You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

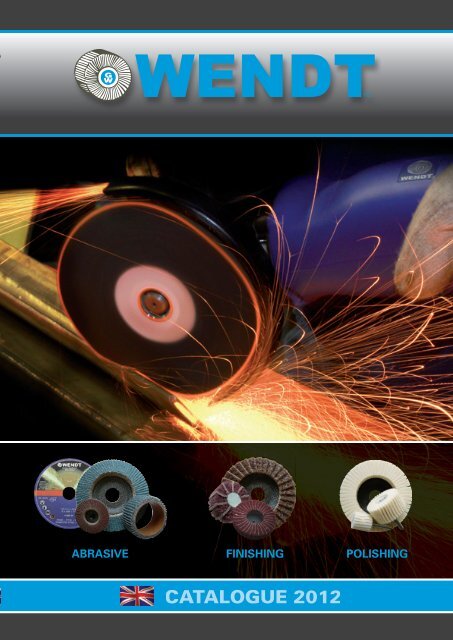

ABRASIVE FINISHING POLISHING<br />

CATALOGUE 2012

CATALOGUE 2012 | English Version

INDEX<br />

SEITE:<br />

CUTTING & GRINDING DISCS 08 - 13<br />

NEW 2012<br />

FLAP DISCS 14 - 33<br />

QUICK CHANGE & RESIN FIBRE DISCS 34 - 40<br />

CARTRIDGE ROLLS 41 - 43<br />

MOUNTED FLAP WHEELS 44 - 53<br />

FLAP BANDS & SPIRAL BANDS 54 - 57<br />

UNMOUNTED FLAP WHEELS 58 - 64<br />

FLAP ROLLS 65 - 67<br />

NEW 2012<br />

FPM 230 68 - 70<br />

SHOP ROLLS & NONWOVEN ROLLS 71 - 72<br />

SOLID CARBIDE BURRS 73 - 75<br />

KITS & ACCESSORIES 76 - 78

WHO WE ARE …<br />

Dipl.-Ing Günter Wendt GmbH is a family-held, privately owned manufacturer specializing in the production of abrasive,<br />

finishing, and poishing products. Our organization was founded in 1971 near Cologne, Germany, by Günter Wendt.<br />

His goal then, as it is today, was to constantly improve abrasive tools to increase their productivity. Our success has<br />

come from making tools of the best quality, as well as developing new products which set us apart from the competition.<br />

In three decades since, we have developed and patented numerous innovative products<br />

and become recognized as a leader in our industry.<br />

THE FIRST manufacturer to produce 10mm (3/8”) diameter Mini <strong>Flap</strong> <strong>Wheels</strong><br />

THE FIRST manufacturer to produce a flap wheel only 3 mm (1/8”) wide.<br />

THE FIRST to produce an aluminium backed flap disc, and the only one to offer an aluminium back<br />

with consumable grinding edge.<br />

THE FIRST to produce flap discs with a fiberglass backing. (85% of flap discs produced world-wide<br />

now use this method)<br />

THE FIRST to produce Mini <strong>Flap</strong> Discs.<br />

THE FIRST to manufacture a <strong>Flap</strong> Band.<br />

ONE OF THE FIRST to manufacture <strong>Flap</strong> Discs made with Surface Conditioning Material (SCM).<br />

THE FIRST to offer Polishing wheels made with Felt <strong>Flap</strong>s.<br />

THE FIRST to produce Felt Polishing Cartridge Rolls.<br />

We are constantly expanding our product offering to satisfy customer needs from rough grinding to fine polishing -<br />

and every step in between. Many times the process can be completed with only one tool, by changing the accessories.<br />

We have developed a very broad, and deep range of abrasive products which operators can utilize with the most common<br />

power tools. Wendt GmbH holds a number of patents for innovative products which are unique to our organization.<br />

Our customers are not restricted to the standard products we list in our catalogue. A significant portion of our business<br />

involves the manufacture of custom products for special needs.

OUR COMMITMENT ...<br />

QUALITY:<br />

All materials used in the production of Wendt products are<br />

extensively tested to ensure our products deliver the best<br />

performance possible. Materials are carefully selected to meet<br />

the needs of the products they will go into. For example, a<br />

abrasive material which performs well in a flap disc might not<br />

be suitable for a flap wheel.<br />

We work with all of Europe’s leading abrasive suppliers, giving<br />

us access to a wide selection of materials and allowing us to pick<br />

from the “best of the best”.<br />

Wendt is a DIN EN ISO 9001 : 2008 manufacturer.<br />

CONSISTENCY:<br />

Although we have access to many suppliers, our standard products are consistently made with the same material.<br />

Once a product is approved, our incoming raw materials are strictly tested to verify they are on grade before they<br />

ever go into production. As part of our made-to-order capabilities, customers can request product in special materials.<br />

Minimum quantities may apply.<br />

SERVICE:<br />

In 2001, Wendt established operations in both the United Kingdom and United States to enhance service to these markets.<br />

Today we have expanded our production with additional manufacturing in each of these locations.<br />

Wendt UK, Ltd.<br />

Glasgow<br />

Wendt USA, LLC<br />

Buffalo, New York<br />

Wendt do Brasil<br />

Indaiatuba<br />

Wendt Sarl<br />

Sarreguemines, Frankreich<br />

In 2005 we established our first sales office to directly service in Eastern Europe, with the opening of Wendt Abrazive RU S.R.L.<br />

in Romania. We have subsequently followed up with additional operations in France and Brazil. Following our tradition we also<br />

serve our clients here with a high quality, professional team of experts from the market.<br />

We constantly find new solutions for the industry that can benefit to all our customers world-wide.

