77120_Product_Information - Gunson

77120_Product_Information - Gunson

77120_Product_Information - Gunson

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

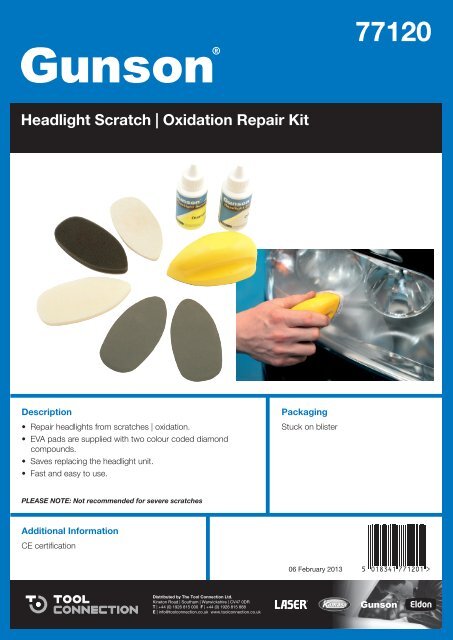

<strong>77120</strong><br />

Headlight Scratch | Oxidation Repair Kit<br />

Description<br />

• Repair headlights from scratches | oxidation.<br />

• EVA pads are supplied with two colour coded diamond<br />

compounds.<br />

• Saves replacing the headlight unit.<br />

• Fast and easy to use.<br />

Packaging<br />

Stuck on blister<br />

PLEASE NOTE: Not recommended for severe scratches<br />

Additional <strong>Information</strong><br />

CE certification<br />

06 February 2013<br />

Distributed by The Tool Connection Ltd.<br />

Kineton Road | Southam | Warwickshire | CV47 0DR<br />

T | +44 (0) 1926 815 000 F | +44 (0) 1926 815 888<br />

E | info@toolconnection.co.uk www.toolconnection.co.uk

INSTRUCTIONS<br />

Fast and easy repair of scratches and scuffing on modern plastic headlight units. Also cleans headlights which<br />

have become extremely clouded and dull over time from a combination of fine scratches and the effects of UV<br />

on the clear plastic.<br />

The kit is supplied with an applicator, 1 x white foam applicator base, 1 x wool polishing pad, 1 x foam<br />

polishing pad, 2 x P1200 grade wet-or-dry abrasive pads.<br />

Part 1:<br />

• Clean the headlight to be repaired with clean,<br />

soapy water, then dry off. Make sure there is no<br />

dirt or grit left on the headlight.<br />

• The P1200 abrasive pad can be mounted directly<br />

onto the applicator for flat surfaces. For curved<br />

surfaces the white foam applicator base is attached<br />

to the applicator first and then the P1200 abrasive<br />

pad is mounted onto the foam applicator base.<br />

• Using the abrasive pad ‘wet’ using clean water,<br />

steadily rub over the area to be repaired in a<br />

straight-line motion, then again at a 90º angle. For<br />

a scratch, keep rubbing until the scratch has been<br />

removed; for scuffing and cloudiness, rub steadily<br />

across the affected area. Keep wiping off the<br />

residue and keep the abrasive pad wet at all times.<br />

• Clean off with a soft cloth or microfiber cloth.<br />

• Fit the wool polishing pad onto the applicator.<br />

Squeeze a small amount of the Part 1 Grey<br />

Diamond Compound onto the polishing pad.<br />

• Polish vigorously over the affected area, adding<br />

more Diamond Compound if necessary. Continue<br />

polishing until the affected area is bright and<br />

transparent again.<br />

• Clean off with a soft cloth or microfiber cloth.<br />

Precautions:<br />

• Always wear eye protection.<br />

• Responsibility for damage or injury lies with the user.<br />

• Clean components after use and ensure that caps are tight on bottles.<br />

Part 2:<br />

• Ensure that all of the residue of the Part 1 Grey<br />

Diamond Compound has been removed from the<br />

surface of the headlight.<br />

• Fit the foam polishing pad onto the applicator.<br />

Squeeze a small amount of the Part 2 Yellow<br />

Diamond Compound onto the foam polishing pad.<br />

• Polish vigorously over the affected area, adding<br />

more Part 2 Yellow Diamond Compound if<br />

necessary. Continue polishing until the affected<br />

area is bright and transparent again. This stage<br />

will restore the optical clarity so keep polishing<br />

until there is no remaining scratches or cloudiness.<br />

• Clean off with a soft cloth or microfiber cloth,<br />

polishing briskly to leave a bright and shiny<br />

finish. If any cloudiness remains, reapply Part 2 to<br />

remove.<br />

When finished, clean off the pads and applicator and<br />

keep clean and dry so that the kit can be used again.