H2Station® MH-100 Product Specifications - H2 Logic

H2Station® MH-100 Product Specifications - H2 Logic

H2Station® MH-100 Product Specifications - H2 Logic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

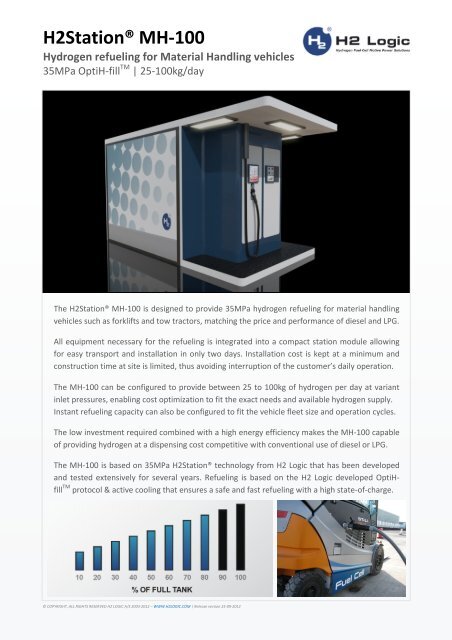

<strong><strong>H2</strong>Station®</strong> <strong>MH</strong>-<strong>100</strong><br />

Hydrogen refueling for Material Handling vehicles<br />

35MPa OptiH-fill TM | 25-<strong>100</strong>kg/day<br />

The <strong><strong>H2</strong>Station®</strong> <strong>MH</strong>-<strong>100</strong> is designed to provide 35MPa hydrogen refueling for material handling<br />

vehicles such as forklifts and tow tractors, matching the price and performance of diesel and LPG.<br />

All equipment necessary for the refueling is integrated into a compact station module allowing<br />

for easy transport and installation in only two days. Installation cost is kept at a minimum and<br />

construction time at site is limited, thus avoiding interruption of the customer’s daily operation.<br />

The <strong>MH</strong>-<strong>100</strong> can be configured to provide between 25 to <strong>100</strong>kg of hydrogen per day at variant<br />

inlet pressures, enabling cost optimization to fit the exact needs and available hydrogen supply.<br />

Instant refueling capacity can also be configured to fit the vehicle fleet size and operation cycles.<br />

The low investment required combined with a high energy efficiency makes the <strong>MH</strong>-<strong>100</strong> capable<br />

of providing hydrogen at a dispensing cost competitive with conventional use of diesel or LPG.<br />

The <strong>MH</strong>-<strong>100</strong> is based on 35MPa <strong><strong>H2</strong>Station®</strong> technology from <strong>H2</strong> <strong>Logic</strong> that has been developed<br />

and tested extensively for several years. Refueling is based on the <strong>H2</strong> <strong>Logic</strong> developed OptiHfill<br />

TM protocol & active cooling that ensures a safe and fast refueling with a high state-of-charge.<br />

© COPYRIGHT, ALL RIGHTS RESERVED <strong>H2</strong> LOGIC A/S 2003-2012 – WWW.<strong>H2</strong>LOGIC.COM | Release version 25-09-2012

<strong>Product</strong> specifications | <strong><strong>H2</strong>Station®</strong> <strong>MH</strong>-<strong>100</strong><br />

CAPACITY<br />

Hydrogen supply inlet pressure<br />

Average daily capacity<br />

1 st hour instant capacity*<br />

1.6 kg tank size example<br />

1MPa<br />

2.5MPa<br />

25 kg/day 60 kg/day<br />

No. of refuelings 2-4 3-5<br />

Hereof back-to-back 1-2 1-3<br />

5MPa<br />

<strong>100</strong> kg/day<br />

*Instant capacity can be configured according to customers vehicle tank type/size, fleet size and operation cycles<br />

5-6<br />

1-3<br />

REFUELING<br />

OptiH-fill TM performance*<br />

1.6 kg tank size example**<br />

Ambient temperature<br />

Refueling time & State-of-Charge***<br />

15°C