Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

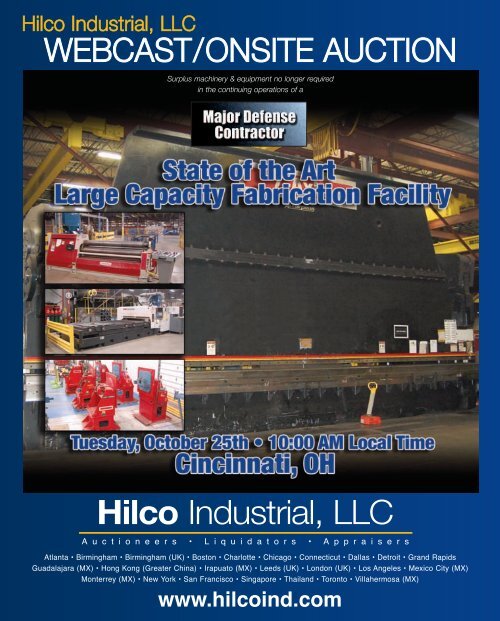

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

WebCast/OnsIte auCtIOn<br />

Surplus machinery & equipment no longer required<br />

in the continuing operations of a<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids<br />

Guadalajara (MX) • Hong Kong (Greater China) • Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX)<br />

Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<br />

www.hilcoind.com

HILCO InDustrIaL, LLC WebCast/OnsIte auCtIOn<br />

Surplus machinery & equipment no longer required<br />

in the continuing operations of a<br />

auCtIOn Date<br />

tuesDay, OCtOber 25 tH<br />

begInnIng at 10am LOCaL tIme<br />

PrevIeW Date<br />

mOnDay, OCtOber 24 tH<br />

4Pm tO 8Pm LOCaL tIme<br />

AdvAnce RegiStRAtion iS neceSSARy in oRdeR to Attend<br />

pReview. pleASe contAct ken plAnet At 248.254.9999 x33 oR<br />

emAil kplAnet@hilcoind.com foR RegiStRAtion infoRmAtion<br />

to Attend the pReview.<br />

auCtIOn LOCatIOn<br />

CrOWne PLaza HOteL - CInCInnatI nOrtH<br />

11320 CHester rOaD, CInCInnatI OH<br />

PrevIeW LOCatIOns<br />

8910 LesaInt DrIve (bLDg. 900)<br />

FaIrFIeLD (CInCInnatI), OH 45014<br />

8779 LesaInt DrIve (bLDg. 600)<br />

FaIrFIeLD (CInCInnatI), OH 45014<br />

traveL InFOrmatIOn<br />

HOteLs<br />

CrOWne PLaza HOteL – CInCInnatI nOrtH 513.771.2080<br />

HILtOn garDen Inn – CInCInnatI/sHarOnvILLe 513.772.2837<br />

Drury Inn & suItes – nOrtH CInCInnatI 513.771.5601<br />

DIreCtIOns tO PrevIeW LOCatIOns<br />

FrOm I-75 (aPPrOx 18 mILes nOrtH OF CInCInnatI), take exIt FOr I-275 W (exIt<br />

#16 – tOWarDs I-74/InDIanaPOLIs). traveL 2 mILes On I-275 W tO OH-747 n (exIt<br />

