zhafir plastics machinery gmbh ningbo zhafir plastics ... - Haitian

zhafir plastics machinery gmbh ningbo zhafir plastics ... - Haitian

zhafir plastics machinery gmbh ningbo zhafir plastics ... - Haitian

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

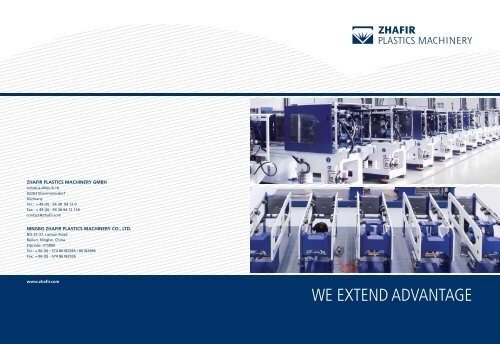

ZHAFIR PLASTICS MACHINERY GMBH<br />

Jubatus-Allee 8-10<br />

92263 Ebermannsdorf<br />

Germany<br />

Tel.:: + 49 (0) - 94 38 94 12 0<br />

Fax:: + 49 (0) - 94 38 94 12 150<br />

contact@<strong>zhafir</strong>.com<br />

NINGBO ZHAFIR PLASTICS MACHINERY CO., LTD.<br />

NO.35-37, Laosan Road<br />

Beilun, Ningbo, China<br />

Zipcode: 315800<br />

Tel.: + 86 (0) - 574 86182985 / 86182986<br />

Fax: + 86 (0) - 574 86182926<br />

www.<strong>zhafir</strong>.com

strategically<br />

positioned.<br />

made in china , Made in Germany.<br />

CONTENT:<br />

01_THE COMPANY. ......................4_5<br />

02_OUR HISTORY. .........................6_7<br />

03_OUR MISSION. ........................8_9<br />

04_Made in Germany. ..............10_11<br />

05_MADE IN CHINA. ....................12_13<br />

06_GLOBAL NETWORK. ................14_15<br />

07_OUR PRODUCTS. ....................16_19

4<br />

_<br />

5<br />

01_THE COMPANY.<br />

We have succeeded in transferring<br />

revolutionary ideas.<br />

THE COMPANY.<br />

Success is a matter of competence and visionary power. But there<br />

is more to it than just this: the courage to tread on an unknown<br />

path; the determination needed to trust one’s own strengths; correct<br />

timing; plus humility and a bit of luck as well.<br />

Zhafir Plastics Machinery GmbH was launched in Germany in the<br />

spring of 2005 with a team of highly-qualified development engineers<br />

and experts in the <strong>plastics</strong> processing field. The goal was to develop<br />

new kinds of technologies for the <strong>plastics</strong> processing industry, while<br />

creating solutions that are equally compelling from an economic<br />

perspective. Innovations that offer multiple value surpluses but that<br />

are also affordable. In the process, the close cooperation between<br />

German and Chinese development engineers has proven to be a<br />

relationship that is extremely durable and productive.<br />

Using the market know-how and experience of <strong>Haitian</strong> International,<br />

we have succeeded in transferring revolutionary ideas and innovative<br />

concepts into professional solutions for our customers: all-electric,<br />

high-grade energy-efficient, precision injection-molding machines at<br />

an attractive price-/performance ratio. These capabilities create vast<br />

competitive advantages for the operator while opening up completely<br />

new horizons.<br />

In August 2007, Zhafir was incorporated into <strong>Haitian</strong> International<br />

Holdings Ltd., a manufacturer renowned for injection-molding machines<br />

of the highest quality. Since then, as its German subsidiary,<br />

Zhafir has complemented <strong>Haitian</strong>’s global, multi-brand strategy.<br />