PRODUCT OVERVIEW<br />

CLEANING<br />

MORE AGGRESSIVE<br />

REX NONWOVEN CLEANING<br />

CUTTING & GRINDING<br />

(BONDED ABRASIVES)<br />

COATED ABRASIVES<br />

Coarse Silicon Carbide grain<br />

dispersed throughout a<br />

strong nylon web.<br />

Aggressively removes rust,<br />

weld spatter, paint and<br />

coatings without loading or<br />

clogging. Tough enough for<br />

deburring.<br />

Easier, safe, and faster<br />

alternative to wire brushes.<br />

Complete selection of<br />

cutting wheels for Steel,<br />

Stainless Steel and Stone.<br />

Extra-thin cutoff wheels<br />

for minimal resistance, yet<br />

maximum life.<br />

Premium grade Type 27<br />

Grinding <strong>Wheels</strong> for heavy<br />

stock removal on Steel and<br />

Stainless.<br />

A variety of premium grains bonded to<br />

a cotton, polyester or poly-cotton backing.<br />

Aluminium Oxide (A) and (N)<br />

An all purpose grain for general grinding,<br />

sanding and finishing.<br />

Zirconia (E), (R) and (X)<br />

More durable and aggressive than aluminium oxide.<br />

Performs best when slight pressure is applied.<br />

Good choice for stainless steel.<br />

Ceramic (K)<br />

Maximum durability with aggressive stock removal and<br />

cooler grinding on stainless steel, hard metals, and alloys.<br />

Silicon Carbide (S)<br />

A brittle, self-sharpening grain for stone, glass,<br />

plastics and very hard materials like titanium.<br />

SPECIFICATIONS SPECIFICATIONS SPECIFICATIONS<br />

Cleaning Cleaning Cleaning<br />

Cutting Cutting Cutting<br />

Grinding Grinding Grinding<br />

Deburring Deburring Deburring<br />

Blending Blending Blending<br />

Finishing Finishing Finishing<br />

Polishing Polishing Polishing<br />

PRODUCTS PRODUCTS PRODUCTS<br />

P. 26<br />

P. 10 ff. P. 13 P. 16 P. 17 P. 19 ff. P. 19 P. 34 ff P. 25<br />

P. 38<br />

P. 49<br />

P. 73 ff.<br />

P. 55<br />

P. 41 ff. P. 45 ff. P. 32<br />

P. 36 ff.<br />

P. 63 P. 12<br />

P. 58 P. 59 P. 56 P. 71<br />

P. 66<br />

P. 65

FINISHING<br />

PRODUCT OVERVIEW<br />

POLISHING<br />

INTERLEAVED FINISHING NONWOVEN FINISHING PRE-POLISHING FELT POLISHING<br />

Alternating flaps of coated<br />

abrasive and nonwoven<br />

finishing materials.<br />

The coated flaps provide light<br />

stock removal or deburring,<br />

while the nonwoven flaps<br />

apply a good finish.<br />

Produces a brushed, or<br />

lightly grained finish, as is<br />

popular with stainless steel<br />

food processing equipment.<br />

Abrasive grain distributed<br />

throughout a 3-dimensional<br />

nylon web.<br />

Conditions, cleans and<br />

finishes the surface without<br />

undercutting the material.<br />

Some products are available<br />

in Surface Conditioning<br />

Material and Convolute<br />

versions with heavier grain<br />

concentrations and densities<br />

for added aggressiveness<br />

and strength.<br />

High concentration of<br />

abrasive grain throughout<br />

a firm, nonwoven base<br />

material.<br />

The additional grain<br />

requires less operator<br />

pressure, increasing tool<br />

life and grinding cooler.<br />

Achieve final finishes and<br />

well prepared surface prior<br />

to Polishing.<br />

For producing up to a<br />

mirror finish!!!<br />

Made from 100% wool felt<br />

and used with a polishing<br />

paste or buffing compound.<br />

Felt is arranged in a flap<br />

pattern to allow cooler air<br />

flow and dissipate the heat.<br />

Felt flap wheels are more<br />

flexible than solid felt points<br />

and eliminate the need for<br />

assorted shapes.<br />

<strong>Wheels</strong> also available in slit<br />

brushes for added flexibility<br />

SPECIFICATIONS SPECIFICATIONS SPECIFICATIONS SPECIFICATIONS<br />

Cleaning Cleaning Cleaning Cleaning<br />

Cutting Cutting Cutting Cutting<br />

Grinding Grinding Grinding Grinding<br />

Deburring Deburring Deburring Deburring<br />

Blending Blending Blending Blending<br />

Finishing Finishing Finishing Finishing<br />

Polishing Polishing Polishing Polishing<br />

PRODUCTS PRODUCTS PRODUCTS PRODUCTS<br />

P. 28 P. 27 P. 25 P. 26 P. 27 P. 25<br />

P. 29 P. 30<br />

P. 49 P. 33<br />

P. 33 P. 50 P. 38<br />

P. 38 P. 50 P. 43<br />

P. 52<br />

P. 33<br />

S. 39<br />

P. 60<br />

P. 72 P. 60 P. 72<br />

P. 63<br />

P. 61 ff. P. 64<br />

P. 66<br />

P. 66<br />

P. 67<br />

P. 67

INTRO TO CUTTING AND GRINDING DISCS<br />

1<br />

2<br />

3<br />

4<br />

USA safety standard<br />

European safety standard<br />

Proof of OSA-Certification<br />

Wear proper protection<br />

Markings on Cutting and Grinding Discs<br />

Wear gloves<br />

Read information<br />

11<br />

Don’t use broken discs<br />

Iron- and sulphur free<br />

1<br />

8<br />

Shape<br />

Only for Cutting<br />

2<br />

7<br />

3<br />

Not for Grinding<br />

10<br />

6<br />

5<br />

Application<br />

4<br />

9<br />

4<br />

6<br />

Dimension<br />

5<br />

7<br />

Part Number<br />

8<br />

Max RPM; max. working speed<br />

9<br />

ISO-identification<br />

A: Aluminium Oxide<br />

C: Silicon Carbide<br />

Z: Zirconium<br />

30: Grit (4 - 24 = rough;<br />

30 - 60 = medium;<br />

70 - 222 = fine)<br />

U: Hardness (A = soft to Z = hard)<br />

BF: Synthetic resin bonding with fibre<br />

reinforced<br />

Cross Beam Colour<br />

Speed<br />

50 m/sec<br />

63 m/sec<br />

Colour<br />

80 m/sec<br />

100 m/sec<br />

10<br />

EAN-Code<br />

11<br />

Wendt Quality-line<br />

Label-Colour Guide<br />

Good Performance on Stainless Steel<br />

Best Performance on Aluminium<br />

Best Performance on Steel<br />

Best Performance on Stainless Steel<br />

Extra Performance and Longest Life on Stainless Steel<br />

8

CUTTING DISCS<br />

Wendt Cutting and Grinding Discs are manufactured to the best<br />

performing specifications for a variety of metal- and stoneworking<br />

applications. Our program includes the most popular sizes used<br />

on angle grinders.<br />

Quality:<br />

All materials used in the production of Wendt products are extensively<br />

tested to ensure our products deliver the best performance possible.<br />

Materials are carefully selected to meet the needs of the products they<br />

will go into.<br />

All our Cutting and Grinding Discs are OSA-certified.<br />

Consistency:<br />

Wendt Grinding and Cutting Discs are manufactured and certified<br />

according to quality standard EN12413.<br />

This ensures consistent quality of the products from order to order.<br />

Thin disc advantages:<br />

Cutting Discs with a thickness<br />

of 1mm are becoming more<br />

and more standard.<br />

These offer a number of<br />

advantages against their thicker<br />

counterparts:<br />

• faster cutting<br />

• narrow cutting joints<br />

• lower heat generation<br />

• lower material losses<br />

• less sparking<br />

• lower machine load<br />

extends tool life<br />

3mm<br />

1,5mm 1mm<br />

Wendt Quality Lines:<br />

To meet all possible requirements Wendt offers a wide range of different<br />

Cutting Discs. Our Cutting Discs are divided into 3 separate lines<br />

with different characteristics. The most important benchmarks are aggressiveness<br />

and product life.<br />

The chart below gives an overview of the product lines and the corresponding<br />

performance characteristics.<br />

Line Characteristics Aggressiveness Product Life<br />

BASIC<br />

GOOD PERFORMING, ECONOMICAL<br />

ENTRY LINE.<br />

POWER<br />

STANDARD LINE WITH FAST CUTTING AND<br />

FAST STOCK REMOVAL COMBINED WITH<br />

A LONG LIFE.<br />

PREMIUM<br />

EXTRA PERFORMANCE AND LONGEST LIFE.<br />

You can find the relevant chart according to each product on the<br />

following product pages.<br />

9

PREMIUM & POWER CUTTING DISCS<br />

Aggressivness<br />

Product Life<br />

Stainless Steel - Extra Performance<br />

Extra-Performance discs deliver longest life on<br />

stainless steel cutting applications.<br />

Iron and Sulphur free specification.<br />

Type T1 A46INOX<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type 41<br />

a x c x b (mm)<br />

115 x 1,0 x 22,23 270 306 13.300 25<br />

125 x 1,0 x 22,23 270 307 12.200 25<br />

115 x 1,5 x 22,23 270 311 13.300 25<br />

125 x 1,5 x 22,23 270 312 12.200 25<br />

178 x 1,5 x 22,23 270 314 8.600 25<br />

230 x 1,9 x 22,23 270 315 6.600 25<br />

Aggressiveness<br />

Product Life<br />

Stainless Steel<br />

Provides fast cutting action on stainless steel. Iron<br />

and Sulphur free specification.<br />

Type T1 A30INOX<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type 41<br />

a x c x b (mm)<br />

115 x 1,0 x 22,23 270 206 13.300 25<br />

125 x 1,0 x 22,23 270 207 12.200 25<br />

115 x 1,5 x 22,23 270 211 13.300 25<br />

125 x 1,5 x 22,23 270 212 12.200 25<br />

125 x 2,5 x 22,23 270 217 12.200 25<br />

178 x 2,5 x 22,23 270 218 8.600 25<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type T2 A30INOX<br />

Type 42<br />

a x c x b (mm)<br />

230 x 1,9 x 22,23 270 245 6.600 25<br />

10

POWER CUTTING DISCS<br />

Steel<br />

Rapid cutting and good life on mild steel applications.<br />

Type T1 A46UNI<br />

Type 41<br />

a x c x b (mm)<br />

115 x 1,0 x 22,23 270 106 13.300 25<br />

125 x 1,0 x 22,23 270 107 12.200 25<br />

115 x 1,5 x 22,23 270 111 13.300 25<br />

125 x 1,5 x 22,23 270 112 12.200 25<br />

178 x 1,5 x 22,23 270 114 8.600 25<br />

Aggressiveness<br />

Product Life<br />

TIP<br />

Special discs for cast iron<br />

and other sizes and specifications<br />

available upon request.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type T1 A24UNI<br />

Type 41<br />

a x c x b (mm)<br />

115 x 3,0 x 22,23 270 127 13.300 25<br />

125 x 3,0 x 22,23 270 128 12.200 25<br />

178 x 3,0 x 22,23 270 130 8.600 25<br />

230 x 3,0 x 22,23 270 131 6.600 25<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type T2 A24UNI<br />

Type 42<br />

a x c x b (mm)<br />

115 x 3,0 x 22,23 270 166 13.300 25<br />

125 x 3,0 x 22,23 270 168 12.200 25<br />

230 x 3,0 x 22,23 270 174 6.600 25<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Aggressiveness<br />