42b). make sLIgHt rIgHt OntO PrInCetOn PIke / OH-747 anD traveL 2.4 mILes<br />

nOrtH tO POrt unIOn rD. turn LeFt (West) OntO POrt unIOn rD anD traveL<br />

6/10 mILe tO Le saInt Dr. turn rIgHt OntO Le saInt Dr anD traveL One<br />

bLOCk tO InsPeCtIOn sIte. WatCH FOr sIgns DIreCtIng yOu tO DesIgnateD<br />

ParkIng area.<br />

DIreCtIOns tO auCtIOn<br />

FrOm I-75 (aPPrOx 18 mILes nOrtH OF CInCInnatI), take exIt FOr sHarOn<br />

rD (exIt #15 – tOWarDs sHarOnvILLe/gLenDaLe). FOLLOW ramP tOWarDs<br />

gLenDaLe, make sLIgHt rIgHt OntO e. sHarOn rD tHen turn rIgHt OntO<br />

CHester rD. traveL 6/10 mILe tO CrOWne PLaza HOteL/auCtIOn sIte.<br />

FurtHer InFOrmatIOn<br />

• a 25% aDvanCe DePOsIt Is requIreD FOr aLL regIstrants PrIOr tO InsPeCtIOn.<br />

• an 18% buyer's PremIum WILL be CHargeD On aLL assets. tHe buyer’s<br />

PremIum WILL be reDuCeD tO 15% FOr Payments maDe by CasH, COmPany<br />

CHeCk Or WIre transFer. auCtIOn WILL be COnDuCteD In engLIsH, aCCePt-<br />

Ing u.s. CurrenCy OnLy.<br />

• REMOVAL DEADLINE IS NOVEMbER 11th WIth hOURS OF REMOVAL bEtWEEN 8AM tO<br />

4PM MONDAY thRU FRIDAY. REMOVAL OF ItEMS REqUIRINg DIScONNEct & RIggINg<br />

tO bE PERFORMED ONLY bY SK RIggINg At PURchASER’S cOSt. cERtAIN ItEMS IN<br />

bUILDINg 600 WILL bE LOADED ONtO bUYER’S tRUcK At NO chARgE. AFtER thE<br />

NOtED DEADLINE At 4PM thE bUYER WILL INcUR A cOSt OF $500 FOR ENtRY INtO thE<br />

FAcILItY.<br />

• FOr FurtHer InFOrmatIOn On maCHInery & equIPment, PLease COntaCt<br />

ken PLanet at 248.254.9999 x33 Or emaIL kPLanet@HILCOInD.COm<br />

• FOr Payments PLease COntaCt LesIa JOsePH at 616.732.1800 x19 Or emaIL<br />

LJOsePH@HILCOInD.COm Or HILCO aCCOunts reCeIvabLe at<br />

HIn_ar@HILCOInD.COm<br />

• FOr CustOmer servICe, PLease COntaCt sanDI neeLy at 248.254.9999 x16 Or<br />

emaIL sneeLy@HILCOInD.COm<br />

6000 Watt<br />

2008<br />

2<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Laser & PLasma Cutters • CnC Press brakes • PLate benDIng rOLLs<br />

