ONLINE AUCTION - Hilco Industrial

ONLINE AUCTION - Hilco Industrial

ONLINE AUCTION - Hilco Industrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

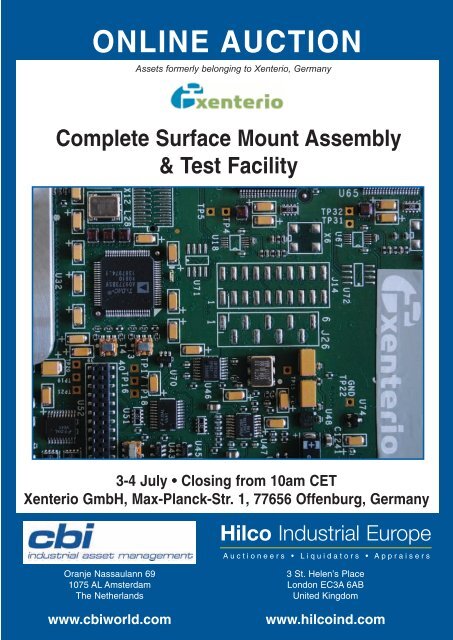

<strong>ONLINE</strong> <strong>AUCTION</strong><br />

Assets formerly belonging to Xenterio, Germany<br />

Complete Surface Mount Assembly<br />

& Test Facility<br />

3-4 July • Closing from 10am CET<br />

Xenterio GmbH, Max-Planck-Str. 1, 77656 Offenburg, Germany<br />

<strong>Hilco</strong> <strong>Industrial</strong> Europe<br />

Auctioneers • Liquidators • Appraisers<br />

Oranje Nassaulann 69<br />

1075 AL Amsterdam<br />

The Netherlands<br />

www.cbiworld.com<br />

3 St. Helen’s Place<br />

London EC3A 6AB<br />

United Kingdom<br />

www.hilcoind.com

HEADER • HEADER • HEADER<br />

HILCO INDUSTRIAL EUROPE <strong>ONLINE</strong> <strong>AUCTION</strong><br />

Assets formerly belonging to Xenterio, Germany<br />

<strong>AUCTION</strong> CLOSING DATE<br />

Tuesday 3 July to Wednesday 4 July<br />

from 10:00am CET<br />

PREVIEW DATES<br />

Thursday 28 to Saturday 30 June, 10:00am to 4:00pm CET<br />

PREVIEW LOCATION<br />

Xenterio GmbH, Max-Planck-Str. 1,<br />

77656 Offenburg, Germany<br />

ACCOMMODATION<br />

MERCURE HOTEL, OFFENBURG<br />

TRANSPORT<br />

AIRPORT: SEVERAL AIRPORTS ARE SUITABLE<br />

• STRASBOURG – BY RENTAL CAR OR TAXI 25 MINS<br />

• BADEN-BADEN/KARLSRUHE (BADEN AIRPORT) – BY RENTAL<br />

CAR OR TAXI 30 MINS<br />

• BASEL/MULHOUSE – BY RENTAL CAR OR TAXI 70 MINS<br />

• FRANKFURT AM MAIN – BY RENTAL CAR OR TAXI 150 MINS<br />

• STUTTGART – BY RENTAL CAR OR TAXI 120 MINS<br />

TRANSPORT<br />

RAIL: OFFENBURG IS ON THE ICE LINE HAMBURG-BASEL<br />

• FRANKFURT – 90 MINS<br />

• BASEL – 60 MINS<br />

ROAD:<br />

• MOTORWAY A5 – EXIT OFFENBURG<br />

• TOWARDS ACHERN, OFFENBURG-NORD-WEST<br />

• TAKE FIRST EXIT (TO THE RIGHT) AT ROUNDABOUT<br />

• STRAIGHT ON, AND AT NEXT ROUNDABOUT TAKE THIRD EXIT INTO<br />

HEINRICH-HERTZ-STRASSE<br />

• AFTER 500M TURN LEFT INTO MAX-PLANCK-STRASSE<br />

FURTHER INFORMATION<br />

• A 16% BUYER’S PREMIUM WILL BE CHARGED ON ALL ASSETS.<br />

THE <strong>AUCTION</strong> WILL BE CONDUCTED IN EURO CURRENCY ONLY.<br />

• REMOVAL DEADLINE IS 26 JULY<br />

• FOR FURTHER INFORMATION PLEASE CONTACT:<br />

DANIEL GRAY AT +44 (0)8453 130 180<br />

OR EMAIL DGRAY@HILCOEUROPE.COM<br />

RODERIK HUBER AT +31(20) 470 0989<br />

OR EMAIL RHUBER@CBIWORLD.COM<br />

• FOR PAYMENT QUERIES PLEASE CONTACT:<br />

YVETTE STREETE + 44 (0)8453 130 140<br />

OR EMAIL YSTREETE@HILCOEUROPE.COM<br />

• FOR COSTUMER SERVICE PLEASE CONTACT:<br />

SHIRLEY PHIPPS +44 (0)121 237 6221<br />

OR EMAIL SPHIPPS@HILCOEUROPE.COM<br />

COMPLETE ASSEMBLY LINES AVAILABLE AS A WHOLE<br />

PRIOR TO <strong>AUCTION</strong><br />

(All lines configured to run Left-to-Right)<br />

Line 1 – Installed 2007<br />

• DEK 265GSX Screen Printer, DEK Vacuum and Filtration, Spare heads (1997)<br />

• Siemens SiPlace S27HM Placement Machine (1998)<br />

• Siemens SiPlace 80S20 Placement Machine (1998)<br />

• Siemens SiPLace F5 HM Placement Machine (2003)<br />

• Rehm SMS-V6-N2 3300/80-460 Reflow Oven (1999)<br />

• Rommel Board Transportation including; LEG 55WA 240, LBS 01,<br />

(3) BM600S, LPR 40S, BM500-3 SHI, LAG55WA 470<br />

• Spare selection of change over tables and quantity of S-Type feeders<br />

Line 2<br />

• Rommel WL 1000 DE 20 Automatic Barcode Printer<br />

• DEK 265 Horizon Screen Printer, DEK Vacuum and Filtration,<br />

Green camera, Spare heads (2000)<br />

• Rommel BM1000/500 SI-A Paste Inspection System<br />

• Siemens SiPlace 80 G2 Gluing Machine (1999)<br />

• Siemens SiPlace S27HM Placement Machine (2004 – Refurbished by<br />

Siemens in 2008)<br />

• Siemens SiPlace 80 S20 Placement Machine (1998)<br />

• Siemens SiPlace 80 F4 Placement Machine (2001)<br />

• Siemens SiPlace 80 F5 HM Placement Machine (2001)<br />

• Rehm SMS-V6-N2 3300/55-400 Reflow Oven (2001)<br />

• Rommel Board Transportation including; LEG 55WA 470 SC, LBS 01A,<br />

WS 45S, (2) BM 600SI, BMS 1500G, BM500-3 SHI, LAG 55 WA-470-SC<br />

• Spare selection of change over tables and quantity of S-Type feeders<br />

Line 3<br />

• Rommel WL 1000 DE 20 Automatic Barcode Printer<br />

• DEK 265 Horizon Screen Printer, DEK Vacuum and Filtration,<br />

Green camera, Spare heads<br />

• Rommel BM1000/500 SI-A Paste Inspection System<br />

• Siemens SiPlace 80 G2 Gluing Machine (1999)<br />

• Siemens SiPlace S27 HM Placement Machine (2004)<br />

• Siemens SiPlace 80 S20 Placement Machine (1998)<br />

• Siemens SiPlace 80 F4 Placement Machine (2001)<br />

• Siemens SiPlace 80 F5 HM Placement Machine (2001)<br />

• Rehm SMS-V6-N2 3300/55-400 Reflow Oven (2001)<br />

• Rommel Board Transportation including; Rommel LEG WA 470 SC,<br />

LBS 01S, WS 45 S, BM 600 SI, LPR 50S, (2) BM 600 S1, BMS 1500G,<br />

BM500-3 SHI, LAG 55 WA-470-SC<br />

• Spare selection of change over tables and quantity of S-Type feeders<br />

Line 4<br />

• DEK Infinity Api Screen Printer, DEK ECM.02 Environmental Control Module,<br />

Spare heads (2005)<br />

• Koh Young Technology KY-3030VAL 3D Solder Paste Inspection Machine (2005)<br />

• Siemens SiPlace 80 G2 Gluing Machine (1995)<br />

• Siemens SiPlace 80 S23 (S25) Placement Machine (2000 - Refurbished by<br />

Siemens in 2008)<br />

• Siemens SiPlace 80 S23 (S25) Upgraded Placement Machine (2000)<br />

• Siemens SiPlace 80 S23 (S25) Upgraded Placement Machine (2000)<br />

• Siemens SiPLace 80 F5 HM Placement Machine (2000)<br />

• Siemens SiPlace HF Placement Machine (2005)<br />

• Rehm SMS-V6-N2 3300/80-400 Reflow Oven (1997)<br />

• Rommel Board Transportation including; LEG 55 WA 470 SC, LBS 01S,<br />

WL2001 T (Thermal Printer conveyor), WS 45 S, (3) BM 600S,<br />

BM 500-2 SI-A, LPR-40S, BMS 1500G, BM 500-3 SHI, LAG 55 WA-470<br />

• Spare selection of change over tables and quantity of S-Type feeders<br />

Line 5<br />

• DEK Horizon 02 Screen Printer, Green Camera, DEK DA68 TCU,<br />

Spare heads (2004)<br />

• Siemens SiPlace S27 HM Placement Machine, with DCA Camera and<br />

vacuum sensor (2004)<br />

• Siemens SiPlace 80 S20 Placement Machine (1998)<br />

• Siemens SiPlace F5 HM Placement Machine (2002 – Refurbished by<br />

Siemens in 2008)<br />

• Rehm SMS-V6-N2 3300/2x80-216 Reflow Oven<br />

• ASYS Board Transportation including; AES 03D, LSB 03, TRM 02, PS30,<br />

TRM 03.05, AMS 03D<br />

• Spare selection of change over tables and quantity of S-Type feeders<br />

Manuals, Service histories, Spare parts available for each line<br />

Test Cells<br />

Lines are available with complete test cells, with Rommel board loading and<br />

unloading, comprising Agilent 5DX Series 5000 (2004) & 5DX Series 3<br />

(2000) X-Ray inspection and Orbotech VT-9300 & VT-8000 AOI’s<br />

2<br />

For more information, visit us on the web @ www.hilcoeurope.com

HEADER PLACEMENT • HEADER MACHINES • HEADER<br />

(24) PLACEMENT MACHINES<br />

4 – Siemens SiPlace S27 HM’s (2008 & 2004)<br />

2 – Siemens SiPlace F5 HM’s (2008 & 2003)<br />

1 – Siemens SiPlace HF c/w MTC 2 Unit (2005)<br />

3 – Siemens SiPlace 80 S23 HM’s - Upgraded to<br />

S25’s (2000)<br />

3 – Siemens SiPlace 80 F5 HM’s (2001 & 2000)<br />

2 – Siemens SiPlace 80 F4’s (2001)<br />

4 – Siemens SiPlace 80 S20<br />

3 – Siemens SiPlace G2 Glue Machines<br />

1 – Siemens SiPlace 80 G2<br />

1 – Zevatech Micron 2<br />

All machines with compliment of Feeder carts<br />

40+ Additional Siemens Feeder carts<br />

800+ Siemens S-Type Feeders 8–88mm<br />

(Silver & Gold)<br />

(5) SCREEN PRINTERS<br />

1 – DEK Infinity APi c/w ECM.02 Module (2005)<br />

1 – DEK Horizon 02 c/w Green camera,<br />

DEK DA68 TCS (2004)<br />

2 – DEK 265 Horizons c/w Green camera,<br />

KDA6000 & SP08 Vacuum (2001)<br />

1 – DEK 265 GSX c/w DEK DA25 TCS<br />

Line 2 Placement Machines<br />

SiPlace HF - Internal<br />

SiPlace HF (2005)<br />

800+ S-Type Feeders<br />

DEK Infinity API (2005)<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140 3

REFLOW OVENS/INSPECTION<br />

Rehm Condenso-Line 1600 (2006)<br />

(6) REFLOW OVENS<br />

1 – Rehm SMS-V6-N 3300/2x80-216<br />

1 – Rehm SMS-V6-N 3300/80-460<br />

1 – Rehm SMS-V6-N 3300/80-400<br />

2 – Rehm SMS-V6-N 3300/55-400<br />

1 – Rehm Condenso-Line 1600 (2006)<br />

Rehm Reflow Ovens<br />

INSPECTION<br />

Orbotech VT-9300 HD AOI<br />

1 – Agilent 5DX Series 5000 X-ray inspection machine (2004)<br />

1 – Agilent 5DX Series 3 X-ray inspection machine (2000)<br />

1 – Koh Young KY-3030VAL Paste Inspection machine (2005)<br />

2 – Orbotech VT-9300 HD AOI’s<br />

1 – Orbotech VT-8000 AOI<br />

Koh Young KY-3030VAL (2005)<br />

Agilent 5DX 5000 (2004)<br />

4<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140

BOARD TRANSPORTATION SYSTEMS/WAVE SOLDERING/<br />

IN CIRCUIT, POWER FUNCTION & FLYING PROBE TESTERS<br />

BOARD TRANSPORTATION SYSTEMS<br />

– ASYS, including: LSB 03, TRM 02, PS30, TRM 03.05,<br />

AMS & AES03D<br />

– Rommel, including: LEG 55 WA 470 SC, WL 1000 DE 20,<br />

BMS 1500G, WS 45S, LBS 01S, LPR 50S, BM 600S<br />

WAVE SOLDERING<br />

1 – Seho MWS 2335-LRT Lead Free & Leaded Wave Soldering<br />

system (2006) c/w Seho Fluxer & ULT LRA 1000<br />

extraction system<br />

Rommel Board Transportation Systems<br />

(5) IN CIRCUIT, POWER FUNCTION &<br />

FLYING PROBE TESTERS<br />

1 – Agilent Medalist 3070 Series 3 ICT (DD Fully Loaded)<br />

1 – HP 3070 Series 3070 Series 2<br />

(upgraded from S1 – SD Loaded)<br />

1 – Spirel ATR 15 Power Functional Test Station<br />

2 – SPEA 4040 Flying Probe Testers (2006 & 2004) c/w<br />

SPEA 500 Conveyor<br />

Rommel Board Unloader<br />

Seho MWS 2335-LRT Wave Soldering System (2006)<br />

Spirel ATR 15<br />

SPEA 4040 Flying Probe Tester (2006)<br />

Agilent Medalist 3070 Series 3 ICT (DD Fully Loaded)<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140 5

ELECTRONIC TEST & MEASUREMENT EQUIPMENT<br />

ELECTRONIC TEST &<br />

MEASUREMENT EQUIPMENT<br />

Rohde & Schwarz FSQ 20Hz – 8.0GHz Signal Analyzer<br />

Rohde & Schwarz FSQ 8 20Hz – 40GHz Spectrum Analyzer<br />

Rohde & Schwarz FSEK 30 20Hz-40GHz Spectrum Analyzer<br />

Rohde & Schwarz NRP Power Meters<br />

Rohde & Schwarz 100kHz – 1000MHz Signal Generators<br />

Agilent E4438C 250kHz – 6.0GHz ESG Vector Signal Generator<br />

Agilent 3499A Switch/ Control System<br />

Agilent E4419B EPM Power Meters<br />

HP 8341B Synthesized Sweeper (10MHz-20GHz)<br />

HP 4192A LF Impedance Analyzer<br />

HP 4275A Multi-Frequency LCR Meter<br />

HP EPM-441A Power meters<br />

HP 6624A, 6633A, 6622A DC Power supplies<br />

Chroma 19032 Electrical Safety Analyzer<br />

Tektronix 576 & 370 Curve Tracers<br />

Rohde & Schwarz FSQ 8 Signal Analyzer<br />

Rohde & Schwarz FSEK 30 Spectrum Analyzer<br />

Agilent E4438C Vector Signal Generator<br />

6<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140

REWORK EQUIPMENT/BONDERS/<br />

WAREHOUSE-GOODS IN EQUIPMENT/ENVIRONMENTAL TEST CHAMBERS<br />

REWORK EQUIPMENT<br />

1 – Zevac Onyx 29<br />

1 – Zevac DRS 22 c/w full set of nozzles<br />

1 – Ersascope c/w MHLS Light source<br />

1 – Ersa IR 550A<br />

– Leica MZ75 Inspection stations<br />

Zevac Onyx 29 (2007)<br />

ERSASCOPE SMT/BGA Inspection<br />

(5+) BONDERS<br />

1 – Kulicke & Soffa 8090 Wedge Bonder<br />

1 – MEI 120 4W Bonder<br />

1 – Hughes 2460-V Bonding Station<br />

1 – Tresky 3002 Bonder<br />

– MECH-EL 829 ZX & 909 ZX Bonders<br />

K&S 8090 Wedge Bonder<br />

WAREHOUSE/<br />

GOODS IN EQUIPMENT<br />

Votsch 4010 Test Chamber<br />

1 – Leitz VRZ-XY Inspection system<br />

1 – Micro-Hite 2-Axis CMM<br />

1 – Kaiser eVision Inspection system<br />

1 – Sander Strapping Systems<br />

1 – SATO Barcode printing systems<br />

1 – Boltless Racking Systems<br />

6 – Industriever/ Megamat Vertical Storage Carousels<br />

– Gravity Conveyor systems<br />

– Internal Transport<br />

Votsch Environmental Test Chamber<br />

ENVIRONMENTAL<br />

TEST CHAMBERS<br />

2 – Votsch VEM 03/2240/W/S Test chambers<br />

1 – Votsch VT 4010 Thermal Test Chamber<br />

2 – Heraeus Votsch Chambers Heraesus LUT 5050<br />

EK Chamber<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140 7

OTHER EQUIPMENT<br />

ProMaster 2500 Schleuniger ES 9300<br />

ERNI Hydraulic-PN Press<br />

OTHER EQUIPMENT<br />

1 – Amsonic EVD 80 Wash System c/w<br />

Siemens Touch screen control (2004)<br />

1 – Systronic SYS 152/2 screen wash system<br />

1 – IBL VPP-M 400 Wash System Speedline<br />

1 – Camalot 3700 Gluing Machine<br />

5 – Steckfuss Wire & Lead Formers Schleuniger<br />

1 – Schleuniger ES 9300 Cut & Strip Machine<br />

4 – Ryonic Assembly stations<br />

1 – ProMaster 2500 Data I/O Programmer<br />

1 – UniSite XPI Programmer<br />

1 – Cab Maestro 4M Board Splitter<br />

1 – Boss NE 2/83 Vacuum sealer<br />

1 – Alternative SMT Feeder Master<br />

1 – Feeder test system<br />

– Zevac SSM 9 & PCB RM Solder units<br />

– Becker automated wire former ERNI EPC 25/10KN<br />

Air Press c/w Press fixtures<br />

– ERNI Hydraulic-PN Press c/w Press fixtures<br />

CAB Maestro 4M<br />

Wire and Lead Formers<br />

Amsonic EVD Wash System (2004)<br />

Typical Assembly Bench<br />

Feeder Master Test Station<br />

8<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140

TRAINING ROOM<br />

Leinen Centre Lathe<br />

TRAINING/TOOL ROOM<br />

1 – Leinen Centre Lathe, 500m BC, 160mm Swing c/w 3-Axis DRO Flott TB16ST<br />

1 – Pillar Drill Solid TB16<br />

1 – Pillar Drill Herkules Werk Pan Folder<br />

1 – F210 Light Work Milling Machine c/w 3-axis DRO<br />

– Vinyl cutter, Work benches, Bench drills, Hand tools 1,000’s of fixtures, Spares and Training components<br />

QTY of Optical Inspection Scopes<br />

Complete Training class rooms and equipment, Offices, IT equipment, PC’s, Hundreds of benches, Solder stations & Optical inspection<br />

equipment. Hand tools, Measurement equipment, Power drivers, Air drivers, Large inventory of unused component stock and<br />

much much more…<br />

To schedule an auction, please contact us at + 44 (0) 8453 130 140 9

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Connecticut • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong<br />

HILCO Irapuato (MX) • INDUSTRIAL Leeds (UK) • London (UK) • Los Angeles • Mexico EUROPE City (MX) • Monterrey (MX) • <strong>ONLINE</strong> New York • San Francisco • Toronto <strong>AUCTION</strong><br />

• Villahermosa (MX)<br />

Complete Surface Mount Assembly & Test Facility<br />

<strong>Hilco</strong> <strong>Industrial</strong> Europe<br />

Auctioneers • Liquidators • Appraisers<br />

European Head Office:<br />

3 St. Helen’s Place • London • EC3A 6AB • UK<br />

Ph + 44 (0) 8453 130 140 • Fx + 44 (0) 8453 130 150<br />

Leeds Office: WESTONE • Wellington Street • Leeds • LS1 1BA • UK<br />

Birmingham Office: 43 Temple Row • Birmingham • B2 5LS • UK<br />

www.hilcoeurope.com<br />

Terms of Sale<br />

A buyer’s premium is in effect. Everything will be sold to the<br />

highest bidder for cash, in accordance with the Auctioneer’s<br />

customary “Terms of Sale”, copies of which will be posted on<br />

the premises of the sale and subject to additional terms<br />

announced the day of sale. All items will be sold “as is,<br />

where-is” without any warranties, express or implied.<br />

Although obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the accuracy<br />

of the information herein contained. Bidders are encouraged<br />

to thoroughly inspect the items on which they intend to bid<br />

prior to sale. Absolutely no items will be removed until the day<br />

after the conclusion of the sale and payment is made in full.<br />

Subject to additions, deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN FULL ON<br />

THE DAY OF THE <strong>AUCTION</strong>. If you intend to pay by wire<br />

transfer, we will accept payment the day after the sale ONLY<br />

IF a deposit of 25% of total purchases is made on the day of<br />

the sale. Contact our office for wire transfer instructions. Only<br />

cash, wire transfer or certified cheque, payable to <strong>Hilco</strong><br />

<strong>Industrial</strong> Europe will be accepted. Company cheques<br />

payable to <strong>Hilco</strong> <strong>Industrial</strong> Europe will be accepted only if<br />

accompanied by a bank letter of guarantee. All sales are<br />

subject to sales tax. Purchasers claiming exemptions from<br />

taxes must provide proof satisfactory to the Auctioneer of<br />

their entitlement to claim such exemptions.<br />

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Connecticut • Chicago • Dallas<br />

Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York<br />

San Francisco • Toronto • Villahermosa (MX)