This is why we are optimally positioned to develop further the advantages<br />

of the Venus and Mercury Series. The potential has been<br />

scratched.<br />

The 3-brand-strategy<br />

High-tech<br />

ZHAFIR<br />

ZHAFIR<br />

Standard<br />

HAITIAN<br />

HAITIAN<br />

Prof. h.c. Dipl.-Ing. Helmar Franz,<br />

CEO of Zhafir Plastics Machinery, and member<br />

of the Executive Board of <strong>Haitian</strong> International<br />

Fu Nanhong,<br />

Chief Engineer and Head of R&D <strong>Haitian</strong> International<br />

Steffen Franz, Managing Director of Zhafir Plastics<br />

Machinery in Germany<br />

Mass market<br />

HAITIAN<br />

TIANJIAN<br />

Company strategy: clear focus on target markets<br />

2004 2007 2012<br />

More about <strong>Haitian</strong> International: www. haitaininter.com<br />

High tech applications<br />

All electrical machines<br />

Latest technology<br />

High quality components<br />

Standard applications<br />

Hydraulic machines<br />

Cost efficient<br />

Solid and high quality<br />

Simple applications<br />

Hydraulic machines<br />

Broad application,<br />

low cost and reliable<br />

Three brands under one roof<br />

With <strong>Haitian</strong> International’s multi-brand strategy, the whole processing<br />

spectrum of the <strong>plastics</strong> industry is covered. Our differentiated<br />

product portfolio offers highly efficient solutions even for the<br />

most varied of customer demands, from rapid mass production to<br />

the manufacture of the smallest high-precision parts or innovative<br />

moldings with complex shapes.<br />

•“Tianjian” machines are tailored to the manufacture of uncomplicated<br />

and low-priced plastic parts. These solidly built injectionmolding<br />

machines have established themselves in mass markets<br />

such as Asia or India.<br />

• The <strong>Haitian</strong> brand, with its Mars, Jupiter and Iapetus Series, covers<br />

all applications in the medium and top-of-the-line standard market<br />

segments.<br />

• With all-electric machine designs of the Venus and Mercury Series,<br />

our Zhafir premium brand covers all production sectors of the dynamically<br />

growing high-tech market. The applications spectrum ranges<br />

from the automotive field through to medical technology.<br />

The board of haitian international<br />

www.<strong>zhafir</strong>.com

6<br />

_<br />

7<br />

02_OUR HISTORY<br />

WE HAVE INCORPORATED OUR<br />

VISION INTO A CONCEPT.<br />

OUR HISTORY.<br />

<strong>Haitian</strong> was first established with 100 RMB of starting capital. In over<br />

four decades the founders, with their passion, persistence and technological<br />

specialist knowledge, have created reliable machine concepts<br />

with crucial competitive advantages for the customers in the <strong>plastics</strong><br />

processing industry. <strong>Haitian</strong> is not only a company name. <strong>Haitian</strong>, in the<br />

Chinese language and culture, means “sea (hai) and sky (tian)”. Right<br />

from the beginning we have incorporated our vision into this concept.<br />

For us, water typifies dignity – it stands for the diversity of technological<br />

potential. The sky, on the other hand, knows no limitations – it allows<br />

every imaginable step forward. Over the last four decades this ideal<br />

has always been the motivation for us to invest a great deal of energy<br />

and capital into our product improvement. Today <strong>Haitian</strong> enjoys an<br />

excellent image worldwide as a brand name. On the one hand, our<br />

quality, high-grade machines fulfill the requirements for precision and<br />

profitable efficiency demanded by our international customers. And on<br />

the other hand, <strong>Haitian</strong> is valued for its customer-oriented and comprehensive<br />

service. In this tradition, we will also be a reliable partner<br />

for our customers, as well as a good employer for our employees.<br />

Delivered machines<br />

30000<br />

27000<br />

24000<br />

21000<br />

18000<br />

15000<br />

12000<br />

9000<br />

6000<br />

3000<br />

0<br />

2006 2007 2008 2009 2010 2011 2012<br />

Total area coverage<br />

987,624.91 qm<br />

Production area<br />

484,887.00 qm<br />

Total employees 4,500<br />

Total production output 22,000 machines in 2012<br />

Total revenues 1,019 million USD in 2012<br />

Total export revenues 307 million USD in 2012<br />

Facts<br />

3<br />

_<br />

1<br />

_<br />

Opening of R&D Center in Zhafir Germany<br />

2005<br />

<strong>Haitian</strong> International Holdings Ltd.<br />

has their initial public offering, and<br />

is listed on the Main Board of the SEHK<br />

(Stock Exchange Hong Kong)<br />

Zhafir Germany intergrated into<br />

<strong>Haitian</strong> International Holding Limited<br />

2007<br />

2007.10: VENUS Generation 1 shown on K-show<br />

2007<br />

2<br />

_<br />

opening of Zhafir Ningbo<br />

2008<br />

Opening of Technology Centers in China South<br />

and East<br />

4<br />

_<br />

2008<br />

Opening of Manufacturing Hall<br />

of Zhafir Germany<br />

5<br />

_<br />

2009<br />

6<br />

_<br />

Opening of Technology Center in Japan<br />

2010<br />

2010.10: MERCURY shown on K-show<br />

2010<br />

<strong>Haitian</strong> International becomes<br />

marketleader<br />

2010<br />

7<br />

_<br />

iIntrocution of Venus Generation 2<br />

2012<br />

2006<br />

1<br />

_<br />

2<br />

_<br />

3<br />

_<br />

_<br />

4<br />

_<br />

5<br />

_<br />

6 _<br />

7

8<br />

_<br />

9<br />

03_our Mission.<br />

Leadership is a commitment<br />

The success of the <strong>plastics</strong> processor is of pivotal importance to our<br />

approach at <strong>Haitian</strong>. As the Planets have orbital reliance on the Sun,<br />

we have branded our products with the same customer commitment.<br />

With consistent customer focus we became a world leader in the injection<br />

molding machine industry.<br />

Belief in our core values is paramount, as is a sincere appreciation for<br />

the trust of our customers and the support of our competent partners<br />

and investors supported by the continuous diligence of all our staff.<br />

An important reason for our success is that we have pursued and lived<br />

our vision in every detail - to offer technology of premium quality at<br />

affordable prices. We have continually questioned our thinking and<br />

actions through our communication with all market partners and other<br />

involved parties. We work on creating innovation – whether it is big<br />

or small, and constantly strive for perfection and the highest efficiency<br />

with our own manufacturing. This is equally true for machine performance<br />

on the customer’s premises.<br />

We continue to maintain this policy with competent expansion. Everything<br />

we do is intended to place our customers in a position to overcome<br />

challenges profitably and sustainably. With this promise we shall<br />

enjoy success together in the future.<br />

Secure growth through stability<br />

We are committed and motivated to maintain <strong>Haitian</strong>’s leading market<br />

position. It is now necessary to combine tradition with an eye on the<br />

future, to protect stability and secure future growth. In Far Eastern philosophy,<br />

Bamboo is synonymous with toughness and strength which<br />

maybe the best symbol for this effort. No other plant combines endurance<br />

with flexibility, lightness with robustness, in such an impressive<br />

way. When used as framework it provides enormously high stability,<br />

even in typhoons. Likewise, <strong>Haitian</strong> is also steadfast and constant to<br />

all its customers and partners, with reliable support in all situations.<br />

Another comparison: Bamboo can be found in many countries around<br />

the world due to its dynamic growth and adaptability to local environments.<br />

Likewise for <strong>Haitian</strong>, the dynamic development of our global<br />

