PUBLIC AUCTION - Hilco Industrial

PUBLIC AUCTION - Hilco Industrial

PUBLIC AUCTION - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

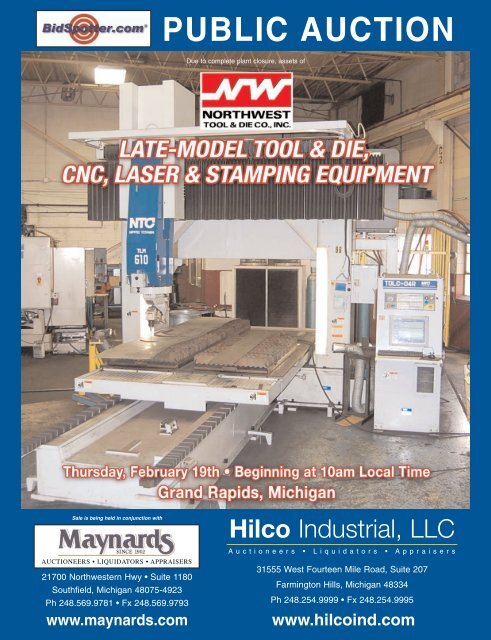

<strong>PUBLIC</strong> <strong>AUCTION</strong><br />

Due to complete plant closure, assets of<br />

Sale is being held in conjunction with<br />

<strong>AUCTION</strong>EERS • LIQUIDATORS • APPRAISERS<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com

PRESSES • BORING MILLS<br />

<strong>PUBLIC</strong> <strong>AUCTION</strong><br />

Due to complete plant closure, assets of<br />

THURSDAY, FEBRUARY 19TH<br />

Beginning at 10am Local Time<br />

Preview Date<br />

Wednesday, February 18th<br />

9am to 4pm Local Time & Morning of Sale<br />

Auction Location<br />

2980 Three Mile Road NW<br />

Grand Rapids, MI 49504<br />

Directions to Preview<br />

From Gerald R Ford International Airport:<br />

Head west on 48th St SE toward Kraft Ave SE. Continue<br />

onto Kraft Ave SE. Turn right at 52nd St SE. Turn right at<br />

Patterson Ave SE. Turn right at 36th St SE. Turn left onto<br />

the ramp to I-96 W. Keep left at the fork, follow signs for<br />

Gd Rapids/Muskegon/I-96 W and merge onto I-96 W.<br />

Proceed for 15.7 miles and take exit 28 for Walker Ave.<br />

Turn left at Walker Ave NW. Turn right at 3 Mile Rd NW.<br />

Watch for auction signs and parking.<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . . . . . 800.435.9792<br />

Hotels:<br />

Baymont Inn . . . . . . . . . . . . . . . . . 616.735.9595<br />

Hampton Inn North . . . . . . . . . . . . 616.647.1000<br />

Radisson Hotel Riverfront . . . . . . 616.363.9001<br />

Further Information<br />

• A buyer’s premium of 13.5% for<br />

all onsite sales and 16.5% for all<br />

webcast sales will be in effect. The<br />

auction will be conducted in English,<br />

accepting U.S. Currency only.<br />

• Removal Deadline is Friday, March 6th<br />

with Hours of Removal between<br />

8am to 4pm Monday thru Friday. After<br />

March 6th at 4pm buyer will incur a cost<br />

of $500 daily for entry into the facility.<br />

• For further information please contact<br />

George Laidlaw at 616.233.0702 or<br />

Email glaidlaw@hilcoind.com<br />

• For Payment & Customer Service<br />

please contact:<br />

Becky Kuznicki at 517.719.8134 or<br />

Email becky@maynards.com<br />

NTC (NIPPEI TOYAMA) TLM-610CWST 5-AXIS CNC LASER SYSTEM<br />

GIDDINGS & LEWIS 6" CNC FLOOR<br />

TYPE BORING MILL<br />

NOMURA B100WP4" HORIZONTAL BORING MILL<br />

2005<br />

CNC 5-AXIS LASER SYSTEM<br />

1 – NTC (NIPPEI TOYAMA) TLM-610CWST5-AXIS CNC LASER SYSTEM, S/N L500676, (2005) With 6' x 10' Table,<br />

30" Under Laser, TDLC-04 Control, PRC STS 2500 Resinator, 2500 Watt, 4915 hours, Precitec Non-contact Head,<br />

Remote Pendant Control, Koolant Koolers HCV10,000-2PR-N-F-L-H-2FILT<br />

CNC HORIZONTAL BORING MILL<br />

1 – GIDDINGS & LEWIS 6" CNC FLOOR TYPE BORING MILL, S/N 425-94-75, Spindle Travels: 6”-X, 288”-Y,<br />

132”-Z, 288” x 144” T-Slotted Floor Plate, 40-HP, 1,200-RPM, Heidenhain TNC 530 Control (Retrofit in 2005)<br />

HORIZONTAL BORING & KNEE MILLS<br />

1 – NOMURA B100WP 4" HORIZONTAL BORING MILL, S/N 3571, (1979) With 96" x 48" Table, 60" Vertical Travel,<br />

1000 RPM, Outboard Supports, Waycovers, Z-Axis Digital Readout, Pendant Control<br />

1 – HURCO KM3 CNC 3-AXIS KNEE MILL, S/N KDD-9009043D, KM-3P Ultimax Control (A# 6988)<br />

