Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

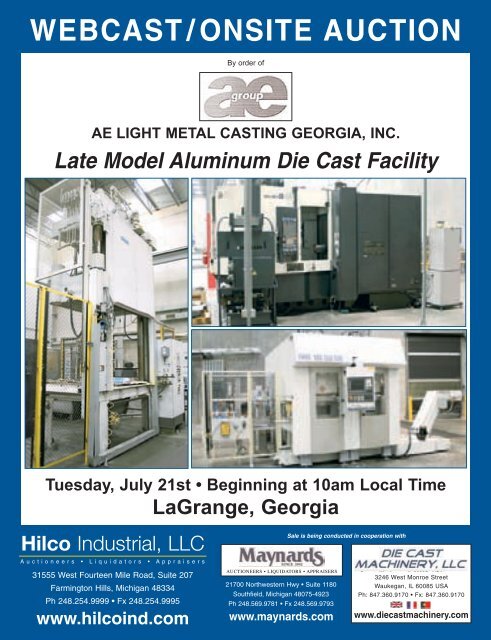

WEBCAST/ONSITE AUCTION<br />

By order of<br />

AE LIGHT METAL CASTING GEORGIA, INC.<br />

Late Model Aluminum Die Cast Facility<br />

Tuesday, July 21st • Beginning at 10am Local Time<br />

LaGrange, Georgia<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com<br />

AUCTIONEERS • LIQUIDATORS • APPRAISERS<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

Sale is being conducted in cooperation with<br />

3246 West Monroe Street<br />

Waukegan, IL 60085 USA<br />

Ph: 847.360.9170 • Fx: 847.360.9170<br />

www.diecastmachinery.com

WEBCAST/ONSITE AUCTION<br />

By order of<br />

DIE CASTING CELL EQUIPMENT<br />

- ALL DIE CAST EQUIPMENT IS 2005 OR NEWER -<br />

2005 2008<br />

AE LIGHT METAL CASTING<br />

GEORGIA, INC.<br />

TUESDAY, JULY 21 ST<br />

Beginning at 10am Local Time<br />

Preview Date<br />

Monday, July 20th<br />

9am to 4pm Local & Morning of Sale<br />

Auction Location<br />

100 Jane Fryer Road<br />

LaGrange, GA 30241<br />

Directions to Sale<br />

From Atlanta Hartsfield-Jackson International Airport:<br />

Exit airport to I-85. Take I-85 South Approximately<br />

55 Miles to Exit #18, GA Route 109. Turn Left<br />

(East) on Rte. 109, Proceed 4/10 Mile to Jim<br />

Hamilton <strong>Industrial</strong> Park. Turn Right on Callaway<br />

Church Rd., Proceed 8/10 Mile to Jane Fryer Rd.<br />

On Right (Across From WalMart Transportation<br />

Center.) Plant is Immediately on Right.<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . . . . . 800.435.9792<br />

Hotels (LaGrange):<br />

Hampton Inn . . . . . . . . . . . . . . . . 706.845.1115<br />

Best Western . . . . . . . . . . . . . . . . 706.884.6175<br />

Holiday Inn Express . . . . . . . . . . . 706.884.5830<br />

Comfort Inn & Suites . . . . . . . . . . 706.882.7700<br />

Baymont Inn & Suites . . . . . . . . . 706.885.9002<br />

Jameson Inn . . . . . . . . . . . . . . . . 706.882.8700<br />

Wingate by Wyndham . . . . . . . . . 706.298.5270<br />

Quality Inn & Suites . . . . . . . . . . . 706.882.9540<br />

Further Information<br />

• A buyer’s premium will be in effect.<br />

The auction will be conducted in English,<br />

accepting U.S. Currency only.<br />

• Removal Deadline is Friday, August 14, 2009<br />

with Hours of Removal between 8am to 4pm<br />

Monday thru Friday. After August 14th at<br />

4pm buyer will incur a cost of $500 daily<br />

for entry into the facility.<br />

• For further information please contact<br />

Mark Reynolds at 205.595.5999 or<br />

Email mreynolds@hilcoind.com<br />

• For payments please contact<br />

Tina Kulick at 248.254.9999 x35 or<br />

Email tkulick@hilcoind.com<br />

• For customer service please contact<br />

Sandi Neely at 248.254.9999 x16 or<br />

Email sneely@hilcoind.com<br />

(1 OF 2) REIS MODEL SEP-16 100 D111 140-TON<br />

HYDRAULIC TRIM PRESS<br />

2008 2006<br />

STRIKO WESTOFEN TYPE W900 SL PRO<br />

DOS DPC HOLDING FURNACE<br />

METAL MECHANICS 65-TON<br />

HYDRAULIC TRIM PRESS<br />

STRIKO WESTOFEN TYPE W 1700 S PRO<br />

DOS HOLDING FURNACE<br />

EQUIPMENT FROM BUHLER DIE CAST CELLS<br />

Peripheral Equipment from Buhler Evolution B120 DS (cell #3) including:<br />

1 – STRIKO WESTOFEN TYPE W900 SL PRO DOS DPC HOLDING FURNACE, S/N 10668 (2008), Capacity 900 Kg. 22 Kw<br />

Electric Heat, Volume Furnace Chamber 820 dm3, Max. Operating Exc. Pressure 200 Mbar, Max. Temperature Furnace<br />

Chamber 1000 Degrees C, Metal-Aluminum, Tare Weight 3200 kg, Pro Dos DPC Die Casting Precision Control/Pre<br />

Co Tech Precision Control Technology Interfaced Controls, Kunz Type HKW06.400 Hydraulic Lift & Tilt System,<br />

S/N F10668A-4070.7 (2008), Max. Payload 60 kn<br />

1 – METAL MECHANICS 65-TON HYDRAULIC TRIM PRESS, S/N 2907 (2008), 4-Post, Overall Platen Size 65"LR x 45"FB,<br />

Area Between Posts 52"LR x 32"FB, 40" Stroke, 59" Open Height, Hydraulic Die Clamping, Independent Top Platen<br />

Hydraulic Ejection, Bottom Platen Scrap Aperture, Air Lift Die Rollers, With (2) Pace Setter Systems Die Roll-Out Support<br />

Arms, 3000-Lb./Arm Capacity, (3) Independent Hydraulic Core Circuits Capacity, Auxiliary Attachment Drive Motor Controls,<br />

Siemens CPU 315-2DP PLC, With Simatic Display/Entry Screen<br />

Peripheral Equipment from Buhler Evolution B140 D (Cell #1 & Cell #2) including:<br />

2 – STRIKO WESTOFEN TYPE W 1700 S PRO DOS HOLDING FURNACES, S/N (Cell #1), 9905 (2006), (Cell #2) N/A,<br />

Capacity 1700 Kg, 36 Kw Electric Heat, Furnace Chamber Volume 1480 dm3, Max. Operating Exc. Pressure 200 Mbar,<br />

Max. Temperature 1000 Degrees C, Metal-Aluminum, Kunz Type HKW - 1000.500 Hydraulic Lift & Tilt System, 100 kn<br />

Payload, Pro Dos DPC Diecasting Precision Control/Pre Co Tech Precision Control Technology Interfaced Controls<br />

2 – ABB MODEL IRB 6400-M2004 6-AXIS CNC ROBOTS, S/Ns 66-52233 (2005) #1, 66-51992 (2005) #2, Foundry Grade<br />

Plus Protection Rating, ABB IRC5-M004 Control With Hand Pendant<br />

2 – STAINLESS STEEL DOUSE TANKS<br />

2 – REIS MODEL SEP-16 100 D111 140-TON HYDRAULIC TRIM PRESSES, S/Ns 141022 (2005), (#1), 141021 (2005), (#2),<br />

Nominal Force 1000 kn, Vertical 4/3 Column Design, Overall Platen Size 82-1/2"LR x 50"FB, Bed Area Between Posts<br />

64-1/2"LR x 33"FB, Max. Open Height 72.8" (1850mm), Stroke 55" (1400mm), Shut Height 17.8", Scrap Removal Bed<br />

Aperture, Siemens PLC - Click here for press drawings<br />

2<br />

For more information, visit us on the web @ www.hilcoind.com

DIE CAST ANCILLARY EQUIP. • CNC GEAR SHAPERS • CNC TURNING CENTER<br />

2005<br />

2008<br />

A.E.L.M (AE LIGHT METAL) TILTING ALUMINUM STACK (TOWER)<br />

TYPE MELTING FURNACE<br />

(1 OF 2) MITSUBISHI MODEL SE25A HEAVY DUTY 4-AXIS<br />

CNC GEAR SHAPING MACHINES<br />

2008<br />

2006 2005<br />

FOSECO TYPE 1-5 201-00 FDU<br />

ROTO-STATIV DEGASSING UNIT<br />

(1 OF 2) ABB MODEL IRB<br />

6400-M2004 6-AXIS CNC ROBOTS<br />

EMAG MODEL VSC 250 DUO TWIN SPINDLE<br />

CNC VERTICAL TURNING CENTER<br />

MAIN ALUMINUM MELT FURNACE SYSTEM<br />

1 – A.E.L.M (AE LIGHT METAL) TILTING ALUMINUM STACK (TOWER) TYPE MELTING FURNACE, (New 2005), Main Bath Capacity 6000<br />

kg (13,200 pounds), Melt Capacity 2500 kg/hr (5,500 pounds), Aluminum Ingot and Scrap Fed, Natural Gas Fired, Melting and Holding<br />

Sections, equipped with (3) Krome Schrader Melt Burners, Hydraulic Ingot/Scrap Dump Loading system, Tilting Furnace Type Molten Metal<br />

Discharge, Holding Section; 6000kg (13,200 pound) Capacity, Holding Section equipped with: (2) - KROME SCHRADER NATURAL GAS<br />

BURNERS, With Gas Pack Control Valve System, Nominal Temperature 1335 Degrees Fahrenheit/750 Degrees C, Hydraulic Pivot Tilt, With<br />

Power Pack Master PLC Control, Air Conditioned Enclosure Cabinet, Touch Screen, Spares Including: (2) Combustion Blowers, With Motors,<br />

Hansa Flex Hydraulic Power Pack Unit, Ceramic & Refractory Poured Transfer Pipes, High Temperature Stainless Steel Pipe Supports,<br />

Thermocouples, Approx. 30' Pivot Seal Ring Material, Refractory Material (SLN)<br />

DIE CAST ANCILLARY EQUIPMENT<br />

1 – FOSECO TYPE 1-5 201-00 FDU ROTO-STATIV DEGASSING UNIT, S/N 1173 (2006), Pressure Sensor Flow Control, Power Lift,<br />

Voltage Transformer<br />

3 – REGLOPLAS MODEL 300S OIL TEMPERATURE CONTROL UNITS, TYPE 300S/6/FM25/1K/RT50, S/Ns 121001350008 (2008), 121000710007<br />

(2006), 121000710008 (2006), 6 Litre, 572 Degrees Fahrenheit<br />

CNC GEAR SHAPING MACHINES<br />

2 – MITSUBISHI MODEL SE25A HEAVY DUTY 4-AXIS CNC GEAR SHAPING MACHINES, S/Ns SE25111C4, SE25110C4 (2008), Fanuc Series 21i-MB<br />

Controls, Max. Workpiece Diameter 9.84” External Gear/4.72” + Cutter Dia. Internal Gear, Max. Diametrical Pitch/Module 4.2DP/6M Module, Max. Work<br />

Width 2.36”, Max. Helix Angle ± 40 Degrees, Max. Cutter Stroke 2.75”, Cutter Strokes 300-1800 Str/Min. Steplessly Variable, Number of Cuts 1-4, Center<br />

Distance From Cutter to Work 10.6” Max. to -2.36” Min., Max. Radial Travel 13.0”, Height Work Table to Cutter Spindle 15.55” Max. to 12.2” Min., Axial<br />

Travel 3.3”, Table Diameter 13.0”, Cutter Spindle OD 3.54”, Cutter Spindle ID 1.97”, 10-HP Main Spindle Motor, Water Soluble Coolant Defense Protection<br />

System, Robot Access Door, Livonia Magnetics Drag Type Chip Conveyor, Enclosure, Showa Oil Mist Collector, Hours as of 6/4/2009, S/N SE25110C4,<br />

Power On Time – 192Hrs. 23Min., Operation Time – 8Hrs. 23Min., Cutting Time – 17Hrs. 11Min., S/N SE25111C4, Power On Time – 192Hrs. 31Min.,<br />

Operation Time 8Hrs. 23Min., Cutting Time – 17Hrs. 11Min.<br />

TWIN SPINDLE CNC VERTICAL TURNING CENTER<br />

1 – EMAG MODEL VSC 250 DUO TWIN SPINDLE CNC VERTICAL TURNING CENTER, S/N 101620 (2008), Siemens 840D CNC Control, Right &<br />

Left Vertical Spindles, With X & Z Axis Control, Left Spindle, With 12-Position Driven Disc Type Turret, Each Position Driven, 40mm Toolholder Size,<br />

Right Spindle, With 12-Position 40mm Disc Type Turret, Max. Speed 6000 RPM, Full Power at 3000 RPM, Pallet Type Thru-Feed Shuttle Conveyor,<br />

Turmoil Model OC-300-DI-MOD High Volume Coolant System, With Chiller, Pumps, Tank, Jorgensen Drag-Out Conveyor, Sermeto Chip Conveyor,<br />

Interlocked Enclosure Doors, Hour Reading NA, Estimated Hours as of 6/4/2009, Approx. 900Hrs. Power On, Approx. 200Hrs. Operation Time<br />

TO 2008<br />

REGLOPLAS MODEL 300S OIL<br />

TEMPERATURE CONTROL UNITS<br />

Bid Live In Person or By<br />

Phone Via the Web at<br />

www.hilcoind.com<br />

To schedule an auction, please contact us at 248.254.9999 3

AXLE HOUSING AUTOMATED MACHINING CELL (NEW 2005)<br />

2005 2004<br />

2005<br />

ROSLER TYPE RHBE – 9/13 HANG-BLAST SHOT BLAST<br />

CLEANING MACHINE<br />

BROTHER MODEL TC-22A CNC VERTICAL<br />

DRILLING/TAPPING CENTER<br />

2005<br />

BROTHER MODEL TC-22A-O<br />

CNC VERTICAL DRILLING/<br />

TAPPING CENTER<br />

2005<br />

MAKINO A51 HIGH SPEED<br />

PALLET TYPE CNC HORIZONTAL<br />

MACHINING CENTER<br />

DURR TYPE ECOCLEAN 22W-BF CONVEYORIZED<br />

THRU-FEED WASHER<br />

1 – AXLE HOUSING AUTOMATED MACHINING CELL, (NEW 2005)<br />

• OP. 10; MANUAL LINE LOAD<br />

• OP. 20; PART ORIENTATION<br />

• OP. 30 SHOT BLAST, ROSLER TYPE RHBE – 9/13 HANG-BLAST SHOT BLAST CLEANING<br />

MACHINE, S/N 35839/05 (2005), Siemens PLC, With Simatic Panel, 50” x 46” x 72” High Chamber,<br />

Spinner Type Parts Hanger, Pneumatic Swing Chamber Doors, (2) 12.0 Kw Shot Wheels, Shot<br />

Reclaim System, Dust Collection, With Type RF-350-NS Filter Type Dust Collector, Collection<br />

Hopper, With Drag-Out Conveyor<br />

• OP. 40 OIL HOLE DRILLING, BROTHER MODEL TC-22A CNC VERTICAL DRILLING/TAPPING<br />

CENTER, S/N 112482 (2004), Table Size 25.59” x 15.74”, Travels: 19.68” X, 15.74” Y, 16.14” Z, Max.<br />

Table Load 441-Lbs., Distance Table Top to Spindle Nose 7.87” – 24.01”, Distance Column Front to<br />

Spindle Axis 11.57”, High Speed Spindle Speeds to 16,000 RPM, HSK-A40 Spindle Taper,<br />

26-Position Automatic Toolchanger, 10 KW Spindle Motor, High Pressure Thru-The-Spindle & Flood<br />

Coolant, With Turbo Model 65868144E Coolant Reservoir/Recirculation Unit, (2) Micron Cartridge<br />

Filters, High Pressure Coolant Control Box, Chip Conveyor, Enclosures, El Baron Electrostatic Air<br />

Cleaner, Brother CNC Control, Hours as of 6/4/2009 – 21413Hrs. 14 Min. Power On, 7506Hrs.<br />

53 Min. Operation Time, 7506Hrs. 53 Min. Run Time<br />

• OP. 30/40, ABB MODEL IRB6600-M2004 ABB MODEL IRB6600-M2004 6-AXIS CNC ROBOT,<br />

S/N 66-51582 (2005), Foundry Grade Protection, ABB Type IRC5-M2004 Control, With Hand Pendant<br />

• OP. 30/40, HARMUT MEYER CABINET TYPE SPRAY WASHER, S/N 05-101/1, Stainless Steel,<br />

Automatic Enclosure Door, Air Blow-Off<br />

• OP. 30/40, INTERFACED SECURITY FENCING<br />

• (2) OP. #s 50/1 & 50/2, PRE MACHINING #1 & #2 BROTHER MODEL TC-22A-O CNC VERTICAL<br />

DRILLING/TAPPING CENTERS, S/Ns 112695 (2005), 112574 (2005), Table Size 33.46” x 15.74”,<br />

Travels: 27.55” X, 15.74” Y, 16.14” Z, Max. Table Load 441-Lbs., Distance Table Top to Spindle Nose<br />

7.87” – 24.01”, Distance Column Front to Spindle Axis 11.57”, High Speed Spindle Speeds to 16,000<br />

RPM, HSK-A40 Spindle Taper, 26-Position Automatic Toolchanger, 10 Kw Spindle Motor, High<br />

Pressure Thru-The-Spindle & Flood Coolant, With Turbo Model 65868144E Coolant<br />

Reservoir/Recirculation Unit, (2) Micron Cartridge Filters, High Pressure Coolant Control Box, Chip<br />

Conveyor, Enclosures, El Baron Electrostatic Air Cleaner, Brother CNC Control, Hours as of<br />

6/4/2009, Power On – 21441Hrs. 12Min. #50/1/21288Hrs. 34Min. #50-2, Operation Time – 9140Hrs<br />

19Min. #50-1/8507Hrs. 33Min. #50-2, Run Time – 9140Hrs. 20Min. #50-1/8507Hrs. 33Min. #50-2<br />

• OP. 50, ABB MODEL IRB6600-M2004 6-AXIS CNC ROBOT, S/N 66-51581 (2005), Foundry Grade<br />

Protection, ABB Type IRC5-M2004 Control, With Hand Pendant<br />

• OP. 50, HARMUT MEYER STAINLESS STEEL CABINET TYPE SPRAY WASHER, S/N 05-101/2,<br />

Automatic Enclosure Door, Air Blow-Off<br />

• OP. 50, INTERFACED SECURITY FENCING<br />

2005<br />

AXLE HOUSING AUTOMATED MACHINING CELL, (NEW 2005)<br />

Note: Cell May Be Offered In Bulk Subject To Piecemeal Bids)<br />

ABB MODEL IRB4400/60 TYPE B<br />

6-AXIS CNC ROBOTS<br />

• (2) OP. #s 60/1 & 60/2 FINISH MACHINING #1 & #2, MAKINO MODEL A51 HIGH SPEED PALLET<br />

TYPE CNC HORIZONTAL MACHINING CENTERS, S/Ns 762 & 761 (2005), (2) 15.74” x 15.74”<br />

Pallets (400mm x 400mm), Travels: 22.04” X, 22.04” Y, 23.62” Z, 360 Degrees Pallet Indexing in 1<br />

Degree Increments, Pallet load Capacity 400 kg., Spindle Speeds to 15,000 RPM, HSK-A63 Spindle<br />

Taper, 60-Position Automatic Toolchanger Magazine, Chip-Blaster Model JV8 High Pressure/High<br />

Volume Thru-The-Spindle Coolant System, 1000 PSI, With Cartridge Filters, (2) Micron Technologies<br />

Cartridge Filters, MOSNIC Type, RD3C-116A-ZMOS92 Coolant Flume/Chip Conveyor, Chip Blaster<br />

Model Mist Blaster Oil Mist Collector, IDF6E Refrigerated Air Dryer, Makino Professional 5 4-Axis<br />

CNC Controls, Interlocked Enclosure Doors, Hours as of 6/4/2009, Power On, 18715Hrs. 32Min.<br />

#60-1/17919Hrs. 48Min. #60-2, Operation, 15234Hrs. 25 Min #60-1/14764Hrs. 47MIn. #60-2, Cut<br />

Time, 8533Hrs. 57Min. #60-1/8242Hrs. 24MIn. #60-2<br />

• (2) OP. #s 60/1 & 60/2, ABB MODEL IRB4400/60 TYPE B 6-AXIS CNC ROBOTS, S/Ns 44-50195,<br />

44-50191 (2005), Foundry Grade Protection, Type IRC5-M2004 Control, With Hand Pendant<br />

• (2) OP. #s 60/1 & 60/2, HARMUT MEYER STAINLESS STEEL CABINET TYPE SPRAY<br />

WASHERS, S/Ns 05-101/4, 05-101/3, Automatic Enclosure Door, Air Blow-Off<br />

• (2) OP. #s 60/1 & 60/2 , INTERFACED SECURITY FENCING<br />

• OP. 70/1, PART WASHER, DURR TYPE ECOCLEAN 22W-BF CONVEYORIZED THRU-FEED<br />

WASHER, S/N 55762 (2005), Job Ref. No. K135-171-122, Multi-Stage, Stainless Steel, Part<br />

Dimension 29.5” x 12.9” x 13.5” Including Pallet, Throughput Capacity 46 Pallets/Hour, Cycle Time<br />

78 Seconds, Electric Heated Wash/Rinse Tanks, 2000 Liter Wash/Rinse Tanks at 60 Degrees C, Air<br />

Blow-Off, Cartridge Filters, Overall Dimensions 32’L x 7-1/2’W x 8-1/2’H, Siemens PLC<br />

• OP. 70/2, PART CONDITIONER, DURR CONVEYORIZED THRU-FEED PART CONDITIONER, S/N NA,<br />

Air Conditioned Forced Cooling Air, 12’ Length<br />

• OP. 80, LEAK TEST, WENO MODEL AO192/01 LEAK TEST UNIT, S/N 242285, Siemens Simatic<br />

PLC, Computer Control Console, 2-Station, (2) Furness Controls Model FC0750 Computerized Leak<br />

Detector Controls<br />

• OP. 85/OP. 90, CHECK/MEASUREMENT, HAFNER DATA MATRIX CHECK/MEASUREMENT<br />

INSTRUMENT, S/N 3331613 (2005)<br />

• OP. 100, PART MARKING, PART DATA MATRIX MARKING 2 HEAD PART MARKING MACHINE<br />

• OP. 80/100, ABB MODEL IRB6600-M2004 6-AXIS CNC ROBOT, S/N 66-51160 (2005), Standard<br />

Protection, Type IRC5-2004 Controls, With Hand Pendant<br />

• OP. 80/100, INTERFACED SECURITY FENCING<br />

• (2) OP. 110 & OP. 120, SPC STATION & VISUAL INSPECTION/PACKAGING<br />

Lot of Ewab Engineering Model ES4-18500 Automated Pallet Carrier Conveyor, Main Computer Control<br />

Cabinet, 13” x 27-1/2” Aluminum Frame Carrier Pallets<br />

Lot of Overhead Electrical Wire, With Aluminum Raceway Trays<br />

4 For more information, visit us on the web @ www.hilcoind.com

CNC MACHINING CENTER • X-RAY • CMMs • INSPECTION/LAB<br />

2005<br />

MAKINO MODEL A61 HIGH SPEED PALLET<br />

TYPE CNC HORIZONTAL MACHINING CENTER<br />

2008<br />

2005 2008<br />

WHEELABRATOR SMARTLINE SLH<br />

2460 SPINNER HANGER SHOT<br />

BLAST CLEANING MACHINE<br />

2005<br />

YXLON INTERNATIONAL MODEL MU-2000<br />

RADIOSCOPIC X-RAY INSPECTION MACHINE<br />

2006<br />

KELCH TYPE KALIMAT<br />

A-38-3/C COMPUTER TOOL<br />

PRE-SETTER<br />

SHEFFIELD CORDAX DISCOVERY<br />

III SERIES D-12 COORDINATE<br />

MEASURING MACHINE<br />

HIGH SPEED CNC HORIZONTAL<br />

MACHINING CENTER<br />

See Also Axle Housing Automated Machining Cell<br />

1 – MAKINO MODEL A61 HIGH SPEED PALLET TYPE CNC<br />

HORIZONTAL MACHINING CENTER, S/N 236 (2005),<br />

(2) 19.68” x 19.68” Pallets (500mm x 500mm), Travels 28.74” X,<br />

25.59” Y, 28.74” Z, 360 Degrees Pallet Indexing in 1 Degree<br />

Increments, Pallet Load Capacity 500 Kg, Spindle Speeds to 20,000<br />

RPM, HSK-A63 Spindle Taper, 60-Position Automatic Toolchanger<br />

Magazine, High-Pressure Thru-The-Spindle Coolant, MOSNIC Type<br />

RD30-116A-ZM0S92 Coolant Flume/Chip Conveyor, S/N 060847-3,<br />

Oil Cooler, IDF6E Refrigerated Compressed Air Dryer, Kason MK8<br />

Oil Mist Collector, Professional 5 4-Axis CNC Controls, Interlocked<br />

Enclosure Doors, Hours as of 6/4/2009, Power On Time, 3169Hrs.<br />

39Min., Operation Time, 403Hrs. 43Min., Cutting Time, 16Hrs.<br />

31Min.<br />

SHOT BLAST CLEANING MACHINE<br />

See Also Axle Housing Automated Machining Cell<br />

1 – WHEELABRATOR SMARTLINE MODEL SLH 2460 SPINNER<br />

HANGER SHOT BLAST CLEANING MACHINE, S/N 3629 (2008),<br />

24” x 60” Dual Blast Chamber, Each Chamber, With<br />

(1) 1500-Lb. Capacity Spindle Hook, (2) 10-HP Direct Drive Blast<br />

Wheels, Abrasive Reclaim System, With Rotary Screen & Air Wash<br />

Separator, Elevator, Storage Hopper, Dust Collection System, With<br />

Model JPSM-2D6 Dust Collector, Pneumatic Pulse Jet Cleaning,<br />

Rotary Airlock Discharge<br />

X-RAY INSPECTION MACHINE<br />

1 – YXLON INTERNATIONAL MODEL MU-2000 RADIOSCOPIC<br />

X-RAY INSPECTION MACHINE, S/N P.0020002708 (2005), Max.<br />

KV 160/4 MA, Lead Equivalence (mm Pb), Front – 4, Rear – 4, Right<br />

Side – 4, Left Side – 6, Top – 4, Bottom – 4, Yxlon<br />

X-Ray Display 1712 Computer Control Console, With XRS<br />

Controller, Operator Central Panel, MGC41 Control<br />

TOOL SETTING MACHINES<br />

1 – KELCH TYPE KALIMAT A-38-3/C COMPUTER<br />

CONTROLLED TOOL PRE-SETTER, S/N 5443 (2006)<br />

1 – MARQUART SPANNTECHNIK TYPE 047.032.00.0.00 HSK<br />

TAPER TOOLHOLDER HEAT SHRINK ELECTRIC HEATER,<br />

S/N 32132-M345, Pyroquart Digital Controls<br />

ZEISS MODEL PRISMO 9/18/7-HTG<br />

BRIDGE TYPE CNC COORDINATE<br />

MEASURING MACHINE<br />

MITUTOYO CONTRACER CV-3100<br />

COMPUTER CONTROLLED<br />

CONTOUR MEASURING SYSTEM<br />

2008<br />

ATLAS COPCO MODEL GA160 223 HP (166KW)<br />

ROTARY SCREW AIR COMPRESSOR<br />

COORDINATE MEASURING MACHINES<br />

1 – SHEFFIELD CORDAX DISCOVERY III SERIES MODEL D-12 COORDINATE MEASURING MACHINE, S/N 3036-1108 (2008 –<br />

BRAND NEW, NEVER INSTALLED – STILL IN ORIGINAL SHIPPING CRATE) Renishaw TP200 Probe & PH10T Probe Head,<br />

Renishaw SCR200 6-Station Linear Probe Changing Docking Station, Renishaw PI200 Probe Interface & PHC 10-2 Probe Head<br />

Controller, PC Control, With Remote Hand Control Unit, Temperature Compensation, PC DMIS Pro Software<br />

1 – SHEFFIELD CORDAX DISCOVERY III SERIES MODEL D-12 COORDINATE MEASURING MACHINE, S/N S-3022-0708 (2007),<br />

22” x 38” Granite Surface Plate, Renishaw TP200 Probe & PH10T Probe Head, Renishaw SCR200 6-Station Linear Probe Changing<br />

Docking Station, Renishaw PI200 Probe Interface & PHC10-2 Probe Head Controller, PC Control, With Remote Hand Control Unit,<br />

Temperature Compensation, PC DMIS Software<br />

1 – ZEISS MODEL PRISMO 9/18/7-HTG BRIDGE TYPE CNC COORDINATE MEASURING MACHINE, S/N 115283 (2005), Granite<br />

Table Size 40” x 83-1/2”, Measuring Range 35.4” X, 70.8” Y, 27.5” Z, 10-Station Linear Probe-Changing Docking Station, (9) Zeiss<br />

Touch Probes, PC System, With Remote Hand Control, Calypso Software<br />

INSPECTION/QUALITY LAB EQUIPMENT<br />

1 – SPECTRO MODEL MAX x – LMM14 STATIONARY METAL ANALYZER, S/N 4R0182, Part No. 7600 4134, Floor Model, With PC Unit<br />

1 – IDECO TYPE VM613ST/VT 161SO VAC-TEST VACUUM TESTING SYSTEM, S/N 76.034/76,025 (2006), With Scale<br />

1 – MITUTOYO MODEL CONTRACER CV-3100 COMPUTER CONTROLLED CONTOUR MEASURING SYSTEM, Code No. 218-<br />

433A, S/N 500101, Model C-3000 Stylus Head, Mitutoyo CPU, With Remote Box Hand Pendant Controller, Dell Optiplex GX620<br />

Operating PC, Mounted on Mitutoyo 17-1/2” x 38-1/2” Black Granite Surface Plate<br />

1 – MITUTOYO MODEL SJ-400 SURFACE ROUGHNESS TESTER, S/N NA, Stylus Type, 75mm Height, Programming Pad, With<br />

Printer, Mounted on Mitutoyo 36” x 48” Black Granite Surface Plate<br />

1 – LECO SPECTRUM SYSTEM 1000 2-STATION LAB SAMPLE POLISHER, S/N 3412, Model 825-300-100<br />

1 – HEMCO VENTLESS LABORATORY EXHAUST HOOD, S/N 18922, Size 36”H x 30”W x 22”D Color 496/496 Enclosure, With Cabinet Base<br />

1 – TRU STONE 36” X 48” X 6” GRANITE SURFACE PLATE, WITH STAND, S/N 26404, Grade A<br />

1 – PRECISION 24” X 36” 2-LEDGE GRANITE SURFACE PLATE, With Stand<br />

Inspection Equipment Including: Olympus Stereo Microscope With Digital Camera, Metal Power Vacuum Pump, Bore Gauges,<br />

Micrometers & Calipers, Surface Checking Gauges, etc.<br />

AIR COMPRESSORS AND DRYERS<br />

1 – ATLAS COPCO MODEL GA160 223 HP (166KW) ROTARY SCREW AIR COMPRESSOR, S/N APF-134591 (2008), 129 PSIG,<br />

Air Cooled, Elektronikon Microprocessor Controls, Sound Enclosure Panels Meter Readings as of 05/21/09 Disconnect: Running<br />

Hours 845, Loaded Hours 329, Motor Starts 2,078, Module Hours 2,557, Load Relay 28,483<br />

1 – INGERSOLL-RAND MODEL IRN100H-CC 100-HP ROTARY SCREW AIR COMPRESSOR, S/N NV7362UO6129 (2006), 145 PSIG<br />

Air Cooled, Sound Enclosure Panels, Intellysis Microprocessor Controls On-Demand Variable Drive<br />

1 – INGERSOLL-RAND MODEL SSR-EP60 60-HP ROTARY SCREW AIR COMPRESSOR, S/N CA2854U06040 (2006), 246 CFM,<br />

125 PSIG, Air Cooled, Sound Enclosure Panels, Intellysis Microprocessor Controls<br />

1 – INGERSOLL-RAND MODEL TMS-0540 REFRIGERATED COMPRESSED AIR DRYER, S/N TMS-0540-0603/8284 (2006),<br />

1 – INGERSOLL-RAND MODEL TS2A REFRIGERATED COMPRESSED AIR DRYER, S/N DN00000110-020606 (2006)<br />

1 – VERTICAL COMPRESSED AIR RECEIVER TANK, (NEW 2006), 48” Diameter x 11’ High, MAWP 155 PSI at 400 Degrees<br />

Fahrenheit<br />

To schedule an auction, please contact us at 248.254.9999 5

WATER TREATMENT & COOLING SYSTEMS • CRANES • FORKLIFTS<br />

WASTE WATER TREATMENT SYSTEM DELTA COOLING TOWERS 105312<br />

WATER COOLING TOWER<br />

2006<br />

2007<br />

RECIRCULATION SYSTEM<br />

SQUARE D SERVICE<br />

DISCONNECT PANEL CAT<br />

NO. 12260132850050001<br />

DESHAZO TYPE TR-DG-BM 32 METRIC TON TOP RIDING<br />

DOUBLE GIRDER BRIDGE CRANES<br />

2006<br />

DESHAZO MODEL TYPE TR-SG-BM 12 METRIC TON<br />

TOP RIDING SINGLE GIRDER BRIDGE CRANE<br />

WASTE WATER<br />

TREATMENT SYSTEM<br />

Note: System May Be Offered in Bulk Subject to Piecemeal Bids<br />

1 – WASTE WATER TREATMENT SYSTEM, Including:<br />

• Foundry Floor Supply/Transfer Pumps<br />

• LK ABWASSERTECHNIK (1) Primary Stainless Steel<br />

Separation/Settling Tank, Gravity Overflow Discharge,<br />

V-Hopper Bottom for Solids Removal<br />

• LK ABWASSERTECHNIK (1) Secondary Stainless Steel<br />

Separation Tank, Gravity Overflow Discharge<br />

• (1) Bulk Holding Tank, 30,000 Liter Capacity, Carbon Steel,<br />

8’ X 20’<br />

• KMU MODEL PROWADEST 1000 (1) INDUSTRIAL WASTE<br />

WATER EVAPORATOR, S/N 05-0707-10001-91 (2005),<br />

Distillation Throughput 1000 Liters/Hour, 90 Degrees Celsius<br />

Evaporating Temperature, Evaporation Pressure 700 mbar, 75<br />

KW Motor, Power Required 48KW, Installed Power 113 KW,<br />

Power Required for Starting Heater 4 x 6 KW, Siemens PLC<br />

Control Panel<br />

• (1) Water Condensate Collection Tank<br />

• 7000 Liter Separated Oils Holding Tank, Carbon Steel<br />

• KMU (2) Acid Base KMU Cleaner Tanks, 3 1/2’ Diam. X 5’<br />

Vertical Size<br />

PROCESS WATER<br />

COOLING SYSTEM<br />

1 – DELTA COOLING TOWERS 105312 WATER COOLING<br />

TOWER, S/N 68145 (2007), 560 GPM, 5-HP, Type TEAO,<br />

1 1/16 Nozzle, Plastic Construction, Outdoor Stand Mounted<br />

1 – RECIRCULATION SYSTEM With, (2) 30 KW Recirculation<br />

Pumps, (2) Approx. 10-HP Recirculation Pumps, (4) Dan Foss<br />

VLT 5000 Microprocessor Variable Pump Drive Controls,<br />

(1) Boll and Kirch Type 6.18 DN 150 Filter, S/N 3840904/1 85<br />

Liter, (1) Nako 3D Trasor Programmable PH Monitor,<br />

(1) Central Air Conditioned Control Enclosure, Piping, Valves<br />

VIEW OF CATERPILLAR FORKLIFTS<br />

TO 8,000-LB. CAPACITY<br />

SIEMENS SERVICE DISCONNECT<br />

CAT. NO. SB2 REV. A, S.O.<br />

3001767526-000100-01<br />

ELECTRICAL DISTRIBUTION EQUIPMENT<br />

1 – SIEMENS SERVICE DISCONNECT CAT. NO. SB2 REV. A, S.O. 3001767526-000100-01, Location MYO System 480Y/277V 60HZ 3O 4W,<br />

Enclosure Type 1, Supply/Section 3000A, Mfg. Date 10/2008, Siemens WLL 2F 330 Integrated Cubicle Bus 3000 AMP Main Disconnect<br />

1 – SIEMENS SERVICE DISCONNECT CAT. NO. SB2-REV-A S.O. 3001767526-000100-02, Location MYO, System 480Y/277V 60HZ 3O<br />

4W, Enclosure Type 1, Supply Section 3000A, Mfg. Date 10/2008, With (4) 1200-AMP Breakers, (1) 600-AMP Breaker<br />

1 – SQUARE D SERVICE DISCONNECT PANEL CAT NO. 12260132850050001, S/N 08541, Ser. E1, Max. Amp 1200, Max Volts 480Y/277 VAC,<br />

3-Phase, 4-Wiere, Type 1 enclosure, With (2) 1200-AMP, (3) 175-AMP, (3) 100-AMP, (5) 80-AMP, (1) 60-AMP, (3) 30-AMP Disconnect Breakers<br />

1 – SQUARE D SORGEL 75 KVA THREE PHASE GENERAL PURPOSE TRANSFORMER, Cat. NO. EE75T3H, 75 KVA, H.V. :480, H.V.<br />

Amps: 90, HZ 60, Percent I.Z. 3.5, L.V. 208Y/120, L.V. Amps 208, Wt: 547, Class AA, Style No. 35349-17212-132, Date Code 0841,<br />

Enclosure Type 2<br />

Interconnecting Copper Wire<br />

Aluminum Electrical Cable Raceway Trays<br />

Transformers, Disconnect Boxes, Wire Electrical Hardware, Etc.<br />

BRIDGE CRANES<br />

2 – DESHAZO TYPE TR-DG-BM 32 METRIC TON TOP RIDING DOUBLE GIRDER BRIDGE CRANES, S/Ns 24019-1, 24019-2<br />

(New 2006), 35/17.5 Ton US Rating, 54’ 6 3/4” Span, Main/Auxiliary Hoist Ratings: 32-Ton Metric/35-Ton US Main, 16-Ton Metric/17.5<br />

Ton US Auxiliary, Main Hoist: Robbins and Myers SpaceMaster SX Model SX60810400P864GGDOF, 37.7’ Lifting Height, 2-Speed,<br />

Hoisting Speed 12.5/2.1 FPM, Duty Class M4, Trolley Speed 65.0/16.0 FPM, Auxiliary Hoist: Robbins and Myers Space Master SX Model<br />

SX606110250P65FFDOF, Duty Class M5, Lifting Height 39.3’, 2-Speed, Hoisting Speed 12.5/2.1 FPM, Trolley Speed 65.0/16.0 FPM,<br />

Independent Main/Auxiliary Trolleys, Variable Frequency AC Trolley and Bridge Drives, Independent or Simultaneous Main and Auxiliary<br />

Hoist and Trolley Action, Built-In Scale System With Digital Load Readout Display, Remote Radio Controlled<br />

2 – SETS OF 200’ CRANE RUNWAY WITH I-BEAM, Track Rail, AC Power Hot Rail, Each Set Supports (1) 32 Metric Ton Bridge Crane<br />

1 – DESHAZO MODEL TYPE TR-SG-BM 12 METRIC TON TOP RIDING SINGLE GIRDER BRIDGE CRANE, S/N 24020, (New 2006), 13.2<br />

US Ton Main Hoist/6.6 US Ton Auxiliary Hoist, 36’ 6 3/8” Span, Stahl Model SH5032-164/1L3 Main Hoist, S/N 3207556, Stahl Model<br />

SH3207556, Stahl Model SH4016-164/1L3 Auxiliary Hoist, S/N 2110598, Main/Auxiliary Hoist Ratings: 2-Speed, Lifting Speed 15.7/2.6<br />

FPM, Lifting Height 33’, Trolley Speed 82/20 FPM Independent Main/Auxiliary Trolleys Independent or Simultaneous Main and Auxiliary<br />

Hoist and Trolley Action, Variable Frequency AC Trolley and Bridge Drives, Built-In Scale System With Digital Load Readout Display,<br />

Remote Radio Controlled, With Approx. 40’ Free Standing Support Structure, Rails, (6) Column Supports<br />

FORKLIFTS<br />

1 – CATERPILLAR MODEL GC 40K-STR 8,000-LB. CAPACITY FORKLIFT, S/N AT8700353, LPG Solid Non-Mar Tires 209” Lift, 3-Stage<br />

Mast, Cascade 360 Degrees Hydraulic Rotator Attachment With Side Shift, 48” Forks<br />

1 – CATERPILLAR MODEL GC 40K 6,000-LB. CAPACITY FORKLIFT, S/N AT87AO1972, LPG, Solid Tires, 218” Lift, 3-Stage Mast ROPS<br />

With Raingard Front and Top Rain Shields, Windshield Wiper, With Long Reach Model CRB6548FD54-8C05B90 6500 Lb. Capacity 360<br />

Degrees Rotator Attachment With Side Shift, S/N LR3019 48” Forks<br />

1 – CATERPILLAR MODEL CG25K 5,000-LB. CAPACITY FORKLIFT, S/N AT82C06523, LPG Solid Tires, 188” Lift, 3-Stage Mast, Side<br />

Shift, 42” Forks<br />

1 – CATERPILLAR MODEL M50D 5,000-LB. CAPACITY SIT-DOWN RIDER ELECTRIC FORKLIFT, S/N 6GC02695, 173” Lift 3-Stage Mast<br />

Side-Shift 42” Forks 36/48 Volt<br />

1 – GNB MODEL FER100 18-600 TI 36 VOLT 105 AMP INDUSTRIAL FORKLIFT BATTERY CHARGER, S/N 97F0044F<br />

6 For more information, visit us on the web @ www.hilcoind.com

CONVEYORS • MISCELLANEOUS MACHINERY • SHOP & FACTORY<br />

2005<br />

DAKE JOHNSON MODEL V-29<br />

24” VERTICAL BAND SAW<br />

VECTRAX MODEL GS16V<br />

3-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE<br />

MSC SERIES 9868 12/18” X 36” GAP BED<br />

ENGINE LATHE<br />

CFM MODEL 01L 220C PORTABLE<br />

OIL MIST VACUUM UNITS<br />

DAYTON MODEL 4YG31 9” X 16” CAPACITY<br />

HORIZONTAL METAL CUTTING BANDSAW<br />

(1 OF 2) TITAN 24” X 17’ PORTABLE HINGED METAL BELT<br />

SCRAP CONVEYORS<br />

MILLER SYNCROWAVE<br />

MODEL 350 LX TIG WELDER<br />

MATERIAL HANDLING<br />

24 – FABRICATED STEEL 30” X 38” X 28” HIGH CASTER<br />

MOUNTED CHIP CARTS<br />

1 – FABRICATED 4-WHEEL MOLD/DIE TRANSFER CART,<br />

Solid Tires, 4’ x 8’ Deck Size<br />

16 – GALBREATH SELF-DUMPING HOPPERS:<br />

• Model H-400 4 Cu. Yd. 4000 Lb. Capacity (2006)<br />

• Model LH-200 2 Cu. Yd. 2000 Lb. Capacity, (2006)<br />

• (2) Model LH-200 2 Cu. Yd. 2000 Lb. Capacity on Casters, (2006)<br />

• (12) Model H-100 1 Cu. Yd. 6000 Lb. Capacity (2008 & 2006)<br />

1 – STAR 4000 LB. CAPACITY TELESCOPIC BOOM FORKLIFT<br />

JIB BOOM ATTACHMENT<br />

1 – VESTIL MODEL WP 3648 CA FORKLIFT TYPE AERIAL<br />

WORK PLATFORM, 1000 Lb. Capacity, 36” x 48”<br />

1 – MANUAL TILTING FORKLIFT 55 GALLON DRUM<br />

ATTACHMENT<br />

1 – 1500 LB. CAPACITY 55 GALLON DRUM GRAB FORK LIFT<br />

ATTACHMENT<br />

8 – ZENITH 2200 LB. CAPACITY SCISSOR LIFT HYDRAULIC<br />

PALLET JACKS 32” LIFT HEIGHT, S/Ns 30396, 30395,<br />

38058, 30594, 30859, N/A, 30593<br />

2 – DAYTON NO. 4Y X 97 5500 LB. CAPACITY HYDRAULIC<br />

PALLET JACKS<br />

1 – HU-LIFT 5000 LB. CAPACITY HYDRAULIC PALLET JACK<br />

12 – ULTRA TECH ULTRA SPILL PALLET P-4 SECONDARY<br />

CONTAINMENT PALLETS, 48” x 48” Working Pallet Size,<br />

53” x 53” Overall Size, 6000 Lb. Capacity, 4-Way Pallet<br />

(OVER) 250 – 48” x 33” x 34” High Rigid Frame Stackable Steel<br />

Wire Baskets With 1/2 Drop Front<br />

CONVEYORS<br />

2 – TITAN 24” X 17’ PORTABLE HINGED METAL BELT SCRAP<br />

CONVEYORS, S/Ns 200636, 200637 9’ Horizontal Load and<br />

8’ Inclined Discharge, 52” Discharge Height<br />

1 – ENDURA-VEYOR 24” X 18’ PORTABLE HINGED METAL BELT<br />

SCRAP CONVEYOR, S/N N/A 69853-A (2008), 8’ Horizontal<br />

Load and 10’ Inclined Discharge, 54” Discharge Height<br />

2 – TITAN INDUSTRIES 42” WIDE X 12’ LENGTH PORTABLE<br />

HORIZONTAL FLAT BELT CONVEYORS, S/Ns 200639, 200638<br />

MISCELLANEOUS MACHINERY<br />

2 – CFM MODEL 01L 220C PORTABLE OIL MIST VACUUM<br />

UNITS, S/N 04AF685 (2005), 04AF684 (2005)<br />

1 – NABERTHERM MODEL N250/65HA SINGLE DOOR<br />

ELECTRIC OVEN, S/N 186739 (2006), Maximum<br />

Temperature 650 Degrees Celsius, ID Size 25” x 25” x 36”<br />

Deep, Model C-290 Digital Controls<br />

1 – BLUE WAVE ULTRASONICS ULTRASONIC PARTS<br />

CLEANING TANK, MODEL & S/N N/A, Stainless Steel Tank<br />

Size 56” x 28” x 36” High, Electric Heat<br />

1 – MSC SERIES 9868 12/18” X 36” GAP BED ENGINE LATHE,<br />

S/N 09517350, (8) Spindle Speeds 260-2000 RPM, Quick<br />

Change Threading, 1 3/8” Hold Through Spindle Acu-Rite<br />

Readout, 3 & 4 Jaw Chucks, Steady Rest<br />

1 – VECTRAX MODEL GS16V 3-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE, S/N 933136, Table Size 9” x<br />

49”, Workhorse AL-400S Variable Power Table Feed, Spindle<br />

Speeds 70-4200 RPM, Acu-Rite 3 Axis Readout<br />

1 – RF MODEL 00685412 / 31 BENCH TOP MILLING AND<br />

DRILLING MACHINE, S/N 530394 (2005), Table Size 8 1/4” x<br />

28 3/4” Spindle Speeds 1150-2500 RPM With Cabinet Base<br />

1 – DAKE JOHNSON MODEL V-29 24” VERTICAL BAND SAW,<br />

S/N 66248, Variable Blade Speed With Digital Readout, Ideal<br />

Blade Welder/Grinder<br />

1 – DAYTON MODEL 4YG31 9” X 16” CAPACITY HORIZONTAL<br />

METAL CUTTING BANDSAW, S/N 3205, Coolant<br />

1 – MILLER SYNCROWAVE MODEL 350 LX TIG WELDER,<br />

S/N LG460089L (2006), Built-In Water Cooler, Integral<br />

Manufacturers Cart, Tig Welding Leads<br />

1 – JET MODEL JDP-20MF 20” STEP PULLEY FLOOR TYPE<br />

DRILL PRESS, S/N 5070214<br />

1 – RYOBI 8” DOUBLE-END BENCH GRINDER, S/N N/A<br />

1 – SUNEX 8” DOUBLE-END GRINDER<br />

1 – GATES MODEL POWER CRIMP 707 HYDRAULIC HOSE<br />

FITTING CRIMPING PRESS, S/N N/A, With 1-HP Electric<br />

Hydraulic Pump, Assorted Dies<br />

1 – RIDGID MODEL CM14500 14” ABRASIVE CUT-OFF SAW,<br />

S/N XX0525-23762<br />

1 – METTER TOLDEO ELECTRONIC PLATFORM SCALE,<br />

S/N N/A, 5’ X 7’ PLATFORM, With Lynx Wall Mounted<br />

Programmable Readout<br />

VIEW OF PORTABLE CHIP/SCRAP CONVEYORS<br />

SHOP AND FACTORY<br />

1 – 5’ X 7’ X 1/2” THICK HEAVY DUTY STEEL WELDING/WORK<br />

TABLE, With Bench Vise<br />

1 – 4’ X 8’ X 3/8” HEAVY DUTY STEEL WELDING/WORK TABLE<br />

2 – LISTA 56” WIDE X 31” DEEP X 39 1/2” HIGH 2-SLIDING<br />

DOOR TOOL CABINETS<br />

3 – LISTA 60” HIGH MULTI-DRAWER TOOL STORAGE CABINETS<br />

4 – LYON 72” HIGH X 39” WIDE X 26” DEEP 2-DOOR SUPPLY<br />

CABINETS, Portable<br />

1 – LISTA PORTABLE TOOLHOLDER CART ADJUSTABLE<br />

HOLDER SHELVES, With HSK-63 and 30T-SK30 Holders<br />

Dust Shield Computer Enclosures Hardwood Top and Steel Work<br />

Benches, Supply Cabinets, Toolholders, Bench Vises, Hand Tools,<br />

Power Tools, Storeroom Supplies, General Shop and Factory<br />

Adjustable Metal Storeroom Shelving<br />

PHONE SYSTEM<br />

Siemens PBX phone system with Siemens Hi Path 400 using<br />

HiPath 4000 v3.0 software. The system has 24 digital ports, 24 analog<br />

ports and 90 IP ports available. The voice mail system is the<br />

Siemens Hi Path Xpressions. It uses the HiPath Xpressions v4.0<br />

software running on an IBM rack mount server. The IBM server is<br />

an X-Series 206m server with a 3.40 GHz Pentium 4 processor and<br />

2 GB Ram operating on a Windows Server 2003 SP 1 platform.<br />

Also included are 22 Siemens optiPoint 500 standard digital<br />

phones, 2 Siemens optiPoint 410 standard IP phones, 10 Siemens<br />

optiPoint WL2 professional wireless phones and 9 Siemens<br />

AP2610 Wireless access points.<br />

To schedule an auction, please contact us at 248.254.9999 7

Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Southampton (UK) • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

WEBCAST / ONSITE AUCTION<br />

By order of<br />

AE LIGHT METAL CASTING GEORGIA, INC.<br />

Late Model Aluminum Die Cast Facility<br />

Tuesday, July 21st • Beginning at 10am Local Time<br />

LaGrange, Georgia<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062 • All rights reserved<br />

Printed in USA • AELI3403 • Auctioneer & Licenses: <strong>Hilco</strong> <strong>Industrial</strong>, LLC #ACNR002368, Jack Washbourn #AUNR002889, IL License #444000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A buyer’s premium of 13.5% for onsite sales & 16%<br />

for webcast sales is in effect. Everything will be sold<br />

to the highest bidder for cash, in accordance with<br />

the Auctioneer’s customary “Terms of Sale”, copies<br />

of which will be posted on the premises of the sale<br />

and subject to additional terms announced the day<br />

of sale. All items will be sold “as is, where-is” without<br />

any warranties, express or implied. Although<br />

obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the<br />

items on which they intend to bid prior to sale.<br />

Absolutely no items will be removed until the day<br />

after the conclusion of the sale and payment is made<br />

in full. Subject to additions, deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN<br />

FULL ON THE DAY OF THE AUCTION. If you intend<br />

to pay by wire transfer, we will accept payment the<br />

day after the sale ONLY IF a deposit of 25% of total<br />

purchases is made on the day of the sale. Contact<br />

our office for wire transfer instructions. Only cash,<br />

wire transfer or certified check, payable to <strong>Hilco</strong><br />

<strong>Industrial</strong>, LLC will be accepted. Company checks<br />

payable to <strong>Hilco</strong> <strong>Industrial</strong> LLC will be accepted only<br />

if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales<br />

tax. Purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the Auctioneer of<br />

their entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees<br />

payment to <strong>Hilco</strong> <strong>Industrial</strong>, LLC from<br />

(Company Name). This guarantee will be valid<br />

for purchases made at the Auction of AE Light<br />

Metal Casting Georgia, Inc. on July 21st.