1500 Ton<br />

LaSEr aND PLaSMa CUTTErS<br />

1 – TANAKA MODEL LMX V11 40 TF6000 CNC LASER CUTTER,<br />

S/N 02-1568 (2008), Fanuc C6000i-A 6000 Watt Resonator,<br />

Effective Cutting Width 159.44”(4050mm), 75’(22,860mm)<br />

Cutting Length, Fanuc 16i LB CNC Controls, 11078 Hours, (2)<br />

Orion Model RKE12000A-VTA Chillers, Down Draft Cutting<br />

Table, (Loc. 900)<br />

1 – MAZAK MODEL SUPER TURBO X612 MKII CNC LASER<br />

CUTTER, S/N 214831 (2009), 4000 Watt Resonator, 79.5”<br />

(2020mm) Y-Axis x 164.8”(4185mm) X-Axis Travels, Mazatrol<br />

Preview CNC Control, Laser Model YB-L400A 8M 6E, Orion<br />

Model RKL15000D-A2 Chiller, (Loc. 900)<br />

1 – KOMATSU MODEL TWISTER TFP 3051 CNC FINE PLASMA<br />

CUTTER, S/N 50611 (2008), Table 5' x 10'(1524mm x 3048mm),<br />

Fanuc Oi-MC CNC Control, 2600 Hours, Cutting Cap. 1", System<br />

Model KPG-9150A, Komatsu Model PU1501 30 kw (150 amp.)<br />

Plasma Power Supply, Down Draft Cutting Table, S/N 1378-2008,<br />

(Loc. 900)<br />

2008<br />

2008<br />

2009 • 4000 Watt<br />

2007<br />

2008<br />

2004<br />

CNC HYDraULIC PrESS BraKES<br />

1 – ACCURPRESS MODEL 7150034 1500 TON x 34' 7-AXIS CNC<br />

HYDRAULIC PRESS BRAKE, S/N 9902 (2008), ETS 3000<br />

CNC Control, Distance Between Housings 30' 4" Segmented<br />

Top Die Holder, 2" Thru 12" Opening, Power Adjustable Bottom<br />

Die w/ Crowning, 6-Axis Back Gauge, Light Curtains, (Loc. 900)<br />

1 – CINCINNATI MODEL 135 CB II 135 TON X 8' 2-AXIS CNC<br />

HYDRAULIC PRESS BRAKE, S/N 52938, (2004), Distance Between<br />

Housings 6' 6", Stroke 8", 40” X-Axis Back Gauge, 8” Manual R-Axis,<br />

Segmented Upper Die Holder, Light Curtains, (Loc. 900)<br />

PLaTE BENDING rOLLS<br />

1 – AKBEND MODEL AHS 340X2600 4-ROLL HYDRAULIC PLATE<br />

BENDING ROLL, S/N S340-047 (2007), Capacity: Length 2600<br />

mm (102”) x Thickness 24 mm (.95”) / Prebend 20 mm (.79”), Cone<br />

Bending Attachment, Hyd. Drop End, Roll Dia. 12", (Loc. 900)<br />

1 – AKBEND MODEL AHS 20/8 4-ROLL HYDRAULIC PLATE BEND-<br />

ING ROLL, S/N SY210-042 (2008), Capacity: Length 2100 mm<br />

(82.7”) x Thickness 10 mm (.4”) / Prebend 8 mm (.32”), Cone<br />

Bending Attachment, Hyd. Drop End, Roll Dia. 8", (Loc. 900)<br />

For more information, please visit us on the web at www.hilcoind.com 3

ObOtIC WeLDIng CeLLs • WeLDIng POsItIOners • WeLDers<br />

2007<br />

rOBOTIC WELDING CELLS<br />

