2-day WebCast/OnsIte auCtIOn - Hilco Industrial

2-day WebCast/OnsIte auCtIOn - Hilco Industrial

2-day WebCast/OnsIte auCtIOn - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

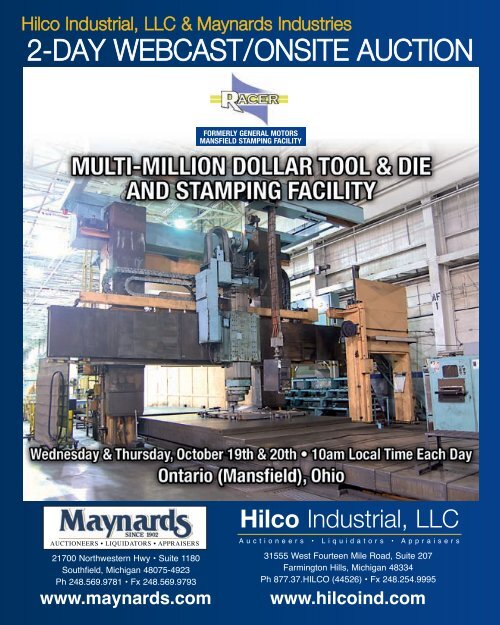

<strong>Hilco</strong> <strong>Industrial</strong>, LLC & Maynards Industries<br />

2-<strong>day</strong> <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong><br />

Formerly General motors<br />

mansField stampinG Facility<br />

Auctioneers • LiquidAtors • ApprAisers<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 877.37.HILCO (44526) • Fx 248.254.9995<br />

www.hilcoind.com

HILCO IndustrIaL, LLC<br />

& Maynards IndustrIes<br />

Formerly General motors<br />

mansField stampinG Facility<br />

<strong>auCtIOn</strong> dates<br />

Wednes<strong>day</strong> & tHurs<strong>day</strong>, OCtOber 19 & 20<br />

begInnIng at 10aM LOCaL tIMe eaCH <strong>day</strong><br />

PrevIeW date<br />

tues<strong>day</strong>, OCtOber 18<br />

9aM tO 4PM & MOrnIng Of saLe<br />

For earlier inspection, please contact ken planet<br />

at 248.254.9999 x33 or email kplanet@hilcoind.com<br />

<strong>auCtIOn</strong> & PrevIeW LOCatIOn<br />

2525 W. 4tH street<br />

OntarIO (MansfIeLd), OH 44906<br />

2-<strong>day</strong> <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong><br />

dIreCtIOns<br />

frOM CLeveLand-HOPkIns InternatIOnaL aIrPOrt (CLe): exIt aIrPOrt tO I-71 s., gO 60.4<br />

MILes and take exIt 176 tO Merge OntO us-30 W tOWard MansfIeLd. gO 8.2 MILes and<br />

take tHe OHIO 309 W exIt tOWard OntarIO. Merge OntO OH-309 W (tOWards OntarIO)<br />

and traveL 1 MILe tO W. 4tH st. raMP. fOLLOW W. 4tH st. fOr 1/2 MILe tO PLant On Left<br />

(sOutH) sIde Of rOad. entranCe tO PLant Is On beer rd OnLy (West sIde Of PLant).<br />

furtHer InfOrMatIOn<br />

• a 15% buyers PreMIuM WILL be CHarged On aLL assets. <strong>auCtIOn</strong> WILL be COnduCted In<br />

engLIsH, aCCePtIng u.s. CurrenCy OnLy.<br />

• Removal foR small / hand-caRRy items not RequiRing heavy Rigging equipment will occuR<br />

on octobeR 21 – 28. Removal foR laRgeR items RequiRing heavy Rigging equipment will begin<br />

on octobeR 31. Removal deadline foR all equipment is febRuaRy 3, 2012 with houRs of<br />

Removal fRom 8am to 4pm mon<strong>day</strong> thRough fRi<strong>day</strong>. afteR the Removal deadline, buyeR will<br />

incuR a cost of $500 peR <strong>day</strong> foR entRy into the facility. theRe aRe seven (7) Rigging<br />

companies authoRized to woRk in the facility – check ouR website foR contact infoRmation.<br />

• fOr furtHer InfOrMatIOn On MaCHInery & equIPMent, PLease COntaCt ken PLanet at<br />

248.254.9999 x33 Or eMaIL kPLanet@HILCOInd.COM Or MarIO MazzuCa at 248.569.9781 Or<br />

MarIO@Maynards.COM<br />

• fOr PayMents PLease COntaCt beCky kuznICkI at 517.719.8134 Or eMaIL<br />

beCky@Maynards.COM<br />

• CustOMer servICe, PLease COntaCt sandI neeLy at 248.254.9999 x16 Or eMaIL<br />

sneeLy@HILCOInd.COM<br />

(9) cnc adJUstaBle rail macHininG centers<br />

& BorinG mills<br />

2 – INGERSOLL 5-AXIS CNC ADJUSTABLE RAIL MACHINING CENTERS, S/N 25785:<br />

Between Columns 3900 mm (153.5”), Table 1 & 2 – 4500 mm x 3500 mm (177.2” x 137.8”),<br />

Travels: X (Cross rail) – 2450 mm (96.5”), Y (Table) – 10,470 mm (412.2”),<br />

Y (Head) – 587.5 mm (23.2”), Z (Ram) 975 mm (38.4”), Nine (9) Spindles including Nutator;<br />

S/N 25779: Between Columns 4310 mm (170”), Table 1 & 2 – 4010 mm x 2508 mm (158”<br />

x 98.75”), Travels: W (Cross rail) – 2450 mm (96.5”), X (Table) – 9,450 mm (372”), Y (Head)<br />

– 487.5 mm (19.2”), Z (Ram) – 1000 mm (39.4”), Spindle Speeds<br />

1150-2500 RPM, Eight (8) Spindles including Nutator S/N 25780-45; Both With: Height<br />

Table to Spindle 3250 mm Max (128”)/ 800 mm Min (31.5”), Length over Joined Tables 9750<br />

mm (383.9”), Bed Length 20500 mm, B (Nutator) 360 Deg Cont Rotation, C (Index Drum)<br />

360 Deg Cont Rotation, 120 HP Masterhead, Allen Bradley Series 8200 CNC Control<br />

2 – TOSHIBA SHIBURA BFD-200 CNC BORING MILLS, S/Ns 910115, 910114,<br />

Spindle Diameter 221.43 mm (8.718”), Ram 450 mm x 520 mm (17.7” x 20.47”), Dual<br />

Indexing Tables 3000 mm x 3000 mm (118.1” x 118.1”), Travels: X (Column Hor Travel)<br />

– 12,300 mm (484.25”), Y (Headstock Vertical Travel) – 3200 mm (126”), U – Heeling Jib<br />

Vertical Travel – 30 mm, Spindle Speeds 10 – 3000 mm, Feeds: X/Y/Z – 6000 mm/min<br />

(236 IPM), V – 4000 mm/min (157.5 IPM), Rapid Feeds: X – 15000 mm/min (591 IPM),<br />

Y/Z/V – 6000 mm/min (236 IPM), Dual 40 Position ATC – No. 60 Taper, Automatic<br />

Attachment Tool Changer, Fanuc CNC Control, S/N 910115 with Nine Spindles,<br />

S/N 910114 with Ten Spindles – Both Including 5-Axis Head<br />

2<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526)

CnC MaCHInIng Centers & bOrIng MILLs • CMM, InsPeCtIOn, edM<br />

(9) cnc adJUstaBle rail macHininG centers<br />

& BorinG mills (continUed)<br />

2 – DROOP & REIN TYPE LFAS 2000 CNC BORING MILLS, S/Ns 105717, 105716, Travels:<br />

X (Table Longitudinal) – 3300 mm (130”), Y1 (Headstock Cross) – 2330 mm (91.7”),<br />

Z (Outrigger Vertical) 1800 mm (70.9”), Y2 (Copying Tracer Support Cross)<br />

– 1830 mm (72”), W (Milling Spindle Quill) – 350 mm (13.8”), Table 78.75” x 216.5”, 24<br />

Position ATC – 50 Taper, GE Fanuc Series 150-M CNC Control, Carriage Station,<br />

Attachments, T56 – Spindle Extension, T55 – Angular Milling Head, T54 – Angular Milling<br />

Head, T53 – Angular Milling Head, S/N 105717 with: Master Machine Copying Tracer<br />

Attachment Travels: X3 – 200 mm (7.8”), Y3 – 150 mm (6”), Z3 – 400 mm (15.7”),<br />

T52 – High Speed Milling Head, DR #5, S/N 105716 with: T51 – 2-Axis Milling Head, DR #4<br />

2 – INGERSOLL BOHLE TYPE W2-140 CNC TABLE TYPE BORING MILLS, S/Ns 800417,<br />

800414, Travels: X (Table Longitudinal) – 39.37”, Z (Column Cross Movement) – 39.37”,<br />

Y (Spindle Head Vertical) – 31.496”, Table to Spindle Center 31.496” Max, Spindle Head<br />

to Table 7.874” Min, Spindle Speeds 11 – 2800 RPM, 40 Position ATC – 50 Taper, Allen<br />

Bradley Series 8200 CNC Control, S/N 800417 with Dual 25” x 25” Rotary Index Tables,<br />

S/N 800414 with Dual 35.5” x 49.5” Rotary Index Tables,<br />

1 – CARLTON 4H FLOOR TYPE BORING MILL, S/N 4H-123, Ohio Rotary Table 96” Diameter,<br />

Spindle Speeds 10-1000 RPM, Vertical Head Travel 50” Approx, Saddle Travel 14’ Approx.<br />

cnc Vertical macHininG centers<br />

1 – HAAS VF-5/50 3-AXIS CNC VERTICAL MACHINING CENTER, S/N 40305 (2005), T-Slotted Table 23” x<br />

52”, Travels: X – 50”, Y – 26”, Z – 25”, Spindle Speeds 7,500 RPM, Coolant Through Spindle,<br />

30 Position Side Mount ATC – 50 Taper, Dual Arm Tool Changer, Vector Drive 40/30 HP, Haas CNC Control<br />

1 – HURCO VMX 64 / 50 T 3-AXIS CNC VERTICAL MACHINING CENTER, S/N M653-06001013CFC (2003),<br />

T-Slotted Table 35” x 66”, Travels: X – 64”, Y – 34”, Z – 30”, Spindle Speeds 8,000 RPM, Coolant Through<br />

Spindle, 32 Position Side Mount ATC – 50 Taper, Dual Arm Tool Changer, Ultimax CNC Control<br />

cnc toolinG<br />

1 – ZOLLER TD 2002 TOOL BALANCER (2004), Type BALAC-00060<br />

1 – ROYAL VARISET TOOL BALANCER, S/N N/A, With<br />

Enclosure, Heidenhain 2-Axis DRO<br />

36 – LISTA TOOL HOLDER STORAGE CARTS & RACKS<br />

1 – DIGITAL TECHNIQUES 50 TAPER TOUCH TOOL PROBE, S/N DP-1070<br />

LARGE QUANTITY OF 50 TAPER & 40 TAPER TOOL HOLDERS<br />

coordinate measUrinG macHines / inspection / edm<br />

1 – DEA LAMBDA BRIDGE TYPE COORDINATE MEASURING MACHINE, S/N 5509-018,<br />

Bridge Travel 22’ Approx, Head Travel 8’ Approx, Head Vertical Travel 80” Approx, Brown &<br />

Sharpe DEA Controller Serial #108213, Renishaw PH10M Probe, S/N OG3943, Pendant,<br />

No Computer<br />

2 – RENISHAW PH10M PROBES, S/Ns 2W7305, R48029<br />

1 – BROWN & SHARPE KRYPTON K600 CAMERA BASED MEASURING SYSTEM,<br />

S/N K6C-12131 (2003), Model SPP02383 Space Probe, Model CLT-02152 Camera Lift<br />

Trolley, PC Trolley, Camera Tri-Pod & Case, NOTE: No Computer<br />

1 – NAC HSV400 HIGH SPEED COLOR VIDEOTAPE CAMERA SYSTEM, Camera with<br />

Monitor & Tripod<br />

2 – LK METRE FOUR CANTILEVER ARM TYPE COORDINATE MEASURING MACHINES, S/Ns 201889,<br />

203647, Approx Travels: X – 136”, Vertical Arm – 50”, Two (2) 39.5” Diameter Lift Tables, NOTE: No Probe &<br />

No Computer, S/N 203647 with Brown & Sharpe Controller S/N 242092-0003,<br />

1 – SHEFFIELD PORTAGE 72-A DUAL CANTILEVER ARM TYPE COORDINATE MEASURING MACHINE,<br />

S/N 78639 / 78532, Dual Horizontal Arms, Steel Plate 10’6” x 20’ Approx<br />

1 – ROCKWELL 4JR HARDNESS TESTER, S/N 458-5269<br />

1 – ELOX SERIES Q WIRE CUT EDM, Submersible Type, Enclosure 32” x 38”, Fanuc Control, Pendant<br />

1 – LIEBERT DATA WAVE 10<br />

LARGE QUANTITY OF HEIGHT GAUGES<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 3

transfer Press LInes<br />

(9) transFer press lines<br />

Presses May Be Offered Separately or In Bulk With Sheet Destackers<br />

1 – TRANSFER PRESS LINE TP1<br />

• IHI AUTOMATIC BLANK DESTACKER (TP1 PRESS), S/N AM2-1, Blank Length 54” – 110”, Width 30” – 78”,<br />

Thickness .020”-.078”, Pallet Capacity 20,000 Lb x 18” Stack Height, Washer, Blank Feeder<br />

• IHI TS8-3000-1500-252-252x132 4500 TON DUAL RAM STRAIGHT SIDE TRANSFER PRESS (TP1 PRESS),<br />

Tonnage, Station 1 – 3000 / Station 2 – 1500, Stroke 40” / 40”, SPM 8-16 Variable, Shut Height 66”, Motorized<br />

Adjustment 2”, Each Station has dual Rolling Bolsters 252” x 132”, Transfer Feed Stroke 84”, Transfer Clamp Stroke<br />

20”, Transfer Lift Stroke 10”<br />

2 – TRANSFER PRESS LINES TP2 & TP3<br />

• (2) IHI AUTOMATIC BLANK DESTACKERS (TP3), Blank Length 54” – 110”, Width 30” – 78”, Thickness .027”-.081”, Pallet<br />

Capacity 20,000 Lb x 18” Stack Height, Washer, Peabody Electrostatic Coater, MARK ONE Model 1211A Blank Feeder<br />

2 – TRANSFER PRESS LINES TP4 & TP6<br />

• IHI AUTOMATIC BLANK DESTACKER (TP6),<br />

Blank Length 54” – 110”, Width 30” – 78”, Thickness<br />

.027”-.081”, Pallet Capacity 20,000 Lb x 18” Stack<br />

Height, Washer, Peabody Electrostatic Coater<br />

Model 16AA, S/N 7139, Centering Station<br />

• (2) IHI TS8-3000-1500-252-252x132 4500 TON DUAL<br />

RAM STRAIGHT SIDE TRANSFER PRESSES<br />

(TP4 & TP6), S/Ns NA & AM2C-2, Tonnage: Station<br />

1 – 3000/ Station 2 – 1500, Stroke 40” / 40”, SPM 8-<br />

• (2) IHI D4-2000-1250-144-96 3250 TON DOUBLE ACTION PRESSES, S/Ns AL3C-1D & NA, Tonnage (Inner / Outer)<br />

16 Variable, Shut Height 66”, Motorized Adjustment 2”,<br />

2000 / 1250, Stroke 42” / 36”, Shut Height 82” / 72”, Motorized Adjustment 10” / 10”, Blankholder Area 96” x 144”,<br />

Each Station has dual Rolling Bolsters 252” x 132”,<br />

Dual Rolling Bolsters, Strokes per Minute 8-15 Variable<br />

Transfer Feed Stroke 84”, Transfer Clamp Stroke 20”,<br />

Transfer Lift Stroke 10”, Exit Conveyor<br />

• (2) IHI TS12-1500-2000-1000-168-252-168x132 4500 TON TRI RAM STRAIGHT SIDE TRANSFER PRESS,<br />

Tonnage: (Station 1 / Station 2 / Station 3) 1500 / 2000 / 1000, Stroke 40” / 40” / 40”, Shut Height 66”, Motorized 4 – TRANSFER PRESS LINES TP10, TP9, TP8 & TP7<br />

Adjustment 2”, Area 132” x 168” / 132” x 252” / 132” x 168”, Each Station Dual Rolling Bolsters, SPM 8-15 Variable, • (4) KOMATSU AUTOMATIC BLANK DESTACK-<br />

Transfer Feed Stroke 84”, Clamp Stroke 24”, Lift Stroke 14”, Qty Work Stations 2-3-2, Exit Conveyor<br />

ERS, Dual Pallet Load Stations, Peabody<br />

Electrostatic Coater Mdl C<br />

• (4) KOMATSU D2-1000-108x48 KOMATSU 1600<br />

TON DOUBLE ACTION PRESS (TP10 – S/N<br />

1901461; TP9 – S/N 1425; TP8 – S/N 1427; TP7 –<br />

S/N 1402), Tonnage (Inner / Outer) 1000 / 600,<br />

Stroke 30” Inner, Shut Height to Carriage 62” / 52”,<br />

Motorized Adjustment 18” / 18”, Area 90” x 36” / 108”<br />

x 48”, SPM 10-20 Variable, Main Drive 250 HP DC,<br />

Micro Inch 100 HP AC<br />

• (4) KOMATSU TS8-2000-1000-108-108x108 3000<br />

TON DUAL RAM STRAIGHT SIDE TRANSFER<br />

PRESSES (TP10 – S/N 1901461; TP9 – S/N NA; TP8<br />

– S/N 1428; TP7 – S/N 1403), Tonnage (Station 1 /<br />

Station 2) 2000 / 1000, Stroke 30” / 30”, Die Height<br />

46” / 46”, Motorized Adjustment 2” / 2”, Dual Rolling<br />

Bolsters 108” x 108”, SPM 10-20 Variable, Main Drive<br />

400 HP DC, Micro Inch 250 HP AC, Transfer Work<br />

Stations 4 or 6, Feed Stroke 48” & 36”, Clamp Stroke<br />

16”, Lift Stroke 8”, Exit Material Conveyor<br />

• (3) AIRFLOAT B07-0116-1 15,000 LB CAP<br />

TURNTABLES (TP10 & TP8 PRESS), Diameter<br />

17’ & 22’<br />

4<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526)

transfer Press LInes • bLankIng Press LInes<br />

(9) transFer press lines (continUed)<br />

Presses May Be Offered Separately or In Bulk With Sheet Destackers<br />

1 – TRANSFER PRESS LINE TP5<br />

• KOMATSU AUTOMATIC BLANK DESTACKER (TP5 PRESS), Dual Pallet Load Stations, Washer, Peabody<br />

Electrostatic Coater, Model B, S/N 7592, Centering Station<br />

• KOMATSU D4-1000-120x84 1600 TON DOUBLE ACTION PRESS (TP5 PRESS), S/N 1396, Tonnage (Inner<br />

/ Outer) 1000 / 600, Stroke 42” Inner, Shut Height to Carriage 82” / 72”, Motorized Adjustment 10” / 10”, Area<br />

92” x 66” / 120” x 84”, SPM 8-15 Variable, Main Drive 250 HP DC, Micro Inch 100 HP AC<br />

• KOMATSU TS8-3000-1000-108-108x108 4500 TON DUAL RAM STRAIGHT SIDE TRANSFER PRESS (TP5<br />

PRESS), S/N 1397, Tonnage (Station 1 / Station 2) 3000 / 1500, Stroke 40” / 40”, Die Height to Carrier 58” / 58”,<br />

Motorized Adjustment 2” / 2”, Dual Rolling Bolsters 216” x 108”, SPM 8-15 Variable, Main Drive 550 HP DC, Micro<br />

Inch 400 HP AC, Transfer Work Stations 6, Feed Stroke 72”, Clamp Stroke 20”, Lift Stroke 10”, Transfer Bar<br />

Closed Inside 60”/72”/84”/96”, Exit Material Conveyor<br />

• AIRFLOAT 15,000 LB CAP TURNTABLE (TP5 PRESS)<br />

• (2) KOMATSU TS8-3000-1500-216-216x108 4500 TON DUAL RAM STRAIGHT SIDE<br />

TRANSFER PRESSES (TP12 – S/N 1901476; TP11 – S/N 1422), Tonnage: Station 1 – 3000 / Station 2 –<br />

1500, Stroke 40” / 40”, SPM 8-15 Variable, Die Height 58”, Main Drive 550 HP DC, Micro Inch Drive 400 HP<br />

AC, NOTE: 3000 Ton Ram Removed, No Rolling Bolsters<br />

BlanKinG press lines<br />

PRESSES AND FEED LINES MAY BE OFFERED SEPARATELY OR IN BULK<br />

6 – WEAN UNITED 40,000 LB COIL FEED LINES, Double Expanding Mandrel<br />

Uncoiler, Coil Load Car, Hold Down Arm, Peeler, Crop Shear, Wash & Flex Unit,<br />

11 Roll Backed-Up Leveler, Feeder, Console Control w/Allen Bradley Panelview<br />

Plus 700 Op Terminal, Some Missing Components<br />

6 – USI CLEARING S4-1000-120-84 1000 TON USI CLEARING STRAIGHT SIDE<br />

4-POINT PRESSES, S/Ns 10-4672, 10-4673, 10-4674, 10-4676, 10-4679, 10-4680, Stroke<br />

12”, SPM 20-60 Variable, Bed 84” x 120”, Shut Height 44”, Motorized Adjustment 2”, Windows<br />

94” Wide, Console Control, Dual Rolling Bolsters, Exit Conveyor, Some Missing Components<br />

6 – WEAN UNITED DUAL STATION STACKERS, S/Ns 39416 & NA, Car Capacity 18,000 Lbs<br />

1 – USI CLEARING S4-600-186-102B 600 TON STRAIGHT SIDE 4-POINT PRESS<br />

(SS3 PRESS), S/N 10-4693, Stroke 12”, SPM 8-30 Variable, Bed 102” x 186”, Shut<br />

Height 44”, Motorized Adjustment 2”, Console Control, Dual Rolling Bolsters<br />

(Col A-23), NOTE: Missing Press Drive Electronics<br />

1 – WEAN UNITED DUAL STATION STACKER (SS3 PRESS)<br />

1 – BUCCICONI STACKER (SS3 PRESS)<br />

1 – WEAN UNITED DUAL STATION STACKER (SS2 PRESS)<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 5

tandeM Press LInes<br />

(5) tandem press lines<br />

Presses May Be Offered Separately or In Bulk With Coil Feed Lines<br />

1 – TANDEM PRESS LINE G<br />

• DANLY D4-1000-108-72 1600 TON DOUBLE ACTION PRESS (G-1 PRESS), S/N<br />

80379502, Tonnage (Inner / Outer) – 1000 / 600, Stroke 36” / 34”, Shut Height To<br />

Carrier 64” / 54”, Motorized Adjustment 18” / 18”, Area 90” x 54” / 108” x 72”, SPM<br />

10-20 Variable, Effective Draw 10.375”, L-R Rolling Bolster, NOTE: Press is incomplete<br />

• (3) DANLY S4-1000-108-60 QDC 1000 TON STRAIGHT SIDE 4-POINT PRESSES<br />

(G-2, G-3 & G-4 PRESSES), S/Ns 80379602, 80379804 & 80379806, Stroke 32”,<br />

SPM 10-20 Variable, Bed 60” x 108”, Shut Height 77” to Bed/60” to Carrier,<br />

Motorized Adjustment 18”, T-slotted Bolster Plate 8” Thick, Two L-R Rolling Bolsters<br />

• (2) DANLY U4-1000-180-96 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESSES (G-6 & G-7 PRESSES), S/Ns 55092813 & 55092814, Stroke 36”, SPM<br />

16”, Bed 96” x 180”, Shut Height 84”, Motorized Adjustment 18”, Rolling Bolster<br />

• DANLY U4-1000-180-96 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESS (G-8 PRESS), S/N 69287202, Stroke 36”, SPM 16, Bed 96” x 180”, Shut<br />

Height 84”, Motorized Adjustment 18”, Rolling Bolster<br />

1 – TANDEM PRESS LINE H<br />

• DANLY DU4-1250-144-84 1950 TON UNDERDRIVE DOUBLE ACTION PRESS<br />

(H-1 PRESS), S/N 55093001, Tonnage (Inner / Outer) – 1250 / 700, Stroke 36” /<br />

27”, Shut Height 74” / 64”, Motorized Adjustment 24” / 24”, Area 126” x 66” / 144”<br />

x 84”, SPM 10, NOTE: Full Bolster Plate covering Inner & Outer Slides<br />

• (2) DANLY U4-1000-132-84 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESSES (H-2 & H-3 PRESSES), S/Ns 55089537 & 55089523, Stroke 30”, SPM<br />

16, Shut Height 69”, Motorized Adjustment 24”, Schuler Rolling Bolster<br />

• DANLY U4-1000-180-96 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESS (H-4 PRESS), Stroke 24”, SPM 16, Shut Height 84”, Motorized Adjustment<br />

30”, T-slotted Bolster Plate 7” Thick<br />

• DANLY U4-1000-132-84 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESS (H-5 PRESS), S/N 55089521, Stroke 30”, SPM 16, Shut Height 69”,<br />

Motorized Adjustment 24”, Schuler Rolling Bolster<br />

• CLEARING B4-1000-180-96 1000 TON UNDERDRIVE STRAIGHT SIDE<br />

4-POINT PRESS (H-6 PRESS), S/N 53-18328P, Stroke 24”, SPM 16, Shut Height<br />

84”, Motorized Adjustment 30”, T-slotted Bolster Plate 12” Thick<br />

• (2) DANLY U4-1000-132-84 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESSES (H-7 & H-8 PRESSES), S/N 55089549s & 55089548, Stroke 24”, SPM<br />

16, Shut Height 69”, Motorized Adjustment 24”, Schuler Rolling Bolster, T-slotted<br />

Bolster Plate 60” x 108” x 8” Thick<br />

1 – TANDEM PRESS LINE J<br />

• OLOFSTROM 4910041 AUTOMATIC BLANK DESTACKER WITH PRESS J-LINE,<br />

S/N C-1039, Allen Bradley Panelview 1200 Op Terminal, Two (2) Handling Specialty<br />

Blank Trays – 88” x 128”, MARK ONE Model 114 Washer, Blank Centering Station<br />

• DANLY DU4-1600-900-144-96 2500 TON UNDERDRIVE DOUBLE ACTION PRESS<br />

(J-1 PRESS), S/N 68267501, Tonnage (Inner / Outer) – 1600 / 900, Hydraulic<br />

Overload, IDC #TM98 Load Monitor, Bed 96” x 144”, No Rolling Bolster, Allen Bradley<br />

Panelview 1200 Op Terminal, Micro Inching, Comau Load & Unload Model Smart 3-<br />

6.75 Robots, S/N 495 & 598 with C3G-900 Controller, S/N 495 & 598<br />

• (4) DANLY U4-1000-132-84 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESSES (J-2, J-3, J-4 & J-5 PRESSES), S/Ns 55089520 & 55089543, Stroke 30”<br />

Approx, SPM 16 Approx, Bed 84” x 132”, Shut Height 69” Approx, Motorized<br />

Adjustment 24” Approx, Rolling Bolster, Clamp System, ISI Robotics Interface Control<br />

• (4) COMAU SMART 3-6.75 TRANSFER ROBOTS, WITH PRESS LINE J, S/Ns 048,<br />

060, 074 & 046, Transfer Robots Cell 1-2, Cell 2-3, Cell 3-4 and Cell 4-5, each with<br />

Model C3G-900 Controller<br />

• (3) ATLAS 130,000 LB. DIE CARTS (J2-3), Cart 200” x 152”, Plate 127” x 84”, Die 132” x 84”<br />

• MARK ONE 132-3 END OF LINE CONVEYOR (J-LINE), S/N 1261-140, Dual<br />

Conveyors Length 65’ Approx, Allen Bradley Automation Console<br />

1 – TANDEM PRESS LINE L<br />

• OLOFSTROM 4680021 AUTOMATIC BLANK DESTACKER WITH PRESS LINE L,<br />

S/N C-1027, Dual Stack, Centering Station<br />

• DANLY U4-1000-180-96 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT PRESS<br />

(L-2 PRESS), S/N 73317403, Stroke 40”, SPM 16, Bed 96” x 180”, Shut Height 84”,<br />

Motorized Adjustment 30”, Micro Inch, Clamp System, ISI Robotics Pathfinder Control,<br />

ISI Load & Unload Arms, Allen Bradley Panelview 1000e Op Terminal<br />

• DANLY U4-1250-180-96 1250 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESS (L-3 PRESS), Stroke 36”, SPM 16, Bed 96” x 180”, Shut Height 84”,<br />

Motorized Adjustment 30”, ISI Load & Unload Arms, Allen Bradley Panelview 1000e<br />

Press Op Terminal<br />

• (2) DANLY U4-1000-180-96 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT<br />

PRESSES (L-4 & L-5 PRESSES), S/N 55092805, Stroke 36”, SPM 16, Bed 96” x<br />

180”, Shut Height 84”, Motorized Adjustment 18”, ISI Load & Unload Arms, Allen<br />

Bradley Panelview 1000e Press Op Terminal<br />

• MARK ONE 180A L PRESS LINE EXIT CONVEYOR<br />

6<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526)

HydrauLIC sPOttIng & gaP fraMe Presses • rObOts • fanuC COntrOLs<br />

(5) tandem press lines (continUed)<br />

Presses May Be Offered Separately or In Bulk With Coil Feed Lines<br />

1 – TANDEM PRESS LINE S<br />

• OLOFSTROM 4910031 AUTOMATIC BLANK DESTACKER WITH PRESS LINE S, S/N C-1037, Dual Stack, MARK ONE 90” Blank Washer, Centering Station<br />

• USI CLEARING DU4-1000-600-108-72 1600 TON UNDERDRIVE DOUBLE ACTION PRESS (S-1 PRESS), Tonnage (Inner / Outer) 1000 / 600, Bed 72” x 108”, Die Clamps,<br />

IDC TM88SHK Tonnage Monitor, Allen Bradley Panelview 1200 Op Terminal, Comau Load & Unload Model Smart 3-6.75 Robots with Model C3G-900 Controllers<br />

• (3) USI CLEARING S4-600-108-72 600 TON STRAIGHT SIDE 4-POINT PRESSES (S-2, S-4 & S-5 PRESSES), S/Ns 10-4553, 10-4557 & 10-4551; Stroke 24”, SPM 25, Bed<br />

72” x 108”, Shut Height 60”, Motorized Adjustment 16”, Torc Pac Clutch<br />

• USI CLEARING S4-1000-108-72 1000 TON STRAIGHT SIDE 4-POINT PRESS (S-3 PRESS), S/N 10-4564, Stroke 24”, SPM 25, Bed 72” x 108”, Shut Height 60”, Motorized<br />

Adjustment 16”, Torc Pac Clutch<br />

• (6) ATLAS 80,000 LB CAP DIE CARTS, S/Ns F808.23 & NA, Cart 146” x 128”, Plate 103” x 72”, Die Space 108” x 72”<br />

• COMAU SMART 3-6.75 LOT (4) TRANSFER ROBOTS WITH PRESS LINE S, S/N 041, 039, 038, 033, Transfer Robots Cell 1-2, Cell 2-3, Cell 3-4 and Cell 4-5, each with Model C3G-900 Controller<br />

• TITAN EXIT CONVEYOR 6’ x 20’, S/N 9510397<br />

• (2) DANLY U4-1000-132-84 1000 TON UNDERDRIVE STRAIGHT SIDE 4-POINT PRESSES (VP-19 & VP-20 PRESSES), S/Ns 63185902 & 55089533; Stroke 30”, SPM 16,<br />

Bed 84” x 132”, Shut Height 68”, Motorized Adjustment 24”, T-slotted Bolster Plate<br />

• DANLY D4-1250-144-84 1950 TON DOUBLE ACTION PRESS (VP-SI PRESS), Tonnage (Inner / Outer) 1250 / 700, Stroke 42” / 38”, Shut Height 74” / 64”, Motorized Adjustment<br />

24” / 24”, Area 128” x 66” / 144” x 84”, SPM 10, Effective Draw 16”<br />

HydraUlic spottinG presses<br />

1 – CLEARING PS-2100-200 100-TON HYDRAULIC SPOTTING PRESS, S/N 55-18427, Bed 100” x 200”,<br />

T-slotted Slide 100” x 188”, Stroke 60”, Shut Height 36”, Motorized Adjustment, Rolling Bolster<br />

1 – CLEARING PS-250-132 50-TON HYDRAULIC SPOTTING PRESS, S/N 55-18432, Bed 84” x 132”,<br />

T-slotted Slide 84” x 120”, Stroke 48”, Shut Height 36”, Motorized Adjustment, Rolling Bolster<br />

1 – CLEARING PS-250-200 50-TON HYDRAULIC SPOTTING PRESS, S/N 52-17659-P, Bed 100” x 200”, Stroke<br />

60”, Daylight 96”, Motorized Adjustment 36”<br />

Gap Frame presses<br />

1 – CLEARING OBS-200-72-42 200-TON DOUBLE CRANK GAP FRAME PRESS, S/N 51-1111, Stroke<br />

20”, Strokes per Minute 25, Bed 42” x 72”, Shut Height 42”, Slide Adjustment 6”, T-slotted Bolster 6” Thick<br />

1 – CLEARING AB50 50-TON ADJUSTABLE BED GAP FRAME PRESS, Stroke 6”, Bed 18” x 32”, Shut<br />

Height 26”, Adjustment 3”<br />

1 – HANNIFIN F150-42XSP 150-TON HYDRAULIC GAP FRAME PRESS, S/N D50800<br />

1 – HANNIFIN 75-TON HYDRAULIC GAP FRAME PRESS, S/N D-31183, Throat 19”<br />

press room accessories<br />

1 – HARMON TRANSMOTIVE DIE TRANSFER CAR, Size 84” x 180”, Powered Car<br />

1 – 60,000 CAPACITY TRANSFER TABLE, Size 66” x 120”<br />

LARGE QUANTITY OF FC TRANSCON 48” &<br />

36” WIDTH SCRAP CONVEYOR SYSTEMS<br />

(56) roBots<br />

3 – FANUC S-420iW 6-AXIS ROBOTS, S/Ns F-22649,<br />

F-35287 & F-35288, R-J2 Controller, Teach Pendant<br />

2 – FANUC S-430iW 6-AXIS ROBOTS, S/Ns F-42420 &<br />

F-42419, R-J3 Controller, NO Teach Pendant<br />

1 – FANUC S-420iS 6-AXIS ROBOT, RJ Controller, Roman<br />

Weld Transformer<br />

3 – FANUC S-420FD 6-AXIS ROBOTS, RJ3 Controller<br />

31 – ROBOTRON WELD CONTROLLERS<br />

47 – KUKA TYPE KR150L150 SP/2 6-AXIS ROBOTS,<br />

Robot Controllers, Some w/Medweld 300S AC Weld<br />

Controls & RoMan Weld Transformers<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 7

Cranes & aCCessOrIes • squarIng sHears • Press brakes<br />

(13) oVerHead BridGe cranes<br />

1 – P&H 50 TON DUAL GIRDER YARD BRIDGE CRANE, S/N C-16388, Loc: Yard, Span 60’, Runway<br />

Approx 270’ Total Length, Support Structure, Crane Lift 27’ 8”<br />

1 – P&H 50 TON DUAL GIRDER BRIDGE CRANE, S/N C-29295, Crane SSC-1, Span 115’ 8”, Lift 35’<br />

6”, Cab Operated<br />

1 – P&H 15-TON DUAL GIRDER BRIDGE CRANE, S/N C-16377, Crane 11, Span 74’ 8.5”, Main Hoist<br />

50-TON x Lift 26’ 4”, Auxiliary Hoist 15-Ton x Lift 28’ 10”, Radio Control<br />

1 – WRIGHT 10-TON DUAL GIRDER BRIDGE CRANE, Span 30’ Approx, 5-Ton Electric Hoist, 6-Way Pendant<br />

3 – CONLIFT (2) 10-TON & (1) 5-TON DUAL GIRDER BRIDGE CRANES<br />

2 – ABELL-HOWE 10-TON SINGLE GIRDER BRIDGE CRANES, S/Ns MC-1672, MC-1874, Span 33’<br />

Approx, Electric Hoist, Rail Length 320’ Total<br />

1 – ABELL-HOWE 5-TON SINGLE GIRDER BRIDGE CRANE, S/N MC-1652, 5-Ton P&H Redi-Lift<br />

Electric Hoist, Crane Span 33’ Approx, Under hung<br />

1 – DETROIT HOIST 5-TON SINGLE GIRDER BRIDGE CRANE, Span 30’ Approx, 5-Ton Electric Hoist, 6-Way Pendant<br />

1 – RELIABLE B220 5-TON SINGLE GIRDER BRIDGE CRANE, Span 35’ Approx, 6-Way Pendant,<br />

Under hung Hoist, Rail Length 240’ Total<br />

1 – TC AMERICAN 3-TON SINGLE GIRDER CRANE, Rail Length 40’, 3-Ton Yale Electric Hoist, 6-Way Pendant<br />

Gantry cranes<br />

7 – CONLIFT 20-TON DUAL GIRDER GANTRY CRANES, Span 20’ Approx, Electric Hoist, 6-Way<br />

Pendant, Cranes 4-2, 3-2, 2-2, 2-1, 3-1, 4-1, 1-1<br />

(13) semi Gantry cranes<br />

6 – PROGRESSIVE 10-TON SEMI-GANTRY BRIDGE CRANES, Span 30’, Dual Girder, Electric Hoist,<br />

6-Way Pendant, Cranes G-1 thru G-6<br />

6 – ABELL-HOWE 10-TON SEMI-GANTRY BRIDGE CRANES, G-7 & G-8 Span 30’, G-9 thru G-12 Span 25’<br />

1 – HANDLING SYSTEMS 10-TON SEMI-GANTRY BRIDGE CRANE, Span 27’ Approx, Dual Girder,<br />

Yale Electric Hoist, 6-Way Pendant, Crane K-13<br />

(8) JiB cranes<br />

2 – ABELL HOWE JIB CRANES, 3-TON, Column Dia. 17” Approx, Arm Length 12’, 1-TON, Column Dia.<br />

14” Approx, Arm Length 10’, Yale Challenger Electric Hoists<br />

2 – GORBEL & MISC. 1-TON JIB CRANES, Column Diameter 13” Approx, Arm Length 8’, Electric Hoist<br />

1 – SPANCO 1/2-TON JIB CRANE, Column Diameter 14” Approx, Arm Length 12’, Pneumatic Hoist<br />

2 – DAVID WRIGHT 1/2-TON JIB CRANES, Column Diameter 8” Approx, Arm Length 6’, Pneumatic Hoist<br />

1 – 1/2-TON WALL MOUNT JIB CRANE, Arm Length 14’, Yale Electric Hoist<br />

poWer sQUarinG sHears<br />

1 – CINCINNATI 4H10 10’ x 1/2” CENTURY HYDRAULIC SQUARING SHEAR, S/N 3C150,<br />

36” Front Operated Power Back Gauge, 10’ Squaring Arm, 2 Front Stock Supports<br />

1 – ADIRA (COMEQ) GHS 0630 10’ x 1/4” HYDRAULIC SQUARING SHEAR, S/N 3354 /<br />

9068D, Capacity 3080 mm x 6.5 mm, 18 KW (24 HP) Motor, 30” Front Operated Power<br />

Back Gauge, Squaring Arm<br />

1 – ACCURSHEAR 82506 LP 6’ x 1/4” HYDRAULIC SQUARING SHEAR, S/N 577,<br />

36” Front Operated Power Back Gauge, 2 Front Stock Supports, 48” Squaring Arm<br />

press BraKes<br />

1 – CINCINNATI 175CBx10’ 175-TON HYDRAULIC PRESS BRAKE, S/N 42727,<br />

Overall Bed & Ram 12’, Between Housings 10’ 6”, Stroke 10”, Stroke Control, 4-Way<br />

Die Holder, Sectional Ram Clamps<br />

1 – BETENBENDER 6-50T 50-TON HYDRAULIC PRESS BRAKE, S/N 87201, Overall<br />

Bed & Ram 6’, Between Housings 64.75”, 10 HP Motor & Hyd. Pump, Two-Speed,<br />

Die Holder, Hours: 3,982<br />

1 – CHICAGO DREIS & KRUMP PBP 10187-8 10’ x 3/16” POWER FINGER<br />

BRAKE, S/N 10187-8, Power Raise & Lower Apron, Qty 25 Finger Dies<br />

1 – CHICAGO SO-412 4’ APRON BRAKE, S/N 311732<br />

8<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526)

IrOnWOrkers • bandsaWs • grInders • LatHes • drILLs<br />

ironWorKers<br />

1 – BUFFALO 675H IRONWORKER, S/N 88500843, Shear Capacity: Angles – 6” x 6” x 1/2”,<br />

Flats – 1/2” x 11”, Coper, Angle/Tees, Punch<br />

2 – EDWARDS 55 – JAWS “IV” 55-TON HYDRAULIC IRONWORKERS, S/Ns 34345502,<br />

34335502, Shear Capacity: Angles – 3”x3”x3/8” / 4”x4”x1”, Flats 1/2” x 12” / 3/8”x14”,<br />

Rounds 1.125”, Punch 1 1/6” diameter hole in 5/8” plate, Notcher<br />

(15) Vertical & HoriZontal Band saWs<br />

1 – MARVEL SERIES 15A6 AUTOMATIC HORIZONTAL BAND SAW, S/N E-151667-I,<br />

Capacity 16” x 20”<br />

2 – WELLSAW 613 & 600 HORIZONTAL BAND SAWS, S/Ns 1545 & 13021<br />

1 – MARVEL SERIES 81 AUTOMATIC UNIVERSAL TILT TYPE VERTICAL BAND SAW,<br />

S/N E-505612PC, PCII Programmable Length Control, Feed Table & Conveyor<br />

3 – MARVEL MARK II SERIES 8 UNIVERSAL TILT TYPE VERTICAL BAND SAWS,<br />

S/Ns 825643-W, 825914-W, 826981<br />

3 – DO ALL 36” MODEL 3613-2 VERTICAL BAND SAWS, S/N 151-61182, Tilt Table 30” x 30”,<br />

Blade Welder, 3613-1, S/N 440-86211, Tilt Table, 36-3, S/N 53-56309, Tilt Table 24” x 30”,<br />

Blade Grinder<br />

1 – KALAMAZOO VS-36 36” VERTICAL BAND SAW, S/N 149, Tilt Table 26” x 31.5”<br />

1 – TANNEWITZ DI-SAW 23” VERTICAL BAND SAW, S/N 3174, Tilt Table 36” x 42”<br />

1 – DO ALL 2013-V 20” VERTICAL BAND SAW, S/N 439-85874, Tilt Table 26” x 26”, Blade Welder<br />

1 – JET JWBS-14CS 14” VERTICAL BAND SAW, S/N 80132092, Tilt Table 15” x 15”<br />

1 – COBRA SAW VERTICAL BAND SAW<br />

(13) radial arm drills<br />

3 – CARLTON 4A 8’ x 19” RADIAL ARM DRILLS, S/Ns 4A-4179, 4A-4178, 4A-2772,<br />

S/Ns 4A-4179 & 4A-4178, Spindle Speeds 15-1500 RPM, Power Clamp, 90 Degree Box<br />

Table, S/N 4A-2772 with Spindle Speeds 12-1200 RPM, (Rebuilt by Natco/Carlton 2001),<br />

S/N 4A-4178 with Base Dia. Approx 19’, Rear Gear Box Cracked<br />

3 – CARLTON 4A 6’ x 19” RADIAL ARM DRILLS, S/N 4A-4177, Power Clamp, 90 Deg Box<br />

Table – 32”x 28”/18” x 28”, S/N 4A-4176, Spindle Speeds 15-1500 RPM, Power Clamp,<br />

No Box Table, (Rebuilt 2001), S/N 4A-3958, Spindle Speeds 15-1500 RPM, Power Clamp,<br />

Two 90 Deg Box Tables, Base Extension<br />

1 – NATCO 3A 6’ x 15” RADIAL ARM DRILL, S/N 3A-6101, Spindle Speeds 15-1500 RPM,<br />

Power Clamp, 90 Deg Box Table, Base Extension, 30 HP Motor<br />

1 – GIDDINGS & LEWIS BICKFORD 6’ x 15” APPROX RADIAL ARM DRILL, S/N 954-00240-<br />

77, Spindle Speeds 12-1500 RPM, Power Clamp, 90 Deg Box Table – 24” x 28”/11” x 28”<br />

1 – CINCINNATI BICKFORD SUPER SERVICE 4’ x 15” RADIAL ARM DRILL, S/N 4E-564,<br />

90 Deg Box Table<br />

1 – AMERICAN HOLE WIZARD 4’ x 11’ APPROX RADIAL ARM DRILL, Spindle Speeds<br />

50-1500 RPM, 90 Deg Box Table<br />

1 – FOSDICK 4’ SENSITIVE 4’ x 11” APPROX RADIAL ARM DRILL, Spindle Speeds 60-1200<br />

RPM, Box Table 24” x 48”<br />

1 – RADIAL COLUMN DRILL PRESS, S/N N/A, Table 8.25” x 28.75”, 2 HP, Travel 5”<br />

1 – OMNIVERSAL 3’ x 6” APPROX RADIAL DRILL, Spindle Speeds 0-1000 RPM<br />

(13) sUrFace Grinders<br />

1 – BROWN & SHARPE NO 13 UNIVERSAL TOOL GRINDING MACHINE,<br />

S/N 525-13-1093, Headstock, Table Speeds 7.7 – 100 IPM, Donaldson<br />

Model VS550 Dust Collector<br />

1 – GALLMEYER & LIVINGSTON 563 14” x 36” HYDRAULIC SURFACE<br />

GRINDER, S/N 563216, Electromagnetic Chuck 14” x 36”, Automatic Feed,<br />

Chucktron Magnetic Chuck Control, Coolant<br />

1 – KENT SGS-1224AHD 12” x 24” AUTOMATIC HYDRAULIC SURFACE<br />

GRINDER, Electromagnetic Chuck 12” x 24”, Automatic Downfeed,<br />

2 HP Motor, Coolant<br />

1 – CHEVALIER SGS-2A1224 12” x 24” SURFACE GRINDER, S/N P284C001<br />

1 – AMW 12” X 24” SURFACE GRINDER, Electromagnetic Chuck 12” x 24”,<br />

Torit Model MC500 – 3 HP Dust Collector, S/N IG574149-001<br />

1 – BROWN & SHARPE MICROMASTER HYDRAULIC SURFACE GRINDERS,<br />

MODEL 1030 10” x 30”, S/N 523-1030-2404, MODEL 818 8” x 18”,<br />

S/N 523-8186-7679, MODEL 618 6” x 18”, All With Electromagnetic Chuck<br />

2 – KENT SGS816MR 8” x 16” SURFACE GRINDERS, S/Ns 88139 & 322042<br />

with Electromagnetic Chuck 8” x 16”<br />

1 – REID 618 HB 6” x 18” SURFACE GRINDER, S/N 30167 FC, Electromagnetic<br />

Chuck 6” x 18”, Torit Model 84 – 3 HP Dust Collector, S/N 209687-1<br />

1 – KENT KGS-616S 6” x 16” SURFACE GRINDER, S/N 98095103, OS Walker<br />

Electromagnetic Chuck 6” x 14”, 2 HP<br />

1 – KO LEE SE618 6” x 18” SURFACE GRINDER, S/N 28343, Electromagnetic<br />

Chuck 6” x 18”, 2 HP,<br />

2 – TRIO TOOL KNEE GRINDERS, S/Ns 85-4412-B, N/A, Electromagnetic<br />

Chuck 14” x 22”, Segmented Wheel, OS Walker Magnetic Chuck Control,<br />

Power Table Elevation, 15 HP<br />

enGine<br />

latHes<br />

1 – LEBLOND 16”<br />

HD 16” HEAVY<br />

DUTY SLIDING<br />

GAP ENGINE<br />

LATHE, S/N<br />

2NE529, Center<br />

Distance 72”, Hole<br />

Through Spindle<br />

1.75”, 15 HP Motor,<br />

Tail Stock, Steady<br />

Rest, Cross Slide,<br />

15” 3-Jaw Chuck,<br />

Speeds 16-2000<br />

RPM, Taper<br />

Attachment<br />

1 – HWACHEON HL-530 23” x 60” ENGINE LATHE, S/N 255192 (2004),<br />

Swing 23”, Center Distance 60”, Hole Through Spindle 3”, Tail Stock, Cross<br />

Slide, Steady Rest, 10 HP, 10” 3-Jaw Chuck, Speeds 28-1350 RPM, Acu-<br />

Rite DRO<br />

1 – JET GH-1340A 13” x 40” ENGINE LATHE, S/N 9021582, Swing 13”,<br />

Center Distance 40”, Hole Through Spindle 1.5”, Tail Stock, Cross Slide,<br />

6.25” 3-Jaw Chuck, Speeds 45-1800 RPM, Sargon 2-Axis DRO, Inch/Metric<br />

1 – AMERICAN PACEMAKER STYLE B 14” x 30” ENGINE LATHE,<br />

S/N 74992-56, Swing 14”, Center Distance 30”, Hole Through Spindle 2”,<br />

Tail Stock, Cross Slide, 12” 3-Jaw Chuck, Taper Attachment<br />

1 – MONARCH EE 10” x 20” TOOLMAKERS ENGINE LATHE, S/N 45956,<br />

Swing 10”, Center Distance 72”, Hole Through Spindle 1.25”, Tail Stock,<br />

Cross Slide, 8” 3-Jaw Chuck, Actual Swing 12.5”<br />

For more information please check our websites at<br />

www.hilcoind.com or www.maynards.com<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 9

vertICaL MILLIng MaCHInes • WeLders • furnaCes • tOOLrOOM<br />

Welders<br />

1 – MILLER INTELLIWELD 650 CP/CC DC ARC WELD POWER SOURCE, S/N JF913250<br />

3 – MILLER DELTAWELD WELD POWER SOURCES, MODELS: 452 CV, S/N LF290446C, (2) 452 CV<br />

DC, S/Ns LF148019, KG177782, Miller 70 & 60 Series 24 V Wire Feeds, 450, S/N JF913311,<br />

Welding Boom Extension, TH-2 and Dual Voltage Controller DW-2, 450 CP DC ARC, S/N JF851642<br />

2 – MILLER SYNCROWAVE CC-AC/DC SQUARE WAVE WELD POWER SOURCES,<br />

MODEL 350X, S/N KK202901, Miller Coolmate 3, MODEL 350LX, S/N LE261830,<br />

Power Cart, Airlux 300, Miller Tig Runner<br />

2 – MILLER SYNCROWAVE WELD POWER SOURCES, MODEL 500 ON POWER<br />

CART, S/N JJ362171, AC/DC Gas Tungsten – Arc or Shielded Metal Arc Welding<br />

Power Source, Eutectic + Castolin Weld Fume Eliminator, MODEL 350, S/N KC279058<br />

2 – MILLER CP DC ARC WELD POWER SOURCES, MODEL 300 MT, S/N JE756902,<br />

Torch Control, MODEL CP300, S/N JG019738, Miller S-52E Wire Feed<br />

1 – MILLER DYNASTY 300DX WELD POWER SOURCE, S/N LC221311, Miller Coolmate 3<br />

S/N LC197162<br />

4 – MILLER MILLERMATIC WIRE WELDERS, (2) 250X, S/Ns LA273366, LB166177,<br />

(2) 250, S/Ns KK259461, KK229223<br />

1 – LINCOLN 350 AC/DC HELIWELDER PLUS SQUARE WAVE POWER SOURCE, S/N M1208119<br />

1 – LINCOLN IDEALARC AC/DC 250 250 AMP WELD POWER SOURCE, S/N 11094 U1040911357<br />

1 – HOBART EXCEL ARC 500CC WELD POWER SOURCE<br />

2 – FILTERMATE MH-60 + FH-21 + F-33 – CF-2x3 FILTER UNITS, S/N 1010974<br />

1 – EUTECTIC + CASTOLIN HD1000 AIRLOX FUME ELIMINATOR, S/N 329671<br />

1 – TORIT PT-1000 PORTABLE 1 HP DUST COLLECTOR, S/N 250568-2<br />

QUANTITY OF WELD TABLES W/VISE, WELDING ROD,CARTS, TORCHES<br />

(7) Vertical millinG macHines<br />

4 – BRIDGEPORT SERIES I VERTICAL MILLS, S/N 233714, 2-Way Power Feed<br />

Table 9” x 42”, Proto-Track Plus Control, S/N 241945, Lyman MK4 Power Feed<br />

Table 9” x 48”, S/N 235021, Table 9” x 42”, S/N 235958, Table 9” x 48”, All With 2<br />

HP Motor, Vari-Speed, Quill Travel 5”<br />

1 – WILTON VS203 VERTICAL MILL, S/Ns 509217, 509158, 509160, Power Feed<br />

Table 9” x 49”, 3 HP Motor, Speeds 60-4200 RPM, S/Ns 509217 & 509158 with<br />

Newall Topaz 2-Axis DRO<br />

2 – CLEVELAND VERTICAL MILLS, S/Ns K2V934553, N/A, Power Feed Table<br />

9” x 42”, Speeds 70-4200 RPM, Power Draw Bar, (1) With Mitutoyo 2-Axis DRO<br />

FUrnaces<br />

1 – LUCIFER 42-R36 ELECTRIC FURNACE, S/N 6410, Approx Inner Dimensions 36”<br />

Deep x 24” Wide x 24” High, Max Temp 1250 Deg F<br />

1 – GRIEVE AA-1000 ELECTRIC FURNACE, S/N 340016, Approx Inner Dimensions<br />

24” Deep x 24” Wide x 20” High, Max Temp 1000 Deg F<br />

1 – EFD / ELVA INDUKSJON SA TYPE FC 30/1.6 CS-10-25MI INDUCTION<br />

HARDENING LINE, S/N 10052 (2000), Freq Range 10-25 khz, MILLER Coolmate<br />

3, S/N LE440612, Quench Tank<br />

miscellaneoUs toolroom eQUipment<br />

20 – CLEEREMAN 25D SLIDING HEAD BOX COLUMN DRILLS, Table<br />

19” x 24”, 5 HP Motor, Feed Trip Dial, Speeds 75-1500 RPM, Some<br />

Rebuilt by Natco Carlton<br />

1 – SELLERS TYPE 6/G DRILL POINT GRINDER, S/N E-8597<br />

5 – WILTON COMBINATION 6” BELT / 12” DISC GRINDERS, 4204,<br />

S/N 28708, 4202A, S/N 0505396, 4200A, S/N 05061622, 3Z856, S/N<br />

312003, N/A, All With Dual Tilt Tables<br />

2 – DAYTON 4TJ97B COMBINATION 6” BELT / 12” DISC GRINDERS,<br />

S/Ns 4505, N/A, 1.5 HP<br />

1 – WILTON 1200 12” DISC GRINDER, S/N 806116, Tilt Table<br />

6 – KINDT-COLLINS OP MASTER OSCILLATING PROFILE GRINDERS,<br />

Standard Grinding Head Type 2717Y, S/N 63667, 2 HP<br />

1 – BROWN & SHARPE PG 2 PROFILE GRINDER, Grinding Wheel 2.5”<br />

Max Diameter, 2 HP, Table 18” x 20”, Power Head Elevation<br />

8 – BOYAR SCHULTZ #2 PROFILE GRINDERS, S/N 6-1122-DS, Torit Dust<br />

Collector Model VS550 (S/N IG476462), 1 HP<br />

3 – BALDOR CATALOG 1216W 3 HP DOUBLE END PEDESTAL<br />

GRINDERS<br />

6 – CINCINNATI, STANDARD & MISC. 2 HP DOUBLE END GRINDERS<br />

3 – FOREDOM ABRASIVE BELT GRINDERS<br />

1 – ENERPAC PAM-3042 HYDRAULIC H-FRAME PRESS<br />

1 – LAMINA 4-STATION HYDRAULIC LIFT SYSTEM, S/N P1596,<br />

Operator’s Monitor<br />

3 – DAKE 3, 2-1/2 & 2 ARBOR PRESSES<br />

1 – ROPER WHITNEY PEXTO 118 4-TON BENCH PUNCH, S/N 3-85<br />

2 – 3/4 HP DRILL PRESSES<br />

3 – TORIT DFT2-12 7.5 HP, DONALDSON TORIT VS 1200 3 HP & TORIT<br />

MC-500 1 HP DUST COLLECTORS<br />

Quantities of Royal Oak Collet Sets, Kurt 6” Anglock Vises, Rotary Bases,<br />

Relieving Fixture, Timken / SKF / FAFNIR / INA Bearings, Parallel Blocks To<br />

12” x 72” x 18” H<br />

10<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526)

OLLIng stOCk • aIr COMPressOrs • sHOP equIPMent<br />

rollinG stocK<br />

1 – CATERPILLAR D5 TRACTOR / DIE TUGGER, S/N 95J387, With Tow Attachment, Power Winch<br />

1 – ELWELL PARKER R15T40SSFD 40,000 LB CAP ELECTRIC FORK LIFT, S/N 2-6472, Lift<br />

120”, Side Shift, Fork Length 84”<br />

1 – ELWELL PARKER ESE 320 ELECTRIC LIFT TRUCK, S/N 2768L (2002)<br />

1 – HANDLING SPECIALTY INC FLJ-25W 25,000 LB CAP ELECTRIC FORK LIFT, S/N XF0396BN<br />

1 – HYSTER E100ZS 10,000 LB CAP ELECTRIC FORK LIFT, S/N D098N01641C,<br />

Lift 155”, Fork Length 72”<br />

1 – CATERPILLAR V80E 8,000 LB CAP. DIESEL FORK LIFT, S/N 27W5046, Lift 162”<br />

1 – PETTIBONE 501-LS 5,000 LB CAP. ELECTRIC FORK LIFT, S/N 157211, Lift 106”<br />

1 – HYSTER MODEL S155XL 15,500 LB. CAP. GAS FORKLIFT, Double Auxiliary Valve, 3-Stage<br />

Mast, Lift 220”, Automatic Transmission<br />

9 – HYSTER LPG FORKLIFTS, Model H300A, 30,000 Lb. Cap., Model S155XL, 15,000 Lb. Cap.,<br />

Model S100XL 10,000 Lb. Cap, 3 Stage Mast, Side Shift, Model S60XL 6000 Lb. Cap., (3)<br />

Model S40XL 4000 Lb. Cap., 3 Stage Mast, Lift 187”, Side Shift, All With Automatic<br />

Transmission<br />

4 – CAT LPG FORKLIFTS, Model T150D, 15,000 Lb. Cap., Model T120C, 12,000 Lb. Cap., Model<br />

GC40K, 8,000 Lb. Cap., 3 Stage Mast, Lifts 209”, Side Shift, Auxiliary Valve, Automatic<br />

Transmission<br />

2 – ELWELL PARKER E31 N615-60 60,000 LB CAP ELECTRIC DIE CARTS, Platform 58” x 58”, Lift 76”<br />

1 – ELWELL PARKER E21N415-40 40,000 LB CAP ELECTRIC DIE CART, S/N 24813<br />

1 – DROTT MODEL 1000 AI STRADDLE CRANE, S/N 4083, 120,000 Lb. Capacity<br />

1 – HYSTER ELECTRIC WALK-BEHIND PALLET LIFT<br />

1 – 25,000 LB CAP 4-POST LIFT<br />

8 – CUSHMAN TITAN PERSONNEL CARRIERS<br />

1 – COLSON M-10 / 8105 1,000 LB CAP WALK BEHIND ELECTRIC LIFT, S/N 820300SV2,<br />

Capacity 1000 Lb with Boom Full Extension<br />

1 – GENIE SLA-10 1,000 LB CAP SUPERLIFT, S/N 5500-8879<br />

LARGE QUANTITY OF HOBART & POWER CHARGE BATTERY CHARGERS & DEKA TYPE 18-D85-25 BATTERIES<br />

air compressors<br />

2 – INGERSOLL RAND SSR-EP25SE INTELLISYS 25 HP AIR COMPRESSORS, S/N KE6720U99057,<br />

Base on Casters, Buckeye Boiler Surge Tank, Intellisys Digital Control, S/N KE0155U94201<br />

2 – INGERSOLL RAND AIR COMPRESSORS, 2420N5, S/N 30 T 750491, T30, S/N 30T 553610<br />

LARGE QUANTITY OF GENERAL ELECTRIC 6857930B CLASS AA & GA TRANSFORMERS<br />

miscellaneoUs sHop eQUipment / Facilities<br />

1 – MARLEY MODEL NC-8312J2CM CROSSFLOW COOLING TOWER, S/N NC-242684-A1 & A2,<br />

Two Modules<br />

1 – TECNOMAGNETE 1100 LB MAGNETIC LIFT<br />

1 – HYDRAULIC H-FRAME PRESS, Between Uprights 60”<br />

24 – DUFF NORTON 75-TON AIR MOTOR HYDRAULIC JACKS, Sustaining Capacity 100 Ton,<br />

Lifting Capacity 75 Ton, (13) MODEL 144, Rise 30”, (11) MODEL 120 75-TON, Rise 13.75”<br />

11 – SQUARE D CAT PT036160GH 600 VOLT x 1000 AMP I LINE BUSWAY SWITCH<br />

1 – ECONOLINE BLAST CABINET<br />

1 – TRINCO 36/300 DELUXE REACH-IN TYPE BLAST CABINET, S/N 55118-1, Trinco DEDC Dust Collector<br />

1 – RECO BC INDUCTION BEARING HEATER<br />

8 – MODERN 4 STATION HYDRAULIC DIE SEPARATORS<br />

1 – LAMINA 4-CYLINDER HYDRAULIC LIFTING SYSTEM, E-300 Control<br />

1 – LYON CANTILEVER MATERIAL RACK<br />

4 – 9’ x 12’ to 10’ x 20’ MODULAR OFFICES<br />

3 – 45 & 30 GALLON FLAMMABLE STORAGE SAFETY CABINETS<br />

1 – TOLEDO 1,000 LB CAPACITY SPRINGLESS SCALE, Platform 24” x 30”<br />

6 – 36” X 66” TO 80” X 100” STEEL LAYOUT TABLES<br />

3 – BELT CONVEYORS 12’ X 60”, 12’ X 48”, 12’ X 42”<br />

2 – AIRCASTER CORP 22’ DIAMETER ROTARY TURN TABLES<br />

1 – TOLEDO 250 LB SPRINGLESS SCALE<br />

2 – MOTORIZED SCOOTERS<br />

1 – INDUSTRIAL ACOUSTICS CO 401 ACOUSTICAL TEST BOOTH<br />

1 – CHATTANOOGA HYDROCOLLATOR MASTER HEAD UNIT<br />

1 – GRASEBY ANDERSON 5401 SPIROMETER, S/N 4010774<br />

LARGE QUANTITY OF ASSORTED EMPLOYEE LOCKERS<br />

LARGE QUANTITY OF C-CLAMPS, AKD-8 SWITCHGEAR, SCAFFOLDING BARRIERS W/CARTS<br />

LARGE QUANTITY OF MATERIAL RACKS W/STEEL CONTENTS, Includes Angle, Rect & Square Tube, Bar, Plate Inventory<br />

LARGE QUANTITY OF STRONG HOLD TWO DOOR STORAGE CABINETS TO 72” WIDE, EQUIP-<br />

TO 10, 9 & 6 DRAWER STORAGE CABINETS, LISTA TWO DOOR STORAGE CABINET<br />

Hilti Power Drill, Greenlee 1801 Mechanical Conduit Benders, Ingersoll Rand Pneumatic Impact<br />

Wrenches, Anvil, Oil Totes, Wire Cages & Baskets, Sizes 32” X 26” X 24” H to 44” X 108” X 37” H, Banding<br />

Carts, 4-Stand Hose Reel Stations, Hose Reels, Wood Top Work Benches, King 10 HP Air Curtain,<br />

Johnstone Power Pumps, (3) Gardner Denver / Invincible Power Vacs, Motors, Cotterman 800 Lb. & 450<br />

Lb Cap. Rolling Staircase, (Over 40) Fiberglass Ladders, Examination Tables, Etc.<br />

to schedule an auction, please call Maynards Industries at 248.569.9781 11

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX)<br />

Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • Phoenix • San Francisco • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 2655<br />

Forwarding Service Requested<br />

HILCO IndustrIaL, LLC<br />

& Maynards IndustrIes<br />

2-<strong>day</strong> <strong>WebCast</strong>/<strong>OnsIte</strong> <strong>auCtIOn</strong><br />

Formerly General motors<br />

mansField stampinG Facility<br />

Terms of Sale<br />

a 15% buyer’s premium will be charged on all assets..<br />

everything will be sold to the highest bidder for cash, in<br />

accordance with the auctioneer’s customary “terms of<br />

sale”, copies of which will be posted on the premises of<br />

the sale and subject to additional terms announced the<br />

<strong>day</strong> of sale. all items will be sold “as is, where-is” without<br />

any warranties, express or implied. although obtained<br />

from sources deemed reliable, the auctioneer makes no<br />

warranty or guarantee to the accuracy of the information<br />

herein contained. bidders are encouraged to thoroughly<br />

inspect the items on which they intend to bid prior to sale.<br />

absolutely no items will be removed until the <strong>day</strong> after the<br />

conclusion of the sale and payment is made in full.<br />

subject to additions, deletions and prior sale.<br />

Payment: all puRchases must be paid in full<br />

on the <strong>day</strong> of the auction. if you intend to pay by<br />

wire transfer, we will accept payment the <strong>day</strong> after the<br />

sale only if a deposit of 25% of total purchases is made<br />

on the <strong>day</strong> of the sale. contact our office for wire transfer<br />

instructions. only cash, wire transfer or certified check,<br />

payable to maynards industries will be accepted.<br />

company checks payable to maynards industries will be<br />

accepted only if accompanied by a bank letter of<br />

guarantee, (see sample letter below). all sales are subject<br />

to sales tax. purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the auctioneer of their<br />

entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(bank name) unconditionally guarantees payment to<br />

maynards industries from (company name). this<br />

guarantee will be valid for purchases made at the<br />

auction of Racer trust on wednes<strong>day</strong> and thurs<strong>day</strong>,<br />

october 19 & 20, 2011.<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters, 5 revere drive, ste. 206 • northbrook, IL 60062 • all rights reserved<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC Ohio auctioneer & License: tim Pfister License #2011000029 • OH License #2011000151 • IL License #444000215<br />

Maynards Industries, Inc. Ohio auctioneer & License: taso sofikitis License #2001000885 • OH License #2007000071<br />

Printed in usa • raCerMansfIeLd • Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Follow<br />

Us on: