WEBCAST AUCTION - Hilco Industrial

WEBCAST AUCTION - Hilco Industrial

WEBCAST AUCTION - Hilco Industrial

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

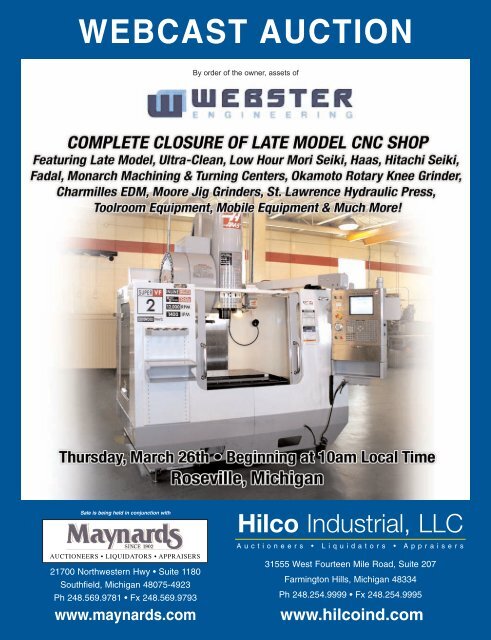

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

By order of the owner, assets of<br />

Sale is being held in conjunction with<br />

<strong>AUCTION</strong>EERS • LIQUIDATORS • APPRAISERS<br />

21700 Northwestern Hwy • Suite 1180<br />

Southfield, Michigan 48075-4923<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

www.maynards.com<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334<br />

Ph 248.254.9999 • Fx 248.254.9995<br />

www.hilcoind.com

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

CNC VERTICAL MACHINING CENTERS<br />

By order of the owner, assets of<br />

2005<br />

THURSDAY, MARCH 26 TH<br />

Beginning at 10am Local Time<br />

Preview Date<br />

Wednesday, March 25th<br />

9am to 4pm Local Time & Morning of Sale<br />

Auction Location<br />

28141 Groesbeck Highway<br />

Roseville, MI 48066<br />

Bid Live in person,<br />

or by phone via the web at<br />

www.hilcoind.com<br />

Directions to Sale<br />

From I-696:<br />

Exit I-696 at Exit #26, Groesbeck Hwy<br />

(M-97) Travel north on Groesbeck Hwy.<br />

3/4 mile to plant on the left. (Plant is on<br />

west side of Groesbeck, between<br />

Martin & 12 Mile Roads).<br />

HAAS SUPER VF2 MODEL VF 2SSYT<br />

EXTENDED TRAVEL 5-AXIS<br />

CNC VERTICAL MACHINING CENTER<br />

FADAL VMC 4020HT MODEL 906-1<br />

CNC VERTICAL MACHINING CENTER<br />

Travel Information<br />

Airlines:<br />

American Airlines . . . . . . . . . 800.433.7300<br />

Northwest Airlines . . . . . . . . . 800.225.2525<br />

United Airlines . . . . . . . . . . . 800.241.6522<br />

Delta Airlines . . . . . . . . . . . . 800.221.1212<br />

Southwest Airlines . . . . . . . . 800.435.9792<br />

Hotels:<br />

Holiday Inn . . . . . . . . . . . . . . 586.754.9700<br />

Best Western Georgian Inn . 586.294.0400<br />

Victory Inn . . . . . . . . . . . . . . 586.294.6140<br />

Further Information<br />

• A buyer’s premium will be in effect.<br />

The auction will be conducted in<br />

English, accepting U.S. Currency only.<br />

• Removal Deadline is April 10, 2009<br />

with Hours of Removal between<br />

8am to 4pm Monday thru Friday. After<br />

April 10th at 4pm buyer will incur a cost<br />

of $500 daily for entry into the facility.<br />

• For further information please contact<br />

George Laidlaw at 616.233.0702 or<br />

Email glaidlaw@hilcoind.com<br />

• For Payment & Customer Service<br />

please contact Sandi Neely at<br />

248.254.9999 x16 or Email<br />

sneely@hilcoind.com<br />

MONARCH MODEL VMC 75B 4-AXIS CNC<br />

VERTICAL MACHINING CENTER<br />

HITACHI SEIKI MODEL HG630 HIGH GRADE<br />

EXPANDABLE MACHINING CELL PALLET TYPE<br />

CNC HORIZONTAL MACHINING CENTER<br />

CNC VERTICAL MACHINING CENTERS<br />

1 – HAAS SUPER VF2 MODEL VF 2SSYT EXTENDED TRAVEL 5-AXIS CNC VERTICAL MACHINING CENTER,<br />

S/N 45220 (2005), Haas Automation 5-Axis CNC Control, Table Size 18” x 36”, Travels: 30” X, 20” Y, 20” Z, 30-HP,<br />

1400 IPM Rapid, Spindle Speeds to 12,000 RPM, Inline Direct Spindle Drive, High Speed Toolchanger, CAT 40<br />

Spindle Taper, 24-Position Automatic Toolchanger, Programmable Flood Coolant, Enclosure Doors, Model STR<br />

160H 6” Motorized Rotary/Tilt 4th/5th Axis Trunnion Attachment (Table To Be Sold Separately), S/N 902149, Full<br />

Probing Package, Haas TS27R Tooling Probe, Renishaw/Haas CAT 40 Taper Part Probe, Programmable Air Blast,<br />

USB Port, Ethernet Network Card<br />

1 – FADAL VMC 4020HT MODEL 906-1 CNC VERTICAL MACHINING CENTER, S/N 9809703 (1998), Table Size<br />

40” x 20”, Travels: 40” X, 20” Y, 20” Z, Spindle Speeds 40 – 10,000 RPM, 22.5-HP, Spindle Nose to Table Surface<br />

4” – 24”, Spindle Center to Column Ways 20”, 1500-Lb. Max. Table Load, CAT 40 Spindle Taper, 21-Position<br />

Automatic Toolchanger, Fadal CNC 88HS Controls, Coolant, Enclosure Doors<br />

1 – MONARCH MODEL VMC 75B 4-AXIS CNC VERTICAL MACHINING CENTER, S/N 98009B (1998), GE Fanuc<br />

Series 16-M Controls, Overall Table Size 21” x 71”, Travels: 40” X, 20” Y, 24” Z, Spindle Speeds 30 – 6000 RPM,<br />

CAT 50 Spindle Taper, 40-Position Automatic Toolchanger, 3500-Lb. Table Load Capacity, 35-HP, Tsudakoma 12”<br />

Full 4th Axis, Chip Auger, Coolant, Enclosure Doors<br />

1 – MONARCH MODEL VMC 75B 4-AXIS CNC VERTICAL MACHINING CENTER, S/N 95021B (1995), Autocon<br />

Dynapath Delta CNC Control, Overall Table Size 21” x 71”, Travels: 40 X, 20” Y, 24” Z, Spindle Speeds 30 – 6000<br />

RPM, CAT 50 Spindle Taper, 40-Position Automatic Toolchanger, 3500-Lb. Table Load Capacity, 35-HP,<br />

Tsudakoma 12” Full 4th Axis, Chip Auger, Coolant, Enclosure Doors<br />

1 – MONARCH MODEL VMC 75B CNC VERTICAL MACHINING CENTER, S/N 90007B, Dynapath Systems Delta<br />

20 CNC Control, Table Size 21” x 49”, Travels: 40” X, 20” Y, 24” Z, Spindle Speeds 30 – 6000 RPM, CAT 45 Spindle<br />

Taper, 32-Position Automatic Toolchanger, Hiperdex 360, 12” 1 Degree Precision Heavy Duty Indexer, Coolant,<br />

Enclosure Doors<br />

CNC HORIZONTAL MACHINING CENTER<br />

1 – HITACHI SEIKI MODEL HG630 HIGH GRADE EXPANDABLE MACHINING CELL PALLET TYPE CNC<br />

HORIZONTAL MACHINING CENTER, S/N HG60202 (1995), (2) 24-3/4” x 24-3/4” Pallets, Fanuc Series 15M<br />

Controls, Travels: 35” X, 31” Y, 28” Z, 1 Degree Pallet Indexing, Spindle Speeds 20 – 4500 RPM, 25-HP, 2200-Lb.<br />

Pallet Load Capacity, 0-31” Spindle Center to Table Surface, 8” – 36” Spindle Nose to Table Center, Parallel Shuttle<br />

Type Pallet Changeover, CAT 50 Spindle Taper, 40-Position Automatic Toolchanger, Thru-The-Spindle High<br />

Pressure Coolant, Pro-Fluid Model CJ-70-15-SF, 1000 PSI Hi-Pressure Coolant Power Supply, S/N CJL-70155-063<br />

(2007), Chip Removal Auger, External Coolant Reservoir, With Recirculation Pumps & Turbo Chip Conveyor,<br />

Enclosure Doors, With Interlocks, Micon 16 III PLC<br />

2<br />

For more information, visit us on the web @ www.hilcoind.com

CNC MACHINING & TURNING CENTERS, LATHE, EDM & BORING MILL<br />

MORI SEIKI MODEL CL-25A CNC TURNING CENTER<br />

CINCINNATI MILACRON CINTURN 10CU COMPACT<br />

UNIVERSAL NC TURNING CENTER<br />

CHARMILLES TECHNOLOGIES<br />

MODEL ROBOFIL 290 5-AXIS<br />

CNC WIRE CUT EDM<br />

HARRISON 600 SERIES MODEL ALPHA 550 PLUS<br />

21/32” X 60” GAP BED CNC LATHE<br />

TOSHIBA SHIBAURA MODEL BTD-9(R) 3.5”<br />

CNC TABLE TYPE HORIZONTAL BORING MILL<br />

LUCAS PRECISION MODEL 441B-48<br />

4” TABLE TYPE HORIZONTAL BORING MILL<br />

CNC TURNING CENTERS<br />

1 – MORI SEIKI MODEL CL-25A CNC TURNING CENTER, S/N 412 (1995/1996), Fanuc 18TA Controls,<br />

20.5” Swing Over Bed, 16.1” Swing Over Cross Slide, 17.7” Maximum Turning Diameter, 17.7” Maximum<br />

Turning Length, Spindle Speeds 30 – 3000 RPM, 3.5” Bar Work Capacity, 4.1” Hole-Thru Spindle, 10-Position<br />

Tool Turret, 10” 3-Jaw Power Chuck, Coolant, Chip Conveyor, Enclosure Door<br />

1 – MONARCH METALIST 20” X 42” CNC TURNING MACHINE, S/N 53929 (1992), GE Fanuc 11T Controls,<br />

3-5/8” Hole-Thru Spindle, 3” Bar Work Capacity, Spindle Speeds 60 – 3000 RPM, 25-HP DC Drive Motor, 8 OD/8<br />

ID Tool Turret, 10” 3-Jaw Power Chuck, Programmable Tailstock, Coolant, Chip Conveyor, Enclosure Doors<br />

1 – CINCINNATI MILACRON CINTURN 10CU COMPACT UNIVERSAL NC TURNING CENTER, S/N 5311U10-<br />

81-028, Model MA-B, Cincinnati Milacron Acramatic 900 Controls, 30-HP Spindle Motor, 10” Diameter Power<br />

Chuck, Spindle Speeds 30 – 3000 RPM, 40” Centers, Programmable Tailstock, Tool Turret, With 7 OD/7 ID<br />

Tool Positions, Coolant, Chip Conveyor, Enclosure Door<br />

CNC LATHE<br />

1 – HARRISON 600 SERIES MODEL ALPHA 550 PLUS 21/32” X 60” GAP BED CNC LATHE, S/N A50558/459<br />

(1998), Harrison-GE Fanuc Alpha 2-Axis CNC Control, (9) Spindle Speeds 15 – 1800 RPM, Inch/mm<br />

Threading, 2-Axis Servo Drive Carriage, Carriage Mounted Controls, Manual Tailstock, 4” Hole-Thru Spindle,<br />

12” 3-Jaw Chuck, Carriage Mounted Traveling Operators Guard, With Worklight, Coolant, Removable Chip<br />

Pan, Splash Guard, Offline Laptop, With WINDOWS 95 Programming System<br />

CNC ELECTRICAL DISCHARGE MACHINE<br />

1 – CHARMILLES TECHNOLOGIES MODEL ROBOFIL 290 5-AXIS CNC WIRE CUT EDM, S/N 335223 (1997),<br />

Max. Part Dimensions 33.5” x 19.7”, Max. Part Height 7.9”, Max. Load 1102-Lbs., Travels: 15.7” X, 9.8” Y, 7.9”<br />

Z, 15.7” U, 9.8” V, Wire Diameter Range .004 – .01”, Automatic Threading, Charmilles CNC Controls,<br />

Self-Contained 80-Gallon Stainless Steel Dielectric Fluid Tank, With (8) Replaceable Cartridge Filters,<br />

Advantage Model IK-2APT-20HFX Chiller, S/N 32986<br />

1 – SYSTEM 3R EDM TOOLING, Parallels, Chucks, Clamps, etc., With Lista 54” 5-Drawer Portable Tool Cabinet<br />

CNC HORIZONTAL BORING MILL<br />

1 – TOSHIBA SHIBAURA MODEL BTD-9(R) 3.5” CNC TABLE TYPE HORIZONTAL BORING MILL,<br />

S/N 147067 (1986), 90mm (3.543”) Spindle Bar Diameter, Table Size 900 x 1050mm (35.4” x 41.3”), Travels:<br />

1000mm (39.4”) Vertical, 1200mm (47.2”) Table Cross, -100 to 700mm (-3.9” – 27.6”) Table Longitudinal,<br />

500mm (19.7”) Spindle, Spindle Speeds 5 – 1250 RPM, CAT 50 Spindle Taper, With Power Drawbar, Built-In<br />

Rotary Table, 90 Degree Table Indexing, Table Weight Capacity 5510-Lbs. Shibaura Tosnuc 3 Console Control,<br />

Servo Drives, Pendant Operators Control<br />

HORIZONTAL BORING MILL<br />

1 – LUCAS PRECISION MODEL 441B-48 4” TABLE TYPE<br />

HORIZONTAL BORING MILL, S/N 41B 3427 (Rebuilt<br />

By Borel & Co. In 2002), 4” Spindle Bar Diameter, Table<br />

Size 36” x 62”, Travels: 36” Vertical, 48” Table, 29”<br />

Saddle, Spindle Speed Range 15 – 1550 RPM, No. 50<br />

Spindle Taper, With Power Drawbar, Pendant Control,<br />

Horsepower Meter, 4-Way Bed<br />

HYDRAULIC PRESS<br />

1 – ST. LAWRENCE PRESS HDT-3-200-100 300-TON<br />

TRIPLE ACTION HYDRAULIC DRAW PRESS,<br />

S/N 9112, Capacity: Main Ram 200 + 100-Tons, Cushion<br />

100-Tons, Stroke: Main Ram 19.50 + 12.25 Inches,<br />

Cushion 12.25 Inches, Pressure: Main Ram 4150 PSI<br />

Max., Cushion 2630 PSI Max., Work Area: 46.00 Inches<br />

Open Height, 26.50 Inches Closed Height, Die Area<br />

42”LR x 34”FB, Pressure Pad 18”LR x 18”FB, Rapid<br />

Advance, 6” T-Slotted Bolster, T-Slotted Ram, Allen<br />

Bradley PLC 5/15 Programmable Controller, Console<br />

Operators Control, Top Mounted Hydraulics, Pit Mounted<br />

A buyers premium of 13.5% for<br />

all onsite sales & 16% for all<br />

webcast sales will be in effect.<br />

Bid Live In Person Onsite or<br />

By Phone Via the Web at<br />

www.hilcoind.com<br />

To schedule an auction, please contact us at 248.254.9999 3

VERTICAL MILLS • LATHES • ROTARY SURFACE, JIG, ID/OD GRINDERS<br />

BRIDGEPORT SERIES I & II, 2 & 4-HP<br />

VARIABLE SPEED VERTICAL MILLING MACHINE<br />

OKAMOTO MODEL PRG-6 HORIZONTAL<br />

SPINDLE ROTARY SURFACE GRINDER<br />

BROWN & SHARPE 1236<br />

MICROMASTER 12” X 36”<br />

HYDRAULIC SURFACE GRINDER<br />

MOORE NO.3<br />

JIG GRINDER<br />

LEBLOND REGAL SERVO SHIFT 19” X 78”<br />

& 15” X 54” ENGINE LATHES<br />

REID FAYSCOTT & PARKER MAJESTIC<br />

HAND FEED SURFACE GRINDER<br />

PARKER MAJESTIC MODEL 1<br />

12” X 24” ID GRINDER<br />

VERTICAL<br />

MILLING MACHINES<br />

1 – BRIDGEPORT SERIES II, 4-HP VARIABLE SPEED<br />

VERTICAL MILLING MACHINE, S/N 767, Table Size<br />

11” x 58”, Power Travels, Spindle Speeds 50 – 3500<br />

RPM, Variable Power Quill Feed<br />

1 – BRIDGEPORT SERIES I, 2-HP VARIABLE<br />

SPEED VERTICAL MILLING MACHINE, S/N 12BR-<br />

254725, 9” x 48” Table, 60 – 4200 RPM, 7” Column<br />

Riser, Sony 2-Axis Readout<br />

1 – BRIDGEPORT SERIES I, 2-HP VARIABLE<br />

SPEED VERTICAL MILLING MACHINE, S/N 12BR-<br />

254728, 9” x 48” Table, 60 – 4200 RPM, Sony 2-Axis<br />

Readout<br />

1 – BRIDGEPORT SERIES I, 2-HP VARIABLE<br />

SPEED VERTICAL MILLING MACHINE, S/N 12BR-<br />

226794, 9” x 42” Table, 60 – 4200 RPM, 7” Column<br />

Riser, Sony 2-Axis Readout<br />

1 – BRIDGEPORT SERIES I, 2-HP VARIABLE<br />

SPEED VERTICAL MILLING MACHINE, S/N 12BR-<br />

182991, 9” x 42” Table, 60 – 4200 RPM, 7”<br />

Column Riser<br />

ENGINE LATHES<br />

1 – LEBLOND REGAL SERVO SHIFT 19” X 78”<br />

ENGINE LATHE, S/N 11E-568, Spindle Speeds 40 –<br />

1600 RPM, Quick Change English/Metric Threading,<br />

3” Hole Thru Spindle, Cross Feed & Carriage Trav-A-<br />

Dials, Micrometer Carriage Stop, Sony 2-Axis<br />

Readout, Coolant, (2) Removable Chip Pans, 15” 3-<br />

Jaw Chuck<br />

1 – LEBLOND REGAL SERVO SHIFT 15” X 54”<br />

ENGINE LATHE, S/N 7C-3466, Spindle Speeds<br />

45 – 1800 RPM, Quick Change Threading, 1-1/2”<br />

Hole-Thru Spindle, Trav-A-Dial, Micrometer Carriage<br />

Stop, Coolant, Removable Chip Pan, 10” 3-Jaw Chuck<br />

ROTARY SURFACE GRINDER<br />

1 – OKAMOTO PRG-6 HORIZONTAL SPINDLE ROTARY SURFACE GRINDER, S/N PRG-6 1150 M/C 1987.9,<br />

24” Diameter Electromagnetic Chuck, With Fuji NS2-FB Automatic IC Contractor Control, Grinding Wheel Size<br />

350mm Diameter x 38mm Width, Variable Power Rotary Table & Longitudinal Table Feeds, Automatic Downfeed,<br />

Power Overhead Wheel Dresser, External Coolant System/Dust Collector, With Magnetic Separator<br />

JIG GRINDER & ACCESSORIES<br />

1 – MOORE NO.3 JIG GRINDER, S/N G766, 11” x 24” Table, 13” Vertical Head Travel<br />

MOORE ACCESSORIES INCLUDING: (1) 40,000 RPM Grinding Head, (1) 55,000 RPM Grinding Head,<br />

(1) Pantograph Wheel Dresser, (1) Slot Grinding Attachment, (1) 11” Precision Rotary Table, (1) Moore Toolmakers<br />

Cabinet, Positive Stop, (1) 12” x 14” Sine Plate<br />

SURFACE GRINDERS<br />

1 – BROWN & SHARPE 1236 MICROMASTER 12” X 36” HYDRAULIC SURFACE GRINDER, S/N 523-1236-2431,<br />

12” x 36” Electromagnetic Chuck, With Minatron II Microprocessor Variable Chuck Control, Hydraulic Overhead<br />

Dresser, Variable Power Cross Feed, Coolant<br />

1 – PARKER MAJESTIC MODEL YV 6” X 12” HAND FEED SURFACE GRINDER, S/N 6219YV97 (1997), Walker<br />

6” x 12” Electromagnetic Chuck, With Walker Microprocessor, Variable Chuck Control, Volkman AD-2<br />

Microprocessor Spindle Control, Parker 1.5-HP 3000 – 6000 RPM Spindle<br />

1 – REID FAYSCOTT MODEL 618HA 6” X 18” HAND FEED SURFACE GRINDER, S/N 16140, Magna-Lock<br />

Electromagnetic Chuck, With Electro-Matic Variable Control, ExCello 1-HP 3500 RPM Spindle<br />

1 – REID ROLLERWAY 6” X 18” HAND FEED SURFACE GRINDER, S/N 22405, Magna Lock Electomagnetic<br />

Chuck, With Flux-Master Variable Control, Pope 1.5-HP 3600 RPM Spindle<br />

ID/OD CYLINDRICAL GRINDER<br />

1 – CINCINNATI 12” X 36” UNIVERSAL HYDRAULIC ID/OD CYLINDRICAL GRINDER, S/N 35323D73-0003,<br />

Motorized Variable Speed Workhead, With Live/Dead Center, 50 – 500 RPM Workhead Speeds, Tailstock,<br />

Motorized Drop-Down ID Spindle Filmatic Wheelhead, 14” x 1-1/2” Wheel Size, Power Table, Pickfeed, Tarry,<br />

Coolant System<br />

ID GRINDER<br />

1 – PARKER MAJESTIC MODEL 1 12” X 24” ID GRINDER, S/N 1920-1-65, Motorized Universal Workhead, With<br />

8” Electromagnetic Chuck, Variable Workhead Speed Control, Power Table, With Variable Speed Control, 1.5-HP<br />

3500 RPM Spindle, Coolant<br />

4 For more information, visit us on the web @ www.hilcoind.com

JIG BORERS • DRILLS • SAWS • EDM • FABRICATING EQUIPMENT<br />

PRATT & WHITNEY NO. 3B<br />

PRECISION JIG BORER<br />

FOSDICK 4’ ARM X 11” COLUMN<br />

SENSITIVE TYPE RADIAL DRILL<br />

DOALL MODEL MP-20<br />

20” VERTICAL BANDSAW<br />

CENTER ENG. METAL<br />

MUNCHER GB50-18<br />

HYDRAULIC IRONWORKER<br />

CINCINNATI 12” X 36” UNIVERSAL<br />

HYDRAULIC ID/OD CYLINDRICAL GRINDER<br />

W.F. WELLS & SONS MODEL F-16-1 16” X 16”<br />

HORIZONTAL METAL CUTTING BANDSAW<br />

VIEW OF PARTS WASHERS<br />

MISCELLANEOUS TOOL GRINDERS<br />

1 – BOYAR SHCULTZ NO.2 PROFILE GRINDER, S/N 3165, Overarm Spindle<br />

1 – DAREX MODEL E-90 PRECISION TOOL SHARPENER, S/N NA,<br />

P/N E-85/90/TR, Single End 5” Diamond Cup Wheel, Air Flow Type<br />

Collet Fixture<br />

1 – CALAMAR MODEL K-K-2100 5” SINGLE END CARBIDE TOOL<br />

GRINDER<br />

1 – WALKER TURNER MODEL 7222-3101 6” DOUBLE END CARBIDE<br />

TOOL GRINDER<br />

1 – DAYTON MODEL 1Z853 8” 1-HP DOUBLE END PEDESTAL GRINDER<br />

1 – DAYTON MODEL 1Z853N 8” 1-HP DOUBLE END GRINDER<br />

1 – BALDOR NO. 673E, 6” DOUBLE END BUFFER<br />

2 – KAR-RY 1” PRECEISION ABRASIVE BELT GRINDERS, S/Ns NA,<br />

Portable Tool Cart Mounted<br />

1 – DELTA MODEL 52-611 6” ABRASIVE BELT SANDER, S/N 97K93419<br />

JIG BORERS<br />

1 – PRATT & WHITNEY NO. 3B PRECISION JIG BORER, S/N 24764, Table<br />

Size 24” x 55”, (12) Spindle Speeds 37 – 1800 RPM, Spindle Feeds .0005<br />

– .010 IPR, Sony 3-Axis Readout<br />

1 – MOORE NO. 3 JIG BORER, S/N B1102, Table Size 11” x 24”, Spindle<br />

Speeds Variable 0 – 2500 RPM, 12” Vertical Head Travel, Moore Paper<br />

Spindle, Toolholder Carousel<br />

DRILLS<br />

1 – FOSDICK 4’ ARM X 11” COLUMN SENSITIVE TYPE RADIAL DRILL,<br />

S/N 21080, Table Size 24” x 48”, Power Table Elevation, (9) Spindle Speeds<br />

60 – 1200 RPM<br />

1 – POWERMATIC MODEL 1200 20” VARIABLE SPEED FLOOR TYPE<br />

DRILL PRESS, S/N 4-4587, Spindle Speeds 105 – 2000 RPM<br />

1 – POWERMATIC MODEL 1200 20” VARIABLE SPEED FLOOR TYPE<br />

DRILL PRESS, S/N 020V145<br />

BANDSAWS<br />

1 – W.F. WELLS & SONS MODEL F-16-1 16” X 16” CAPACITY HORIZONTAL METAL<br />

CUTTING BANDSAW, S/N 9054, 2-Post Frame, Hydraulic Head Raise/Lower, Manual<br />

Clamping, Blade Speeds 100 – 400 FPM, Coolant<br />

1 – W.F. WELLS & SONS MODEL 2-9 9” X 12” CAPACITY HORIZONTAL METAL CUTTING<br />

BANDSAW, S/N 762422, 2-Post Frame, Blade Speeds 100 – 300 FPM, Coolant<br />

1 – DOALL MODEL MP-20 20” VERTICAL BANDSAW, S/N 32-52522, Hydraulic Power Table<br />

Feed, Variable Blade Speeds 40 – 10,800 FPM, Blade Welder/Grinder<br />

1 – POWERMATIC MODEL 143 14” VERTICAL BANDSAW, S/N 243471<br />

ELECTRICAL DISCHARGE MACHINE<br />

1 – EX-CELL-O MODEL E-20 RAM TYPE EDM, S/N 2510855, Work Table Size 14-1/2” x<br />

7-1/2”, Work Tank Size 21” x 14” x 13”, Self-Contained 25 AMP Power Supply, Variable<br />

Frequency, Dielectric Fluid System<br />

FABRICATING EQUIPMENT<br />

1 – CENTER ENG. METAL MUNCHER GB50-18 HYDRAULIC IRONWORKER, S/N 2089485,<br />

49-Ton Punch, Punch Capacity 13/16” Thru 3/4” to 1-1/16” Thru 1/2”<br />

1 – LOVELAND HYDRA SHEAR MODEL 60-25 60” POWER SHEAR, S/N 099<br />

1 – 16 GAUGE X 24” BENCH TOP FINGER TYPE MANUAL BENDING BRAKE<br />

1 – 16 GAUGE X 24” BENCH TOP MANUAL SHEAR<br />

PARTS WASHING & FINISHING<br />

1 – ADF SYSTEMS MODEL M810 ROTARY CABINET TYPE PARTS WASHER,<br />

S/N 612-5026, 32” Diameter Rotary Basket, Stationary Spray Heads, Electric Heat, Hot Air<br />

Dry Cycle, Variable Wash/Rinse/Hot Air Timers, Auto-Fill, Oil Skimmer, Portable<br />

1 – ADF SYSTEMS MODEL 550 PRESSURE BLAST CABINET PARTS WASHER,<br />

S/N 9701-3263, 2-Hole Blast Type Cabinet, 30” x 48”, Electric Pre-Heat, Auto-Fill,<br />

Oil Skimmer<br />

1 – ALMCO SUPERSHEEN 7” X 12” MOTORIZED ROTARY PARTS FINISHING DRUM, S/N NA<br />

1 – TRINCO MODEL 36 ABRASIVE BLAST CABINET, S/N 3425/0, With Dust Collector<br />

1 – MAC-BLAST 36” BEAD BLAST CABINET, With Dust Collector, S/N NA<br />

To schedule an auction, please contact us at 248.254.9999 5

AIR COMPRESSORS • DUST COLLECTORS • CMMs • COMPARATORS<br />

BROWN & SHARPE VALIDATOR MODEL<br />

XCEL 9-12-9 BRIDGE TYPE CNC<br />

COORDINATE MEASURING MACHINE<br />

JONES & LAMSON EPIC 30<br />

30” OPTICAL COMPARATOR<br />

BROWN & SHARPE VALIDATOR<br />

BENCH TOP COORDINATE<br />

MEASURING MACHINE<br />

VSI AUTOMATION<br />

TM 23 ORBITAL<br />

RIVETING MACHINE<br />

CINCINNATI 24” STANDARD TOOLROOM SHAPER<br />

LEROI DRESSER 25-HP HORIZONTAL TANK MOUNTED<br />

ROTARY SCREW AIR COMPRESSOR<br />

VIEW OF INSPECTION EQUIPMENT<br />

AIR COMPRESSORS & DRYER<br />

1 – LEROI DRESSER 25-HP HORIZONTAL<br />

TANK MOUNTED ROTARY SCREW AIR<br />

COMPRESSOR, S/N 4141X108<br />

1 – LEROI DRESSER MODEL 25SST 25-HP<br />

HORIZONTAL TANK MOUNTED ROTARY<br />

SCREW AIR COMPRESSOR, S/N 4239X40<br />

1 – COMPARTS AR-100 REFRIGERATED<br />

COMPRESSED AIR DRYER, S/N 3989<br />

WELDING EQUIPMENT<br />

1 – AIRCO MODEL 3A/DDR-224HPA/B-D 300<br />

AMP AC/DC HELIWELDER, S/N R404552<br />

1 – HYPERTHERM POWERMAX 1250 80 AMP<br />

PLASMA CUTTER, S/N 1250-016275<br />

1 – LARKIN 10 KVA ROCKER ARM SPOT<br />

WELDER, S/N 5056<br />

DUST COLLECTORS<br />

1 – DCE UNIMASTER UMA354G11AD CENTRALIZED<br />

DUST COLLECTOR, S/N 86-1776, 7.5 KW<br />

1 – TORIT DONALDSON 84 3-HP CABINET TYPE<br />

DUST COLLECTOR, S/N 181196<br />

1 – SMOG HOG CEILING SUSPENDED AIR<br />

CLEANER, S/N N/A<br />

MISCELLANEOUS<br />

SHOP MACHINES<br />

1 – VSI AUTOMATION MODEL TM 23 ORBITAL<br />

RIVETING MACHINE, S/N 27910 (1994), 1-HP,<br />

16 x 14” Table, Steel Stand<br />

2 – KR WILSON MODEL 37FX 75-TON H-FRAME<br />

HYDRAULIC SHOP PRESSES, S/Ns S-3689,<br />

AS3956, Manual Hydraulics, Adjustable Rail<br />

1 – CINCINNATI 24” STANDARD TOOLROOM<br />

SHAPER, S/N 36472, Universal Table<br />

COORDINATE<br />

MEASURING MACHINES<br />

1 – BROWN & SHARPE VALIDATOR XCEL<br />

9-12-9 BRIDGE TYPE CNC COORDINATE<br />

MEASURING MACHINE, S/N 0591-116,<br />

Measuring Range, Granite Worktable, Renishaw<br />

PH9A, Touch Probe, Renishaw PHC9, MK2<br />

Probehead, Control Unit, Operators Joy Stick<br />

Control, Brown & Sharpe Control Desk with PC,<br />

Brown & Sharpe Avail Measurement, Version 3.0<br />

Software WINDOWS XP Based.<br />

1 – BROWN & SHARPE VALIDATOR BENCH TOP<br />

COORDINATE MEASURING MACHINE,<br />

S/N N/A, 18” X 24” Steel Worktable, Renishaw<br />

TP1s Touch Probe, Manual PC with Micro<br />

Measure III Software<br />

OPTICAL COMPARATORS<br />

1 – JONES & LAMSON EPIC 30 30” OPTICAL<br />

COMPARATOR E42629, Quadra-Chek 2000<br />

Programmable Readout<br />

1 – JONES & LAMSON 14” OPTICAL COMPARA-<br />

TOR, S/N N/A<br />

INSPECTION<br />

1 – ANTONIK MODEL 3JS ROCKWELL<br />

HARDNESS TESTER, S/N 2929<br />

1 – CLARK MODEL C8A ROCKWELL<br />

HARDNESS TESTER, S/N 50052<br />

1 – STARRETT 48” X 96” X 10” CRYSTAL PINK<br />

GRANITE SURFACE PLATE, S/N N/A, With<br />

Steel Stand<br />

1 – 36” X 60” X 6” BLACK GRANITE SURFACE<br />

PLATE<br />

1 – 36” X 60” 2-LEDGE BLACK GRANITE<br />

SURFACE PLATE<br />

Numerous Small Bench Top Granite Surface Plates<br />

LARGE QUANTITY INSPECTION ROOM<br />

EQUIPMENT AND GAUGES INCLUDING:<br />

Micrometers, Outside, Inside, Depth, etc.,<br />

Inter-Mic’s, Height Gauges, Calipers, Pin Gage<br />

Sets, Gage Block Sets, Surface Testers, Bore<br />

Gauges, Parallels, Risers, Sine Bars, etc.<br />

6 For more information, visit us on the web @ www.hilcoind.com

TRUCK • FORKLIFT • MACHINE ACCESSORIES • SHOP & FACTORY<br />

CATERPILLAR MODEL 2EC25 5000-LB. CAPACITY<br />

SIT-DOWN RIDER ELECTRIC FORKLIFT<br />

NSS MODEL WRANGLER 26 BATTERY POWERED<br />

WALK-BEHIND FLOOR SCRUBBER<br />

VIEW OF VIDMAR CABINETS<br />

2003 GMC SIERRA 2500HD PICK UP TRUCK VIEW OF CAT 50/40 TAPER TOOLING<br />

STEVENS ENGINEERING<br />

PRECISION SET-UP FIXTURES<br />

& SUB PLATES<br />

PICK UP TRUCK<br />

1 – 2003 GMC SIERRA 2500HD PICK UP TRUCK,<br />

VIN: 1GTHC24U23E312511, Standard Cab, 2WD,<br />

CAP, 71,000 Miles<br />

FORKLIFT<br />

1 – CATERPILLAR MODEL 2EC25 5000-LB.<br />

CAPACITY SIT-DOWN RIDER ELECTRIC<br />

FORKLIFT, S/N A2EC2-62706, 188” Lift, 36/48 Volt,<br />

Solid Non-Mar Tires<br />

1 – POWER BOSS MODEL EMS18-96503 36 VOLT<br />

INDUSTRIAL FORKLIFT BATTERY CHARGER,<br />

S/N 101692, VPII Control<br />

PORTABLE HANDLING<br />

EQUIPMENT<br />

1 – NSS MODEL WRANGLER 26 BATTERY POWERED<br />

WALK-BEHIND FLOOR SCRUBBER, S/N 262610B-<br />

40S84449<br />

1 – AMERICAN PULLEY KWIK-STAK MODEL 10-56<br />

HYDRAULIC LIFT CART, S/N 382323<br />

1 – HYDRAULIC PALLET JACK<br />

1 – FORKLIFT PERSONNEL LIFT BASKET<br />

1 – PORTABLE HYDRAULIC SHOP CRANE, 3-Ton<br />

Hydraulic Jack, Cable Winch<br />

1 – 1 CU. YD. SELF-DUMPING HOPPER<br />

OFFICE<br />

LIMITED QUANTITY OFFICE EQUIPMENT<br />

2003<br />

MACHINE ACCESSORIES, TOOLING, SHOP & FACTORY<br />

1 – WALTER MODEL R5630-G 24-1/2” ROTARY SINE TABLE, S/N 2516<br />

1 – PRATT & WHITNEY 30” MOTORIZED ROTARY TABLE, S/N 25807<br />

1 – DEVLIEG 30” X 30” AIRLIFT ROTARY TABLE, S/N 94785<br />

3 – BRIDGEPORT 15” ROTARY TABLES<br />

1 – NIKKEN 12” COMPOUND ROTARY TABLE<br />

2 – TROYKE 15” X 15” CROSS-SLIDE ROTARY TABLES<br />

1 – TROYKE 12” X 12” CROSS-SLIDE ROTARY TABLE<br />

4 – HARTFORD/CUSHMAN 8” DIVIDING/INDEXING HEADS, Machine Vises<br />

Over 150 CAT 50 Taper Tool Holders, Over 75 CAT 40 Taper Tool Holders, Over 100 CAT 45 Taper Tool<br />

Holders, Over 700 Collets Including Kennemetal, Erickson, Universal. TG100, TG75, DA100, DA200,<br />

DA300 Sizes, Collet Holders, Insert Holders, Carbide Inserts, Perishable Tool Cutters, Set-up and<br />

Clamping Tooling, Grinding Tooling and Accessories, Dressers, Whirly-Gigs, Precision Fixtures, Sine<br />

Chucks, Collets, Motorized Precision Indexes, 1-2-3 Blocks, Lathe Tooling, Quick Change Tool Posts with<br />

Holders<br />

2 – VIDMAR 60” 14-DRAWER CABINETS<br />

2 – VIDMAR 44” 8-DRAWER CABINETS<br />

1 – VIDMAR 44” 7-DRAWER CABINET<br />

1 – LISTA 45 TOOL CAT 50 TOOL CART<br />

3 – 40 TOOL CAT 50 TOOL CARTS<br />

1 – 60” 72 TOOL CAT 40 TOOL RACK<br />

1 – 60” 45 TOOL CAT 45 TOOL RACK<br />

GROUND, DRILLED & TAPPED, DOWELED SUB PLATES, 30” X 21” X 1-1/2, 14” X 26-3/4” X 1-1/4”,<br />

21-1/4” X 47-3/4”, 1-7/16”, 18” X 36” X 1-1/2”, 21” X 30” X 1-1/2” 12-1/2” Diameter – 11, 11” X 11” X 7”<br />

Right Angle Plates, 6” X 6” X 6-1/2” Right Angle Plates, 12-1/2” X 6” X 2” Parallels, 12-1/2” X 4” X 2”<br />

Parallels, 12-1/2” X 2” X 2” Parallels, 5” Precision Vise<br />

Work Benches, Bench Vises, General Shop & Factory<br />

Assorted Steel & Aluminum Stock<br />

To schedule an auction, please contact us at 248.254.9999 7

Atlanta • Birmingham • Boston • Charlotte • Chicago • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong • Irapuato (MX) • Leeds (UK)<br />

London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Southampton (UK) • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

Auctioneers • Liquidators • Appraisers<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 248.254.9999<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 100<br />

Forwarding Service Requested<br />

<strong>WEBCAST</strong> <strong>AUCTION</strong><br />

– Real Estate Available by Private Negotiation –<br />

• Land Area: 2.110 Acres • Zoned <strong>Industrial</strong><br />

• Office Area: 2,000 Sq. Ft.<br />

• Ceiling Heights: 16’ to 19’<br />

• (2) Grade Level Doors 12’ x 14’<br />

• Gas Heat • Air Conditioned<br />

Questions regarding the sale of the real estate should be directed to:<br />

Joseph T. Hamway, Principal<br />

Email: jhamway@signatureassociates.com<br />

Ph: 248.948.0113 • Cell: 248.568.4640<br />

SIGNATURE ASSOCIATES<br />

28141 Groesbeck Hwy.<br />

Roseville, MI 48066<br />

17,750 SQ. FT.<br />

FACILITY<br />

An independently owned and operated member of the<br />

CUSHMAN & WAKEFIELD ALLIANCE<br />

One Town Square, Suite 1200<br />

Southfield, MI 48076<br />

Ph: 248.945.9000 • Fx: 248.799.3168<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> Trading, Co. • Headquarters 5 Revere Drive, Ste. 430 • Northbrook, IL 60062<br />

All rights reserved • Printed in USA • WEBS3377 • IL License #444000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A buyer’s premium of 13.5% for onsite sales & 16%<br />

for webcast sales is in effect. Everything will be sold<br />

to the highest bidder for cash, in accordance with<br />

the Auctioneer’s customary “Terms of Sale”, copies<br />

of which will be posted on the premises of the sale<br />

and subject to additional terms announced the day<br />

of sale. All items will be sold “as is, where-is” without<br />

any warranties, express or implied. Although<br />

obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the<br />

accuracy of the information herein contained.<br />

Bidders are encouraged to thoroughly inspect the<br />

items on which they intend to bid prior to sale.<br />

Absolutely no items will be removed until the day<br />

after the conclusion of the sale and payment is made<br />

in full. Subject to additions, deletions and prior sale.<br />

Payment: ALL PURCHASES MUST BE PAID IN<br />

FULL ON THE DAY OF THE <strong>AUCTION</strong>. If you intend<br />

to pay by wire transfer, we will accept payment the<br />

day after the sale ONLY IF a deposit of 25% of total<br />

purchases is made on the day of the sale. Contact<br />

our office for wire transfer instructions. Only cash,<br />

wire transfer or certified check, payable to <strong>Hilco</strong><br />

<strong>Industrial</strong>, LLC will be accepted. Company checks<br />

payable to <strong>Hilco</strong> <strong>Industrial</strong> LLC will be accepted only<br />

if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales<br />

tax. Purchasers claiming exemptions from taxes<br />

must provide proof satisfactory to the Auctioneer of<br />

their entitlement to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees<br />

payment to <strong>Hilco</strong> <strong>Industrial</strong>, LLC from<br />

(Company Name). This guarantee will be valid<br />

for purchases made at the Auction of Webster<br />

Engineering on March 26th.