Product Life<br />

Aluminium<br />

Fast cutting and lasting power on aluminium and NFmetals.<br />

Special filling materials prevent the disc from<br />

clogging, thus guaranteeing an efficient, sharp cut and<br />

a long lifetime.<br />

Type T1 C46A<br />

Type 41<br />

a x c x b (mm)<br />

115 x 1,5 x 22,23 270 706 13.300 25<br />

125 x 1,5 x 22,23 270 707 12.200 25<br />

178 x 1,5 x 22,23 270 710 8.600 25<br />

230 x 1,9 x 22,23 270 712 6.600 25<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

11

BASIC & POWER CUTTING DISCS<br />

Aggressiveness<br />

Product Life<br />

Basic<br />

Best choice for customers looking for an economical<br />

disc and standardized product features.<br />

Type T1 A46BASIC<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type 41<br />

a x c x b (mm)<br />

115 x 1,0 x 22,23 270 406 13.300 25<br />

125 x 1,0 x 22,23 270 407 12.200 25<br />

115 x 1,5 x 22,23 270 411 13.300 25<br />

125 x 1,5 x 22,23 270 412 12.200 25<br />

178 x 1,5 x 22,23 270 414 8.600 25<br />

230 x 1,9 x 22,23 270 415 6.600 25<br />

Aggressiveness<br />

Product Life<br />

TIP<br />

Special discs for cast iron<br />

and other sizes and specfications<br />

available upon request.<br />

Steel<br />

Provides a lot of power and a high cuttig speed<br />

on mild steel applications. Achieves excellent<br />

cutting results on machines with weak drives.<br />

Works ideally on chop saws (up to 3KW driving<br />

power), but is also suitable for desk machines.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type T1 A36UNI<br />

Type 41<br />

a x c x b (mm)<br />

300 x 2,8 x 25,4 271 203 5.100 10<br />

350 x 2,8 x 25,4 271 205 4.400 10<br />

12

GRINDING DISCS<br />

Steel<br />

Excellent stock removal and good life on mild<br />

steel applications.<br />

Aggressiveness<br />

Product Life<br />

Type S7 A30UNI<br />

Type 27<br />

a x c x b (mm)<br />

115 x 6,5 x 22,23 270 176 13.300 10<br />

125 x 6,5 x 22,23 270 178 12.200 10<br />

178 x 7,0 x 22,23 270 182 8.600 10<br />

230 x 7,0 x 22,23 270 186 6.600 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Stainless Steel<br />

Provides fast stock removal on stainless steel.<br />

Iron and Sulphur free specification.<br />

Aggressiveness<br />

Product Life<br />

Type S7 A24INOX<br />

Type 27<br />

a x c x b (mm)<br />

115 x 6,0 x 22,23 270 276 13.300 10<br />

125 x 6,0 x 22,23 270 278 12.200 10<br />

178 x 6,0 x 22,23 270 282 8.600 10<br />

230 x 6,0 x 22,23 270 286 6.600 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

TIP<br />

Other sizes and specifications<br />

available upon<br />

request.<br />

13

FLAP DISCS<br />

They are easy to use, quiet, and<br />

can perform many jobs that previously<br />

used a grinding wheel to<br />

remove stock, followed by a<br />

sanding disc to create a smooth<br />

finish. This saves both time and<br />

labour.<br />

<strong>Flap</strong> Discs were developed in the 1980’s, and have continued to gain popularity<br />

while the demand for many abrasive products has declined in that same period.<br />

One of the keys to their success is that they allow an operator to grind material<br />

and create a good finish in one step. <strong>Flap</strong> discs are very versatile, and the tools<br />

they are used on can be found in almost every factory, fabrication shop, and<br />

maintenance department.<br />

Wendt was one of the first manufacturers of flap discs, and is one of the largest<br />

volume producers world wide. In addition to constantly improving our products,<br />

we have developed a number of unique flap discs to satisfy a wide range of needs.<br />

Wendt customers can select from:<br />

While not as aggressive as an grinding<br />

wheel, <strong>Flap</strong> Discs:<br />

- Are much easier to control<br />

- Are much quieter to operate<br />

- Do not chatter<br />

- Are less likely to gouge, undercut<br />

or otherwise ruin the workpiece<br />

A choice of shapes:<br />

Depending on the customer demand and preferences Wendt offers a variation of<br />

shapes. Our customers can choose from a soft flat, small angled and an aggressive<br />

angled style.<br />

Type 27 (Conical 8°) - The original style flap disc with<br />

slight taper on the flaps.<br />

Type 28 (Flat) - for finishing applications.<br />

TIP<br />

Customers should always<br />

use the full surface of the<br />

flaps to obtain maximum productivity.<br />

Type 29 (Conical 15°) - with “built-in grinding<br />

angle” for more aggressive stock removal.<br />

14

FLAP DISCS<br />

Abrasive materials to match your application:<br />

Aluminium Oxide (A, N)<br />

with standard cotton backing for mild steels.<br />

Zirconia (E, R)<br />

with standard cotton backing for exceptional performance<br />

in both mild and stainless steel.<br />

100% Zirconia (X)<br />

with poly-cotton backing for the very best performance.<br />

Combines long life with aggresive stock removal.<br />

Ceramic (K)<br />

including top coating with polyester backing for faster stock<br />

removal, increased life, and cooler grinding on stainless<br />

steel, harder metals and alloys.<br />

A variety of backings:<br />

Fiberglass<br />

Very strong, yet wears away as the disc<br />

is consumed.<br />

Aluminium<br />

AluEdge<br />

For rigid support. Zirconia grains in particular<br />

become more aggressive and productive as you<br />

apply slight pressure.<br />

Our patented AluEdge which combines an<br />

aluminium backing with a unique consumable<br />

edge.<br />

Plastic<br />

Provides firm support, yet more economical<br />

than aluminium.<br />

15

FLEXTREME<br />

FLAP DISC<br />

PATENT by<br />

NEW 2012<br />

A Patented Wendt Exclusive!<br />

Wendt’s new FLEXTREME <strong>Flap</strong> Disc stands alone in the world<br />

of abrasives. The innovative design provides a number of<br />

outstanding benefits.<br />

Conventional flap disc backings provide strength and<br />

support. FLEXTREME’s revolutionary backing is contructed<br />

of abrasive material. The backing wears down evenly with<br />

the flaps. It can be used to grind and blend interior corners<br />

without interference from a backing plate. Eliminates the<br />

need to trim the backing.<br />

FLEXTREME comes standard with an M14 threaded arbor. Allows<br />

faster, tool-free changes from disc to disc. No additional backing<br />

pads or accessories needed.<br />

Advantages WENDT FLEXTREME:<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

• High flexibility due to the unique flap design<br />

• Reduced vibration allows more comfort and control.<br />

• Blends into corners, reducing undercut. Perfect control on edges<br />

• Long Life / Less waste – use the disc down to the hub.<br />

• Faster tool changes with the M14 thread<br />

• Excellent finish<br />

• Considerably more usable abrasive<br />

than a traditional flap disc<br />

Type FLEXTREME<br />

A used FLEXTREME in<br />

comparison to a new one:<br />

TIP<br />

The FELXTREME <strong>Flap</strong> Discs are<br />

also available with a 5/8-11 arbor.<br />

(mm) X40 X60 X80<br />

115 x M14 237 012 237 013 237 014 13.300 10<br />

125 x M14 237 022 237 023 237 024 12.200 10<br />

16

FOLDED FLAP DISCS<br />

Patterned after our larger folded flap discs, this latest<br />

version has a M14 threaded arbor for quick mounting<br />

on 125mm angle grinders. Unique folded flaps allow<br />

grinding and finishing within narrow grooves or<br />

channels. Folded <strong>Flap</strong> Discs are also being used at a<br />

shallow angle if flexible finishing is required.<br />

Aluminium Oxide<br />

Available in a wider grit range for improved finish.<br />

Type FS<br />

(mm) N40 N60 N80 N120 N180<br />

115 x M14 245 746 245 747 245 748 13.300 10<br />

125 x M14 245 750 245 751 245 752 245 753 245 755 12.200 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Zirconia<br />

Tough zirconia grain for more aggressive stock removal and longer life.<br />

Best choice for stainless steel.<br />

Type FS<br />

(mm) R40 R60 R80<br />

115 x M14 245 785 245 786 245 787 13.300 10<br />

125 x M14<br />

245 790 245 791 245 792<br />

12.200 10<br />

TIP<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

The Folded <strong>Flap</strong> Discs are also<br />

available with a 5/8-11 arbor.<br />

17

QUALITY LINES FLAP DISCS<br />

Wendt Quality Lines<br />

For the flap discs we do have several different lines:<br />

BASIC, POWER and PREMIUM.<br />

This is all relatetd to performace, agressiveness, and product life.<br />

This is our standard line with<br />

standard material.<br />

Here we work with much more material<br />

than standard discs, which gives a long<br />

life. We combine this with improved grade<br />

of abrasive to create a perfect match between<br />

life and high stock removal.<br />

Here we offer a very aggressive disc with<br />

Ceramic or a long lasting one which is<br />

Type GH.<br />

For the flap discs, we offer several different lines: Premium, Powerflex and<br />

PowerEx. This is all related to performance, aggressively and product life.<br />

Within all lines we never would compromise on one topic, which is the<br />

safety of our discs. Each disc undergoes strict safety controls!<br />

TIP<br />

We also produce custom<br />

flap discs to meet specific<br />

needs.<br />

Line Product Aggressiveness Life Time<br />

BASIC<br />

POWER<br />

PREMIUM<br />

HiTec<br />

Keramik<br />

18

PREMIUM-LINE FLAP DISCS<br />

HiTec with Fiberglass Backing<br />

Made with even more and longer flaps than our<br />

standard version to significantly increase product<br />

life. Thicker construction provides more cushioning<br />

for finishing applications.<br />

with x-tra lifetime<br />

Our <strong>Flap</strong> Discs are produced with the<br />

abrasive cloth which will assure your<br />

customer the highest performance<br />

and life of the product.<br />

The following <strong>Flap</strong> Discs are made<br />

with an aggressive abrasive containing<br />

100% Zirconia grain. Professional<br />

operators will recognize the<br />

quality and long life of these discs.<br />

Type GH1 (Flat, soft)<br />

(mm) X40 X60 X80 X120<br />

115 x 22,23 235 112 235 113 235 114 235 116 10.500 10<br />

125 x 22,23 235 132 235 133 235 134 235 136 9.600 10<br />

178 x 22,23 235 142 235 143 235 144 235 146 6.700 10<br />

Type GH29 (Conical 15°)<br />

Aggressiveness<br />

Product Life<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

(mm) X40 X60 X80 X120<br />

115 x 22,23 236 112 236 113 236 114 236 116 10.500 10<br />

125 x 22,23 236 132 236 133 236 134 236 136 9.600 10<br />

178 x 22,23 236 142 236 143 236 144 236 146 6.700 10<br />

with Ceramic<br />

Aggressiveness<br />

Product Life<br />

Made with a specially engineered Ceramic<br />

grain for the most aggressive stock removal<br />

and exceptional life on hard materials like<br />

stainless steel. This abrasive performs best as<br />

pressure is applied by the operator.<br />

Type G 19 (Conical 15°)<br />

(mm) K40 K60 K80<br />

115 x 22,23 229 412 229 413 229 414 13.300 10<br />

125 x 22,23 229 432 229 433 229 434 12.200 10<br />

G19 after several minutes of<br />

heavy grinding!<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

TIP<br />

Best used with powerful<br />

angle grinders and<br />

more pressure.<br />

19

POWER-LINE FLAP DISCS<br />

Aggressiveness<br />

Product Life<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

with Zirconia<br />

More durable than aluminium oxide. Best choice when<br />

working on a variety of materials including carbon steel,<br />

stainless steel, aluminium, fiberglass and plastics.<br />

Wendt Powerflex <strong>Flap</strong> Discs are made with a higher concentration<br />

of exceptional abrasive cloth which results in<br />

a long life time as well as high aggressiveness.<br />

Type G 29 (Konical 15°)<br />

100% Zirconica (X)<br />

with poly-cotton backing for the<br />

very best performance.<br />

Combines long life with aggresive<br />

stock removal.<br />

(mm) X36 X40 X60 X80 X120<br />

100 x 16 229 101 229 102 229 103 229 104 229 106 15.300 10<br />

115 x 22,23 229 111 229 112 229 113 229 114 229 116 13.300 10<br />

125 x 22,23 229 131 229 132 229 133 229 134 229 136 12.200 10<br />

178 x 22,23 229 141 229 142 229 143 229 144 229 146 8.600 10<br />

Type G 28 (Flat)<br />

(mm) X36 X40 X60 X80 X120<br />

100 x 16 228 101 228 102 228 103 228 104 228 106 15.300 10<br />

115 x 22,23 228 111 228 112 228 113 228 114 228 116 13.300 10<br />

125 x 22,23 228 131 228 132 228 133 228 134 228 136 12.200 10<br />

178 x 22,23 228 141 228 142 228 143 228 144 228 146 8.600 10<br />

Type G 27 (Conical 8°)<br />

(mm) X36 X40 X60 X80 X120<br />

100 x 16 227 101 227 102 227 103 227 104 227 106 15.300 10<br />

115 x 22,23 227 111 227 112 227 113 227 114 227 116 13.300 10<br />

125 x 22,23 227 131 227 132 227 133 227 134 227 136 12.200 10<br />

178 x 22,23 227 141 227 142 227 143 227 144 227 146 8.600 10<br />

TIP<br />

We also produce custom<br />

flap discs to meet specific<br />

needs.<br />

20

POWER-LINE FLAP DISCS<br />

Aggressiveness<br />

Product Life<br />

with Aluminium Oxide<br />

For general grinding and finishing on carbon steel,<br />

stainless steel, and aluminium.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type G 29 (Conical 15°)<br />

(mm) N40 N60 N80 N120<br />

100 x 16 229 002 229 003 229 004 229 006 15.300 10<br />

115 x 22,23 229 012 229 013 229 014 229 016 13.300 10<br />

125 x 22,23 229 032 229 033 229 034 229 036 12.200 10<br />

178 x 22,23 229 042 229 043 229 044 229 046 8.600 10<br />

Aluminium Oxide (A, N)<br />

with standard cotton backing for<br />

mild steels.<br />

Type G 28 (Flat)<br />

(mm) N40 N60 N80 N120<br />

100 x 16 228 002 228 003 228 004 228 006 15.300 10<br />

115 x 22,23 228 012 228 013 228 014 228 016 13.300 10<br />

125 x 22,23 228 032 228 033 228 034 228 036 12.200 10<br />

178 x 22,23 228 042 228 043 228 044 228 046 8.600 10<br />

Type G 27 (Conical 8°)<br />

(mm) N40 N60 N80 N120<br />

100 x 16 227 002 227 003 227 004 227 006 15.300 10<br />

115 x 22,23 227 012 227 013 227 014 227 016 13.300 10<br />

125 x 22,23 227 032 227 033 227 034 227 036 12.200 10<br />

178 x 22,23 227 042 227 043 227 044 227 046 8.600 10<br />

TIP<br />

Other Grit Sizes available<br />

upon request. Minimum<br />

order requirements may apply.<br />

21

BASIC-LINE FLAP DISCS<br />

Aggressiveness<br />

Product Life<br />

Manufactured under the same<br />

extensive quality standards and<br />

safety requirements as our<br />

Powerflex lines.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

with Zirconia<br />

PowerEx <strong>Flap</strong> Discs are made with a standard Zirconium<br />

cloth with cotton backing. They are manufactured under<br />

the same quality standards and safety requirements as<br />

our more premium grades. They are the best choice for<br />

customers looking for an economical solution.<br />

Type G 19 (Conical 15°)<br />

(mm) E40 E60 E80 E120<br />

115 x 22,23 229 712 229 713 229 714 229 716 13.300 10<br />

125 x 22,23 229 732 229 733 229 734 229 736 12.200 10<br />

178 x 22,23 229 742 229 743 229 744 229 746 8.600 10<br />

Type G 18 (Flat)<br />

(mm) E40 E60 E80 E120<br />

115 x 22,23 228 712 228 713 228 714 228 716 13.300 10<br />

125 x 22,23 228 732 228 733 228 734 228 736 12.200 10<br />

178 x 22,23 228 742 228 743 228 744 228 746 8.600 10<br />

Type G 17 (Conical 8°)<br />

(mm) E40 E60 E80 E120<br />

115 x 22,23 227 712 227 713 227 714 227 716 13.300 10<br />

125 x 22,23 227 732 227 733 227 734 227 736 12.200 10<br />

178 x 22,23 227 742 227 743 227 744 227 746 8.600 10<br />

with Aluminium Oxide<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type G 19 (Conical 15°)<br />

(mm) A40 A60 A80<br />

115 x 22,23 229 912 229 913 229 914 13.300 10<br />

125 x 22,23 229 932 229 933 229 934 12.200 10<br />

Type G 18 (Flat)<br />

(mm) A40 A60 A80<br />

115 x 22,23 228 912 228 913 228 914 13.300 10<br />

125 x 22,23 228 932 228 933 228 934 12.200 10<br />

Type G 17 (Conical 8°)<br />

22<br />

(mm) A40 A60 A80<br />

115 x 22,23 227 912 227 913 227 914 13.300 10<br />

125 x 22,23 227 932 227 933 227 934 12.200 10

SPECIALITIES FLAP DISCS<br />

<strong>Flap</strong> Discs with Plastic Backing<br />

with Zirconia<br />

PowerEx <strong>Flap</strong> Discs are made with a standard<br />

Zirconium cloth with cotton backing. They are<br />

manufactured under the same quality standards<br />

and safety requirements as our more premium<br />

grades. They are the best choice for customers<br />

looking at an economical solution.<br />

Aggressiveness<br />

Product Life<br />

Manufactured under the same<br />

extensive quality standards and<br />

safety requirements as our<br />

Powerflex lines.<br />

Type K11 (Flat)<br />

(mm) E40 E60 E80 E120<br />

115 x 22,23 230 712 230 713 230 714 230 716 13.300 10<br />

125 x 22,23 230 732 230 733 230 734 230 736 12.200 10<br />

178 x 22,23 230 742 230 743 230 744 230 746 8.600 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Aggressiveness<br />

Speciality <strong>Flap</strong> Discs<br />

Product Life<br />

with reduced Fiberglass Backing<br />

The Powerflex with reduced backing lets you<br />

benefit from all the advantage of a regular<br />

Powerflex combined with the ability to work on<br />

edges and corners as the resulting flexible edge<br />

adjusts perfectly to the angle of the workpiece.<br />

Type G 17 (Conical 8°)<br />

(mm)<br />

Diameter<br />

Backing<br />

(mm) R40 R60 R80 R120<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

115 x 22,23 100<br />

240 812 240 813 240 814 240 816<br />

13.300 10<br />

125 x 22,23 108<br />

240 832 240 833 240 834 240 836<br />

12.200 10<br />

Type G18 with reduced backing in dia. 125mm is also available upon request.<br />

23

SPECIALITIES FLAP DISCS<br />

PATENT by<br />

with Aluminium<br />

Backing and Patented AluEdge<br />

Grinding Edge<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Our patented grinding edge offers the rigid support<br />

of an aluminium backing. The outer grinding edge<br />

supports the flaps, yet wears away allowing full use<br />

of the disc. Our best performing design for aggressive<br />

applications!<br />

Type S 29 (Conical 15°)<br />

Aggressiveness<br />

Product Life<br />

(mm) X40 X60 X80 X120<br />

115 x 22,23 234 112 234 113 2341 14 234 116 13.300 10<br />

125 x 22,23 234 132 234 133 234 134 234 136 12.200 10<br />

Aggressiveness<br />

Product Life<br />

The Aluminium Backing is ideal<br />

for heat absorption.<br />

The Backing is far lighter and<br />

easier to use than conventional<br />

Steel Backings.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

with Zirconia<br />

The Aluminium Backing is ideal for heat absorption and<br />

provides firm support. It is a light material and will not<br />

scratch the metal work piece.<br />

Type A 29 (Conical 15°)<br />

(mm) X40 X60 X80 X120<br />

115 x 22,23 244 112 244 113 244 114 244 116 13.300 10<br />

125 x 22,23 244 132 244 113 244 114 244 116 12.200 10<br />

178 x 22,23 244 142 244 143 244 144 244 146 8.600 10<br />

Type A 27 (Conical 8°)<br />

(mm) X40 X60 X80 X120<br />

100 x 16 233 102 233 103 233 104 233 106 15.300 10<br />

Aggressiveness<br />

Product Life<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

with Aluminium Oxide<br />

The Aluminium Backing is ideal for heat absorption and<br />

provides firm support. It is a light material and will not<br />

scratch the metal work piece.<br />

Type A 29 (Conical 15°)<br />

(mm) N40 N60 N80 N120<br />

115 x 22,23 244 012 244 013 244 014 244 016 13.300 10<br />

125 x 22,23 244 032 244 033 244 034 244 036 12.200 10<br />

178 x 22,23 244 042 244 043 244 044 244 046 8.600 10<br />

24

UNMOUNTED FLAP WHEELS FOR ANGLE GRINDERS<br />

ABRASIVE<br />

FLAP WHEELS<br />

FOR<br />

ANGLE GRINDERS<br />

Threaded Abrasive <strong>Flap</strong> <strong>Wheels</strong><br />

This latest version has a M14 threaded arbor for<br />

quick mounting on 115mm and 125mm angle<br />

grinders. Recommended for weld dressing,<br />

removing rust, paint, coatings and heat discoloration.<br />

Works well for general purpose grinding<br />

on steel and stainless steel workpiece contours.<br />

Type LS M14<br />

a x b (mm) c (mm) A40 A60 A80 A120 A180 A240 A320<br />

115 x 20 M14 325 302 325 304 325 305 325 307 325 309 325 311 325 312 13.300 1<br />

125 x 20 M14 325 322 325 324 325 325 325 327 325 329 325 331 325 332 12.200 1<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Threaded Interleaved <strong>Flap</strong> <strong>Wheels</strong><br />

for angle polishers<br />

Alternating flaps of abrasive cloth and nonwoven finishing material.<br />

Provides some stock removal while producing a brushed<br />

finish. Also good for deburring and finishing in one step.<br />

Type LK M14<br />

a x b (mm) c (mm) A80/ Med A150/ Fine A240/ V.Fine<br />

115 x 20 M14 325 952 325 954 325 956 2.800 3.700 1<br />

125 x 20 M14 325 962 325 964 325 966 2.000 3.200 1<br />

Threaded Nonwoven <strong>Flap</strong> <strong>Wheels</strong><br />

for angle polishers<br />

Non-aggressive nylon material produces a smooth surface<br />

finish.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

TIP:<br />

The <strong>Flap</strong> <strong>Wheels</strong> for angle<br />

grinders are also available<br />

with a 5/8-11 arbor.<br />

Type LV M14<br />

a x b (mm) c (mm) Medium Fine Very Fine<br />

115 x 20 M14 326 851 326 852 326 853 2.800 3.700 1<br />

125 x 20 M14 326 861 326 862 326 863 2.000 3.200 1<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

25

SCM &<br />

REX FLEX<br />

FLAP DISCS<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

SURFACE CONDITIONING MATERIAL (SCM)<br />

Finishing <strong>Flap</strong> Discs with Fiberglass Backing<br />

For general surface preparation and finishing<br />

with more durable surface conditioning material<br />

of highest available quality. Layered flaps provide<br />

up to 7 times more life than traditional Hook<br />

& Loop version.<br />

Micro section after use with<br />

SCM <strong>Flap</strong> Disc<br />

Type SCM G27 (Conical)<br />

(mm)<br />

Coarse/<br />

Brown<br />

Medium/<br />

Maroon<br />

V. Fine/<br />

Blue<br />

100 x 16<br />

245 421 245 422 245 424<br />

6.600 15.300 10<br />

115 x 22,23<br />

245 431 245 432 245 434<br />

5.800 13.300 10<br />

Coarse<br />

(Brown)<br />

Medium<br />

(Maroon)<br />

Very Fine<br />

(Blue)<br />

125 x 22,23<br />

245 451 245 452 245 454<br />

5.300 12.200 10<br />

178 x 22,23<br />

245 471 245 472 245 474<br />

3.700 8.600 10<br />

Type SCM G29 with a conical shape also available on request.<br />

Cleaning of metal surfaces with<br />

Rex Flex Discs<br />

Colour Rust Heat<br />

discoloration<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

REX FLEX Nonwoven Cleaning Discs<br />

with Fiberglass Backing<br />

For aggressive cleaning, or removing rust, paint,<br />

epoxy or weld spatter.<br />

Type RF G27 (Flat)<br />

(mm)<br />

S-Coarse<br />

100 x 16<br />

245 400<br />

7.000 12.800 5<br />

115 x 22,23<br />

245 401<br />

6.000 11.000 5<br />

125 x 22,23<br />

245 403<br />

5.600 9.800 5<br />

178 x 22,23<br />

245 404<br />

3.900 6.800 5<br />

26

POLYPOWER<br />

Interleaved Polypower<br />

with Fiberglass Backing<br />

Alternating flaps of coated abrasive and nonwoven<br />

material for finishing applications with minimal<br />

sanding. Provides a brushed finish.<br />

Type GK (Flat)<br />

Micro section after use with our<br />

INTERLEAVED POLYPOWER<br />

A80/<br />

Medium<br />

A150/<br />

Fine<br />

A240/<br />

Very Fine<br />

(mm)<br />

A80/<br />

Medium<br />

A150/<br />

Fine<br />

A240/<br />

V. Fine<br />

115 x 22,23<br />

245 013 245 016 245 018<br />

3.300 8.500 5<br />

125 x 22,23<br />

245 033 245 036 245 038<br />

3.000 7.700 5<br />

178 x 22,23<br />

245 043 245 046 245 048<br />

2.100 5.500 5<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Micro section after use with our<br />

POLYPOWER<br />

Polypower<br />

with Fiberglass Backing<br />

<strong>Flap</strong>s of nonwoven material for fine surface finishing.<br />

A-Medium A-Fine A-Very Fine<br />

Type GV (Flat)<br />

(mm) A-Medium A-Fine A-V. Fine<br />

115 x 22,23<br />

245 212 245 214 245 215<br />

3.300 8.500 5<br />

125 x 22,23<br />

245 232 245 234 245 235<br />

3.000 7.700 5<br />

178 x 22,23<br />

245 242 245 244 245 245<br />

2.100 5.500 5<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

27

HYBRID FLAP DISC<br />

Hybrid Disc<br />

Thanks to the advanced and innovative construction<br />

of our Hybrid Disc, combining high<br />

quality Surface Conditioning Material and<br />

Coated Abrasives, you will need only one<br />

step to achieve a pleasing finish instead<br />

of usually 2 steps using conventional abrasive<br />

methods. This saves time, labor and<br />

money.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type HG29 (Conical)<br />

Medium/<br />

(mm)<br />

Maroon<br />

115 x 22,23 245 173 3.500 13.300 10<br />

125 x 22,23 245 183 3.000 12.200 10<br />

Hybrid discs are ideal for the<br />

following applications:<br />

• Removing and finishing light weld seams in a<br />

single step<br />

• Deburring flashings after plasma and laser<br />

cuttings<br />

• Decorative finish for builders hardware<br />

• Removing of small surface imperfections<br />

• Blending of rough sanding lines<br />

• Cleaning of oxidation, discoloration, welding<br />

spatter<br />

• Homogenizing surfaces and work pieces<br />

• Light deburring<br />

• Removing of parting lines<br />

• Preparing of Surface prior to the final finish<br />

• Removing paints, coatings<br />

Hybrid discs can be used on a wide range of different materials such<br />

as steel, stainless steel, Aluminium and different alloys.<br />

28<br />

TIP:<br />

Other grades and dimensions<br />

are available upon<br />

request.<br />

You are just two steps away from a mirror surface finish!

UNITIZED<br />

FINISHING DISCS<br />

Unitized Finishing Discs with Fiberglass Backing<br />

High concentration of abrasive grain throughout a firm,<br />

nonwoven base material. The additional grain requires<br />

less operator pressure, increasing disc life and<br />

cooler grinding. Exceptional choice for deburring<br />

and blending stainless steel, and providing a<br />

smooth finish.<br />

Type U G27 (Flat)<br />

(mm)<br />

4 - Medium 6 - Hard<br />

A-Coarse S-Medium S-Very Fine S-Very Fine<br />

115 x 22,23<br />

245 814 245 817 245 819 245 871<br />

4.000 11.000 5<br />

125 x 22,23<br />

245 834 245 837 245 839 245 873<br />

3.600 9.800 5<br />

Wendt Unitized Finishing Discs provid an extreme long life combined with a<br />

comfortable handling to achieve final finishes and well prepared surface prior<br />

to Polishing. These discs are designed to work on angle grinder. The compact<br />

3-dimensional construction is very resistant to loading and provides<br />

solutions to both ferrous and non-ferrous finishing operations.<br />

Micro section after use with our<br />

Unitized Finishing Disc<br />

4A-Coarse 4S-Medium 4S-Very Fine<br />

Harder (6):<br />

• Removal of Aluminium Flashings<br />

• To radius stamped parts<br />

• To remove sharp edges of machined parts<br />

• Cleaning of metal conductors<br />

• Removing resins , excessive glue and adhesive<br />

overspray<br />

• Removal of rust and corrosion<br />

Softer (4):<br />

• A decorative finish on stainless steel for builders<br />

hardware<br />

• Blending parting lines<br />

• Prepare surfaces of Stainless Steel and<br />

Titanium prior to polishing<br />

• Pre plate polish on Aluminium, Copper and<br />

Brass<br />

• As the last step prior to polishing<br />

• Blending surface defects<br />

Type U G29 (Conical)<br />

4 - Medium<br />

(mm) A-Coarse S-Medium S-Very Fine<br />

115 x 22,23 245 914 245 917 245 919 4.000 11.000 5<br />

125 x 22,23 245 934 245 937 245 939 3.600 9.800 5<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

TIP:<br />

Wendt recommends for<br />

most nonwoven abrasives<br />

applications speeds lower than the<br />

listed maximum operation speeds to<br />

ensure optimum results and maximum<br />

product life.<br />

You are just one step away from a mirror surface finish!<br />

29

FELT POLISHING<br />

FLAP DISCS<br />

PATENT by<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Felt Polishing Discs<br />

With Fiberglass Backing<br />

<strong>Flap</strong> discs made of 70% wool felt affixed to a fiberglass backing<br />

plate to create a thick polishing pad. The individual flaps are<br />

flexible, and allow a cool air flow. Felt discs are used with<br />

polishing compounds or pastes to provide up to a mirror finish.<br />

Ideal for work on irregular or contoured surfaces. Available in<br />

several Densities and <strong>Flap</strong> Thicknesses for softer and<br />

more flexible performance.<br />

(D=<strong>Flap</strong> thickness, H=Felt Density)<br />

Type FG 27 (Flat)<br />

(mm)<br />

Standard Flexibility<br />

Soft<br />

D5 / H25<br />

Medium<br />

D5 / H40<br />

Extra Flexibility<br />

Soft<br />

D3 / H25<br />

Medium<br />

D3 / H40<br />

100 x 16 245 601 245 602 245 606 245 607 1.900 9.700 5<br />

115 x 22,23 245 611 245 612 245 616 245 617 1.650 8.500 5<br />

115 x M14 249 911 249 912 249 916 249 917 1.650 8.500 5<br />

125 x 22,23 245 631 245 632 245 636 245 637 1.520 7.700 5<br />

125 x M14 249 921 249 922 249 926 249 927 1.520 7.700 5<br />

178 x 22,23 245 661 245 662 1.100 5.500 5<br />

178 x M14 249 941 249 942 1.100 5.500 5<br />

Note: Felt Polishing products are designed to be used with polishing compounds.<br />

For further information on compounds see page 77.<br />

TIP:<br />

Felt Products should<br />

always be run at lower<br />

speeds (eg. 10 m/s) than coated abrasives.<br />

30<br />

This is your last step to your target of a mirror finish!

Three Winners build<br />

a perfect Team!<br />

THREE STEPS TO MIRROR FINISH<br />

Also available as a full set,<br />

please see page 77.<br />

The fastest, quickest, and easiest way<br />

in the abrasive industry to achieve<br />

a perfect mirror finish!<br />

You fi nished at First just with 3 Steps!!!<br />

31

MINI FLAP DISCS<br />

Zirconia with Plastic Backing<br />

The versatility of Zirconia grain on a small diameter<br />

plastic backing. Offers more aggressive stock removal<br />

and longer life than quick change sanding discs.<br />

Ideal for working in confined spaces where larger flap<br />

discs will not fit.<br />

Standard<br />

Fastener<br />

Type K1 (Flat)<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

(mm) V40 V60 V80 V120<br />

50<br />

230 672 230 673 230 674 230 676<br />

75<br />

230 682 230 683 230 684 230 686<br />

Type K1 (Flat) R-Type Fastener<br />

(mm) V40 V60 V80 V120<br />

50<br />

230 688 230 689 230 690 230 691<br />

75<br />

230 695 230 696 230 697 230 698<br />

19.100 10<br />

12.700 10<br />

19.100 10<br />

12.700 10<br />

Reusable 6 mm Shank for<br />

Mini <strong>Flap</strong> Discs<br />

The reusable threaded shaft on 6mm shank fits both 50mm<br />

and 75mm Wendt Mini <strong>Flap</strong> Discs with Standard<br />

Fastener<br />

a x b (mm)<br />

6 x 40<br />

230 998<br />

1<br />

32

MINI FLAP DISCS<br />

Interleaved Mini Polypower<br />

with Plastic Backing<br />

Alternating flaps of coated abrasive and nonwoven<br />

material for finishing applications with minimal sanding.<br />

Provides a brushed finish.<br />

Micro section after use with our<br />

Interleaved Mini-Polypower<br />

Type KK (Flat)<br />

A80/<br />

Medium<br />

A150/<br />

Fine<br />

A240/<br />

Very Fine<br />

(mm)<br />

A80/<br />

Medium<br />

A150/<br />

Fine<br />

A240/<br />

V.Fine<br />

50<br />

245 063 245 066 245 068<br />

7.600 19.100 10<br />

75<br />

245 073 245 076 245 078<br />

5.000 12.700 10<br />

R-Type Fastener<br />

50<br />

245 083 245 085 245 087<br />

7.600 19.100 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

75<br />

245 093 245 095 245 097<br />

5.000 12.700 10<br />

Mini-Polypower<br />

with Plastic Backing<br />

<strong>Flap</strong>s of nonwoven material for fine surface finishing.<br />

Micro section after use with our<br />

Mini-Polypower<br />

Type KV (Flat)<br />

A-Medium A-Fine A-Very Fine<br />

A-Medium A-Fine A-V.Fine<br />

(mm)<br />

50<br />

245 262 245 264 245 265<br />

7.600 19.100 10<br />

75<br />

245 272 245 274 245 275<br />

5.000 12.700 10<br />

R-Type Fastener<br />

50<br />

245 282 245 284 245 285<br />

7.600 19.100 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

75<br />

245 292 245 294 245 295<br />

5.000 12.700 10<br />

Finishing Mini <strong>Flap</strong> Discs<br />

with Plastic Backing<br />

Use with a rouge or paste for polishing applications.<br />

For further information on paste see page 77.<br />

Type FK (Flat)<br />

(mm)<br />

Standard Flexibility<br />

Soft<br />

D3 / H25<br />

Medium<br />

D3 / H40<br />

Extra Flexibility<br />

Soft<br />

D2 / H25<br />

Medium<br />

D2 / H40<br />

50<br />

245 681 245 682 245 686 245 687<br />

3.800 19.100 10<br />

75<br />

245 691 245 692 245 696 245 697<br />

2.500 12.700 10<br />

R-Type Fastener<br />

50<br />

245 680 245 683 245 685 245 688<br />

3.800 19.100 10<br />

75<br />

245 690 245 693 245 695 245 698<br />

2.500 12.700 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

TIP:<br />

PATENT by<br />

The Mini <strong>Flap</strong> Discs with<br />

R-Type Fastener can be used<br />

with the R-Type Quick Change Holders,<br />

please see 39 for further information.<br />

33

RESIN FIBRE DISCS<br />

Resin Fibre Discs<br />

Resin Fibre Discs comprise a multilayer, heavy duty vulcanized fibre backing.<br />

Covered with a resin bond coat formulated to resist loading, glazing and grain<br />

stripping. This bond coat is then covered with specially processed abrasive grains<br />

formulated for toughness, sharpness and bond. Resin Fibre Discs are powerful,<br />

versatile, flexible, safe and economical. Choosing the right disc for the job assures<br />

improved productivity.<br />

Wendt Fibre Discs are produced with<br />

an 8-slit core.<br />

This makes them much more flexible<br />

and easier to mount than conventional<br />

cross holes.<br />

Grinding and abrading requirements cover a wide spectrum of<br />

applications for metal work:<br />

• Stock removal<br />

• Finishing and Blending<br />

• Varying materials incl. steel and stainless steel<br />

• Flat surfaces<br />

• Contour Surfaces<br />

Some of the commonly used tools for these applications include depressed center<br />

wheels, cup wheels, wire brushes and specialty products. While each of these<br />

products perform well in a specific application none of them have the all around<br />

capability of resin fibre discs.<br />

Wendt Resin Fibre Discs are produced with a 8-slit core which makes them easier<br />

to mount than the common 4-slit discs.<br />

Aluminium Oxide<br />

Provides overall economy, with good performance in an<br />

all purpose resin fibre disc.<br />

They contain no halogen producing grinding additives.<br />

Designed to excel in a wide variety of applications providing<br />

both cost effective stock removal and a safer working<br />

environment.<br />

- Low cost general purpose industrial quality disc<br />

- Clean bonding system promotes a safer, healthier working<br />

environment<br />

Type RFD<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

(mm) N36 N40 N60 N80 N120<br />

115 x 22,23<br />

264 362 264 363 264 365 264 366 264 368<br />

13.300 25<br />

125 x 22,23<br />

264 372 264 373 264 375 264 376 264 378<br />

12.200 25<br />

180 x 22,23<br />

264 382 264 383 264 385 264 386 264 388<br />

8.600 25<br />

34

RESIN FIBRE DISCS<br />

Zirconium<br />

Superior grinding performance in a premium<br />

Zirconium resin fibre disc. The extremely hard<br />

Zirconium abrasive alloy sharpens itself in use<br />

delivering outstanding cutting rates and maximum<br />

useful life. The advanced bond extends disc life by<br />

minimizing grain shedding, while promoting a cool<br />

grinding action which reduces glazing and loading.<br />

Zirconium Resin Fibre Discs are most cost effective<br />

when used in high production applications where<br />

cutting rates are monitored.<br />

- Premium Zirconium grit delivers superior grinding<br />

performance<br />

- Advance bonding formulation provides cool grinding<br />

action and extending disc life<br />

Type RFD<br />

(mm) Z36 Z40 Z60 Z80 Z120<br />

115 x 22,23<br />

264 412 264 413 264 415 264 416 264 418<br />

13.300 25<br />

125 x 22,23<br />

264 422 264 423 264 425 264 426 264 428<br />

12.200 25<br />

180 x 22,23<br />

264 442 264 443 264 445 264 446 264 448<br />

8.600 25<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Resin Fibre Discs Backing Pads<br />

Wendt Backing Pads are made of premium materials<br />

to ensure maximum life and performance.<br />

If you need a rigid, durable pad to increase the aggressiveness<br />

when working with coarser grit discs<br />

(grit 50 and coarser) you should choose our Heavy<br />

Duty Ribbed Pads. You also benefit from the special<br />

design which allows air flow behind the fibre disc,<br />

substantially increasing the life of the disc.<br />

Finer grit discs (60 and finer) should be used with<br />

the Smooth surface pads. Their more flexible backing<br />

provide a better finsih.<br />

Type BP<br />

(mm)<br />

Standard<br />

(soft)<br />

Specification<br />

Heavy Duty<br />

(hard)<br />

115 x M14<br />

263 225 263 244<br />

13.300 1<br />

125 x M14<br />

263 229 263 246<br />

12.200 1<br />

180 x M14<br />

263 235 263 248<br />

8.600 1<br />

35

QUICK CHANGE<br />

ABRASIVE DISCS<br />

Quick Change Abrasive Discs<br />

Available in either Aluminium Oxide or Zirconia grain on a durable, yet flexible<br />

backing. Popular R-Type fasteners allow quick changeovers between grits, or to<br />

nonwoven products (refer to page 40). Excellent for general grinding, blending and<br />

finishing.<br />

Aluminium Oxide<br />

Durable Aluminium Oxide grain for general<br />

purpose grinding and finishing on both ferrous<br />

and non-ferrous materials.<br />

R-Type<br />

Fastener<br />

Type QC with R-Type Fastener<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

(mm) A36 A60 A80 A120 A180 A240<br />

38<br />

262 021 262 024 262 025 262 027 262 029 262 031<br />

25.000 100<br />

50<br />

262 041 262 044 262 045 262 047 262 049 262 051<br />

25.000 100<br />

75<br />

262 061 262 064 262 065 262 067 262 069 262 071<br />

20.000 50<br />

Type QC with S-Type Fastener<br />

38<br />

262 121 262 124 262 125 262 127 262 129 262 131<br />

25.000 100<br />

50<br />

262 141 262 144 262 145 262 147 262 149 262 151<br />

25.000 100<br />

75<br />

262 161 262 164 262 165 262 167 262 169 262 171<br />

20.000 50<br />

TIP:<br />

For extended life select<br />

mini flap discs on page 32.<br />

Other materials like Silicon Carbide<br />

available upon request.<br />

S-Type<br />

Fastener<br />

Quick Change Disc Holders<br />

available on page 39.<br />

36

QUICK CHANGE ABRASIVE DISCS<br />

Zircon+ with Grinding Aid<br />

Premium Zirconia plus a Grinding Aid to dissipate<br />

heat and allow cooler grinding on Stainless Steel and<br />

hard alloys. Application requires moderate to heavy<br />

pressure to activate the grinding aid.<br />

Grinding aid also inhibits loading of softer materials<br />

like aluminium and brass.<br />

Type QC with R-Type Fastener<br />

(mm) Z+36 Z+60 Z+80 Z+120<br />

50<br />

262 771 262 774 262 775 262 777<br />

25.000 100<br />

75<br />

262 781 262 784 262 785 262 787<br />

20.000 50<br />

Type QC with S-Type Fastener<br />

50<br />

262 821 262 824 262 825 262 827<br />

25.000 100<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

75<br />

262 831 262 834 262 835 262 837<br />

20.000 50<br />

Ceramic with Grinding Aid<br />

Ceramic grain plus a Grinding Aid for aggressive stock<br />

removal on harder materials like stainless and alloys.<br />

Grinding aid dissipates heat, particularly under heavy<br />

pressure, while providing maximum life.<br />

Type QC with R-Type Fastener<br />

(mm) K36 K60 K80 K120<br />

50<br />

262 511 262 514 262 515 262 517<br />

25.000 100<br />

75<br />

262 521 262 524 262 525 262 527<br />

20.000 50<br />

Type QC with S-Type Fastener<br />

50<br />

262 561 262 564 262 565 262 567<br />

25.000 100<br />

75<br />

262 571 262 574 262 575 262 577<br />

20.000 50<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

TIP:<br />

Other sizes and grits<br />

available upon request.<br />

37

QUICK CHANGE NONWOVEN DISCS<br />

Micro section after use with our<br />

SCM Quick Change Discs<br />

Quick Change Surface Conditioning Discs<br />

Premium Surface Conditioning material is ideal for<br />

deburring, surfaces preparation, weld and gasket<br />

cleaning, and finishing stainless steel. Abrasive grain is<br />

evenly dispersed throughout a cushioned nylon web.<br />

Provides even surfaces finished without undercutting,<br />

as well and resists loading.<br />

Available in R- or S-Type locking fastener.<br />

Coarse<br />

(Brown)<br />

Medium<br />

(Maroon)<br />

Very Fine<br />

(Blue)<br />

Type QC with R-Type Fastener<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

(mm)<br />

Coarse/<br />

Tan<br />

Medium/<br />

Maroon<br />

Very Fine/<br />

Blue<br />

38 262 906 262 907 262 908 30.000 100<br />

50 262 911 262 912 262 913 23.000 100<br />

75 262 916 262 917 262 918 20.000 50<br />

Type QC with S-Type Fastener<br />

38 262 931 262 932 262 933 30.000 100<br />

50 262 936 262 937 262 938 23.000 100<br />

75 262 941 262 942 262 943 20.000 50<br />

Unitized Quick Change Finishing Discs<br />

Unitized Quick Change discs are perfect for fast and<br />

efficient surface preparation and finishing work.<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Type QCU with R-Type Fastener<br />

(mm)<br />

4S-VeryFine<br />

50<br />

263 022<br />

4.500 18.000 10<br />

75<br />

263 027<br />

3.100 12.000 10<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

REX Quick Change Cleaning Discs<br />

Extra Coarse Silicon Carbide grain on a heavy nylon<br />

web. Aggressively removes rust and weld spatter.<br />

Strips paint and epoxy quickly without loading.<br />

Type QCR with R-Type Fastener<br />

TIP:<br />

Type-S button, additional<br />

formulations, or grit sizes<br />

available upon request.<br />

Minimum order quantity may apply.<br />

(mm)<br />

S-Coarse<br />

50<br />

262 914<br />

4.500 8.000 10<br />

75<br />

262 919<br />

3.100 5.500 10<br />

38

Felt Quick Change Discs<br />

Nonabrasive wool felt in solid disc form. Use in<br />

combination with Wendt polishes and compounds<br />

(found on page 78) to remove light scratches and<br />

polish the surface. The soft felt material absorbs the<br />

polishing media, and provides a smooth operation.<br />

Also available with Type S fastener upon request.<br />

See also our patented felt mini flap discs on page 33.<br />

FELT QUICK CHANGE DISCS & QUICK CHANGE HOLDERS<br />

Type QC FELT with R-Type Fastener<br />

Specification<br />

(mm)<br />

Medium<br />

50 263 016<br />

2.000 - 4.000 100<br />

75 263 017<br />

1.200 - 2.500 50<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

Quick Change Holders<br />

All Wendt quick change holders are industrial grade for<br />

long life in flexible finishing applications. Combo versions<br />

have a removable shank, and can thread directly onto<br />

grinders with M14 spindle.<br />

Type QCH<br />

Fastener<br />

a x b (mm) R-Type S-Type<br />

38 x 6mm<br />

263 160 263 161 1<br />

50 x 6mm<br />

263 170 263 171 1<br />

75 x 6mm<br />

263 180 263 181 1<br />

75 x M 14<br />

263 185 263 187 1<br />

39

SURFACE CONDITIONING DISCS<br />

Micro section after use with our<br />

Surface Conditioning Discs<br />

Surface Conditioning Discs<br />

Surface Conditioning Discs are ideal for deburring,<br />

surface preparation, and finishing applications.<br />

Abrasive grain is distributed throughout an open<br />

nylon web which resists loading and will not<br />

undercut the work surface. Scrim backing affix<br />

quickly and securely to Hook & Loop Gripper Pads.<br />

Coarse<br />

(Brown)<br />

Medium<br />

(Maroon)<br />

Very Fine<br />

(Blue)<br />

Type FSCM<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

(mm)<br />

Coarse/<br />

Tan<br />

Medium/<br />

Maroon<br />

V. Fine/<br />

Blue<br />

100<br />

262 986 262 987 262 988<br />

3.800 11.500 10<br />

115<br />

262 991 262 992 262 993<br />

3.300 10.000 10<br />

125<br />

262 996 262 997 262 998<br />

3.000 9.000 10<br />

150<br />

263 001 263 002 263 003<br />

2.600 7.500 10<br />

175<br />

263 006 263 007 263 008<br />

2.200 6.500 10<br />

TIP:<br />

Surface Conditioning<br />

Material is also available<br />

in a layered <strong>Flap</strong> Disc version for<br />

extended life.<br />

See page 26 for more information.<br />

Hook & Loop Gripper Pads<br />

Gripper pads have a threaded insert with flat collars<br />

for easy removal from the tool. Pad surface is flat,<br />

with “T” hooks to hold the the surface conditioning<br />

discs securely in place.<br />

Type ST<br />

Hook & Loop<br />

(mm)<br />

100 x M10-1.25<br />

263 201<br />

1<br />

100 x M10-1.5<br />

263 202<br />

1<br />

115 x M14<br />

263 204<br />

1<br />

125 x M14<br />

263 206<br />

1<br />

TIP:<br />

Suface Conditioning<br />

should always be run at<br />

lower speeds than coated abrasives.<br />

This will extend the disc life and improve<br />

the finish.<br />

175 x M14<br />

263 210<br />

1<br />

40

CARTRIDGE ROLLS<br />

Straight Cartridge Rolls<br />

Cartridge Rolls are an effective tool for grinding,<br />

deburring, cleaning and blending in confined spaces.<br />

Their narrow diameter allows you to work inside channels,<br />

corners, holes and tubes. Wendt cartridge rolls are made<br />

with premium aluminium oxide material for good life on<br />

carbon steel, stainless steel and castings. Other sizes and<br />

grits available on request.<br />

Type SR<br />

a x b (mm) c (mm) A60 A80 A120<br />

3mm<br />

Fitting Mandrel<br />

6mm<br />

4,8 x 19 2,4 158 084 158 086 26.000 100 161 901 1<br />

4,8 x 25 2,4 158 104 158 106 26.000 100 161 902 161 905 1<br />

6 x 19 3,2 158 143 158 144 158 146 26.000 100 161 910 1<br />

6 x 25 3,2 158 163 158 164 158 166 26.000 100 161 911 161 921 1<br />

6 x 38 3,2 158 183 158 184 158 186 26.000 100 161 913 161 927 1<br />

8 x 38 3,2 158 283 158 284 158 286 26.000 100 161 913 161 927 1<br />

10 x 25 3,2 158 363 158 364 158 366 26.000 100 161 911 161 921 1<br />

10 x 38 3,2 158 383 158 384 158 386 26.000 100 161 913 161 927 1<br />

10 x 50 3,2 158 403 158 404 158 406 26.000 100 161 915 161 933 1<br />

QUICK GUIDE<br />

Cleaning<br />

Cutting<br />

Grinding<br />

Deburring<br />

Blending<br />

Finishing<br />

Polishing<br />

13 x 25 3,2 158 463 158 464 158 466 26.000 100 161 911 161 921 1<br />

13 x 38 3,2 158 503 158 504 158 506 26.000 100 161 913 161 927 1<br />

13 x 50 3,2 158 543 158 544 158 546 26.000 100 161 915 161 833 1<br />

19 x 25 4,8 159 083 159 084 159 086 18.000 100 161 945 161 948 1<br />

19 x 38 4,8 159 143 159 144 159 146 18.000 100 161 952 1<br />

25 x 25 6,4 159 343 159 344 159 346 15.000 100 161 963 1<br />

25 x 38 6,4 159 403 159 404 159 406 15.000 100 161 966 1<br />

25 x 50 6,4 159 443 159 444 159 445 15.000 100 161 972 1<br />

Other sizes and specifications upon request.<br />

TIP:<br />

The Wendt Cartridge Rolls<br />

are also available as a kit<br />

with the most common<br />

sizes. See page 76 for<br />

further details.<br />

41

TRIZACT TM AND FELT CARTRIDGE ROLLS<br />