1 – PROGRESSIVE SYSTEMS MODEL PRO-SYSTEM 2102 DUAL HEAD<br />

ROBOTIC WELDING CELL, System No. JO-543-1 (2007), (2) 6-Axis Fanuc<br />

ArcMate 120iBe Robots Type A05B-1216-B451 (F-81247 & F-81248, 141”<br />

Centers, (2) Fanuc Robot Power Supplies Type A05B-2512-B101, Fanuc<br />

System R-J3iC Control, Teach Pad, 69,536 Hours, (2) Lincoln Power Wave<br />

455M Welding Power Supplies, (2) Abicor Binzel BWC-3 Water Coolers, (2)<br />

Trunnion Tables – Work Stations, Fume Hood, Light Curtains, (Loc. 900)<br />

1 – KC ROBOTICS ROBOTIC WELDING CELL, 6-Axis Fanuc Model M16i Robot<br />

F-52828, 84" Centers, Fanuc R-J3 Control, Teach Pad, Fanuc Robot Power<br />

Supply Type A05B-2403-B101 S/N E01505687, Miller Axcess 450 Welding<br />

Power Supply, Abicor Binzel BWC-3 Water Cooler, (2) KC Robotics Trunnion<br />

Tables – Work Stations, Fume Hood, Light Curtains, (Loc. 900)<br />

1 – KC ROBOTICS ROBOTIC WELDING CELL, 6-Axis Fanuc Model M16i<br />

Robot, 87” Centers, Fanuc R-J2 Control, Teach Pendant, Fanuc Robot Power<br />

Supply Type A05B-2375-B002, S/N E98405225, OTL DP 400 Welding Power<br />

Supply, Abicor Binzel BWC-3 Water Cooler, (2) KC Robotics Trunnion Tables<br />

Work Stations, Fume Hood, Light Curtains, (Loc.900)<br />

WELDING POSITIONErS<br />

1 – ARONSON 20,000 LB. HEADSTOCK/TAILSTOCK WELDING<br />

POSITIONERS, Model HS20AB Headstock, S/N 8289, Table 48" x 48",<br />

Adjustable Base Height, Model TS20AB Tailstock, S/N 8266, Table 48"<br />

x 48", Adjustable Legs, (Loc. 600)<br />

1 – ARONSON KOIKE 10,000 LB. HEADSTOCK/TAILSTOCK WELDING<br />

POSITIONERS, Model HS10DP Headstock, S/N 99455, Table 42" x 42",<br />

Model TS10 Tailstock, S/N 99266, Table 42" x 42", (Loc. 600)<br />

1 – ARONSON KOIKE 10,000 LB. HEADSTOCK/TAILSTOCK WELDING<br />

POSITIONERS, Model HS10DP Headstock, S/N 99454, Table 42" x 42",<br />

Model TS10 Tailstock, S/N 99267, Table 42" x 42", (Loc. 600)<br />

CIrCULar WELDING HEaD<br />

1 – BANCROFT MODEL 500 WELDA-ROUND WELDING HEAD,<br />

S/N 4465/136-507, A/B Panelview C600 Control Interface, 8"<br />

Adjustable Vertical Stroke, (Loc. 900)<br />

WELDErS<br />

20 – MILLER MODEL SS-74D X 12’ BOOM WELD SYSTEMS, (All 2007), All with Series 70 Wire Feeds and Miller<br />

Deltaweld 452 Power Supplies S/N LH260430C (All 2007) (Loc. 600)<br />

20 – MILLER MODEL AXCESS 450 PROGRAMMABLE MIG WELDERS, S/N LJ060368U (All 2008), All with Axcess 40V<br />

Wire Feeds, (Loc. 600)<br />

1 – SOYER MODEL BMK-16i STUD WELDER, S/N PO13400 00339, (Loc. 600)<br />

2008<br />

2007<br />

4<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

sHOtbLastIng & FInIsHIng • Dust COLLeCtOrs • brIDge Cranes<br />

SHOTBLaSTING & FINISHING<br />

1 – WHEELABRATOR MODEL A3-54350 PASS THRU PLATE SHOT<br />

BLASTER, S/N 3558 (2008), Opening Width 8', (4) Wheels, Total H.P.<br />

268, 1373 Hours, 8’ Wide x 25’ Long Heavy Duty Power Entry and Exit<br />

Roller Conveyors, (Loc. 900)<br />

1 – MIDWEST SANDRIGHT MODEL P4375M PASS THRU DRY BELT<br />

GRINDER, S/N 2845-0702, Width 37", Max. Ht. 5", (Loc. 900 B3)<br />

1 – EARNST MODEL EG3M/11 PASS THRU PLATE DEBURRER, S/N<br />

580055 (2004), Sheet Width 54", Sanding Head, (2) Brush Wheels, Main<br />

Motor 15 kw, Tag No. 000399 (Loc. 600)<br />

(15) DUST COLLECTOrS<br />

1 – AMTECH MODEL AV-9 DUST COLLECTOR, S/N 1210-15591-02,<br />

(Loc. 900)<br />

4 – TORIT MODEL DFT3-6 DUST COLLECTORs, S/Ns 2456114-1,<br />

3045395-1 Unit 1, 3045395-1 Unit 2, 2343791-1, 7.5 H.P., (Loc. 900)<br />

1 – TORIT MODEL DFT2-8 DUST COLLECTOR, S/N 2456114-9, 5 H.P.,<br />

w/ Model 20 Cyclone S/N 2343791, (Loc. 600)<br />

1 – TORIT MODEL DFT2-8 DUST COLLECTOR, S/N 2694824-1, 7.5 H.P.,<br />

Tag No. 000539 (Loc. 900)<br />

1 – TORIT MODEL AT3000QD DUST COLLECTOR, S/N 2745243, 3 H.P.,<br />

Tag No. 000535 (Loc. 900)<br />

1 – TORIT MODEL AT3000 DUST COLLECTOR, S/N 2850172, 3 H.P.,<br />

(Loc. 900 D2)<br />

3 – TORIT MODEL TD573 DUST COLLECTORS, S/Ns 2814572, 2814572,<br />

2814572, 15 H.P., (Loc. 900)<br />

1 – TORIT MODEL EASY TRUNK PORTABLE DUST COLLECTOR,<br />

S/N 2335666-002, 1.5 H.P., (Loc. 600)<br />

1 – TORIT MODEL EASY TRUNK QS PORTABLE DUST COLLECTOR,<br />

S/N 2813782, 1.5 H.P., (Loc. 600)<br />

1 – TORIT MODEL EASY TRUNK PORTABLE DUST COLLECTOR,<br />

S/N 2335666-01, 1.5 H.P., (Loc. 600)<br />

2008<br />

BrIDGE CraNES<br />

1 – R&M 7.5 TON FREE STANDING SINGLE GIRDER UNDERHUNG BRIDGE CRANE, Pendant<br />

Control, Span 35', Length 60', (Loc. 900)<br />

12 – TIME SAVERS 2 TON SINGLE GIRDER UNDERHUNG BRIDGE CRANES, 2 Ton R&M Hoist,<br />

Pendant Control, Span 56', (Loc. 900)<br />

1 – FREE STANDING BRIDGE CRANE RUNWAY, Approx. Dimensions 60' x 320', (Loc. 900)<br />

1 – GORBEL FREE STANDING BRIDGE CRANE SYSTEM, Span 34', Length 240', (10) 2 Ton<br />

Bridges w/ 2 Ton Air Hoist, (Loc. 600)<br />

1 – GORBEL FREE STANDING BRIDGE CRANE SYSTEM, Span 34', Length 80', (4) 2 Ton Bridges<br />

w/ 2 Ton Air Hoist, (Loc. 900)<br />

1 – GORBEL FREE STANDING BRIDGE CRANE SYSTEM, Span 15', Length 90', (2) 2 Ton Bridges<br />

w/ 2 Ton Air Hoist, (Loc. 900)<br />

2 – GORBEL FREE STANDING BRIDGE CRANE SYSTEMS, Span 15', Length 80', (2) 2 Ton<br />

Bridges w/ 2 Ton Air Hoist, (Loc. 900)<br />

1 – GORBEL FREE STANDING BRIDGE CRANE SYSTEM, Span 15', Length 60', (2) 2 Ton Bridges<br />

w/ 2 Ton Air Hoist, (Loc. 900)<br />

1 – GORBEL FREE STANDING BRIDGE CRANE SYSTEM, Span 15', Length 70', 2 Ton Bridge<br />

w/ 2 Ton Air Hoist, (Loc. 900)<br />

2 – GORBEL FREE STANDING BRIDGE CRANE SYSTEMS, Span 16', Length 50', (2) 500 Lb.<br />

Bridges w/ 500 Lb. Air Hoist, (Loc. 900)<br />

1 – SPANCO 2 TON FREE STANDING BRIDGE CRANE, Span 23' x 50', (Disassembled), (Loc. 600)<br />

2 – GORBEL 2 TON ADJUSTABLE BASE GANTRY CRANES, Span 18', Height Under Beam<br />

16' – 19', 2 Ton Air Hoist, Mounted On Casters,<br />

2 – GORBEL 2 TON ADJUSTABLE BASE GANTRY CRANES, Span 10' 6", Height Under Beam<br />

11' 3" – 14' 3", Mounted On Casters<br />

For more information, please visit us on the web at www.hilcoind.com 5

materIaL HanDLIng • sHeet LIFters • aIr COmPressOrs<br />

2008<br />

MaTErIaL HaNDLING<br />

1 – DREXEL MODEL SLT30 SWINGMAST ELECTRIC<br />

FORKLIFT, S/N 942907-865, Cap. 3000 Lb., 36 Volt,<br />

Cushion Tire, Hobart Battery Charger, (Loc. 600 A19)<br />

1 – MERCURY MODEL 460D TUG, S/N AG1186, LP Fuel,<br />

Cushion Tire, (Loc. 600 A19)<br />

6 – CART CADDY MODEL 5W ELECTRIC CART MOVERS,<br />

S/N 305179, 305130, 305176, 305079, 305077, 305080,<br />

(All 2008), 36 Volt, (Loc. 600)<br />

1 – NU STAR MODEL SUPER POWER PUSHER ELECTRIC<br />

WALK BEHIND CART MOVER, S/N 88-1386, 36 Volt, Fifth<br />

Wheel Attachment, (Loc. 600 A19)<br />

1 – NU STAR MODEL POWER PUSHER ELECTRIC WALK<br />

BEHIND CART MOVER, 24 Volt, Fifth Wheel Attachment,<br />

(Loc. 600 A19)<br />

6 – ARI-HERTA MODEL HDML-8W ELECTRIC MOBILE<br />

LIFTS, S/Ns 07121676, 07121678, 07121677, 07121681,<br />

07121680, 07121679, Capacity 15,000 Lb., (Loc. 600)<br />

5 – AIRFLOAT MODEL D36-0023 LIFTING PLATFORMS,<br />

S/Ns 07-21708-06, 07-21708-10, 07-21708-09, 07-21708-08,<br />

07-21708-07, Capacity 40,000 Lb., Lifting Area 30" x 15' 6"<br />

, w/ Airfloat Drive Tractor, (Loc. 600)<br />

1 – AIRFLOAT LOT OF (2) BOXES OF SPARE BLADDERS<br />

FOR AIRFLOAT LIFTING TABLES, (Loc. 600)<br />

1 – AIRFLOAT MODEL U4872-01 LIFTING PLATFORM<br />

w/ BOOM, S/N 07-21702-01, Capacity 500 Lb., (Loc. 600)<br />

1 – AIRFLOAT MODEL U4872-01 LIFTING PLATFORM<br />

w/ BOOM, S/N 07-21702-02, Capacity 500 Lb., (Loc. 600)<br />

1 – AIRFLOAT MODEL SD11-008 DRIVE TRACTOR<br />

w/ LIFTING ATTACHMENT, S/N 07-21820-01, Capacity,<br />

20000 Lbs., (Loc. 600)<br />

1 – COX HOSE REEL, S/N 20071012 1007 (Loc. 600)<br />

1 – POSI-TURNER MODEL 16LS-120 DRUM STYLE<br />

MATERIAL HANDLING SYSTEM, S/N 08-90621 (2008),<br />

Capacity 16,000 Lbs., Max. Sling Span 120", Pendant<br />

Control, Tag No. 000322 (Loc. 600)<br />

2008<br />

SHEET LIFTErS<br />

1 – ANVER MODEL 82000837 VACUUM SHEET LIFTER, S/N S0080005930 (2008),<br />

Lifting Cap. 8800 Lb., Max. Sheet Size 8' x 24', (Loc. 600)<br />

1 – ANVER MODEL L120M8-150-4/44 VACUUM SHEET LIFTER, S/N 609246 (2006),<br />

Lifting Cap. 1200 Lb., Max. Sheet Size 8' x 16', (Loc. 600)<br />

1 – ANVER MODEL M100M-L MECHANICAL VACUUM SHEET LIFTER,<br />

S/N S0070013522 (2007), Lifting Cap. 1000 Lb., Max. Sheet Size 6' x 12', (Loc. 600)<br />

1 – ANVER MODEL PA128-S-3/EZ TILT VACUUM SHEET LIFTER, S/N 611927-15B<br />

(2006), VPF -57 Vacuum Generator, Lifting Cap. 100 Lb., Tag No. (Loc. 600)<br />

2 – ANVER MODEL L100M2-6L VACUUM SHEET LIFTERS, S/Ns 15956-14, 615953-<br />

1B (Both 2006), VPF-57 Vacuum Generator, Lifting Cap. 1000 Lb., Max. Sheet Size<br />

6' x 10', (Loc. 600)<br />

2 – ANVER MODEL ATL25S-MROT VACUUM SHEET LIFTERS, S/Ns 611927-1B,<br />

611927-1D (Both 2006), Lifting Cap. 250 Lb., (Loc. 600 H18)<br />

1 – ANVER MODEL M100M-QDI MECHANICAL VACUUM SHEET LIFTER,<br />

S/N 80090011372 (2009), Lifting Cap. 750 Lb., (Loc. 600 H18)<br />

1 – GCI VACUUM SHEET LIFTER, Capacity 250 Lb., Tag No. 001115 (Loc. 600 H18)<br />

aIr COMPrESSOrS & DrYEr<br />

1 – QUINCY MODEL QMA150ACA31E 150 H.P. ROTARY SCREW AIR COMPRESSOR,<br />

S/N 74621, 66547 Hours, 460 Volt, (Loc. 600)<br />

1 – QUINCY MODEL QSB40ANA21P 40 H.P. ROTARY SCREW AIR COMPRESSOR,<br />

S/N 93664H, 41497 Hours, 230-460 Volt, (Loc. 600)<br />

1 – AIR CELL AIR DRYER, S/N V1CGJK2353V, 200 cfm, (Loc. 600)<br />

6<br />

to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1-877-37-HILCO (44526)

Laser markIng / measurIng • mIsCeLLaneOus maCHInery<br />

LaSEr MarKING / MEaSUrING UNITS<br />

1 – LASER PHOTONICS FLM MODEL LPQ50-1.0iS HAND<br />

HELD FIBER LASER MARKING MACHINE, S/N LPC-009-<br />

349 (2009), I Series Power Supply, Wave Length 1060-1070<br />

nm, Scanlab Scancube 10 Scan Head, S/N 301431, (Loc. 600)<br />

1 – API MODEL LTS-3000 PORTABLE LASER MEASURING<br />

DEVICE, S/N LTS37821009 (2009), Model AT1 Tracker<br />

Head, S/N 1019, Dell Laptop, Brunson Stand<br />

MISCELLaNEOUS MaCHINErY<br />

1 – WEBB MODEL T321050 3 H.P. VERTICAL MILL, S/N<br />

76572 (1987), Table 10” x 50”, 2-Axis D.R.O. Spindle RPM<br />

60-4200 (Loc. 600)<br />

1 – BLUE M MODEL POM7-32BI-E/F ELECTRIC OVEN,<br />

S/N P39-852, Temp. 392 Deg. F., 240 Volt, Chamber<br />

Dimensions 48” W x 24”D x 48”H, (Loc 600)<br />

1 – SPX POWER TEAM 55 TON HYDRAULIC H-FRAME<br />

SHOP PRESS, Distance Between Housings 36", Max.<br />

Daylight 42", Stroke 13", 1 H.P. Pump, (Loc. 900)<br />

1 – SPX POWER TEAM 55 TON HYDRAULIC H-FRAME<br />

SHOP PRESS, Distance Between Housings 36", Max.<br />

Daylight 42", Stroke 13", 1 H.P. Pump, (Loc. 900)<br />

1 – WEBB & STILES TOW LINE SYSTEM w/ (14) TRUNNION<br />

WELD CARTS, (2007) Oval Track Dimensions Aprox. 110'<br />

x 30', Allen Bradley PanelView 300 Micro Control Interface,<br />

(10) Portable Platform Stairs, (Loc. 900)<br />

1 – TRUNNION, Swing 96", Centers 96", Air Motor, Air Brakes<br />

2 – TRUNNIONS, Swing 108", Centers 102", Air Motor, Air<br />

Brakes, Mounted On Casters<br />

1 – TELESIS MODEL TMP4210 PINSTAMP, S/N 608081923,<br />

TMC420 Control, Mounted On Cart, (Loc. 600)<br />

LOT OF ASSORTED ROLLER CONVEYOR<br />

LOT OF ASSORTED GUARD RAIL<br />

LOT OF ASSORTED ALUMINUM AIR PIPE<br />

LOT OF (2) RISER BLOCKS, 36" x 44" x 36" High (Loc. 600)<br />

QUANTITY OF PALLET JACKS<br />

2009 2009<br />

2004<br />

For more information, please visit us on the web at www.hilcoind.com 7

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong (Greater China) •<br />

Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<br />

<strong>Hilco</strong> <strong>Industrial</strong>, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 2655<br />

Forwarding Service Requested<br />

HILCO WebCast/OnsIte auCtIOn<br />

Surplus machinery & equipment no longer required<br />

in the continuing operations of a<br />

HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters 5 revere Drive, ste. 206 • northbrook, IL 60062 • all rights reserved<br />

Printed in usa • DeFenseCOntraCtOr • Ohio auctioneer & License: tim Pfister License #2011000029 • OH License #2011000151 • IL License #444.000215<br />

Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

A 25% advance deposit is required for all registrants prior<br />

to inspection. An 18% buyer's premium will be charged on<br />

all assets. the buyer’s premium will be reduced to 15% for<br />

payments made by cash, company check or wire transfer.<br />

Everything will be sold to the highest bidder for cash, in<br />

accordance with the Auctioneer’s customary “terms of<br />

Sale”, copies of which will be posted on the premises of the<br />

sale and subject to additional terms announced the day of<br />

sale. All items will be sold “as is, where-is” without any warranties,<br />

expressed or implied. Although obtained from<br />

sources deemed reliable, the Auctioneer makes no warranty<br />

or guarantee to the accuracy of the information herein<br />

contained. bidders are encouraged to thoroughly inspect<br />

the items on which they intend to bid prior to sale.<br />

Absolutely no items will be removed until the day after the<br />

conclusion of the sale and payment is made in full. Subject<br />

to additions, deletions and prior sale.<br />

Payment: ALL PURchASES MUSt bE PAID IN FULL ON<br />

thE DAY OF thE AUctION. If you intend to pay by wire<br />

transfer, we will accept payment the day after the sale<br />

ONLY IF a deposit of 25% of total purchases is made on<br />

the day of the sale. contact our office for wire transfer<br />

instructions. Only cash, wire transfer or certified check,<br />

payable to hilco <strong>Industrial</strong>, LLc will be accepted. company<br />

checks payable to hilco <strong>Industrial</strong>, LLc will be accepted<br />

only if accompanied by a bank letter of guarantee, (see<br />

sample letter below). All sales are subject to sales tax.<br />

Purchasers claiming exemptions from taxes must provide<br />

proof satisfactory to the Auctioneer of their entitlement to<br />

claim such exemptions.<br />

Sample Bank Letter<br />

(bank Name) unconditionally guarantees payment to<br />

hilco <strong>Industrial</strong>, LLc from (company Name). this guarantee<br />

will be valid for purchases made at the Auction<br />

of a Major Defense contractor on October 25, 2011.<br />

Follow<br />

Us on: