entertained.<br />

Fur<strong>the</strong>r bidders are requested to submit price – bid (Schedule-B) on-line only <strong>and</strong> not to<br />

submit <strong>the</strong> price bid in physical <strong>for</strong>m. This is m<strong>and</strong>atory. If price bid is submitted in<br />

physical <strong>for</strong>m, same will not be opened <strong>and</strong> only on-line submitted price bid will be<br />

considered <strong>for</strong> evaluation. Fur<strong>the</strong>r if <strong>the</strong> quantity quoted differs in <strong>the</strong> any <strong>of</strong> <strong>the</strong> technical<br />

bid <strong>for</strong>ms <strong>and</strong> in price bid <strong>for</strong>ms, it is at <strong>the</strong> discretion <strong>of</strong> CE Committee / ED Committee –<br />

GSECL to consider <strong>the</strong> quoted quantity.<br />

03. It is m<strong>and</strong>atory <strong>for</strong> all <strong>the</strong> bidders to submit <strong>the</strong>ir tender documents by both <strong>for</strong>ms viz. on –<br />

line (e-tendering) <strong>and</strong> physically in schedule time. Tender documents submitted in only any<br />

one, say ei<strong>the</strong>r by on line or physically, in that case <strong>the</strong> same tender will not be considered.<br />

04. Any technical questions, in<strong>for</strong>mation <strong>and</strong> clarifications that may be required pertaining to<br />

this enquiry should be referred to <strong>the</strong> Chief Engineer (Gen.) <strong>Gujarat</strong> State<br />

<strong>Electricity</strong> Corporation Ltd., Thermal Power Station, Sikka – 361 141 (Dist.<br />

Jamnagar).<br />

GSECL reserve <strong>the</strong> rights to accept / reject any or all tenders without assigning any reasons<br />

<strong>the</strong>re<strong>of</strong>.<br />

Signature <strong>of</strong> Contractor with Place /<br />

Date / Firm Seal / Stamp<br />

For, <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd.<br />

Sd/-<br />

Chief Engineer<br />

Thermal Power Station, Sikka.

GSECL TPS SIKKA Page 3 <strong>of</strong> 19<br />

DETAILS OF BIDDER<br />

01. Name <strong>of</strong> Firm & Contact Person<br />

02. Full Postal Address<br />

Phone/Fax No.<br />

Mobile No.<br />

E-mail Address :<br />

03. GST / CST / ECC / TIN No.<br />

04. Status <strong>of</strong> <strong>the</strong> firm with supporting documents Proprietary / Partnership / Pvt. / Public<br />

Limited.<br />

05. Name <strong>of</strong> Agencies / Directors if not prop. Name<br />

<strong>of</strong> owner, if propriety, with phone / Fax Nos.<br />

06. Registration certificate No. with GSECL<br />

07. SSI No. ( Enclose copy)<br />

08. Labour License No.<br />

09. P.F. A/C. Code No.<br />

10. Service Tax No.<br />

11. PAN No.<br />

12. Latest bank solvency certificate at least 20 % <strong>of</strong><br />

estimated cost (Not more than One year old)<br />

13. Tender fee Amount DD No. & Date<br />

14. EMD Amount DD No. & Date<br />

IMPORTANT NOTE<br />

01. This tender should be submitted duly signed without removing a single page. O<strong>the</strong>rwise<br />

<strong>the</strong> tender is liable to be rejected.<br />

02. For SUPPLY TENDER, TIN number should be invariable mentioned in <strong>the</strong>ir technical bid<br />

o<strong>the</strong>rwise your <strong>of</strong>fer will be ignored <strong>and</strong> price bid will not be opened.<br />

Signature <strong>of</strong> Contractor with Place /<br />

Date / Firm Seal / Stamp<br />

For, <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd.<br />

Sd/-<br />

Chief Engineer<br />

Thermal Power Station, Sikka.

GSECL TPS SIKKA Page 4 <strong>of</strong> 19<br />

E - TENDER GENERAL TERMS & CONDITIONS<br />

01. Tender Fee & Earnest Money Deposit - will be accepted by D.D. in favour <strong>of</strong> <strong>Gujarat</strong> State<br />

<strong>Electricity</strong> Corp. Ltd., payable at State Bank <strong>of</strong> India, Sikka TPS Branch only (Branch Code No.<br />

60417). Cheque are not accepted & Tenders submitted without tender fee / EMD will not<br />

be accepted.<br />

02. Tender “Technical Bid” Cover Packing & EMD + Tender Fee…<br />

Earnest Money Deposit is to be paid as per Tender Advertisement.<br />

Subject & Tender Notice No. & Item No. Clearly written on all covers.<br />

(01) EMD + Tender Fee DD Cover<br />

(02) Technical Bid Cover<br />

Also clearly mention on <strong>the</strong> covers. DD <strong>for</strong> payment <strong>of</strong> EMD & Tender Fee Dem<strong>and</strong> Draft must<br />

be placed in <strong>the</strong> cover super scribing “EMD & Tender Fee” along with requisite documents as<br />

mentioned in <strong>the</strong> Condition. EMD + Tender Fee both should be kept in one separate cover &<br />

should be submitted with Technical Bid Covers.<br />

The Tender documents are to be submitted in namely Technical Bid with all enclosures <strong>of</strong> <strong>the</strong><br />

tender documents respective covers accordingly along with <strong>the</strong> tender number.<br />

03. Technical Bid : The technical bid shall comprise <strong>of</strong> all <strong>the</strong> technical details <strong>of</strong> <strong>the</strong> stores /<br />

materials <strong>of</strong>fered in accordance with <strong>the</strong> Corporation guaranteed technical particulars <strong>and</strong><br />

conditions, etc.<br />

The Technical Bid shall be opened at 15.30 Hrs. on Due Date (If Possible), in <strong>the</strong> presence <strong>of</strong><br />

those tenderers who wish to be present. If <strong>the</strong> Authorized Representative is likely to be<br />

present <strong>the</strong>n he must submit <strong>the</strong> authorization letter <strong>of</strong> <strong>the</strong> representing company at <strong>the</strong><br />

time <strong>of</strong> opening <strong>of</strong> Bids <strong>and</strong> this is compulsory. Only One authorized Representative shall<br />

be allowed.<br />

Please note that <strong>the</strong> required documents should be invariably submitted with tender copy. And<br />

tender without documents is liable to be ignored.<br />

04. Price Bid : Bidders are requested to submit Price Bid (Schedule-B) on-line only <strong>and</strong> not to<br />

submit <strong>the</strong> price bid in physical <strong>for</strong>m. This is m<strong>and</strong>atory. If price bid is submitted in physical<br />

<strong>for</strong>m, same will not be opened <strong>and</strong> only on-line submitted price bid will be considered <strong>for</strong><br />

evaluation. Fur<strong>the</strong>r if <strong>the</strong> quantity quoted differs in <strong>the</strong> any <strong>of</strong> <strong>the</strong> technical bid <strong>for</strong>ms <strong>and</strong> in<br />

price bid <strong>for</strong>ms, it is discretion <strong>of</strong> Committee – GSECL to consider <strong>the</strong> quoted quantity.<br />

Any technical questions in<strong>for</strong>mation <strong>and</strong> clarifications that may be required pertaining to this<br />

Tender should be referred to The Chief Engineer, GSECL, TPS, Sikka, who also reserves <strong>the</strong><br />

right to reject any OR all tenders without assigning any reasons <strong>the</strong>re<strong>of</strong>.<br />

05. Experience <strong>of</strong> Criteria Condition <strong>for</strong> Pre-qualification in Technical Bid… (Civil Works)<br />

The bidder should produce evidence <strong>of</strong> having experience <strong>of</strong> execution <strong>of</strong> similar nature <strong>of</strong><br />

works <strong>for</strong> Rehabilitation work <strong>of</strong> high rise structures in Government / Semi Government /<br />

GSECL / State / Central / Railway with <strong>the</strong> documentary evidence, preferably certified copy <strong>of</strong><br />

work order <strong>and</strong> satisfactorily work completion certificate from respective department <strong>the</strong>re<strong>of</strong>.<br />

06. “Technical Bid” duly filled must be accompanied by <strong>the</strong> following documents….<br />

The reputed contractors with sound engineering back ground, experience <strong>and</strong> financial<br />

capability, fulfilling qualifying requirement stated hereunder at Sikka TPS, <strong>Gujarat</strong>.<br />

(a) Registration <strong>of</strong> appropriate class with State / Central Government / Railway / <strong>Electricity</strong><br />

Board etc. (<strong>for</strong> Civil Works)<br />

(b) Experience certificate <strong>for</strong> execution <strong>of</strong> similar works <strong>of</strong> <strong>the</strong> magnitude (as specified in<br />

Special Note <strong>for</strong> Pre qualification) successfully completed by <strong>the</strong> contractor.<br />

(c) Solvency Certificate <strong>for</strong> 20 % value <strong>of</strong> <strong>the</strong> estimated cost <strong>of</strong> any <strong>Nation</strong>alized Bank.

GSECL TPS SIKKA Page 5 <strong>of</strong> 19<br />

(d) Certificate <strong>of</strong> separate provident fund account number. (For Works)<br />

(e) Details <strong>of</strong> Tools, tackles, equipments <strong>and</strong> personals available with firm.<br />

(f) Tenderer should down load <strong>the</strong> tender documents from <strong>the</strong> above Website <strong>and</strong> submit<br />

<strong>the</strong> same as per instruction <strong>the</strong>rein by RPAD / Speed Post only.<br />

(g) The tenders duly filled in sealed covers will be received by RPAD / Speed Post at “The<br />

Chief Engineer, <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation, Thermal Power Station, Sikka –<br />

361 141, Dist. Jamnagar” Up to 15.30 hrs. on last date <strong>of</strong> submission <strong>and</strong> will be<br />

opened at 15.30 hrs. on <strong>the</strong> scheduled date (if possible) in <strong>the</strong> presence <strong>of</strong> bidders who<br />

wish to remain present.<br />

(h) Tender Fee <strong>and</strong> EMD will be accepted by DD only in favour <strong>of</strong> GSECL payable at<br />

Sikka TPS. No cheques or FDR will be accepted. Tenders received without EMD &<br />

Tender Fee are liable <strong>for</strong> rejection.<br />

(i) Tenderer should quote <strong>the</strong> reference <strong>of</strong> payment <strong>of</strong> EMD & Tender Fee i.e. DD No. &<br />

Date <strong>for</strong> EMD - DD No. & Date <strong>for</strong> Tender Fee on cover page <strong>of</strong> Technical Bid<br />

o<strong>the</strong>rwise Bid will not be considered <strong>for</strong> opening. Tenderer should also certify as<br />

“unconditional tender” on tender cover it self.<br />

(j) <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation, reserves <strong>the</strong> right to accept or to reject any or all<br />

<strong>the</strong> tender without assigning any reasons <strong>the</strong>re<strong>of</strong>.<br />

(k) Contractor shall have to submit <strong>the</strong> attested copy <strong>of</strong> EPF Code No. Certificate received<br />

from RPFC without fail o<strong>the</strong>rwise tender will not be opened.<br />

07. O<strong>the</strong>r Condition….<br />

(a) The detailed description <strong>and</strong> full particulars will be available in <strong>the</strong> Tender Copy (Non<br />

transferable)<br />

(b) EMD at 1 % <strong>of</strong> <strong>the</strong> estimated cost is to be paid by D.D. in favour <strong>of</strong> <strong>Gujarat</strong> State <strong>Electricity</strong><br />

Corporation Ltd. payable at State Bank <strong>of</strong> India, Sikka. Tenders without EMD are liable <strong>for</strong><br />

rejection. The SSI / NSIC will be accepted <strong>for</strong> exemption <strong>of</strong> EMD <strong>for</strong> supply <strong>of</strong> subjected<br />

material only, o<strong>the</strong>rwise tender / <strong>of</strong>fer will be ignored. The Xerox copy submitted <strong>for</strong> SSI /<br />

NSIC shall be notarized only. SSI / NSIC submitted o<strong>the</strong>r than indented material will not be<br />

accepted <strong>for</strong> waival <strong>of</strong> EMD / SD <strong>and</strong> without payment <strong>of</strong> EMD, tender will be rejected out<br />

rightly without intimation to <strong>the</strong> party. No correspondence will be entertained fur<strong>the</strong>r in <strong>the</strong><br />

matter.<br />

(c) Security Deposit : Lowest party shall have to pay Security Deposit as, 5 % in case <strong>of</strong> Works<br />

& 10 % in case <strong>of</strong> Supply <strong>of</strong> order value be<strong>for</strong>e placement <strong>of</strong> order.<br />

(d) Small, Cottage <strong>and</strong> tiny industrial units <strong>of</strong> <strong>Gujarat</strong> State having <strong>the</strong> registrations numbers <strong>for</strong><br />

production <strong>of</strong> goods <strong>and</strong> having <strong>the</strong> registration numbers from Govt. <strong>of</strong> <strong>Gujarat</strong> to submit<br />

Security Deposit <strong>and</strong> per<strong>for</strong>mance guarantee as under.<br />

(01) Wherever in <strong>the</strong> purchase policy, <strong>the</strong> Security Deposit <strong>and</strong> Per<strong>for</strong>mance Bank<br />

Guarantee rate <strong>of</strong> 5 % is stipulated, <strong>the</strong> same be considered at 3 % <strong>for</strong> Small,<br />

Cottage & tiny industrial units <strong>of</strong> <strong>Gujarat</strong> State.<br />

(e)<br />

(02) Wherever <strong>the</strong> rate <strong>of</strong> Security Deposit & per<strong>for</strong>mance Bank Guarantee <strong>of</strong> 10 % is<br />

stipulated in <strong>the</strong> purchase policy, <strong>the</strong> same be considered as 6 % <strong>for</strong> Small, Cottage<br />

& tiny industrial units <strong>of</strong> <strong>Gujarat</strong> State.<br />

(03) Security Deposit <strong>and</strong> Per<strong>for</strong>mance Bank Guarantee shall not be insisted<br />

concurrently <strong>and</strong> <strong>the</strong>re<strong>for</strong>e Security Deposit may be converted into Per<strong>for</strong>mance<br />

Bank Guarantee or once PBG is submitted, SD will be refunded<br />

Technical bid should contain legible <strong>and</strong> attested copies <strong>of</strong> requisite documents like…….<br />

(01) Necessary Experience <strong>of</strong> <strong>the</strong> work / supply <strong>of</strong> similar nature.<br />

(02) Satisfactory completion certificate <strong>of</strong> work / supply orders executed.<br />

(03) Conditional tenders are liable <strong>for</strong> rejection.<br />

(04) Party should submit <strong>of</strong>fice, factory, <strong>and</strong> residence address with phone, fax <strong>and</strong><br />

mobile number.<br />

(05) Class <strong>of</strong> Registration certificate.<br />

(06) Solvency certificate <strong>for</strong> 20 % <strong>of</strong> estimate cost.<br />

(07) Labour Licence from Govt. Dept.<br />

(08) P.F. Registration No. & Service Tax Registration No.

GSECL TPS SIKKA Page 6 <strong>of</strong> 19<br />

(f)<br />

(g)<br />

(h)<br />

(i)<br />

(j)<br />

(k)<br />

(l)<br />

(09) Last three years balance sheet, PAN No. & I. T.Return.<br />

(10) Sales Tax Registration certificate etc. at <strong>the</strong> time <strong>of</strong> application.<br />

(11) The rates may invariably be filled up in Corporation’s schedule <strong>for</strong>m only.<br />

N.B.: The submission <strong>of</strong> documents 5, 6, 7, 8, 9 above will not apply <strong>for</strong> supply order.<br />

The submission <strong>of</strong> documents 10 above will not apply <strong>for</strong> work order, in case <strong>of</strong><br />

less than 1.00 crores.<br />

This <strong>of</strong>fice will not responsible <strong>for</strong> postal delay on ei<strong>the</strong>r ways.<br />

Sealed Tenders Super scribed with <strong>the</strong> Tender Notice No., Sr. No., Details <strong>of</strong> Work / Supply<br />

<strong>and</strong> Due date <strong>of</strong> opening <strong>and</strong> detail <strong>of</strong> D.D. No <strong>of</strong> EMD will be accepted on or be<strong>for</strong>e due<br />

date <strong>and</strong> time through Registered Post only. Corporation does not take any responsibility <strong>for</strong><br />

delay <strong>of</strong> <strong>the</strong> tenders sent under RPAD on <strong>the</strong> due date at local post <strong>of</strong>fice.<br />

<strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd. reserves <strong>the</strong> right to itself not to accept or reject<br />

any or all <strong>the</strong> <strong>of</strong>fers at any stage <strong>of</strong> <strong>the</strong> process <strong>and</strong> /or modify <strong>the</strong> process without assigning<br />

any reason whatsoever <strong>the</strong>re<strong>of</strong>.<br />

<strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd. reserves <strong>the</strong> right to accept / reject / cancel any or<br />

all tenders, extend dates <strong>and</strong> / or re-advertise tender without assigning any reasons <strong>the</strong>re<strong>of</strong>.<br />

Subletting <strong>of</strong> tender is not permitted.<br />

Opening <strong>of</strong> price bids will be decided on evaluation <strong>of</strong> technical bids <strong>and</strong> only eligible<br />

parties will be in<strong>for</strong>med / intimated.<br />

Part order has to be accepted by party.<br />

- Arbitration clause <strong>for</strong> indivisible (i.e. combined supply <strong>and</strong> works orders / tenders….)<br />

“ All questions, disputes or differences, whatsoever which may at any time arise between <strong>the</strong><br />

parties to this contract in connection with <strong>the</strong> contract or any matter arising out <strong>of</strong> or in<br />

relation <strong>the</strong>reto, shall be referred to <strong>the</strong> <strong>Gujarat</strong> Public Works Contract Dispute Arbitration<br />

Tribunal as per <strong>the</strong> provisions <strong>of</strong> <strong>the</strong> <strong>Gujarat</strong> Public works Contract Disputes Arbitration<br />

Tribunal Act, 1992”.<br />

Signature <strong>of</strong> Contractor with Place /<br />

Date / Firm Seal / Stamp<br />

For, <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd.<br />

Sd/-<br />

Chief Engineer<br />

Thermal Power Station, Sikka.

GSECL TPS SIKKA Page 7 <strong>of</strong> 19<br />

> TECHNICAL BID <<br />

No. Description <strong>of</strong> Item Qty. Unit<br />

1.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 200 KW to 275KW<br />

2.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 400 KW to 450 KW<br />

3.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong>6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 600 KW to 650 KW<br />

4.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 750 KW to 900 KW<br />

5.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 1800 KW to 2000 KW<br />

6.<br />

Re-staggering <strong>of</strong> stator core <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 200 KW to 275KW<br />

7.<br />

Re-staggering <strong>of</strong> stator core <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 400 KW to 450 KW<br />

8.<br />

Re-staggering <strong>of</strong> stator core <strong>of</strong>6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 600 KW to 650 KW<br />

9.<br />

Re-staggering <strong>of</strong> stator core <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 750 KW to 900 KW<br />

10.<br />

Re-staggering <strong>of</strong> stator core <strong>of</strong> 6.6 KV Motors <strong>of</strong> unit no.1 <strong>and</strong> no.2 having 1 Number<br />

following rating 1800 KW to 2000 KW<br />

11.<br />

Re-barring / Re-caging with Dynamic balancing <strong>of</strong> Rotor <strong>of</strong> 6.6 KV motors 1 Number<br />

having following rating 200 KW to 450 KW<br />

12.<br />

Re-barring / Re-caging with Dynamic balancing <strong>of</strong> Rotor <strong>of</strong> 6.6 KV motors 1 Number<br />

having following rating 600 KW to 900 KW<br />

13.<br />

Re-barring / Re-caging with Dynamic balancing <strong>of</strong> Rotor <strong>of</strong> 6.6 KV motors 1 Number<br />

having following rating Above 1800 KW to 2000 KW<br />

14. Providing Grease pipe including supply <strong>of</strong> material. 10 Number<br />

15.<br />

Providing labyrinthine ring as per our H.T. motor samples size including 10 Number<br />

supply <strong>of</strong> material.(Ball bearing & Roller bearing Motors)<br />

16.<br />

Providing space heater including supply <strong>of</strong> material. Also submit its technical 28 Number<br />

data (specifications) with drawings.<br />

17.<br />

Charge <strong>for</strong> metalizing <strong>and</strong> machining <strong>of</strong> Bearing housing <strong>for</strong> bear-ing fitting 3000 Square<br />

<strong>for</strong> various motor as per requirement <strong>and</strong> scope <strong>of</strong> work<br />

Centimeter<br />

18.<br />

Charge <strong>for</strong> metalizing <strong>and</strong> machining <strong>for</strong> preparation <strong>of</strong> motor shaft diameter 2213 Square<br />

Centimeter<br />

Charges <strong>of</strong> miscellaneous work like, fabrication, repairing, modi-fication <strong>of</strong> 1 Lumpsum<br />

19. HT motor spares as per sample on as <strong>and</strong> when re-quirement i.e.Bearing<br />

housing, Bearing cover,labyrinth ring <strong>for</strong> sleeve bearing etc.<br />

The Rates are Exclusive <strong>of</strong> Service Tax. Service Tax at prevailing rate, if applicable will be paid<br />

by GSECL extra on production <strong>of</strong> paid evidence/challan.<br />

The contractor shall at his own expense comply with all labour laws <strong>and</strong> keep <strong>the</strong> board indemnified in<br />

respect <strong>the</strong>re<strong>of</strong>. Some <strong>of</strong> <strong>the</strong> major liabilities under various labour <strong>and</strong> industrial laws which <strong>the</strong><br />

contractor shall comply which are as under.

GSECL TPS SIKKA Page 8 <strong>of</strong> 19<br />

1) Payment <strong>of</strong> contributing <strong>of</strong> way <strong>of</strong> Employer’ s contribution towards provident fund, family<br />

pension scheme, deposit linked insurance scheme, administrative charges etc, at <strong>the</strong> rates made<br />

applicable from time to time by Government <strong>of</strong> <strong>Gujarat</strong> / Government <strong>of</strong> India or o<strong>the</strong>r Statutory<br />

Authorities.<br />

2) Payment <strong>of</strong> deposit in respect <strong>of</strong> each contract labour at rate <strong>of</strong> Rs. 30/- with <strong>the</strong> <strong>of</strong>fice <strong>of</strong><br />

Commissioner <strong>of</strong> labour as per contract labour (Regulation <strong>and</strong> Abolition) Act.<br />

3) License as prescribed under <strong>the</strong> contract labour (Regulation <strong>and</strong> Abolition) Act, <strong>and</strong> rules farmed<br />

<strong>the</strong>re under depending upon <strong>the</strong> number <strong>of</strong> workman employed by <strong>the</strong> contractor License is<br />

compulsory if ten or more labours engaged during day.<br />

4) Identity cards as prescribed under <strong>the</strong> factories Act, with photo affixed <strong>the</strong>re to <strong>the</strong> same <strong>for</strong><br />

identification.<br />

5) Payment <strong>of</strong> retrenchment compensation, Notice pay <strong>and</strong> o<strong>the</strong>r liabilities as per Industrial Disputes<br />

Act. Payment to <strong>the</strong> contractor’s employees arising out <strong>of</strong> any claim or disputes under <strong>the</strong><br />

industrial Disputes Act. 1947 or any o<strong>the</strong>r labour laws.<br />

6) Payment <strong>of</strong> compensation in case <strong>of</strong> accidental injury.<br />

7) Provision <strong>of</strong> Creche if female labour employed is more than 30 numbers.<br />

8) Maternity leave as per <strong>the</strong> provision <strong>of</strong> <strong>the</strong> Maternity <strong>Benefit</strong> Act.<br />

SCOPE OF WORK<br />

IMPORTANT TERMS & CONDITIONS<br />

1) In case <strong>of</strong> o<strong>the</strong>r than rewinding work (i.e item no. 6 to 18 <strong>of</strong> Schedule-B ), <strong>the</strong> party has<br />

to take prior confirmation from GSECL be<strong>for</strong>e commencement <strong>of</strong> <strong>the</strong> work.<br />

2) The validity <strong>of</strong> <strong>the</strong> work order will be considered from <strong>the</strong> date <strong>of</strong> actual commencement<br />

<strong>of</strong> <strong>the</strong> first allotted work to <strong>the</strong> party.<br />

SCOPE OF WORK<br />

1) WORK :- Dismantling <strong>of</strong> <strong>the</strong> old/burnt coils from <strong>the</strong> stator slots. Cleaning <strong>of</strong> stator laminated core,<br />

removal <strong>of</strong> old varnish <strong>of</strong> blocking radial air vent in slot <strong>and</strong> core. Complete cleaning <strong>of</strong> blocking <strong>of</strong> stator<br />

slot by removing dirt,oil, grease <strong>and</strong> insulation paper stick up in slots. The rubbing part <strong>of</strong> stator core may<br />

be cleaned with s<strong>and</strong> paper <strong>and</strong> verify that core laminations on surface area should not be shorted. Take<br />

full flux loop test <strong>of</strong> stator at rated flux density <strong>and</strong> test results shall be furnished by party be<strong>for</strong>e insertion<br />

<strong>of</strong> new coils <strong>for</strong> rewinding.<br />

2) REWINDING OF STATOR: - The complete rewinding means manufacturing <strong>of</strong> sets <strong>of</strong> new coils with<br />

br<strong>and</strong> new electrolytic grade copper conductor strips with class-F insulation having double layer polyester<br />

glass mica epoxy tape insulation.<br />

(A)The class-F insulation shall be used as under:-<br />

a) Inter turn insulation by polyester <strong>and</strong> glass mica epoxy tape.<br />

b) Coil ground/slot insulation by semica term <strong>and</strong> woven terelyne tape.<br />

c) Semica Flex <strong>and</strong> EPO flex PGMA tape in overhang portion <strong>of</strong> <strong>the</strong> coil <strong>for</strong> suitable flexibility.<br />

d) Coil portion to be placed in slot should be epoxy molded with pressure not less than 7 tones <strong>and</strong> at<br />

temperature 160 degree centigrade as per requirement <strong>of</strong> size <strong>of</strong> slot. The slot molding should be extended<br />

beyond slot length at both end <strong>for</strong> better track resistance <strong>and</strong> it should be painted with conducting paint.<br />

(B) Number <strong>of</strong> RTD type PT-100 shall be provided at equal distance between two layers <strong>of</strong> coils in<br />

stator slots core as per OEM <strong>of</strong> motor .RTD shall be provided by contractor. The RTD lead wire should<br />

be brought out to terminal strips with proper insulation.<br />

(C) All <strong>the</strong> tested coils to be inserted in stator core <strong>and</strong> coils should be placed properly by using spacers at<br />

equal distance. Woolen felt/fiber glass spacer to be used <strong>and</strong> bounds <strong>the</strong>m with fiber glass string. Top &

GSECL TPS SIKKA Page 9 <strong>of</strong> 19<br />

bottom coils are to be bound properly. Overhang portion <strong>of</strong> coils to be bound with non magnetic<br />

insulation winding supporting ring at both side <strong>of</strong> <strong>the</strong> winding. If double rings are provided at both end in<br />

original design <strong>the</strong>n <strong>the</strong>y should be bound twice to prevent displacement <strong>of</strong> winding coils while starting <strong>of</strong><br />

motor against heavy magnetizing <strong>for</strong>ce developed due to mutual inductance between each o<strong>the</strong>r coils.<br />

(D) Proper size new fiber glass wedges <strong>and</strong> wedge packing fiber glass strips to be used <strong>for</strong> tight fitting <strong>of</strong><br />

coils in stator slot.<br />

(E) The motor terminal HT lead wire on phase side <strong>and</strong> star-point side brought out as per original<br />

sequence so that <strong>the</strong> direction <strong>of</strong> rotation <strong>of</strong> motor is maintained.<br />

(F) The coils inter-connection phase group connection <strong>and</strong> lead wire connection should be brazed with<br />

silver brazing rod <strong>and</strong> <strong>the</strong> joint should be properly insulated <strong>for</strong> 6.6 KV grade insulation.<br />

(G) The complete rewound stator should be dry out in hot air circulation drying chamber till <strong>the</strong> IR value<br />

<strong>and</strong> PI value comes to maximum value. The dry out winding should be varnish impregnated by<br />

elmo<strong>the</strong>rm F-50 varnish <strong>of</strong> M/s. DR. BACK. & co. make, after drying, backing etc. as per st<strong>and</strong>ard best<br />

work procedure. The winding should be varnished with final coat <strong>of</strong> epoxy gel coat red which has<br />

adequate resistive so that not absorb moisture, oil <strong>and</strong> grease etc.<br />

(3) TESTING OF STATOR WINDING:-<br />

The complete rewound stator winding to be tested as under:<br />

a) The IR / PI value be<strong>for</strong>e HV test <strong>and</strong> after HV test.<br />

b) The HV test at 15KV, 50 HZ, A.C. shall be applied between each phase to earth, phase to earth <strong>for</strong> one<br />

minute <strong>and</strong> should with st<strong>and</strong> <strong>for</strong> that period. The leakage current to be recorded <strong>for</strong> that.<br />

c) The winding resistance per phase at ambient temperature to be measured.<br />

d) The RTD resistance value to be measured.<br />

e). The No Load Test run shall be done at contractors workshop <strong>for</strong> vibration test <strong>and</strong> smooth running <strong>of</strong><br />

motor if complete motor assembly is sent to <strong>the</strong> contractors works. The balance load test shall be carried<br />

out if only stator is sent <strong>for</strong> rewinding.<br />

f) The Full Load Test at our site shall be done <strong>for</strong> complete satisfactory per<strong>for</strong>mance <strong>of</strong> <strong>the</strong> rewound<br />

motor if any difficulty arise <strong>the</strong> contractor has to attend it with out any extra cost.<br />

5) Motor space heater wiring should be replaced with new heat resistive wire <strong>of</strong> good quality at every<br />

work <strong>of</strong> rewinding <strong>and</strong> heater to be tested at 230 volt A.C .supply.<br />

6) The contractor should produce documents <strong>for</strong> having used class-F insulation materials<br />

indigenous/imported <strong>for</strong> best quality <strong>of</strong> rewinding whenever dem<strong>and</strong>ed by GSECL.<br />

7) The contractor should preserve old coils till <strong>the</strong> motor is rewound with new copper conductor coils.<br />

8) Stage inspection:-<br />

Complete rewound stator winding should be tested as per IS-325.<br />

Representative <strong>of</strong> M/s GSECL will witness <strong>the</strong> test at above stages as far as possible. However M/s<br />

GSECL reserve right to waive any above stage inspection. If contractor rewound <strong>the</strong> motor without<br />

<strong>of</strong>fering above stage inspection, <strong>the</strong> rewound motor will not be accepted.<br />

9) The contractor must submit all <strong>the</strong> test results <strong>of</strong> <strong>the</strong> subject motor along with <strong>the</strong> invoice/bill <strong>for</strong><br />

passing payment.<br />

10) Complete restaggering / recagging <strong>of</strong> rotor core:-<br />

After Removing <strong>the</strong> shorting ring <strong>of</strong> rotor at both end <strong>and</strong> <strong>the</strong> rotor bars, unlock <strong>the</strong> locking device <strong>of</strong><br />

rotor core. Remove <strong>the</strong> lamination leaves from <strong>the</strong> rotor;cleaning <strong>of</strong> burnt varnish, oil, grease, dirt from<br />

<strong>the</strong> lamination leave <strong>the</strong>n varnishing <strong>the</strong>m with core plate varnish <strong>of</strong> Dr.back & co. make. Backing, drying<br />

<strong>the</strong> leaves, retargeting <strong>the</strong> lamination across <strong>the</strong> periphery by distributing damaged core leaves in such a<br />

way that uni<strong>for</strong>m flux density may be produced as developed in healthy rotor core. Pressing <strong>the</strong> core<br />

lamination with required pressure so that radial air vent duct may not be de<strong>for</strong>med. Locking <strong>the</strong> Core on<br />

shaft <strong>of</strong> rotor as per original one. Remove <strong>the</strong> burrs in slot portion by smooth filing. Apply anti corrosive<br />

varnish <strong>and</strong> final coat <strong>of</strong> Bactol red by spraying.<br />

The repair rotor core may be tested <strong>for</strong> full flux loop test <strong>and</strong> confirm that <strong>the</strong>re should not be any hot spot

GSECL TPS SIKKA Page 10 <strong>of</strong> 19<br />

generated. GSECL representative shall be called to witness <strong>the</strong> test & also after stage inspection <strong>for</strong><br />

checking core lamination leaves while work in progress.<br />

After satisfactory completion <strong>of</strong> full flux loop test, prepare new rotor copper bars <strong>and</strong> copper bar shorting<br />

rings from electrolyte grade copper. The bar size should be as per slot size so that <strong>the</strong>y shall be tight fitted<br />

in rotor core. <strong>the</strong> bar shorting ring shall be fabricated in such a way so that all bar tip shall be deep groove<br />

fit as per depth <strong>and</strong> width <strong>of</strong> <strong>the</strong> bar size on milling machine. Then <strong>the</strong> entire cage bar should be brazed<br />

with end ring with 43 % silver brazing rod, skimming, machining <strong>the</strong> same.<br />

The repaired rotor should be dynamically balanced at <strong>the</strong> rated speed. The rotor cage must be kept free to<br />

allow expansion/contraction against <strong>the</strong>rmal stresses. The partly repair charges <strong>for</strong> any part <strong>of</strong> above job<br />

work shall be as per schedule-c.<br />

11) Metallizing & Machining <strong>of</strong> bearing housing <strong>of</strong> motor:-<br />

After checking ovality, necessary metal cut shall be carried out. Then filling <strong>the</strong> metal by using l & t-2240<br />

welding electrode by keeping required temperature <strong>of</strong> bearing housing pedestal plate so that any<br />

de<strong>for</strong>mation/hair crack shall not develop in pedestal plate <strong>of</strong> bearing housing due to <strong>the</strong>rmal stresses.<br />

after natural cooling <strong>of</strong> <strong>the</strong> plate using lime powder, machining <strong>of</strong> <strong>the</strong> bearing housing as per bearing<br />

outer rim diameter <strong>and</strong> tolerance to fit bearing tightly in bearing house <strong>and</strong> in <strong>the</strong> center line <strong>of</strong> <strong>the</strong> stator<br />

core.<br />

12) Metal sing <strong>and</strong> machining <strong>of</strong> rotor shaft:-<br />

Thoroughness <strong>of</strong> <strong>the</strong> rotor shaft shall be check; minor machine cut may be done on <strong>the</strong> damage part <strong>of</strong><br />

shaft/bearing portion as per requirement. Then fill <strong>the</strong> metal by using l & t-680 welding electrode on<br />

machined portion <strong>of</strong> <strong>the</strong> shaft. Then shaft to be cooled naturally. Machining <strong>the</strong> shaft as per requirement<br />

<strong>of</strong> dimension <strong>and</strong> tolerance to fit <strong>the</strong> bearing tightly on rotor shaft. Final checking <strong>of</strong> thoroughness <strong>of</strong><br />

shaft through out <strong>the</strong> length <strong>of</strong> <strong>the</strong> shaft. The repair charge <strong>for</strong> <strong>the</strong> job work shall be as per schedule-c.<br />

(13) Fabrication/miscellaneous repairing, modification <strong>of</strong> ht motor spares as per sample:-<br />

After checking <strong>of</strong> HT. motor spare sample necessary measurements are to be taken <strong>and</strong> accordingly <strong>the</strong><br />

job has to be prepared. The fabricated job/spare must be exactly matching with our sample. in case <strong>of</strong> any<br />

deviation from our sample necessary modification as per our sample has to be accomplished by <strong>the</strong> party<br />

at his own cost.<br />

Any kind <strong>of</strong> miscellaneous repairing/modification <strong>of</strong> ht motor spares have to be accomplished by <strong>the</strong><br />

party as per <strong>the</strong> instruction <strong>of</strong> EICc <strong>of</strong> GSECL<br />

14) Contractor should arrange <strong>for</strong> bearing replacement, if existing found defective at free <strong>of</strong> cost. New<br />

bearing will be provided by GSECL.<br />

15) On completion <strong>of</strong> job motor; two coat <strong>of</strong> primer <strong>and</strong> one coat <strong>of</strong> Grey Asian Acolyte paint should be<br />

applied on motor body.<br />

TERMS AND CONDITIONS<br />

1) The winding copper scrap <strong>and</strong> insulating materials will be retained by <strong>the</strong> contractor, <strong>the</strong> rates<br />

quoted <strong>for</strong> rewinding shall be after considering <strong>the</strong> rebate <strong>for</strong> Copper scrap to be retained by <strong>the</strong><br />

contractor.<br />

2) The contractor will show all <strong>the</strong> removed old coils to GSECL representative when called <strong>for</strong> visits<br />

<strong>for</strong> inspection/testing <strong>of</strong> motor as soon as damaged coils are dismantled <strong>and</strong> old insulation is<br />

scrapped out.<br />

3) Incase <strong>of</strong> any motor <strong>of</strong> HP/KW rating o<strong>the</strong>r than <strong>the</strong>se covered in schedule-B <strong>and</strong> listed in<br />

annexure-iii shall be payable on proportional rate <strong>of</strong> <strong>the</strong> nearby capacity rates <strong>of</strong> items covered in<br />

schedule-b.<br />

4) The quantity <strong>and</strong> items mentioned in schedule-B may increase or decrease as per requirement <strong>of</strong> site.

GSECL TPS SIKKA Page 11 <strong>of</strong> 19<br />

The quantity <strong>and</strong> items <strong>for</strong> <strong>the</strong> rewinding <strong>of</strong> faulty motors are <strong>for</strong> rate approval only.<br />

5)You have to collect <strong>the</strong> burnt stator/rotor from on receiving in<strong>for</strong>mation from chief engineer<br />

SIKKA <strong>and</strong> to carryout rewinding /repairing <strong>the</strong> same at your works.<br />

6) The rates will be firm through out <strong>the</strong> period <strong>of</strong> contract no extra charges will be paid on account <strong>of</strong> price<br />

variation <strong>of</strong> material <strong>and</strong> lab our etc.<br />

7) (a)The contractor has to arrange transportation <strong>for</strong> collecting failed motor from SIKKA site within 48<br />

hrs from intimation <strong>of</strong> site EIC <strong>of</strong> failed motor.<br />

(b)The contractor has to arrange to <strong>and</strong> fro transportation <strong>of</strong> failed/rewound motor <strong>for</strong><br />

rewinding/repairing during normal as well as during <strong>the</strong> guarantee period also.<br />

8) Over all time limit <strong>of</strong> this work order is 24 months while <strong>the</strong> time completion per job <strong>of</strong> shall be max. To<br />

30 days in normal course. However you will have to complete <strong>the</strong> job in shortest possible time<br />

incase <strong>of</strong> emergency/exigency.<br />

9) The contract period is two year. However this can be extended <strong>for</strong> fur<strong>the</strong>r six months with no change in<br />

rates till <strong>the</strong> total amount <strong>of</strong> order is exhausted whichever is earlier without any fur<strong>the</strong>r confirmation<br />

from you.<br />

10) The penalty will be levied at <strong>the</strong> rate <strong>of</strong> 1 % <strong>of</strong> <strong>the</strong> rate <strong>of</strong> <strong>the</strong> motor rewinding/repairing per week <strong>of</strong><br />

delay beyond time completion. The maximum penalty shall be 10 % <strong>of</strong> <strong>the</strong> above rates.<br />

11) Guarantee:- The guarantee period shall be 12 months from <strong>the</strong> date <strong>of</strong> commissioning or 18 months<br />

from <strong>the</strong> date <strong>of</strong> receipt <strong>of</strong> motor at GSECL site whichever is earliest, if it fails in <strong>the</strong> above<br />

guarantee period, <strong>the</strong> contractor shall repair/rewind <strong>the</strong> same motor free <strong>of</strong> cost at <strong>the</strong><br />

earliest without any delay.. If motor fails due to mechanical problem i.e. bearing driven equipment etc.<br />

within guarantee period, charges <strong>for</strong> rewinding will be paid after joint inspection reports which will be<br />

conveyed to party in advance.<br />

12 ) No octroy charges/any o<strong>the</strong>r charges will be paid by GSECL ,<strong>the</strong> contractor will arrange to clear<br />

octroy incase <strong>of</strong> normal as well as under <strong>the</strong> guarantee period.<br />

13) if at any stage, contractor fails to complete <strong>the</strong> job , <strong>the</strong> same will be got done, any where else at his<br />

risk <strong>and</strong> cost, <strong>the</strong> additional expenditure incurred by GSECL will be recovered from his bills/security<br />

deposit or any payment due to him with 15 % supervision charges.<br />

14) Contractor shall be responsible <strong>for</strong> <strong>the</strong> safety <strong>of</strong> motors coming under this contract. Motor should be<br />

covered properly while transportation, contractor shall have to take insurance <strong>for</strong> <strong>the</strong> motor during repairing<br />

while in <strong>the</strong>ir custody.<br />

15) Any modification/ alteration as suggested by GSECL shall be decided on mutually agreed reasonable<br />

rate <strong>and</strong> actual work involved.<br />

16) Submission <strong>of</strong> bills: - The contractor will submit his bills in triplicate section wise separate<br />

along with advance stamped receipt. <strong>the</strong> entries <strong>of</strong> gate pass (number & date) <strong>for</strong> incoming <strong>and</strong><br />

outgoing shall be indicated on each bill by <strong>the</strong> contractor, <strong>and</strong> also a list <strong>of</strong> motor repaired <strong>for</strong> which<br />

<strong>the</strong> bills are raised be furnished. Serial number <strong>of</strong> motor/rotor shall be indicated with service <strong>of</strong> motor.<br />

Date <strong>of</strong> bill shall be <strong>the</strong> date <strong>of</strong><br />

Submission <strong>of</strong> bill.<br />

17) The contractor has to submit CPF code number received from <strong>the</strong> CPF commissioner?s <strong>of</strong>fice.<br />

18) The discrepancies arising out <strong>of</strong> <strong>the</strong> job, decision <strong>of</strong> Chief Engineer GSECL TPS SIKKA shall be final<br />

<strong>and</strong> binding to <strong>the</strong> party.

GSECL TPS SIKKA Page 12 <strong>of</strong> 19<br />

19) Items <strong>and</strong> quantity <strong>of</strong> each <strong>and</strong> all <strong>of</strong> schedule-B <strong>for</strong> rewinding/repairing depend upon any motor as <strong>and</strong><br />

when fails during <strong>the</strong> period <strong>of</strong> contract. .<br />

20) When <strong>the</strong> motor stator is sent <strong>for</strong> complete rewinding with new copper <strong>the</strong> old coils will be cut in<br />

overhang portion by GSECL be<strong>for</strong>e sending to contractor?s works<br />

21) Service tax if applicable will be reimbursed by GSECL <strong>for</strong> which you have to obtained registration no.<br />

<strong>and</strong> provide certified copy <strong>of</strong> <strong>the</strong> paid challan against payment <strong>of</strong> service tax as a documentary evidence as<br />

per GOVT. SERVICE TAX applicable rules <strong>and</strong> regulations.<br />

22) The workshop <strong>of</strong> <strong>the</strong> HT motor rewinding must be in GUJARAT state <strong>and</strong> not be away more than<br />

500 KM From SIKKA T.P.S.<br />

QUALIFICATION CRITERIA<br />

(1) Details <strong>of</strong> Order <strong>for</strong> simillar nature/kind <strong>of</strong> job/ work carried out during last 3 years amounting Rs.40<br />

lacs <strong>and</strong> more than it,along with documentary evidence <strong>and</strong> per<strong>for</strong>mance certificate <strong>the</strong>re <strong>of</strong> indicating <strong>the</strong><br />

names <strong>of</strong> <strong>the</strong> organizations,order number <strong>and</strong> date is to be submitted with tech bid.<br />

(2) Details <strong>of</strong> skilled/semi skilled persons presently employed by <strong>the</strong> contractor having sufficient<br />

knowldge <strong>of</strong> simillar kind <strong>of</strong> job.<br />

(3) Details <strong>of</strong> tools tackels,equipment possessed <strong>and</strong> testing facility relevent to <strong>the</strong> job/subject tender.<br />

Signature <strong>of</strong> Contractor with Place /<br />

Date / Firm Seal / Stamp<br />

For, <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd.<br />

Sd/-<br />

Chief Engineer<br />

Thermal Power Station, Sikka.

GSECL TPS SIKKA Page 13 <strong>of</strong> 19<br />

GENERAL SAFETY RULES / NORMS TO BE OBSERVED BY<br />

THE CONTRACTORS<br />

All <strong>the</strong> contractors working at Sikka Thermal Power Station shall have to strictly observe <strong>the</strong> following<br />

safety rules. The contractors shall be responsible <strong>for</strong> in<strong>for</strong>ming <strong>and</strong> observing <strong>the</strong>se rules by <strong>the</strong>ir supervisors<br />

/ employees / labours as well as <strong>the</strong> supervisors / employees / labours <strong>of</strong> <strong>the</strong>ir sub agencies / sub contractors<br />

engaged, if any. Prior to commencement <strong>of</strong> <strong>the</strong> work, contractor shall have to submit a written assurance on<br />

<strong>the</strong>ir letter head to <strong>the</strong> concerned sectional heads / Engineer In charge that <strong>the</strong>y have thoroughly gone<br />

through <strong>the</strong>se rules, have educated <strong>the</strong>ir employees / employees <strong>of</strong> <strong>the</strong>ir sub contractor <strong>and</strong> will strictly<br />

observe <strong>the</strong> said rules while execution <strong>of</strong> work under work contract awarded to <strong>the</strong>m. They will have to<br />

indemnify <strong>the</strong> Corporation <strong>for</strong> any loss or damage / accident / injury to <strong>the</strong> Corporation’s property /<br />

employees or employee <strong>of</strong> <strong>the</strong>ir own in default <strong>of</strong> non observing <strong>the</strong>se rules.<br />

Persons to be employees <strong>for</strong> carrying out <strong>the</strong> work shall possess required qualification, be fully trained <strong>and</strong><br />

conversant <strong>for</strong> works to be done. All persons should have gate pass, register consisting <strong>the</strong> full details [i.e.<br />

address, phone no. details <strong>of</strong> nearest relative etc] <strong>of</strong> all persons is to be maintained. During <strong>the</strong> work<br />

execution, one trained <strong>and</strong> competent supervisor should always remain present at site.<br />

The contractor shall take all <strong>the</strong> required safety measure prior to commencement <strong>of</strong> work on dangerous<br />

substances, machineries or area at which cautionary notice is displayed <strong>and</strong> obtain “Line Clear” or “Work<br />

Permit” through <strong>the</strong> concerned department / section.<br />

Prior to carry out welding, gas cutting, furnace heating or any o<strong>the</strong>r hot work job, <strong>the</strong> contractor shall<br />

remove al <strong>the</strong> inflammable material lying at or nearby worksite or cover it properly by suitable protective<br />

covering. Also, special care shall be taken be<strong>for</strong>e carrying out such job <strong>and</strong> see that all possible contributing<br />

factors to set fire shall be removed / vanished prior to commencement <strong>of</strong> <strong>the</strong> work. Advance intimation shall<br />

be given to concerned section / fire section to commence <strong>the</strong> work in fire prone areas. They should also keep<br />

ready all <strong>the</strong> first aid fire extinguishers / equipment <strong>and</strong> fire extinguishing media / material like s<strong>and</strong> / water<br />

buckets or o<strong>the</strong>r appropriate equipment at such place.<br />

While carrying out work in confined space or inside vessel, <strong>the</strong> contractor shall obtain necessary “Confined<br />

Space / Vessel Entry Permit” from concerned department prior to commencement <strong>of</strong> <strong>the</strong> work. Fire lighting<br />

in such areas, only 24 volt [ISI certified <strong>and</strong> with proper guard] h<strong>and</strong> lamp shall be used.<br />

For taking care <strong>of</strong> <strong>the</strong> persons working inside <strong>the</strong> confined space / vessel, a supervisor / person capable to<br />

keep continuous watch on person [s] working inside, assist <strong>the</strong>m incase <strong>of</strong> emergency or arrange to get<br />

immediate outside help, shall remain present at entry joint <strong>and</strong> shall use full body safety belt without fail.<br />

While working inside sewage, trench, or in depth, a person to warn outsiders / entrants / passers etc. shall<br />

remain available near entry point or <strong>the</strong> entry point shall be cordoned by a barricaded tape with a cautionary<br />

notice. After completion <strong>of</strong> <strong>the</strong> works, all <strong>the</strong> lids / covers / grills / grits opened, shall be re-fixed / replaced<br />

in <strong>the</strong> original position as it were prior to commencement <strong>of</strong> <strong>the</strong> work <strong>and</strong> leave <strong>the</strong> work place in safe<br />

condition in all respect, so as to prevent accident to fellow workers.<br />

The contractor shall see that he / his persons do not block [by stacking materials, spares parts, tools-tackles,<br />

equipment etc] any passages / walkways / gangways / aisles / staircases / ladders / lifts or any o<strong>the</strong>r<br />

approaches / roads / leading to plant or its auxiliaries, on which <strong>the</strong>re is a traffic movement or possible traffic<br />

movements in case <strong>of</strong> emergency. Such passages are meant <strong>for</strong> safe escape in <strong>the</strong> event <strong>of</strong> emergency. If it is<br />

utmost necessary to carry out work in such area with blocking. Passage, prior permission <strong>of</strong> competent<br />

authority or <strong>the</strong> Engineer-In-charge shall be obtained. To demarcate / declare <strong>the</strong> area <strong>of</strong> UNSAFE, cordon it<br />

using barricading tape <strong>and</strong> display suitable caution notice or keep a person to restrict / divert <strong>the</strong> traffic on<br />

this route through o<strong>the</strong>r safe passage<br />

Prior to use power electrically operated h<strong>and</strong> tools / equipment / machines / gadgets like welding machine,<br />

h<strong>and</strong> grinder, h<strong>and</strong> drill etc. ensure <strong>for</strong> its safe operation <strong>and</strong> use it only if it is found safe to use. Do not use<br />

defective, unsafe or improperly maintained equipment.<br />

The electrical power supply required to run such equipment shall not be taken directly at <strong>the</strong>ir own, but shall<br />

be obtained through concerned electrical maintenance departments, or <strong>the</strong>ir authorized persons or under<br />

<strong>the</strong>ir observation / guidance only. The electrical section shall provide temporary electrical connection up to<br />

contractor’s mains board on which it is compulsory to install mains switch, ELCB <strong>and</strong> fuses <strong>of</strong> adequate

GSECL TPS SIKKA Page 14 <strong>of</strong> 19<br />

capacity. All such equipments shall invariably be ear<strong>the</strong>d adequately to prevent electrical shock, sparking,<br />

short circuit etc. Power cord to be used shall be <strong>of</strong> adequate capacity, without any joint <strong>and</strong> shall consist <strong>of</strong><br />

earth wire also. Hence, it is necessary to use adequate capacity 3-wire power cord <strong>for</strong> single <strong>and</strong> 5-wire<br />

power cord <strong>for</strong> three phase power connections. The plugs, receptacles pins, holders etc. shall be <strong>of</strong> adequate<br />

capacity <strong>and</strong> safe to use.<br />

All electrical / mechanical equipment / tools – tackles viz. welding machine, cutting machine, grinder, drill,<br />

chain pulley blocks, hook, chooks, etc. equired to be used during work execution shall be <strong>of</strong> st<strong>and</strong>ard make<br />

<strong>and</strong> bear ISIcertification mark on it. The consumables like welding electrodes, grinding wheels / discs etc.<br />

which has specific life span shall not be used in any case if its expiry dates is over.<br />

It is compulsory to use st<strong>and</strong>ard make Personal Protective Equipment [PPEs] as per <strong>the</strong> job requirement. Do<br />

not work without use <strong>of</strong> required PPEs. Contractor is responsible to provide st<strong>and</strong>ard make [ISI approved].<br />

Personal Protective Equipment / Safety gadgets suitable to give sufficient protection against hazards<br />

involved in <strong>the</strong>ir work / job to <strong>the</strong>ir staff, as per <strong>the</strong> job requirement <strong>and</strong> insist / en<strong>for</strong>ce <strong>the</strong>ir staff to put on<br />

<strong>the</strong> same while at works.<br />

The ongoing work is liable to be stopped at any time if <strong>the</strong> contractor’s staff is found working without PPEs.<br />

Following is <strong>the</strong> list <strong>of</strong> various PPEs to beused <strong>for</strong> arious works / worksites.<br />

LIST OF SAFETY EQUIPMENTS<br />

01 Industrial Safety Helmet For protection <strong>of</strong> head against falling objects or during<br />

fall <strong>of</strong> person from height.<br />

02 Safety Goggles [Grinding,<br />

Welding etc]<br />

For protection <strong>of</strong> eyes against flying particles / dust /<br />

chemical splash , spark, arc flashover etc.<br />

03 Face Shield [Half <strong>of</strong> full] For protection <strong>of</strong> face against flying particles / dust,<br />

chemicals splash, spark arc, flashover etc.<br />

04 Earplug / ear muffs For ear / hearing system protection while working in high<br />

noise level area.<br />

05 Apron [Rubber / PVC / Asbestos /<br />

Lea<strong>the</strong>r / Cotton]<br />

For body protection against chemicals / oils / sharp,<br />

edged objects, heat, hot objects etc.<br />

06 Gloves [Rubber / PVC / Asbestos<br />

/ Lea<strong>the</strong>r / Electrical shock pro<strong>of</strong>]<br />

For protection <strong>of</strong> h<strong>and</strong>s against chemicals, oils, sharps<br />

edges object, heat hot metals / objects, electrically etc.<br />

07 Safety / Lea<strong>the</strong>r / Asbestos shoes<br />

/ gum boots etc]<br />

For protection <strong>of</strong> leg / feet against falling objects / sharp<br />

edges objects, heat, hot metals / objects, electrically etc.<br />

08 Safety belt [full body] / rope / life<br />

line / fall prevention system etc.<br />

For all prevention while working at heights or in depth,<br />

working in vessel or in confined space.<br />

09 Dust respirator / scarf Protection <strong>of</strong> respiratory system against dust.<br />

10 Chemical cartridge respirator Protection against chemical fume / vapor etc.<br />

11 Canister gas mask Protection against toxic / poisonous fumes / gases.<br />

12 Air supply respirators Working in Oxygen deficient zone.<br />

Be<strong>for</strong>e using lifting machines / tackles like [C.P.Bs, Hooks, chooks, winch, <strong>for</strong>klift, mobile crane, EOT<br />

crane etc] <strong>and</strong> its attachments [like D-shackles, slings, U-clamp, eye bolts or any fixtures] it shall be checked<br />

<strong>and</strong> used only if found safe to use. Also, ensure that, <strong>the</strong>se are tested, examined <strong>and</strong> certified in <strong>for</strong>m no.9 /<br />

10 by competent person as per <strong>the</strong> Factory act 1948 <strong>and</strong> its validity is not expired. Fur<strong>the</strong>r, it shall be fixed<br />

properly <strong>and</strong> firmly prior to lifting he weight.<br />

Scaffoldings to be used <strong>for</strong> working at height shall be adequate size <strong>and</strong> capacity. Obtain <strong>the</strong> work permit<br />

when working at height. While climbing on such scaffolding or working on any structure at height, use <strong>of</strong><br />

full body safety belt <strong>and</strong> helmet is compulsory. It is also necessary to fasten chinstraps <strong>of</strong> <strong>the</strong> helmet.<br />

Contractor or <strong>the</strong>ir employees shall not interfere n day to day routine plant activities / works except <strong>the</strong> work<br />

assigned to <strong>the</strong>m, shall not loiter in <strong>the</strong> areas o<strong>the</strong>r than <strong>the</strong>ir work jurisdiction, as well as shall not temper /<br />

operate / touch <strong>the</strong> machineries / equipment / auxiliaries with which <strong>the</strong>y are not concerned. Also, <strong>the</strong><br />

contractor shall strictly instruct <strong>the</strong>ir staff not to sit or take rest at / near / below running plants, auxiliaries,<br />

system or any place which is risky, hazardous <strong>and</strong> prone to accident.

GSECL TPS SIKKA Page 15 <strong>of</strong> 19<br />

The cylinders containing poisonous / toxic or inflammable / explosive gas like Oxygen, Acetylene, LPG,<br />

Hydrogen, Ammonia, Chlorine, CO2 etc. shall be h<strong>and</strong>led safely taking due care. To h<strong>and</strong>le / shift such<br />

cylinders a special trolley / cage meant <strong>for</strong> it must be used but in no case it should be rolled. Domestic LPG<br />

cylinder shall not be used / permitted.<br />

On completion <strong>of</strong> <strong>the</strong> work, cotton waste, spilled oil / grease, pieces <strong>of</strong> welding rod <strong>and</strong> o<strong>the</strong>r waste material<br />

shall be removed from work site <strong>and</strong> <strong>the</strong> area shall be left safe, neat <strong>and</strong> clean.<br />

In case <strong>of</strong> any injury / accident while working, it shall immediately reported to Safety Department through<br />

concerned sectional head / engineer. The prescribed <strong>for</strong>m no.21 may be obtained from concerned section or<br />

Safety <strong>of</strong>ficer. For any incident occurred, but have no injury to any person should also be in<strong>for</strong>med to<br />

Safety Officer as “Near Miss Incident”.<br />

In all risky jobs, be<strong>for</strong>e starting <strong>the</strong> work, contractor should obtain General safety works permit from<br />

concerned section well in advance.<br />

In case <strong>of</strong> noticing smoke or fire during <strong>the</strong>ir work execution, <strong>the</strong>y shall make immediate ef<strong>for</strong>ts to<br />

extinguish / control it <strong>and</strong> simultaneously in<strong>for</strong>m <strong>the</strong> Fire Brigade on phone no. 444 / 421, shall shift <strong>the</strong><br />

casualty to nearby hospital after rendering first aid in case <strong>of</strong> accident<br />

Over <strong>and</strong> above <strong>the</strong>se, contractor shall have to follow all <strong>the</strong> safety requirement / rules <strong>and</strong> regulations /<br />

norms <strong>and</strong> legal provision laid down in various statutes, particularly <strong>the</strong> provisions <strong>of</strong> <strong>the</strong> Factories Act 1948<br />

<strong>and</strong> <strong>the</strong> <strong>Gujarat</strong> State Factories Rules 1963 [amended up to date] shall be followed strictly. The contractor<br />

shall also obey <strong>the</strong> rules / regulations / instructions <strong>of</strong> <strong>the</strong> local competent authority <strong>for</strong> safety requirement.<br />

No women or young person shall be allowed to clean, lubricate or adjust any part <strong>of</strong> primer mover or <strong>of</strong> any<br />

transmission machinery, while <strong>the</strong> rime movers or transmission machine is in motion. Examination or<br />

operation <strong>of</strong> motion machinery shall be made or carried out only by a specially trained adult male workers<br />

wearing tight fitting clothing as per section 22 <strong>of</strong> factories act 1948.<br />

No women or your person shall be employed or permitted to work in Lead Compound area like battery room<br />

etc. as per schedule –IV <strong>of</strong> <strong>Gujarat</strong> Factory Rule 1963.<br />

All <strong>the</strong> relevant labour <strong>and</strong> industrial laws shall also be followed compulsorily.<br />

It is felt necessary to deploy safety <strong>of</strong>ficers / safety supervisors by contractors / agencies involved in<br />

carrying out hazardous activities / operations inside TPS to have better <strong>and</strong> constant supervision in terms <strong>of</strong><br />

Health, Safety <strong>and</strong> Environment activities.<br />

In case, it comes to <strong>the</strong> notice <strong>of</strong> GSECL Sikka TPS management that, <strong>the</strong> safety guidelines / safety rules /<br />

safety norms are not being followed <strong>the</strong>n a minimum sum <strong>of</strong> Rs.1,000/- [Rs. One thous<strong>and</strong> only] shall be<br />

penalized on <strong>the</strong> contractor / agency <strong>and</strong> <strong>for</strong> subsequent such violation, a severe penalty / action as deemed<br />

fit shall be imposed which may please be noted.<br />

The above rules shall be scrupulously followed <strong>and</strong> where required, <strong>the</strong>y may contact <strong>the</strong> Safety Officer <strong>for</strong><br />

any ambiguity / fur<strong>the</strong>r guidance in this regard.<br />

For per<strong>for</strong>mance evaluation <strong>of</strong> contractor, safety factors <strong>of</strong> work, accident, first incident <strong>and</strong> near miss<br />

accident will be considered. Steps can be taken to review <strong>the</strong> job assignment up to cancellation <strong>for</strong><br />

negligence.<br />

Signature <strong>of</strong> Contractor with Place /<br />

Date / Firm Seal / Stamp<br />

For, <strong>Gujarat</strong> State <strong>Electricity</strong> Corporation Ltd.<br />

Sd/-<br />

Chief Engineer<br />

Thermal Power Station, Sikka.

GSECL TPS SIKKA Page 16 <strong>of</strong> 19<br />

> ANNEXURE <<br />

TENDER FOR SUPPLY OF<br />

____________________________________________________<br />

ON FIRM'S LETTER HEAD<br />

I / We_______________________________________________________________<br />

Authorised signatory <strong>of</strong> M/s._____________________________________________<br />

here by certify that…<br />

M/s._______________________________________________________________ is<br />

not related with o<strong>the</strong>r firms who have submitted tenders <strong>for</strong> <strong>the</strong> same items under this<br />

Tender.<br />

Seal <strong>of</strong> <strong>the</strong> Firm :<br />

Place :<br />

Signature <strong>of</strong> <strong>the</strong> Tenderer :<br />

Date with Designation :

GSECL TPS SIKKA Page 17 <strong>of</strong> 19<br />

GUJARAT STATE ELECTRICITY CORPORATION LTD.<br />

INTEGRITYPACT OUR ENDEAVOUR<br />

To create an environment where Business Confidence is built through Best Business Practices <strong>and</strong><br />

is fostered in an atmosphere <strong>of</strong> trust <strong>and</strong> respect between providers <strong>of</strong> goods <strong>and</strong> services <strong>and</strong> <strong>the</strong>ir<br />

users <strong>for</strong> <strong>the</strong> ultimate benefit <strong>of</strong> society <strong>and</strong> <strong>the</strong> nation.<br />

GSECL’S COMMITMENT<br />

% To maintain <strong>the</strong> highest eithical st<strong>and</strong>ards<br />

in business <strong>and</strong> pr<strong>of</strong>essions.<br />

% Ensure maximum transparency to <strong>the</strong><br />

satisfaction <strong>of</strong> stakeholders.<br />

% To ensure to fulfill <strong>the</strong> terms <strong>of</strong> agreement /<br />

contract <strong>and</strong> to consider objectively <strong>the</strong><br />

viewpoint <strong>of</strong> parties.<br />

% To ensure regular <strong>and</strong> timely release <strong>of</strong><br />

payments on due dates <strong>for</strong> work done.<br />

% To ensure that no improper dem<strong>and</strong> is made<br />

by employees or by any one on our behalf.<br />

% To give maximum possible assistance to all<br />

<strong>the</strong> Vendors / Suppliers / Service Provider<br />

<strong>and</strong> o<strong>the</strong>r to enable <strong>the</strong>m to complete <strong>the</strong><br />

contract in time.<br />

% To provide all in<strong>for</strong>mation to Suppliers /<br />

Contractors relating to contract / job which<br />

facilitate him to complete <strong>the</strong> contract / job<br />

successfully in time.<br />

% To ensure minimum hurdles to vendors /<br />

suppliers / contractors in completion <strong>of</strong><br />

agreement / contract / work order.<br />

PARTY’S COMMITMENT<br />

% Not to bring pressure recommendations<br />

from outside GSECL to influence its<br />

decision.<br />

% Not to use intimidation, threat, inducement<br />

or pressure <strong>of</strong> any kind on GSECL or any <strong>of</strong><br />

it’s employees under any circumstances.<br />

% To prompt <strong>and</strong> reasonable in fulfilling <strong>the</strong><br />

contract, agreement, legal obligations.<br />

% To provide goods <strong>and</strong> / or services timely as<br />

per agreed quality <strong>and</strong> specifications at<br />

minimum cost to GSECL.<br />

% To abide by <strong>the</strong> general discipline to be<br />

maintained in our dealings.<br />

% To be true <strong>and</strong> honest in furnishing<br />

in<strong>for</strong>mation.<br />

% Not to divulge any in<strong>for</strong>mation, business<br />

details available during <strong>the</strong> course <strong>of</strong><br />

business relationship to o<strong>the</strong>r without <strong>the</strong><br />

written consent <strong>of</strong> GSECL.<br />

% Not to enter in to carter / syndicate /<br />

underst<strong>and</strong>ing whe<strong>the</strong>r <strong>for</strong>mal / non-<strong>for</strong>mal<br />

so as to influence <strong>the</strong> price.<br />

Seal & Signature<br />

(GSECL’s Authorized Signatory)<br />

Name :<br />

Designation :<br />

Seal & Signature<br />

(Party’s Authorized Person)<br />

Name :

GSECL TPS SIKKA Page 18 <strong>of</strong> 19<br />

SCHEDULE - B PRICE BID (RFQ NO. 26106)<br />

Work <strong>of</strong> complete rewinding / repairing <strong>of</strong> 6.6 KV HT Motors <strong>for</strong> Unit No. 1&2<br />

Sr. Description Unit Qty. Rate Amount<br />

1.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong> 6.6 KV Motors<br />

<strong>of</strong> unit no.1 <strong>and</strong> no.2 having following rating 200 Number 1 232732.5 232732.5<br />

KW to 275KW<br />

2.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong> 6.6 KV Motors<br />

<strong>of</strong> unit no.1 <strong>and</strong> no.2 having following rating 400 Number 1 328212.5 328212.5<br />

KW to 450 KW<br />

3.<br />

Complete rewinding <strong>of</strong> stator <strong>of</strong>6.6 KV Motors<br />

<strong>of</strong> unit no.1 <strong>and</strong> no.2 having following rating 600 Number 1 384532.6 384532.6<br />

KW to 650 KW<br />

4.<br />