manufacturing and service network is a logical progression. We use all<br />

of our collective knowledge and experience in new research projects<br />

for the benefit of our market partners and customers anywhere in the<br />

world.<br />

Knowledge with understanding, learning for improvement<br />

communication.<br />

Our machine and solution concepts have<br />

reached a secure design status for specific<br />

market and customer requirements. For<br />

mutual inspiration, we continually pursue<br />

information between all market partners to<br />

gain perspectives, understand trends and<br />

fulfill customer desires to create a stronger<br />

than ever influence on our product design.<br />

Innovative thinking is thinking in terms of the customer<br />

Innovative thinking is thinking in terms of the customer<br />

INNOVATION.<br />

INNOVATION.<br />

Whatever the future may bring, we will be<br />

ready for it, with machines that do exactly<br />

what our customers really need, and with<br />

innovative technologies, new peripheral<br />

interfaces, and new possibilities for processing<br />

the materials of the future.<br />

:: Communicative networking in all directions<br />

:: International exchange with regard to<br />

markets and trends in Asia, Europe and<br />

America<br />

:: Interdisciplinary cooperation in R&D for new,<br />

demand-oriented solutions<br />

:: Innovative machine design for the<br />

premium segment<br />

:: High engineering for the latest,<br />

application-oriented technologies<br />

:: Intensive process development for<br />

new materials<br />

LEADERSHIP HAS<br />

MANY DIMENSIONS<br />

Our MISSION:<br />

Clear cost advantages and open new opportunities<br />

Clear cost advantages open new opportunities<br />

Efficency.<br />

EfficIency.<br />

Standardized highly developed machines,<br />

provide a higher return on investment at<br />

lower unit costs. Our highly efficient overall<br />

concepts bring clear cost advantages and<br />

open new opportunities – all with the option<br />

of optimising one or the other, ad hoc<br />

or in the future.<br />

:: Machines with increased efficiency and<br />

energy savings<br />

:: Production-cost advantages from<br />

reduced unit costs<br />

:: Competitive advantages gained from<br />

the highest levels of performance and<br />

precision<br />

www.<strong>zhafir</strong>.com

10 _<br />

11<br />

04_Made in Germany.<br />

Ebermannsdorf:<br />

FaCTS ...<br />

:: Location: Ebermannsdorf, Germany<br />

:: Commissioned: December 2007<br />

:: Workforce: around 40 employees<br />

:: Production area: 4,500 m 2<br />

:: Application center: 250 m 2<br />

:: Core business: R&D and manufacturing<br />

:: Assembling and manufacturing of all-electric machines<br />

between 350kN and 5,500 kN<br />

Quality and precision is<br />

essential to our work.<br />

Made in<br />

Germany.<br />

The think tank of the <strong>plastics</strong> industry<br />

Germany continues to be the think tank of the <strong>plastics</strong> industry and<br />

offers special advantages in regards to location. We make full use of<br />

this. Our direct proximity to experts such as raw material suppliers,<br />

electronics manufacturers and drive technology designers gives us<br />

easy access to new application possibilities and future trends. It’s an<br />

inspiring environment and one in which our teams of engineers have<br />

already developed many innovative concepts and made them ready<br />

for the market.<br />

Zhafir Germany’s core business includes the further development of<br />

the Mercury principle and the optimization of corporate technologies<br />

also for all other <strong>Haitian</strong> brands, for example, the optimized toggle<br />

system design for the new <strong>Haitian</strong> Mars II Series. Other focal points<br />

are the series production, optimisations of assembly processes and<br />

procedures, and, last but not least, fine-tuning of our machines in line<br />

with market requirements and in accordance with EU standards and<br />

customer needs.<br />

Sustainable production and assembly<br />

Our employees are highly skilled in production and assembly and<br />

are a further guarantee of the premium quality of our products and<br />

solutions. The various assemblies are manufactured in the 4,000 m²<br />

manufacturing hall on the premises of Zhafir Plastics Machinery in<br />

Ebermannsdorf from top-quality standard parts and components in<br />

accordance with CE safety guidelines. Machines assembled on-site<br />

are checked for compliance with the rigorous safety and quality<br />

criteria that are customary in Germany, in close cooperation with<br />

the responsible German test centers, such as the TÜV, the German<br />

Technical Inspection Agency. Quality and performance are also the focus<br />

in our 250 m² technology center, which serves as a ready contact point<br />

close to the Global Players with its Headquarters in Europe. Here they<br />

can see in detail for themselves the many different performance benefits<br />

of our machines and technologies; aspects such as precision, energy<br />

consumption, safety and ergonomics are regularly examined at the test<br />

station. Upon request, the technology center is also available to our<br />

sales partners for application support purposes.<br />

www.<strong>zhafir</strong>.com

12 _<br />

13<br />

05_Made in china.<br />

Ningbo:<br />

FaCTS ...<br />

:: Location: Ningbo, China<br />

:: Commissioned: January 2008<br />

:: Workforce: around 190 employees<br />

:: Production area: 18,000 m² (since 2012)<br />

:: Core business: manufacture of all-electric machines<br />

between 400 and 5,500 kN<br />

:: Output 2012: approx. 1,000 machines<br />

EFFICIENT production for<br />

quality and availability.<br />

Made in<br />

China.<br />

Lean Production<br />

Zhafir´s success in Ningbo is based on the carefully detailed<br />

planning of structure and scheduling, in all areas of our plant.<br />

In addition to this, we have also been able to rely on our highly<br />

specialised management and the forty years of experience of<br />

the whole <strong>Haitian</strong> Group.<br />

At the same time, the combined use of innovative technologies,<br />

lean organisation and highly motivated employees ensures<br />

smooth performance right through all assembly and production<br />

processes – and quality controls from A to Z are included. This<br />

allows us to achieve a total production output of around 1,000<br />

units per year, with a plant area of now some 18,000 m².<br />

Short response times<br />

Efficient robotics and sophisticated logistics are the keys to such<br />

high productivity. Components, structural elements and important<br />

small parts are not only centrally stored but are also kept<br />

ready in side stores next to the assembly lines.<br />

Increased efficiency and output<br />

This guarantees continuously uninterrupted procurement of<br />

materials throughout our modularised assembly. In addition,<br />

the u-shaped design of our modern production lines increases<br />

both efficiency and output. Not only does it shorten<br />

transport routes in-house, but it gives us a high degree of<br />

flexibility so that we can react very specifically and with unusual<br />

speed to individual changes in our customers’ needs.<br />

Last but not least, our comprehensive testing and control measures<br />

at each stage of modular assembly guarantee excellent<br />

quality and availability of the machines delivered. And, thanks<br />

to efficiency in production, all of this is offered on attractive<br />

terms.<br />

www.<strong>zhafir</strong>.com

14 _<br />

15<br />

06_GLOBAL NETWORK<br />

Zhafir in Ningbo<br />

Zhafir in Germany<br />

3<br />

_<br />

2<br />

_<br />

4<br />

_<br />

1<br />

_<br />

1<br />

_<br />

Regional Office South East Asia<br />

:: Located in Binh Duong Province, Vietnam<br />

:: Sales and service organisation<br />

:: Manufacturing site with 6,600 m 2<br />

:: 80 m 2 application center for mould tests<br />

60<br />

sales and service<br />

partners support<br />

in more than<br />

80<br />

countries<br />

Global Presence of <strong>Haitian</strong> International<br />

5<br />

_<br />

Original Zhafir Blue is<br />

Pantone 648 C<br />

C100M0Y0K52<br />

Original Zhafir Blue is<br />

Pantone 648 C<br />

C100M0Y0K52<br />

2<br />

_<br />

3<br />

_<br />

Regional Office Europe<br />

Regional Office Russia<br />

:: Located in Nuremberg, Germany<br />

:: Sales and service and technical support for<br />

20 European distributors<br />

:: 250 m 2 application center for mould testing<br />

:: Located in Moscow, Russia<br />

:: Sales & service organisation<br />

:: Application center for mould testing<br />

Regional Offices<br />

Sales- and Service Partner<br />

R&D, Headquarters<br />

4<br />

_<br />

Regional Office Turkey<br />

:: Located in Istanbul, Turkey<br />

:: Sales and service organisation<br />

:: Manufacturing site with 2.220 m 2<br />

:: Application center for mould testing<br />

Global Places<br />

5<br />

_<br />

Regional Office South America<br />

:: Located in Sao Paolo, Brazil<br />

:: Sales & service organisation<br />

:: Manufacturing site with 4,600 m 2<br />

Original Zhafir Blue is<br />

OUR CUSTOMERS GET CLEAR<br />

COMPETITIVE ADVANTAGES.<br />

GLOBAL<br />

Pantone 648 C<br />

C100M0Y0K52<br />

NetwORK.<br />

Proximity to customers extend advantage<br />

As a subsidiary of <strong>Haitian</strong> International Ltd., we are part of a continuously<br />

expanding support network around the globe. There are currently<br />

60 regional sales and service centers for customers in over 80<br />

countries. In cooperation with the experts and service partners of the<br />

<strong>Haitian</strong> Group, we are not only able to react speedily to new market<br />

and sector requirements, but also to implement individual equipment<br />

features, certifications, and new application levels for our customers<br />

on site. Because of the permanent availability of important customer<br />

services, replacement parts and service features, our customers are<br />

always able to develop clear competitive advantages and to use them<br />

lucratively, both now and in the future.<br />

www.<strong>zhafir</strong>.com

16 _<br />

17<br />

07_our products.<br />

PREMIUM PRODUCTS FOR A<br />

PREMIUM MARKET.<br />

OUR<br />

PRODUCTS.<br />

Zhafir Venus<br />

Series<br />

VENUS<br />

Efficient Precision - Zhafir Venus II Series<br />

The Zhafir Venus II Series was designed with a clamping force of 400 kN to 5,500<br />

kN for applications in the upper mid-tech and high-tech markets. Because of its<br />

outstanding performance capabilities (processing stability, high molding quality,<br />

zero-defect production), it is highly versatile and can be used, for example, in the<br />

electrical industry, the optical industry or for clean-room applications. Since the<br />

introduction of the product in 2008, about 2,000 machines have been delivered.<br />

2,000<br />

delivered machines<br />

Basic product characteristics of the Zhafir Venus Series are: its reliable and precise<br />

injection unit; a constantly regulated cylinder temperature; its optimised<br />

plasticising unit; and a fully-engineered control system.Because of its decentralised<br />

drive concept, it can run parallel movements on all axes. This flexibility<br />

reduces the production cycle time significantly.<br />

0.01mm accuracy<br />

:: Up to four injection units per clamping unit with a high-speed version for<br />

each<br />

:: Kinematically optimised 5-point double-toggle system for dynamically accurate<br />

mold movements<br />

:: Servo-driven twin-ball spindles with precision to within 0.01 mm<br />

:: Energy savings from 20% to 70% compared with hydraulic machines<br />

:: Water savings without tool cooling: 80-90% compared with traditional<br />

hydraulic injection-molding machines<br />

:: Suitable for clean-room applications, since no hydraulic oil is needed<br />

www.<strong>zhafir</strong>.com

18 _<br />

19<br />

PREMIUM PRODUCTS FOR A<br />

PREMIUM MARKET.<br />

OUR<br />

PRODUCTS.<br />

Zhafir Mercury Series<br />

08_our products.<br />

MERCURY<br />

New horizons<br />

70%<br />

MORE MOLD SURFACE<br />

The new Mercury Series offers new potential for complex mould designs<br />

and for <strong>plastics</strong> that are innovative and difficult to process. Devised<br />

in modular design and high-end options as standard, the Mercury<br />

makes it possible to vary the machine design according to individual<br />

customer requirements. Optimal connection at the periphery ensures<br />

easy removal of parts, short cycles and full workload.<br />

INJECTION SPEED UP TO<br />

:: New type of machine design with 70% more mold surface<br />

500mm/s<br />

:: Simplified toggle system for high precision<br />

:: Injection speeds of up to 500 mm/s<br />

:: Separate injection and plasticising<br />

:: 3 piston diameters with 3 screw diameters each per clamping force<br />

:: Energy-efficient servo-motors<br />

:: Central power supply with brake-energy recuperation<br />

:: Ergonomic operation at the (mobile) touch terminal<br />

www.<strong>zhafir</strong>.com