CNC WIRE EDM<br />

1 – CHARMILLES TECHNOLOGIES ROBOFIL 510 CNC WIRE ELECTRICAL DISCHARGE MACHINE, S/N 550032, With<br />

Enclosure, Remote Pendant Control, Charmilles Control, Dielectric Filter System, Advantage Refrigerated Air Dryer<br />

1 – CHARMILLES TECHNOLOGIES ROBOFIL 290 CNC WIRE ELECTRICAL DISCHARGE MACHINE, S/N NA,<br />

Travels: 9.8” Y-Axis, 15.75” Y-Axis, 7.9” Z-Axis, +/- 30° Taper, 1,100-Lb. Max Work Piece, 26 Sq. In Per Hr. Cutting Rate<br />

1 – ARD MODEL M50CA RAM ELECTRICAL DISCHARGE MACHINE, S/N 50139, Table Travels: 300mm/11.81”<br />

X-Axis, 250mm/9.84” Y-Axis, 300mm/11.81” Z-Axis, 45 Max Current, 850x300mm/33.46”x11.81” Work Table, Work<br />

Tank Outer Dimensions: 850 x 400 x 400mm/33.46” x 15.75” x 15.75”, 400 cubic mm/min Max Erosion Speed, 0.16<br />

m/6.3” Best Roughness Dimension,

CNC VERTICAL MACHINING CENTERS • CNC 5-AXIS LASER SYSTEM<br />

2004<br />

OKK MCV-1260 CNC VERTICAL MACHINING CENTER<br />

OKK VM5-2 CNC VERTICAL<br />

MACHINING CENTER<br />

2004<br />

MILLTRONICS VM15XT<br />

CNC VERTICAL MACHINING CENTER<br />

2006<br />

HARDINGE/BRIDGEPORT VMC1500XP3HD<br />

CNC VERTICAL MACHINING CENTER<br />

PMC 10T24 VERTICAL<br />

MACHINING CENTER<br />

CHARMILLES TECHNOLOGIES<br />

ROBOFIL 510CNC WIRE EDM<br />

(9) CNC VERTICAL MACHINING CENTERS<br />

1 – OKK MCV-1260 CNC VERTICAL MACHINING CENTER, S/N 131 (2004),<br />

With 95" x 50" Table, CAT 50 Taper Spindle, 36-Position Automatic Tool<br />

Changer, 12,000 rpm, 1000 PSI Through Spindle Coolant, Z-Axis Travel 36",<br />

Chip Auger, 6" Table Riser, Flood Coolant, Fanuc 160is-MB CNC Control<br />

1 – OKK VM5-2 CNC VERTICAL MACHINING CENTER, S/N 1267 (2004), With<br />

42" x 22" Table, CAT 50 Taper Spindle, 36-Position Automatic Tool Changer,<br />

12,000 rpm, 1000 PSI Through Spindle Coolant, Double Chip Auger, Flood<br />

Coolant, Fanuc 160is-MB CNC Control<br />

1 – HARDINGE/BRIDGEPORT VMC1500XP3HD CNC VERTICAL MACHINING<br />

CENTER, S/N 204LB033, (2006) With 57" x 28" Table, 7,000 rpm, Through<br />

Spindle Coolant, Cat 50 Taper Spindle, Rigid Tapping, 30-Position Automatic<br />

Tool Changer, Chip Conveyor, Fanuc 18i-MB CNC Control<br />

1 – HARDINGE/BRIDGEPORT VMC1500XP3HD CNC VERTICAL MACHINING<br />

CENTER, S/N 2041A007, (2005) With 57" x 28" Table, 7,000 rpm, Through<br />

Spindle Coolant, Cat 50 Taper Spindle, Rigid Tapping, 30-Position Automatic<br />

Tool Changer, Chip Conveyor, Fanuc 18i-MB CNC Control<br />

1 – MILLTRONICS VM15XT CNC VERTICAL MACHINING CENTER, S/N 7428,<br />

With 40" x 16" Table, 16-Position Automatic Tool Changer, 6,000 rpm, 40-Taper<br />

Spindle, Centurion 7 CNC Control, Coolant System, Lubrication System<br />

1 – MILLTRONICS VM17-H CNC VERTICAL MACHINING CENTER, S/N 7278,<br />

With 45" x 16" Table, 16-Position Automatic Tool Changer, 6,000 rpm, 40-Taper<br />

Spindle, Centurion 7 CNC Control, Coolant System, Lubrication System<br />

1 – SHARNOA SVC-52D CNC VERTICAL MACHINING CENTER,<br />

S/N 393035201, With 54" x 28" Table, 20-Position Automatic Tool Changer,<br />

3,000 rpm, 50 Taper Spindle, Tiger 5 CNC Control, Coolant System<br />

1 – SHARNOA HPM-85 CNC VERTICAL MACHINING CENTER, S/N 998028501,<br />

(1998) With 85" x 30" Table, 30-Position Automatic Tool Changer, 6,000 rpm,<br />

50 Taper Spindle, Tiger 6 CNC Control, Chip Auger, Coolant System<br />

1 – PMC 10T24 VERTICAL MACHINING CENTER, S/N ES10T0086, 43.3” x<br />

19.291” Table Size, 27.56”, 5.51” Distance Between Table Surface & Spindle,<br />

21.65” Distance Between Column & Spindle Center, 14.7-HP (30 Min.) 12-HP<br />

(Cont.) Spindle Motor, 4P 180W Coolant Pump Motor, 4P 5W Lubrication Pump<br />

Motor, 1,763-Lb. Permissible Work Place Weight, Travels: X=39.37”, Y=20”,<br />

Z=22”, 0.00015748” Table Positioning Accuracy, 100-8,000 RPM Spindle<br />

Speed Range, BT 40 Tooling System, 24 Tool Holders<br />

PRESSES<br />

1 – DANLY U4-1350-200-80 1,350-TON 4 POINT UNDER-DRIVEN STRAIGHT SIDE PRESS,<br />

With 80" x 200" Bed, Rolling Bolster, 31" Stroke, 62 1/2" Shut Height, Cushion,<br />

Air Counter-Balance, 41" x 32" Windows, Trabon Lubrication System<br />

1 – HAMILTON 4E180-900 900-TON TRY-OUT PRESS, S/N 2272, With 100" x 180" Bed,<br />

36" Stroke, 31 1/2" - 61" Shut Height, 29 1/2" Slide Adjustment, Air clutch,<br />

Air Counter-Balance, Link Electric System 1100 Tonnage Monitor<br />

1 – CLEARING F-4450-126 450-TON STRAIGHT SIDE PRESS, S/N 35-2576-19351, with<br />

4-Point Air Clutch Eccentric, 12 SPM, 24" Stroke, 18" Slide Adjustment, 42 1/2" Shut Height,<br />

81" x 126" Bed, 25" x 53" Windows, Air Counter-Balance, Motors & Controls, Link Electric<br />

System 1100 Tonnage Monitor, MetalTech Jobber Plus controls, Light Curtain<br />

1 – BLISS 8-120 290-TON STRAIGHT SIDE DOUBLE CRANK PRESS, S/N T32842,<br />

With 60" x 120" Bed, 18" Stroke, Air Clutch, Air counter-Balance, Link Logic Tonnage<br />

Monitor, MetalTech Jobber Plus Controls<br />

1 – CLEARING OBS-200-72-42 200-TON DOUBLE CRANK GAP FRAME PRESS,<br />

S/N 10-1240, With 72" x 42" Bed, 20" Stroke, 42" Shut Height,25 SPM<br />

1 – CLEARING SD-784 200-TON STRAIGHT SIDE DOUBLE CRANK PRESS, With<br />

85" x 48" Bed, 14" x 14" Windows, 14.5" - 23.75" Shut Height<br />

PRESS EQUIPMENT<br />

1 – CHS AUTOMATION DRFS-554 COIL<br />

STRAIGHTENER AND FEEDER,<br />

S/N 07-5600, With 54" Wide Capacity,<br />

8-Rollers, Rexroth System 200 Controls<br />

1 – COLT AUTOMATION CHDR-1500-48<br />

10,000-LBS. POWERED UNCOILER,<br />

With Overarm Hold Down Roll<br />

1 – BROWN BOGGS MODEL 48-14 COIL<br />

STRAIGHTENER, S/N 72114 & 72145,<br />

7 1/2 -HP, 550 Volts, 3 Phase, 60 Cycle<br />

Please Make All Payments Payable to Maynards.<br />

For more information regarding payments please visit www.maynards.com<br />

To schedule an auction, please contact us at 248.254.9999 3

FABRICATING • MILLING MACHINES • GRINDERS<br />

SHARP 3 HP CNC<br />

VARIABLE SPEED VERTICAL<br />

MILLING MACHINE<br />

ATRUMP/BRIDGEPORT<br />

K3FVS-1054 SUPREME<br />

VERTICAL MILLING MACHINE<br />

KEARNEY & TRECKER MODEL 205 S-12<br />

PLAIN HORIZONTAL MILLING MACHINE<br />

BLANCHARD 18 42" ROTARY<br />

SURFACE GRINDER<br />

CINCINNATI 1008R8' X 3/16" POWER<br />

SQUARING SHEAR<br />

KENT KSG-250 8" X 18" HAND-<br />

FEED SURFACE GRINDER<br />

FABRICATING EQUIPMENT<br />

1 – DRIES & KRUMP 6L8 MECHANICAL PRESS BRAKE, S/N L6683, With 96" Bed,<br />

3" Stroke, 8" Throat, Mechanical Clutch<br />

1 – CINCINNATI 1008R 8' x 3/16" POWER SQUARING SHEAR, S/N 20737, With 36"<br />

Rear Operated Manual Backgauge, 6' Squaring Arm, Air Actuated Foot Pedal,<br />

One Shot Lubrication System<br />

1 – TENNSMITH HBV48-124 8" x 12-GAUGE HAND BRAKE, S/N 14354<br />

WELDING & CUTTING<br />

1 – MILLER SYNCROWAVE 350LX 350 AMP CC-AC/DC PORTABLE WELDING<br />

MACHINE, S/N KK147907, With Welding Leads, Coolmate Cooling System<br />

1 – MILLER MILLERMATIC 251 200 AMP WIRE WELDING SYSTEM, S/N LC703139<br />

1 – MILLER S[ECTRUM 2050 PLASMA CUTTING SYSTEM, S/N LC536396,<br />

With Hand Torch, & Cart<br />

(11) MILLING MACHINES<br />

1 – SHARP 3 HP CNC VARIABLE SPEED VERTICAL MILLING MACHINE,<br />

S/N 60400919, With 10" x 51" Power Feed Table, 4500 RPM, Proto-Trak M2 2-Axis<br />

CNC Control, One-Shot Lubrication System<br />

1 – SHARP 3 HP VARIABLE SPEED VERTICAL MILLING MACHINE, S/N 84050553,<br />

With 10" x 51" Power Feed Table, Acu-Rite 2-Axis Digital Readout, 5" Quill Travel,<br />

One-Shot Lubrication System<br />

1 – BRIDGEPORT/SHARP VERTICAL MILLING MACHINE, S/N 213781, With<br />

Bridgeport Base, 9" x 42" Table, Sharp 3 hp Milling Head, 4500 rpm, Acu-Rite III<br />

2-Axis Digital Readout<br />

1 – ATRUMP/BRIDGEPORT K3FVS-1054 SUPREME VERTICAL MILLING<br />

MACHINE, With 2 hp Series I Bridgeport Milling Head, 9" x 42" Power Feed Table,<br />

2-Axis Digital Readout<br />

1 – BRIDGEPORT 1 1/2 HP VERTICAL MILLING MACHINE, With 9" x 42" Table<br />

1 – BUFFALO 837VERTICAL MILILNG MACHINE, S/N 1942, With 3 hp Milling Head,<br />

9" x 42" Table, Sony 2-Axis Digital Readout<br />

1 – CINCINNATI 4VERTICAL MILLING MACHINE, S/N 314V12-4, With 18" x 60"<br />

Table<br />

1 – KEARNEY & TRECKER 415-S15 UNIVERSAL MILLING MACHINE,<br />

S/N CP51094, With 15" x 76" Table, Horizontal and Vertical Milling Heads<br />

1 – BRIDGEPORT MODEL 6-115-06-267 VERTICAL MILLING MACHINE<br />

1 – KEARNEY & TRECKER MODEL TF-17 MILLING MACHINE<br />

1 – KEARNEY & TRECKER MODEL 205 S-12 PLAIN HORIZONTAL MILLING<br />

MACHINE, S/N 129482, 12” x 56” Working Surface Table, Feed Range: 28” Long,<br />

10” Cross, Vertical 18”, (16) Feeds Range: 1/4 to 32 ipm, Vertical 1/8 to 16 ipm,<br />

Rapid Traverse: Longitudinal & Cross 150 ipm, Vertical 75 ipm, Spindle Size #50,<br />

(24) Spindle Speeds 25-2,000 RPM, Drive Motor 5-HP, Feed Drive Motor 1 1/2-HP,<br />

Coolant Pump Drive 1/4-HP, Equipped With Double Over Arm<br />

KENT KSG-510AHD 20" X 40"<br />

HYDRAULIC SURFACE GRINDER<br />

KURODA GSDHF 12" X 23"<br />

HYDRAULIC SURFACE GRINDER<br />

(17) GRINDERS<br />

1 – BLANCHARD 18 42" ROTARY SURFACE GRINDER, S/N 10090, With 42"<br />

Electromagnetic Chuck, 19 1/2" Segmented Wheel, Coolant, 25 hp Motor<br />

1 – ABRASIVE 18 14" x 22" HORIZONTAL FACE GRINDER, S/N 18-72, With 14" x 22"<br />

Electromagnetic Chuck, Coolant, 15 hp Motor<br />

1 – THOMPSON 4CD 20" x 50" HIGH COLUMN HYDRAULIC SURFACE GRINDER,<br />

S/N 646820, With 20" x 50" Electromagnetic Chuck, Wheel Dresser, Coolant System,<br />

20 hp Spindle<br />

1 – KENT KSG-510AHD 20" X 40" HYDRAULIC SURFACE GRINDER, S/N 00017307,<br />

(2000) With 20" x 40" Electromagnetic Chuck, Wheel Dresser, Coolant Filter<br />

1 – KENT KSG-306AHD 12" x 24" HYDRAULIC FEED SURFACE GRINDER,<br />

S/N 99043305, (1999) With 12" x 24" Electromagnetic Chuck, Wheel Dresser,<br />

Coolant System, Lubrication System, Control Panel<br />

1 – KURODA GSDHF 12" X 23" HYDRAULIC SURFACE GRINDER, S/N 556,<br />

With Electromagnetic Chuck, Wheel Dresser, Coolant Separator<br />

1 – KENT KSG-250 8" x 18" HAND-FEED SURFACE GRINDER, S/N 99015206, (1999)<br />

With Chuck Control<br />

1 – KENT KSG-250 8" x 18" HAND-FEED SURFACE GRINDER, S/N 99015207, (1999)<br />

With Chuck Control<br />

1 – REID 618H 6" x 18" HAND-FEED SURFACE GRINDER, S/N 13480, With 6" x 18"<br />

Permanent Magnetic Chuck<br />

1 – REID HR 6" x 18" HAND-FEED SURFACE GRINDER, S/N 2149, With 6" x 18"<br />

Permanent Magnetic Chuck<br />

1 – BOYAR SCHULTZ 2 PROFILE GRINDER, S/N 2653<br />

1 – MATTSON 48” TUB GRINDER, S/N 48-516<br />

1 – TYCO END GRINDER<br />

1 – SOUTH BEND MODEL 2A-20 8” X 18” HYDRAULIC SURFACE GRINDER,<br />

S/N 2A-0250, 60 Hz, 1 1/2”-HP, 230/640 Volt, 4.8/2.4 Amps, 3,450 RPM, 6 1/2” Wheel Size<br />

1 – REID MODEL 618-H 6” x 18” PRECISION SURFACE GRINDER, S/N 11093, Work<br />

Height 15”, 7” Cross Slide Travel, 20” Table Travel, 1 1/2-HP / 3,450 RPM Motor<br />

1 – GRAND RAPIDS MODEL 335 HYDRAULIC SURFACE GRINDER, S/N S-351405,<br />

8” X 24” Chuck Size 8” x 24”, 115 fpm Max. Long Table Speed, 26” Automatic Table<br />

Travel, Longitudinal (max), 9 1/4” Automatic Table Travel, Transverse (Max), 8” x 24”<br />

Working Surface of Table, 12” Vertical Movement of Wheel Head, 10” x 1” x 2”<br />

Standard Wheel Size, 12” Max Distance from Wheel of Table Under Full Wheel,<br />

2,300 & 3,ooo RPM Spindle Speeds, 1/2 & 3-HP Standard Motor Sizes, Pump &<br />

Spindle, Equipped With An Over Wheel Dresser & 8” x 24” Walker Chuck<br />

1 – TRIO MODEL F-18 KNEE TYPE FACE GRINDER, S/N 3790-B-81, Chuck Size<br />

14” x 22”, Wheel Size 18” Diameter, Spindle Motor 15-HP, Coolant Pump Motor 1/4-<br />

HP, Trabon Automatic Lubrication, Machine is Equipped With Fail Safe Disc Brake,<br />

Motorized Gear Head Knee Elevating Motor, Power Elevation, Coolant Tank in Base<br />

of Grinder, Emergency Stop Button, Magnetic Chip Separator, Low Friction Air Float<br />

Table (A# 4245)<br />

4 For more information, visit us on the web @ www.hilcoind.com

RADIAL ARM DRILL PRESSES • SAWS • AIR COMPRESSORS<br />

CINCINNATI-BICKFORD 951<br />

RADIAL ARM DRILL<br />

CARLTON 4A RADIAL ARM DRILL<br />

MARVEL 8 MANUAL<br />

VERTICAL BANDSAW<br />

2006<br />

ROMER 5030SC PORTABLE<br />

COORDINATE MEASURING MACHINE<br />

1999<br />

SHARNOA HPM-85<br />

CNC VERTICAL MACHINING CENTER<br />

RADIAL ARM DRILL PRESSES<br />

1 – CARLTON 4A RADIAL ARM DRILL, S/N 4A3212, With<br />

19" Column x 7' Arm, 1200 RPM, Power Clamp &<br />

Elevation, Lubrication System, T-Slot Base Table<br />

1 – CARLTON 5A RADIAL ARM DRILL, S/N 5A3533, With<br />

22" Column x 8' Arm, 1200 RPM, Power Clamp &<br />

Elevation, Double Sided Base<br />

1 – CINCINNATI-BICKFORD 951 RADIAL ARM DRILL,<br />

S/N 1R949, With 9" Dia. Column x 3' Arm, 1500 RPM,<br />

Box Table, T-Slot Base<br />

1 – KAO MING KMR-1100S RADIAL ARM DRILL,<br />

S/N 10174, With 11" Dia. Column x 3' Arm,<br />

1677 RPM, 3 hp, Box Table, One Shot Lubrication<br />

System, Coolant System<br />

1 – KAO MING KMR-1100S RADIAL ARM DRILL,<br />

S/N 10159, With 11" Dia. Column x 3' Arm,<br />

1677 RPM, 3 hp, Box Table, One Shot Lubrication<br />

System, Coolant System<br />

1 – CARLTON 10' ARM X 26” DIAMETER COLUMN<br />

DRILL PRESS<br />

LATHES<br />

1 – VICTOR 164016" X 40" GEARED HEAD GAP BED<br />

ENGINE LATHE, S/N 56647, With 16" Swing,<br />

40" Centers, 24" Swing in Gap, 2" Spindle Through<br />

Hole, Inch/Metric Threading, 8" 3-Jaw Chuck, 1800<br />

RPM, Steady Rest<br />

1 – MORI-SEIKI 16X50 LATHE, SAE & Metric Threading,<br />

Trak DRO (A# 7135)<br />

INGERSOLL RAND<br />

MODEL 25E<br />

25-HP AIR<br />

COMPRESSOR<br />

MORI-SEIKI 16X50 LATHE<br />

SAWS<br />

1 – MARVEL 8 MANUAL VERTICAL BANDSAW,<br />

S/N 86806<br />

1 – PEERLESS 12" x 12" HORIZONTAL POWER<br />

HACKSAW, With Coolant System, Vise, Controls<br />

1 – DO ALL 20-12-2A20" VERTICAL BAND SAW,<br />

S/N 389-83386<br />

1 – MAKITA 14" ABRASIVE CHOP SAW<br />

1 – KALAMAZOO K-10 CUT-OFF SAW<br />

1 – DOALL MODEL 2612-2H BAND SAW<br />

1 – MARVEL MODEL 8 SERIES 8 BAND SAW, 174” x<br />

3/4” Blade<br />

1 – JOHNSON MODEL J 9X18 SAW<br />

1 – DAKE MEP COBRA 350AX PROGRAMMABLE<br />

AUTOMATIC COLD SAW, S/N NA, 5” Round<br />

Capacity, 3” x 7” Rectangle, 12” Blade Size, 2 Blade<br />

Speeds, 0-45° Left Head Tilt, 45° L, 45° R Cutting,<br />

Equipped With Control & Programming Panel With<br />

LCD Display & Auto Diagnostic Messages, Pneumatic<br />

Feeder, Regulation Head Stroke<br />

AIR COMPRESSORS<br />

1 – SULLAIR LS16-75H75 HP FULLY ENCLOSED<br />

ROTARY SCREW AIR COMPRESSOR, S/N 003-<br />

123558, With 125 PSI, 38DA Refrigerated Air Dryer<br />

1 – QUINCY QS123550 HP FULLY ENCLOSED ROTARY<br />

SCREW AIR COMPRESSOR, S/N 204-102-0-6080,<br />

With Refrigerated Air Dryer<br />

1 – QUINCY QT-55 HP VERTICAL TANK-MOUNTED AIR<br />

COMPRESSOR<br />

1 – QUINCY QT-15 AIR COMPRESSORS, 80-Gallon<br />

1 – 10-HP AIR COMPRESSOR, With Saylor Beall Pump<br />

1 – SULLAIR 25-HP HORIZONTAL AIR COMPRESSOR,<br />

S/N 006-84000429, 230/640 Volts, 60 Hz, 1,740 RPM<br />

1 – INGERSOLL RAND MODEL 25E 25-HP AIR COM-<br />

PRESSOR, S/N NA, 3-Stage, 3-Cycle, 120-Gallon<br />

Receiver Size, 3.21-Sq. M/Min.<br />

ZEISS DB900CNC COORDINATE<br />

MEASURING MACHINE<br />

QUALITY & INSPECTION<br />

1 – ROMER 5030SC PORTABLE COORDINATE<br />

MEASURING MACHINE, S/N 164, (2006) With<br />

Perception Laser Scanner, & Stand<br />

1 – ZEISS DB900CNC COORDINATE<br />

MEASURING MACHINE, S/N 990604900,<br />

(1999) With Motorized Probe Bridge, Renishaw<br />

Probe, Tapped 16" Granite Surface Plate, 60" x<br />

80" x 60" Work Area, Zeiss C99 Drive, Joystick<br />

Pad Controller, PC<br />

1 – LASERMARK LM-30DUAL BEAM ROTARY<br />

LASER LEVEL WITH TRIPOD<br />

1 – KRAUTKRAMER MIC 10HARDNESS TESTER<br />

1 – OD MICROMETERS<br />

1 – PIN GAGES WITH CASES<br />

1 – CALIPERS<br />

1 – 72” X 96” SURFACE PLATE<br />

1 – ROMER COORDINATE MEASURING MACHINE ARM<br />

To schedule an auction, please contact us at 248.254.9999 5

MATERIAL HANDLING • CRANES<br />

HYSTER S155XL 14,600-LB. FORKLIFT<br />

HYSTER S120XM 12,000-LB. LPG FORKLIFT<br />

HYSTER S55XM5000 LBS. LPG FORKLIFT<br />

MEC 2548H ELECTRIC SCISSOR LIFT<br />

HYSTER MODEL H25XL<br />

3,000-LB. LPG FORKLIFT<br />

CROWN 20-MS 2,000 LBS. ELECTRIC<br />

WALK BEHIND FORKLIFT<br />

VIEW OF CAT 40<br />

TOOLHOLDERS & CART<br />

1 – HYSTER MODEL S180XL17,800-LB.<br />

LPG FORKLIFT, 2 Speed Automatic, 72”<br />

Forks, 2-Stage<br />

1 – HYSTER S155XL 14,600-LB. FORKLIFT,<br />

S/N B024D035035, 6' Forks, 2-Speed<br />

Auto Transmission, 2-Stage (A# 6860)<br />

1 – HYSTER S120XM 12,000-LB. LPG<br />

FORKLIFT, Non-Marking Tires, 3-Stage<br />

Mast (A# 7151)<br />

1 – CLARK MODEL C500Y580 8,000-LB.<br />

LPG FORKLIFT, S/N 11685-9-3845,<br />

Hard Tires, 3-Stage Mast, 42” Forks,<br />

Pneumatic<br />

1 – CATERPILLAR M100B 10,000 LBS.<br />

ELECTRIC FORKLIFT, S/N TTB00507,<br />

With 154" Lift, 52" Forks, Triple Mast,<br />

Side Shift, Battery Charger<br />

1 – CLARK MODEL C500YS80 8,000-LB.<br />

FORKLIFT, Pneumatic Style<br />

3 – YALE ELECTRIC 8,000-LB. FORKLIFTS,<br />

(1997) 3-Stage Mast, With Battery<br />

1 – ALLIS CHAMBERS MODEL ACC50PS<br />

5,000-LB. LP FORKLIFT, Cushion Tire,<br />

3-Stage Mast<br />

1 – HYSTER S55XM 5000 LBS. LPG FORK-<br />

LIFT, S/N D187V186-30X, With 131" Lift, 42"<br />

Forks, 8 Deg Tilt, Double Mast, Side Shift<br />

1 – HYSTER MODEL H25XL 3,000-LB. LPG<br />

FORKLIFT, Automatic Transmission,<br />

Pneumatic Style, 2-Stage Mast<br />

1 – YALE 2000 LBS. STAND UP ELECTRIC<br />

FORKLIFT, S/N P35370, With 36" Forks,<br />

130" Lift, Overhead Guard, Solid Tires<br />

MATERIAL HANDLING<br />

1 – MEC 2548H ELECTRIC SCISSOR LIFT<br />

(1997) With 24' Height, 850 Lbs. Capacity,<br />

36 Volt<br />

1 – CROWN 20-MS 2,000 LBS. ELECTRIC<br />

WALK BEHIND FORKLIFT, S/N<br />

IA128805, With 40" Forks, 57" Lift<br />

1 – NEW ERA 3-SHELF MODULAR<br />

STORAGE SYSTEM, With 1000 lbs. per<br />

shelf Capacity<br />

1 – CHECKMATE CM-30K 30,000 LBS.<br />

DIGITAL CRANE SCALE, S/N 33492<br />

1 – WEN MAGNETICS MLX-500 LIFTING<br />

MAGNET<br />

1 – WEN MAGNETICS MLX-250 550 LBS.<br />

LIFTING MAGNET<br />

1 – STARCH 5 5000 LBS LIFTING MAGNET,<br />

12 VOLT<br />

1 – WALKER BUX CM-3 2000 LBS. LIFTING<br />

MAGNET<br />

1 – PRESTO B-562 1000 LBS. HYDRAULIC<br />

LIFT TABLE<br />

1 – WESCO 6 600 LBS PALLET JACK<br />

1 – 5-TON COIL LIFT<br />

1 – SINGLE SIDED CANTILEVER RACKING<br />

1 – 1 CU. YD SELF-DUMPING SCRAP HOPPERS<br />

1 – LIFTING EYE-BOLTS<br />

1 – LIFTING CHAINS<br />

1 – COIL LIFTING HOOKS<br />

1 – SIGNODE STRAPPING CARTS WITH<br />

TOOLS<br />

1 – WRIGHT CHAIN HOIST<br />

1 – ROLLING SHOP CARTS<br />

1 – STEEL SAW HORSES<br />

(17) CRANES<br />

1 – STEWART 20/10-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 30' Span, Yale 20-Ton & 10-Ton Hoist, Pendant Control<br />

1 – STEWART 15/7.5-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 26' Span, RM SpaceMaster 15-Ton & 7-1/2-Ton Electric Hoist, Pendant<br />

Control (15)<br />

1 – STEWART 15-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 30' Span, RM SpaceMaster 15-Ton Electric Hoist, Pendant Control (16)<br />

1 – STEWART 15-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 26' Span, RM SpaceSaver 15-Ton Electric Hoist, Pendant Control (5)<br />

1 – STEWART 15-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 30' Span, RM SpaceMaster 15-Ton Electric Hoist, Pendant Control (12)<br />

1 – STEWART 10-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With<br />

30' Span, RM SpaceMaster 10-Ton Electric Hoist, Pendant Control (10)<br />

1 – STEWART 10-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With<br />

26' Span, RM Space Saver 10-Ton Electric Hoist, Pendant Control (14)<br />

1 – CHAMPCO 10-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With<br />

30' Span, 10-Ton Detroit Electric Hoist, Pendant Control (11)<br />

1 – CHAMPCO 10-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With<br />

30' Span, 10-Ton Detroit Electric Hoist, Pendant Control (8)<br />

1 – CHAMPCO 7 1/2-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 30' Span, RM SpaceSaver 7 1/2-Ton Electric Hoist, Pendant Control (6)<br />

1 – CHAMPCO 7 1/2-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 30' Span, 7 1/2-Ton Detroit Electric Hoist (9)<br />

1 – CHAMPCO 7 1/2-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 26' Span, 7 1/2-Ton Detroit Electric Hoist, Pendant Control (3)<br />

1 – CHAMPCO 7 1/2-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE,<br />

With 26' Span, 7 1/2-Ton Detroit Electric Hoist, Pendant Control (4)<br />

1 – 5-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With 26' Span,<br />

Shaw Box Electric Hoist, Pendant Control (2)<br />

1 – 3-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With 30' Span,<br />

3-Ton Electric Hoist, Pendant Control (7)<br />

1 – 3-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With 26' Span,<br />

3-Ton Electric Hoist, Pendant Control (1)<br />

1 – 3-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE, With 15' Span,<br />

3-Ton Electric Hoist, Pendant Control<br />

6 For more information, visit us on the web @ www.hilcoind.com

VEHICLES • TOOLING & ACCESSORIES • SHOP EQUIPMENT<br />

STEWART 15-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE<br />

STEWART 15-TON DOUBLE GIRDER OVERHEAD &<br />

STEWART 10-TON SINGLE GIRDER OVERHEAD BRIDGE CRANE<br />

STEWART 15-TON DOUBLE GIRDER OVERHEAD BRIDGE CRANE LINCOLN SQUAREWAVE 350<br />

TIG WELDER<br />

LINCOLN PROCUT 60-AMP<br />

PLASMA CUTTER<br />

VEHICLES<br />

1 – PETERBUILT 330STAKE BODY TRUCK, VIN 1XPNHF7X1SN38664,<br />

(1995) With Tandem Axle, 18' x 96" Bed, Eaton 9-Speed Transmission,<br />

271,975 miles<br />

1 – FORD F-250XL3/4 TON PICK UP TRUCK, VIN 3FTNF20L63MB40274, (2003)<br />

With Bedliner, Automatic Transmission, AM/FM Radio, Gas Engine, 128,267 miles<br />

1 – DODGE GRAND CARAVAN, 3.3L (2002)<br />

1 – KIA SEDONA EX MINI VAN, VIN: KNDUP132556694687, (2005) 3.5L,<br />

55,000 Miles, Under Factory Warranty<br />

TOOLING & ACCESSORIES<br />

65 – BT 40 TOOL HOLDERS<br />

65 – BT 50 TOOL HOLDERS<br />

100 – CAT 50 TOOL HOLDERS<br />

6 – KURT D-8108" ANG LOK MACHINE VISES<br />

3 – KURT 6" MACHINE VISES<br />

2 – KURT 6" MACHINE VISES WITH SWIVEL BASE<br />

1 – HARIG GRIND-ALL FIXTURE<br />

4 – HUOT TOOL SCOOT CART<br />

2 – 29" X 74" ANGLE PLATES<br />

2 – 18" X 46" ANGLE PLATES<br />

2 – 18" X 36" ANGLE PLATES<br />

2 – 132" X 60" ANGLE PLATES<br />

1 – LOT END MILLS, DRILL BITS, CUTTERS<br />

1 – LOT COLLETS<br />

1 – LOT C-CLAMPS<br />

1 – LOT STRAP CLAMPS, T-BOLTS, AND SET-UP FIXTURES<br />

1 – 8" 3-JAW CHUCK<br />

1 – 12" 4-JAW CHUCK<br />

1 – TRINCO SL8P48" x 48" SAND BLAST<br />

CABINET, S/N 42564-5, With Dust<br />

Collector<br />

1 – PORTER CABLE G-88" WET-DRY<br />

BELT GRINDER, S/N 632<br />

1 – PORTER CABLE 8" ANGLE GRINDER<br />

1 – ENERPAC HYDRAULIC HOSE<br />

CRIMPER<br />

1 – CLARKE FLOOR SCRUBBING<br />

MACHINE<br />

1 – RIDGID WET/DRY SHOP VACS<br />

1 – GREENERD 3ARBOR PRESS<br />

1 – TORIT DUST COLLECTORS<br />

1 – LELAND GIFFORD COLUMN DRILL<br />

PRESS, With 1/2" Chuck<br />

1 – CINCINNATI SUPER SERVICE 21”<br />

DRILL PRESS<br />

1 – CAROLINA 30-GALLON PARTS<br />

WASHER<br />

1 – MILWAUKEE MAGNETIC BASE DRILL<br />

1 – LISTA 5-DRAWER STORAGE CABI-<br />

NETS<br />

1 – VIDMAR 5-DRAWER STORAGE CABI-<br />

NETS<br />

1 – JUST-RITE 110 GALLON FLAMMABLE<br />

LIQUID STORAGE CABINET<br />

1 – LYON HEAVY DUTY STEEL STORAGE<br />

CABINETS<br />

SHOP EQUIPMENT<br />

1 – DELTA 8" DOUBLE END PEDESTAL<br />

BENCH GRINDER<br />

1 – 5" DOUBLE END PEDESTAL BENCH<br />

GRINDER<br />

1 – LINDE MODEL VI-253 CV/DC MIG<br />

WELDER, S/N B80-C20772, Input<br />

Voltage: 230/460 Volt, 60 Hz, 3 Phase,<br />

29/14.5 Amps, Output Voltage: 45 Max<br />

OCV, 35 Volts, 250 Amps, 100% Duty<br />

Cycle<br />

1 – LINCOLN SQUAREWAVE 350 TIG<br />

WELDER<br />

1 – LINCOLN PROCUT 60-AMP PLASMA<br />

CUTTER (A#6971)<br />

1 – ELLIOTT SELF-PROPELLED OIL<br />

SUMP/PUMP, TANK, S/N 2380, CART<br />

S/N 21HI-SI, Kalamazoo Mfg. Speed<br />

Truck, Electric Power, Approx. 500-<br />

Gallon Tank Size, Exide 24-Volt Charger,<br />

Tank Equipped With Inline Flow Meter,<br />

Hose Reel, Sight Gauge & Float Needle<br />

1 – PNUEMATIC TOOLS<br />

1 – ELECTRIC POWER TOOLS<br />

1 – CORDLESS POWER TOOLS<br />

1 – 5-TON FLOOR JACK<br />

1 – NUMEROUS WOOD TOP WORK<br />

BENCHES<br />

1 – 30" MAGNETIC FLOOR SWEEPER<br />

Quantity of Die Bars, Hand Tools, Nibbler<br />

Auction Will Be Conducted Onsite and Online at Bidspotter.com<br />

Please Make All Payments Payable to Maynards.<br />

For more information regarding payments please visit www.maynards.com<br />

To schedule an auction, please contact us at 248.254.9999 7

Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Southampton (UK) • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

<strong>PUBLIC</strong> <strong>AUCTION</strong><br />

Due to complete plant closure, assets of<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062<br />

All rights reserved • Printed in USA • NORT3370 • IL License #444000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A buyer’s premium of 13.5% for onsite sales & 16.5%<br />

for webcast sales is in effect. Everything will be sold<br />

to the highest bidder for cash, in accordance with the<br />

Auctioneer’s customary “Terms of Sale”, copies of<br />

which will be posted on the premises of the sale and<br />

subject to additional terms announced the day of<br />

sale. All items will be sold “as is, where–is”<br />

without any warranties, express or implied. Although<br />

obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained. Bidders<br />

are encouraged to thoroughly inspect the items on<br />

which they intend to bid prior to sale. Absolutely no<br />

items will be removed until the day after the conclusion<br />

of the sale and payment is made in full. Subject<br />

to additions, deletions and prior sale. For full terms<br />

and conditions please go to www.maynards.com<br />

Payment: ALL PURCHASES MUST BE PAID IN<br />

FULL ON THE DAY OF THE <strong>AUCTION</strong>. If you intend<br />

to pay by wire transfer, we will accept payment the<br />

day after the sale ONLY IF a deposit of 25% of total<br />

purchases is made on the day of the sale. Contact<br />

our office for wire transfer instructions. Only cash,<br />

wire transfer or certified check, payable to Maynards<br />

will be accepted. Company checks payable to<br />

Maynards will be accepted only if accompanied by a<br />

bank letter of guarantee, (see sample letter below).<br />

All sales are subject to sales tax. Purchasers<br />

claiming exemptions from taxes must provide proof<br />

satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees<br />

payment to Maynards from (Company Name).<br />

This guarantee will be valid for purchases made<br />

at the Auction of Northwest Tool & Die Co., Inc.<br />

on February 19, 2009.